Liquid impact prevention device of equipment for gathering and transporting liquid-containing oil well head gas in desert oil field

A technology for oil fields and oil wells, applied in the field of anti-liquid shock devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

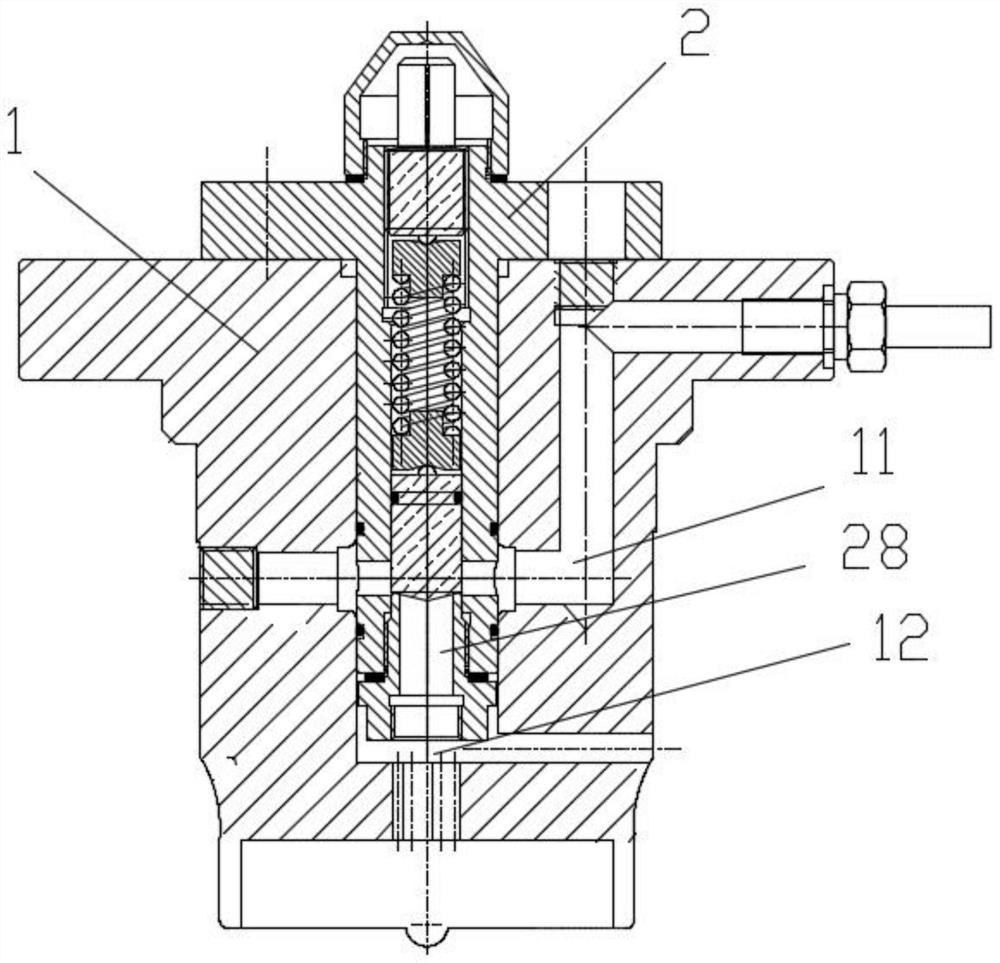

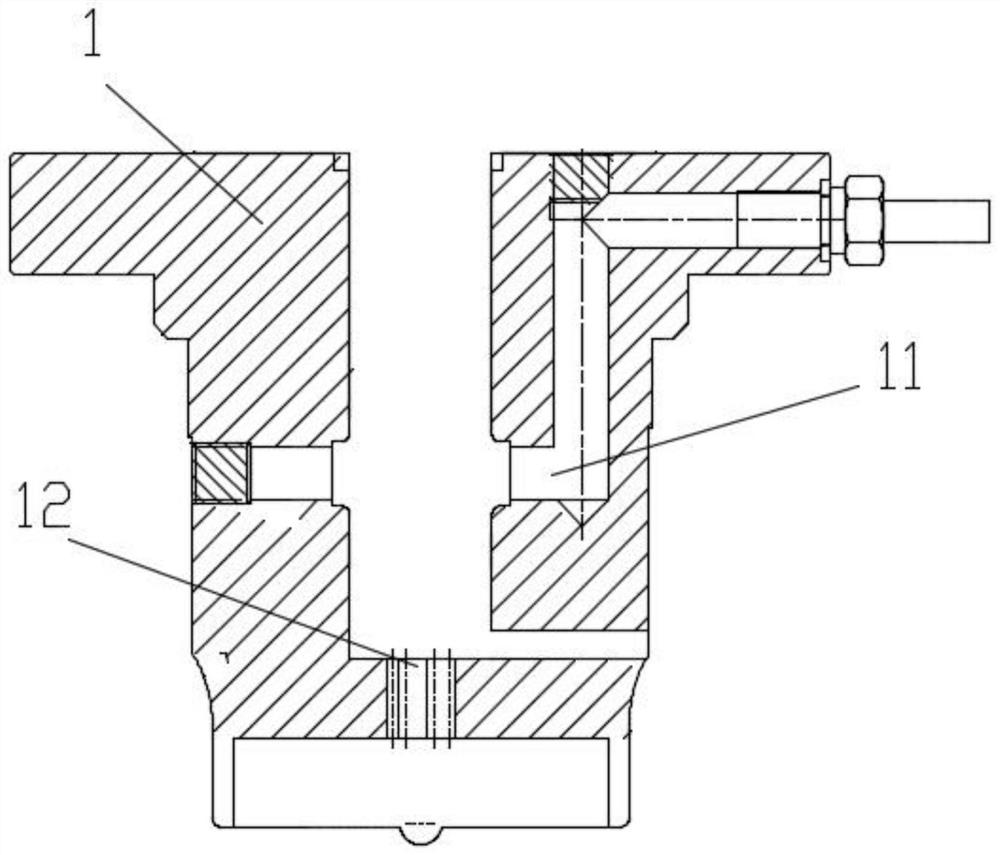

[0023] see Figure 1-2 , the present invention provides a technical solution: an anti-liquid shock device for gas gathering and transportation equipment for liquid-containing oil wellheads in desert oilfields, including an end cover 1, and a built-in pressure relief valve 2 arranged on the axial center of the end cover 1, The outer end of the pressure relief valve 2 is fixed on the outer end surface of the end cover 1; the end cover 1 is provided with a pressure relief passage 11 and a pressure relief circuit 12, and one end of the pressure relief passage 11 is opened on the inner side wall of the end cover 1. The other end opening of the pressure relief passage 11 is arranged on the side wall of the outer end of the end cover 1, and the pressure relief passage 11 is connected or closed through the pressure relief valve 2; the two openings of the pressure relief circuit 12 are arranged on the inner end of the end cover 1, and The pressure relief valve 2 is arranged on the pres...

Embodiment 2

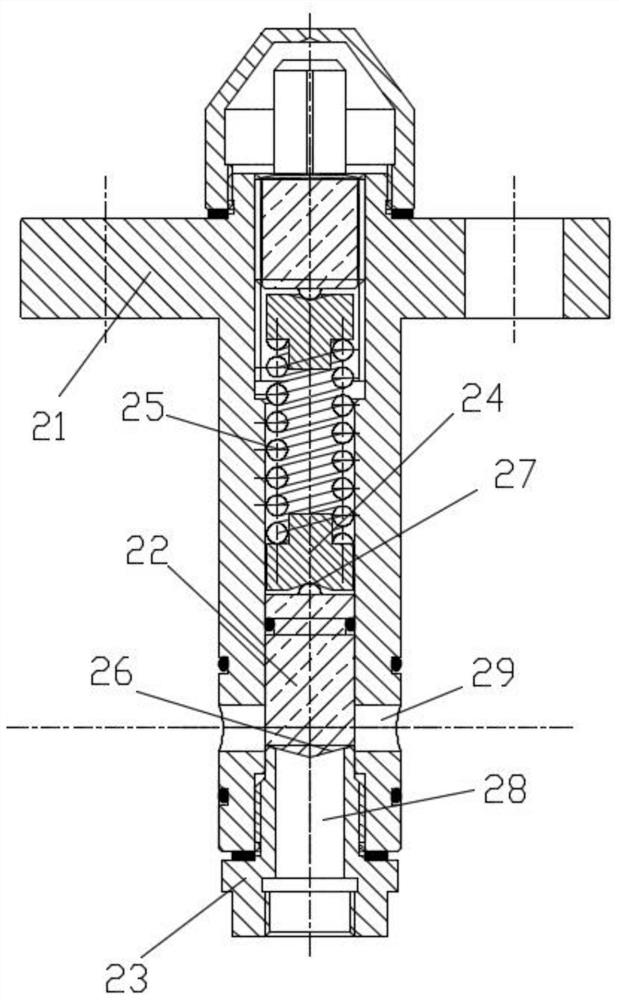

[0032] An anti-liquid shock device for gas gathering and transportation equipment at a wellhead containing liquid oil in a desert oilfield, comprising a pressure relief valve 2, an anti-tilt mechanism, a valve core 22 and a spring 25, a pressure relief passage 11, a pressure relief circuit 12, and an end cover 1.

[0033] The device is equipped with a pressure relief valve 2. If there is a liquid shock (an abnormal shock accident occurs when oil-containing wellhead gas is sucked by the gathering and transportation equipment and then discharged), and the pressure at the end cover 1 is instantaneously high, the pressure relief valve 2 will be released immediately. Load protection, so as to avoid excessive pressure in the cylinder and avoid damage to the moving mechanism and cylinder of the gathering and transportation equipment and cause it to fail to work normally;

[0034] The pressure relief valve 2 is a spring 25 pressure relief device built in the end cover 1 of the cylinder...

Embodiment 3

[0040] When the pressure at the end cover 1 is in a normal state, the lower valve core 22 is under the action of the elastic force of the spring 25, and the conical sealing surface 26 at the bottom of the lower valve core 22 is in sealing fit with the conical sealing surface 26 at the top of the valve seat 23. On the one hand, the core 22 closes the transverse passage 29 on the valve body 21 to realize the closure of the pressure relief passage 11; The outer end of the opening is connected;

[0041]When the pressure at the end cover 1 is extremely high instantaneously, the liquid in the cylinder enters the liquid flow channel 28 of the valve seat 23 through the opening of the pressure relief circuit 12, thereby pushing back the lower valve core 22 which is sealingly matched with the top of the valve seat 23 , so that the valve seat 23 is separated from the lower valve core 22; at this time, the inner and outer openings of the pressure relief passage 11 communicate, and the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com