Patents

Literature

31results about How to "Guarantee a tight fit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

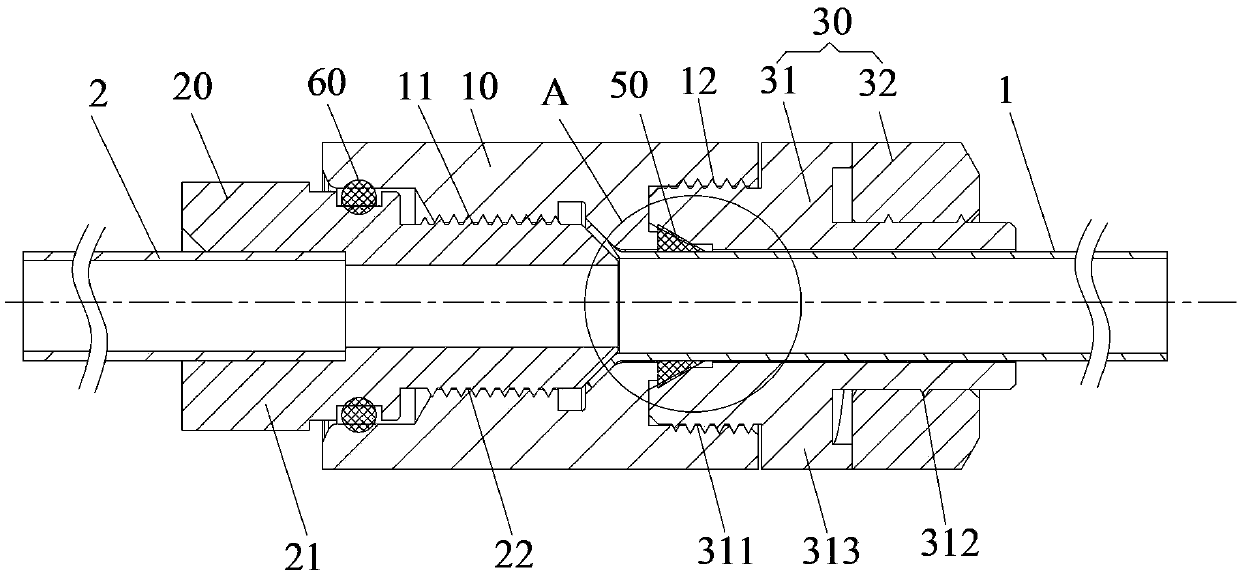

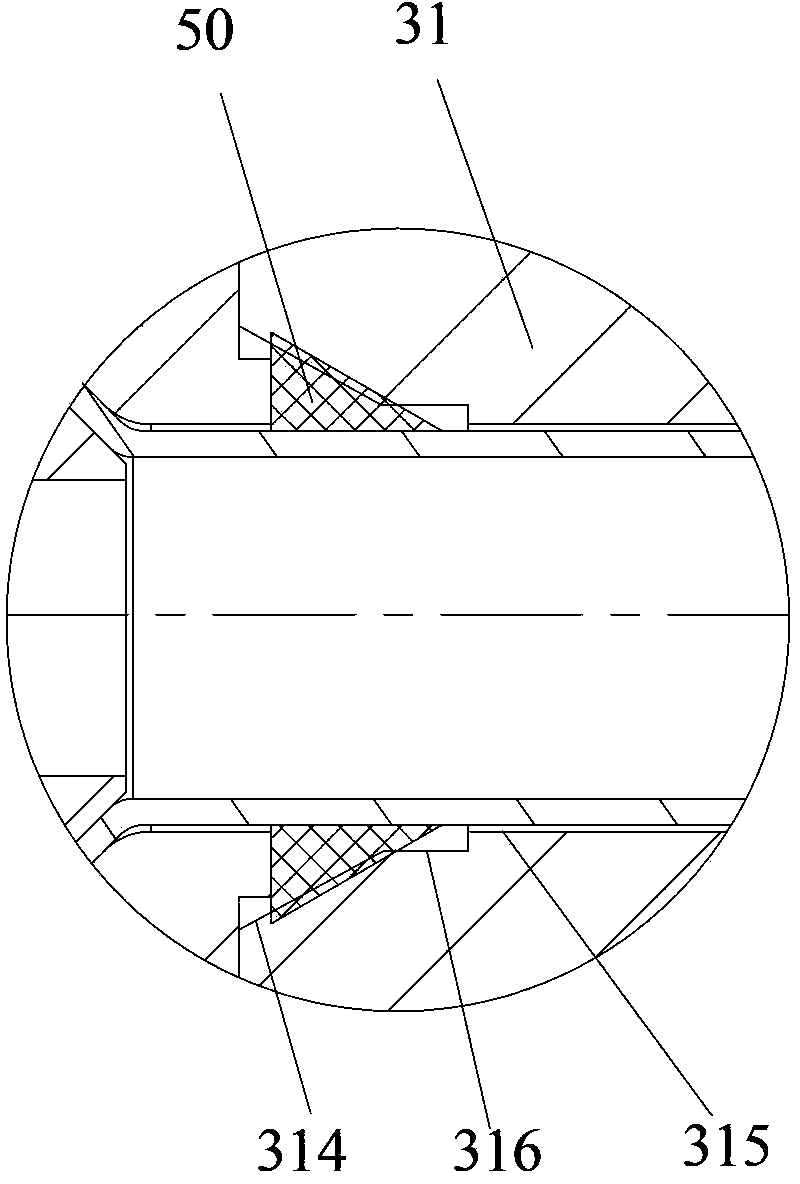

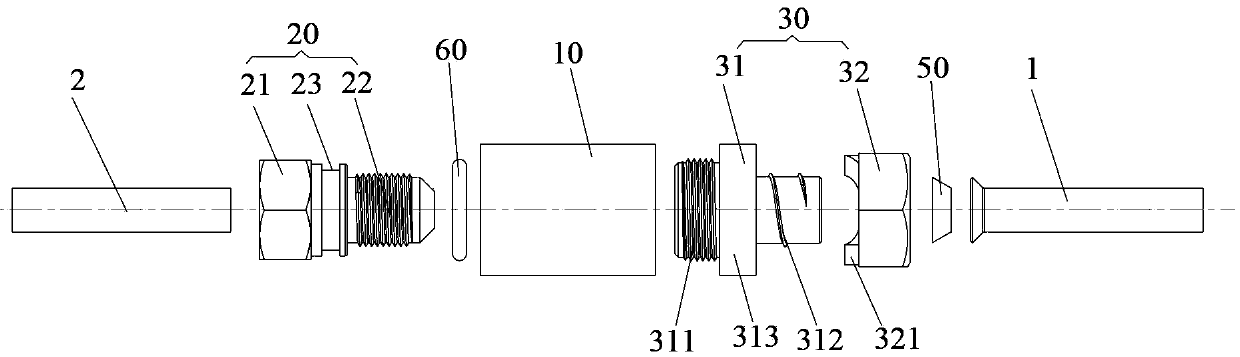

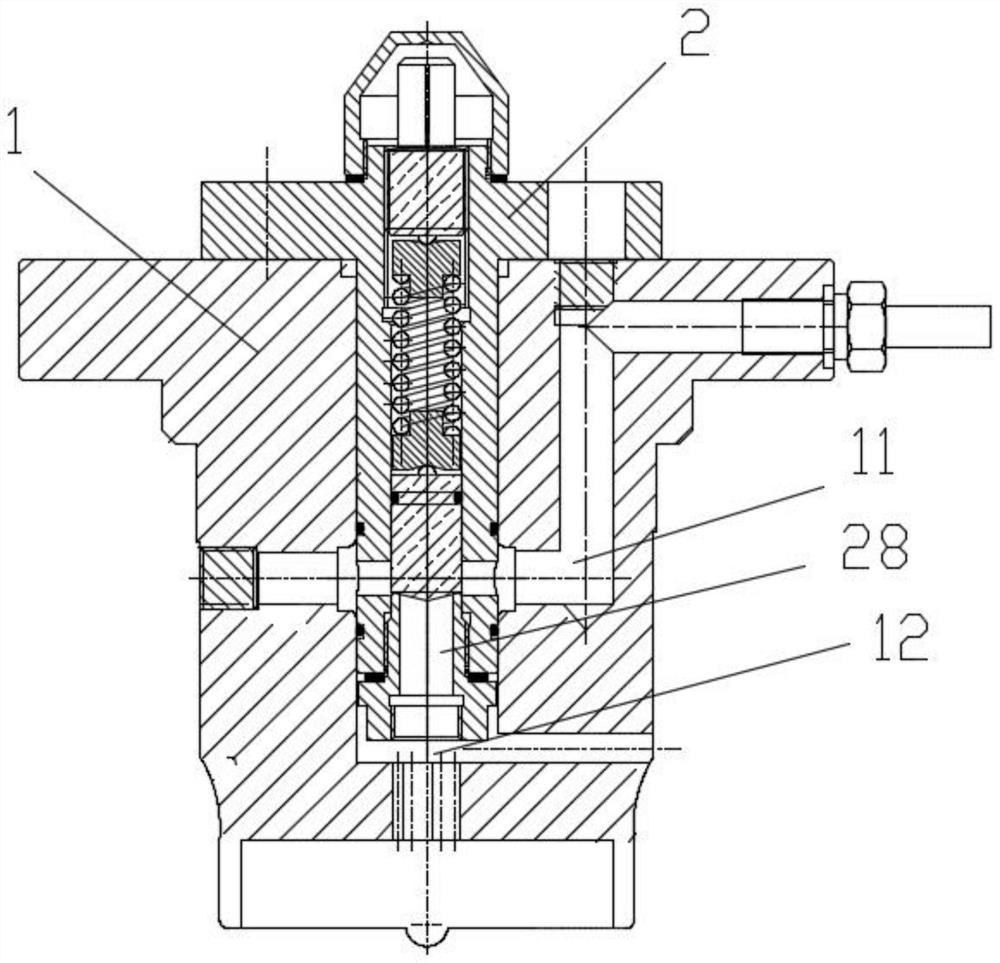

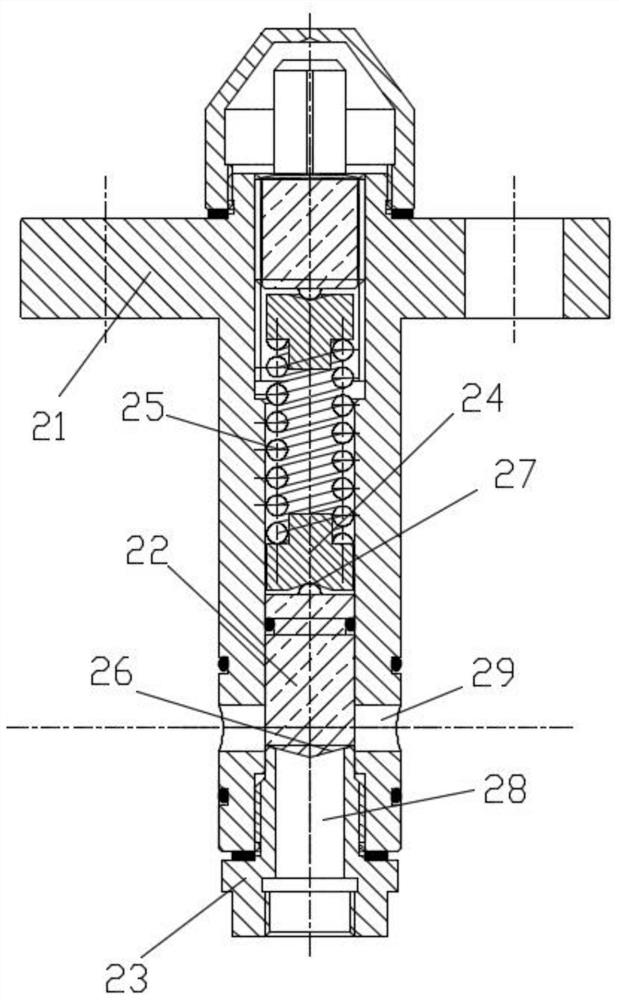

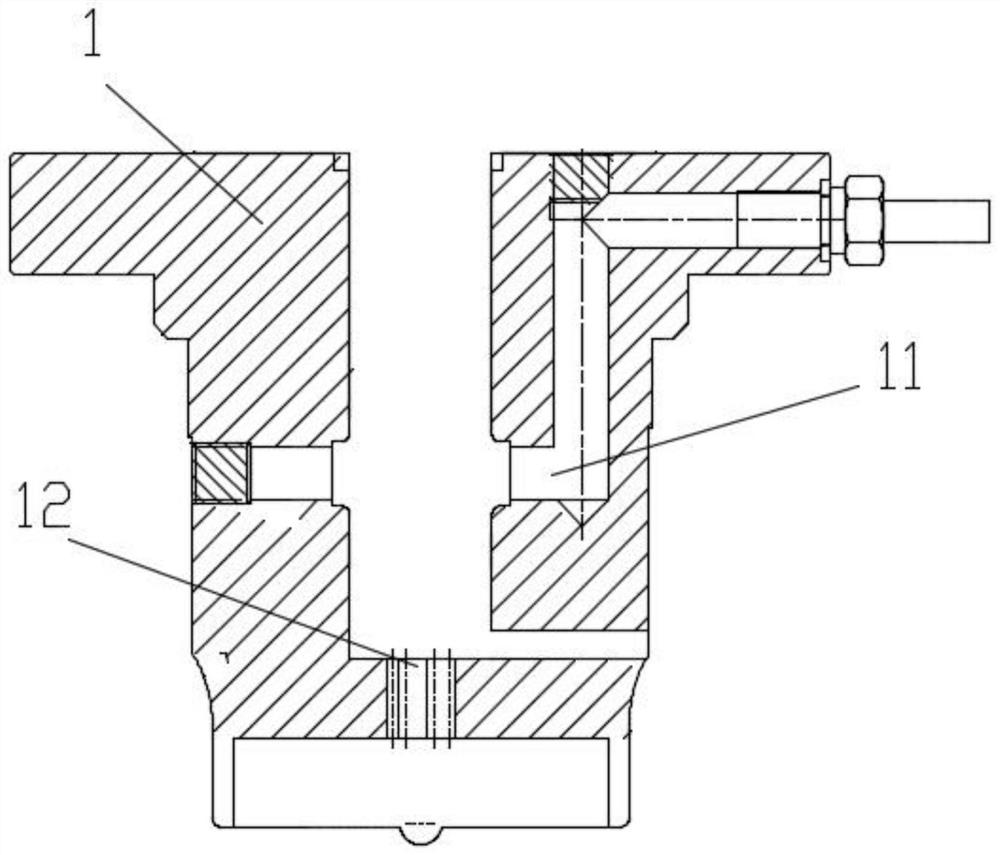

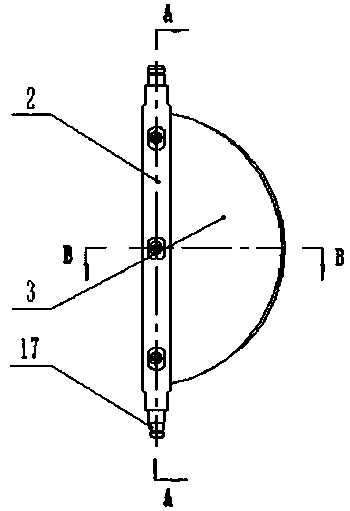

Pipeline connection assembly and air conditioner with same

ActiveCN103672224AAvoid noiseGuarantee a tight fitLighting and heating apparatusJoints with sealing surfacesRefrigerantStructural engineering

The invention provides a pipeline connection assembly and an air conditioner with the same. The pipeline connection assembly comprises a connection pipe nut, a first pipe joint and a second pipe joint, wherein the connection pipe nut comprises a first internal thread section located at the first end, a second internal thread section located at the second end, and a cylindrical outer surface, and a first connected pipe fitting is installed on the connection pipe nut; the first pipe joint comprises a force application section and a first external thread section, the first external thread section is matched with the first internal thread section, and a second connected pipe fitting is installed on the first pipe joint; the second pipe joint is arranged on the first connected pipe fitting in a sleeved mode and comprises a pipe joint body and an auxiliary nut, and the first pipe joint is provided with a first axial through hole enabling the first connected pipe fitting to be communicated with the second connected pipe fitting. According to the pipeline connection assembly, demounting prevention of connection pipes can be truly achieved, the problem that refrigerants are leaked due to disassembling of existing pipelines after being connected is solved, and pipeline connection can be more compact; after-scale installation and maintenance cost is reduced, and the use range of flammable refrigerants is enlarged.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

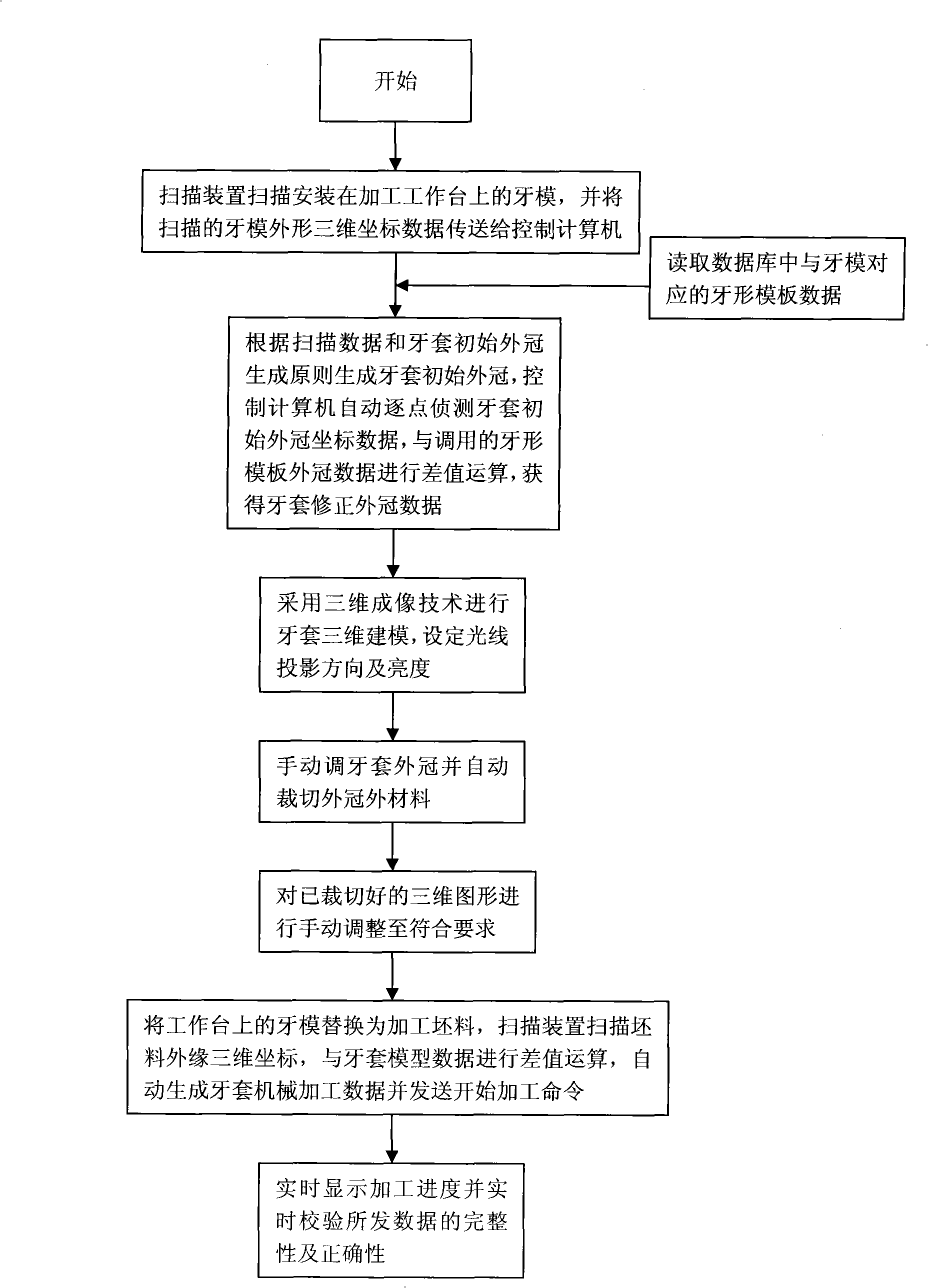

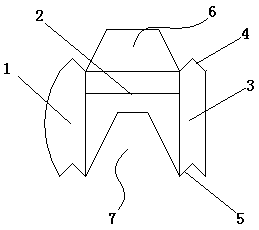

Tooth cap processing method

ActiveCN101259038AImprove dental careGuarantee a tight fitTeeth fillingTeeth cappingMachine toolDental cast

The invention relates to a method for processing teeth braces. Three dimensional coordinate data of a tooth model are scanned by a scanning device in a scanning and processing worktable and are transmitted to a control computer for reading corresponded data of a tooth shape template; initial external crowns of the teeth braces are formed according to the scanning data and a forming principle of the initial external crowns of the teeth braces; the coordinate data of the initial crowns of the teeth braces and the data of the initial external crowns of the tooth shape template are scanned for a differential value operation to obtain the data of amended external crowns of the teeth braces; a three-dimensional modeling is carried out according to the scanning data of the tooth model and data of the amended external crown of the teeth braces; then the models of the teeth braces are obtained; an automatic trimming of materials other than the external crowns is carried out; direction and brightness of a light projection are set; the tooth model on the processing worktable is scanned for the differential value operation with the data of the models of the teeth braces so as to obtain point-by-point processing data of the teeth braces and send a processing order to a processing machine to process the teeth braces. The method has the advantages that: the teeth braces with external crowns almost close to a natural tooth shape can be obtained and the amendment of the external crowns of the teeth braces is convenient; internal crowns of the teeth braes closely are matched with the shape of teeth; dental treatment level is enhanced.

Owner:深圳市金悠然科技有限公司

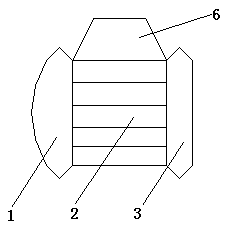

Maintenance-free fully-preventive floor drain

ActiveCN105625554AImplement active connectionAvoid easy accumulation problemsSewerage structuresFiberMechanical engineering

The invention discloses a maintenance-free fully-preventive floor drain, comprising a hollow floor drain core, wherein a seal plate for spacing the upper and lower parts of the floor drain core is arranged in the floor drain core, a water outlet is arranged on the seal plate, a water retaining structure is arranged below the seal plate and comprises a lever, a rotating shaft used as a lever fulcrum, a clump weight arranged at one end of the lever and a water-retaining plate arranged between the water outlet and the other end of the lever, the water-retaining plate is in rotary connection with the rotating shaft and is used for seal fit with the water outlet, and the moment of the clump weight is greater than the moment of the water-retaining plate. The invention aims at providing the maintenance-free fully-preventive floor drain which is capable of thoroughly solving the problem of hair fiber accumulation, has good seal effect and prevents blow-by.

Owner:哈尔滨千奇环境技术有限公司

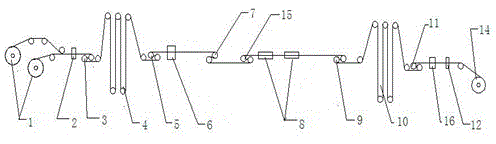

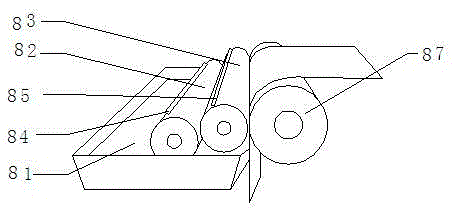

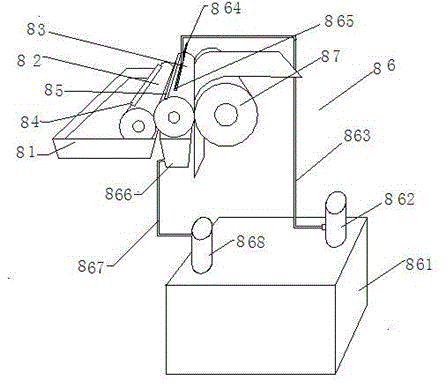

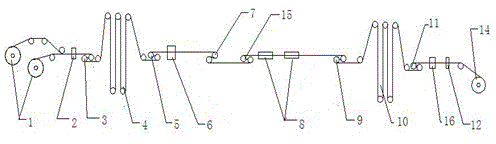

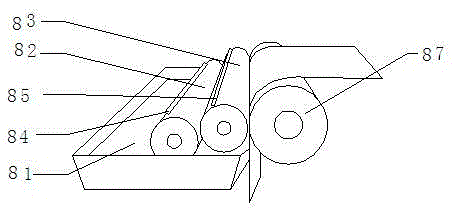

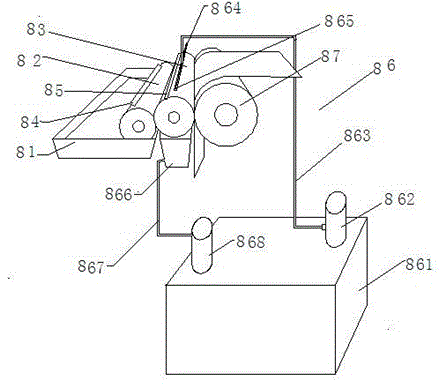

Production line for roller-coated color steel plate

InactiveCN102975019AGuaranteed uptimeGood molding effectOther manufacturing equipments/toolsRotary pressesProduction lineSurface roughness

The invention provides a production line for roller-coated color steel plates. Steel bands at all process sections are flattened through a plurality of tension rollers and stable and constant tension is particularly provided for a roller coating section. Moreover, since corona treatment is conducted to the surfaces of the steel bands before the steel bands enter the roller coating section to form a plurality of pits on the surfaces of the steel bands, the surface roughness of the steel bands is improved, the adhering force between the surfaces of the steel bands and color pattern layers is improved, the color pattern layers are not apt to peel off and the formability of the steel bands is improved.

Owner:LIAONING CHAOSHUO TOMA TECH STEEL PLATE PRINTING

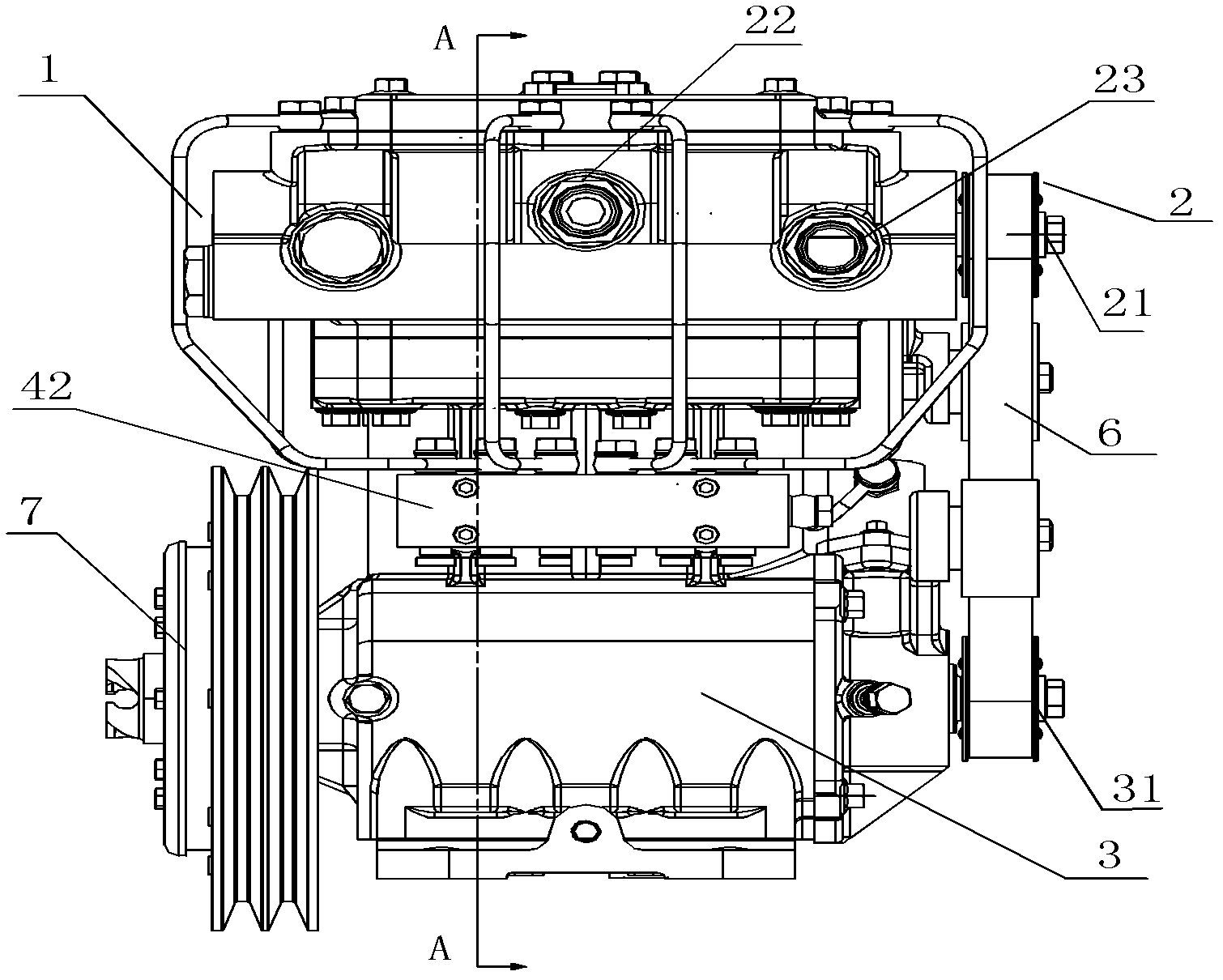

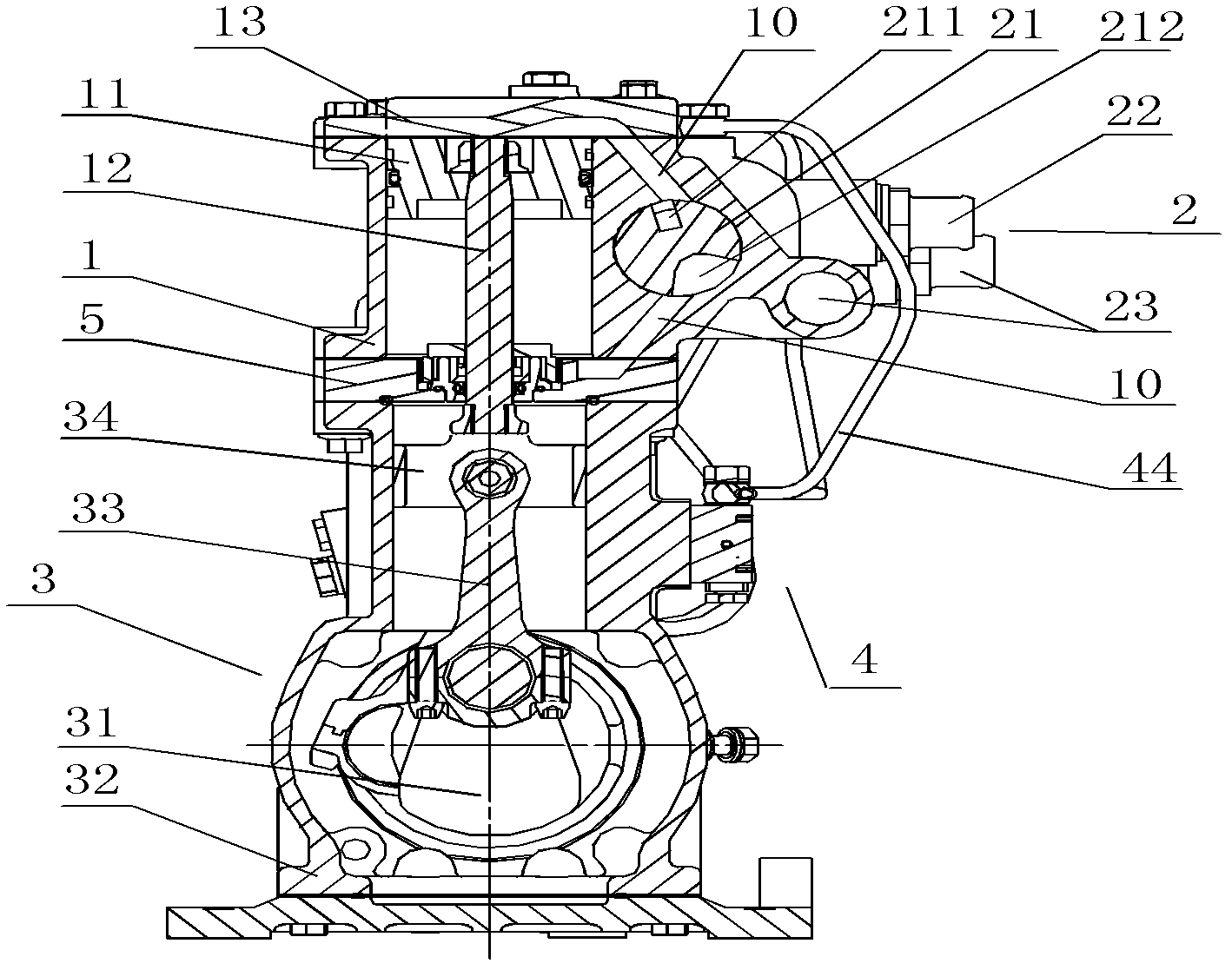

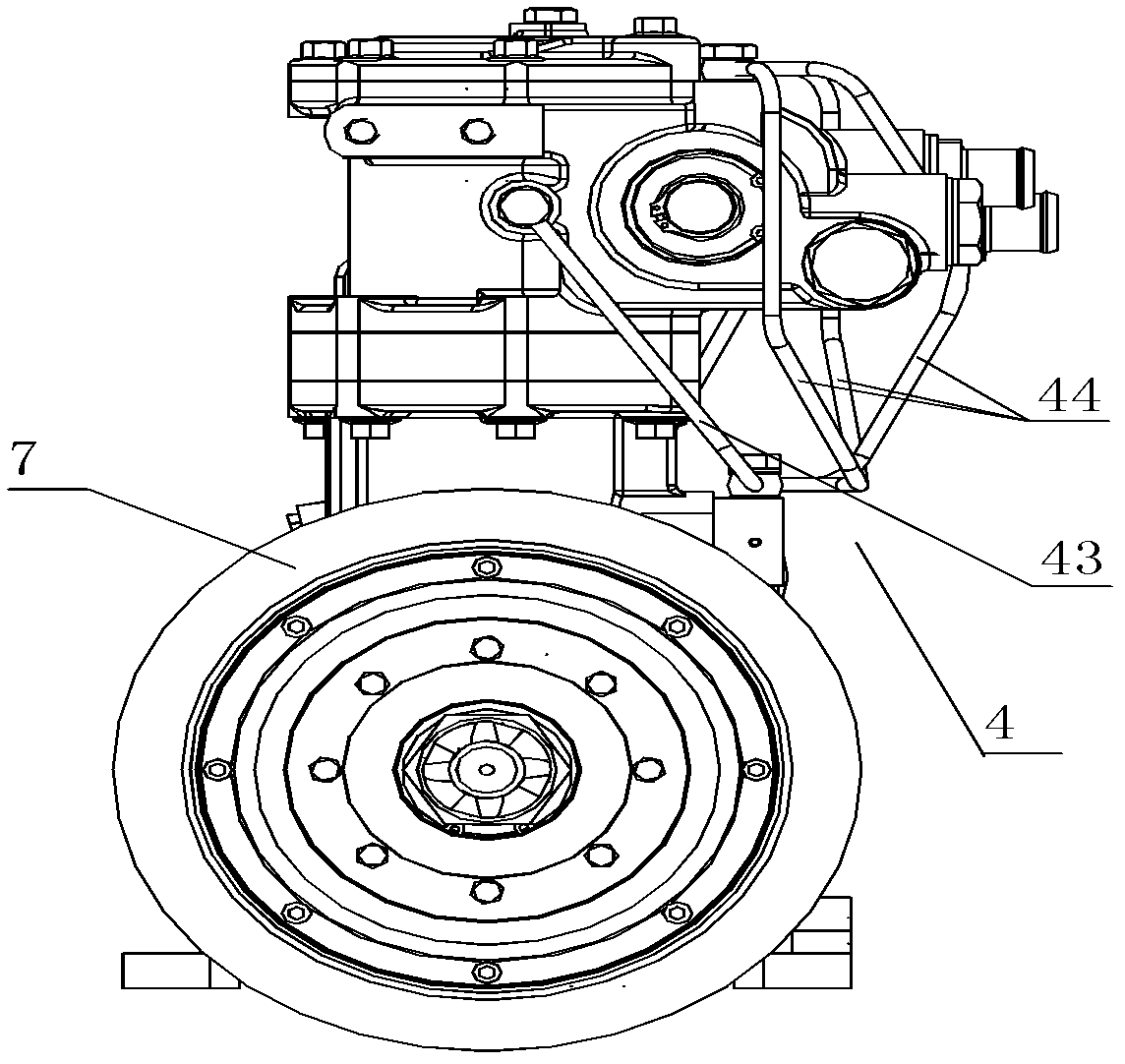

Steam motor

ActiveCN103122773AGuarantee a tight fitReduce resistanceInternal combustion piston enginesEngine componentsPistonExhaust gas

The invention discloses a steam motor. The steam motor aims at solving the defect caused by the fact that the existing exhaust gas can not be recycled. The steam motor comprises a valve mechanism, a power output mechanism and an air cylinder body. The air cylinder body is in a sealing arranged cylinder body shape. A piston is installed in the air cylinder body. The piston can move in a reciprocating mode along a lengthways direction of the air cylinder body under the driving of the piston. The valve mechanism is provided with a valve shaft. An air inlet groove and an air outlet groove are formed in the valve shaft, wherein the air inlet groove and the air outlet groove are communicated with the air cylinder body. The external exhaust gas can be entered into or discharged the air cylinder body through the air inlet groove and the air outlet groove. The power output mechanism is in fit connection with the valve mechanism. The power output mechanism is provided with a bent shaft. One end of the bent shaft is in fit connection with the piston and the other end of the bent shaft is connected with an engine through a driving assembly. The discharged exhaust gas in an air exhaust pipe of the engine steam motor can heat water into steams and the steams are fed into the air cylinder body. Then, formative energy is delivered to the engine through the driving assembly so that energy conversion and recycling of exhaust gas waste heat are achieved.

Owner:GUANGXI YUCHAI MASCH CO LTD

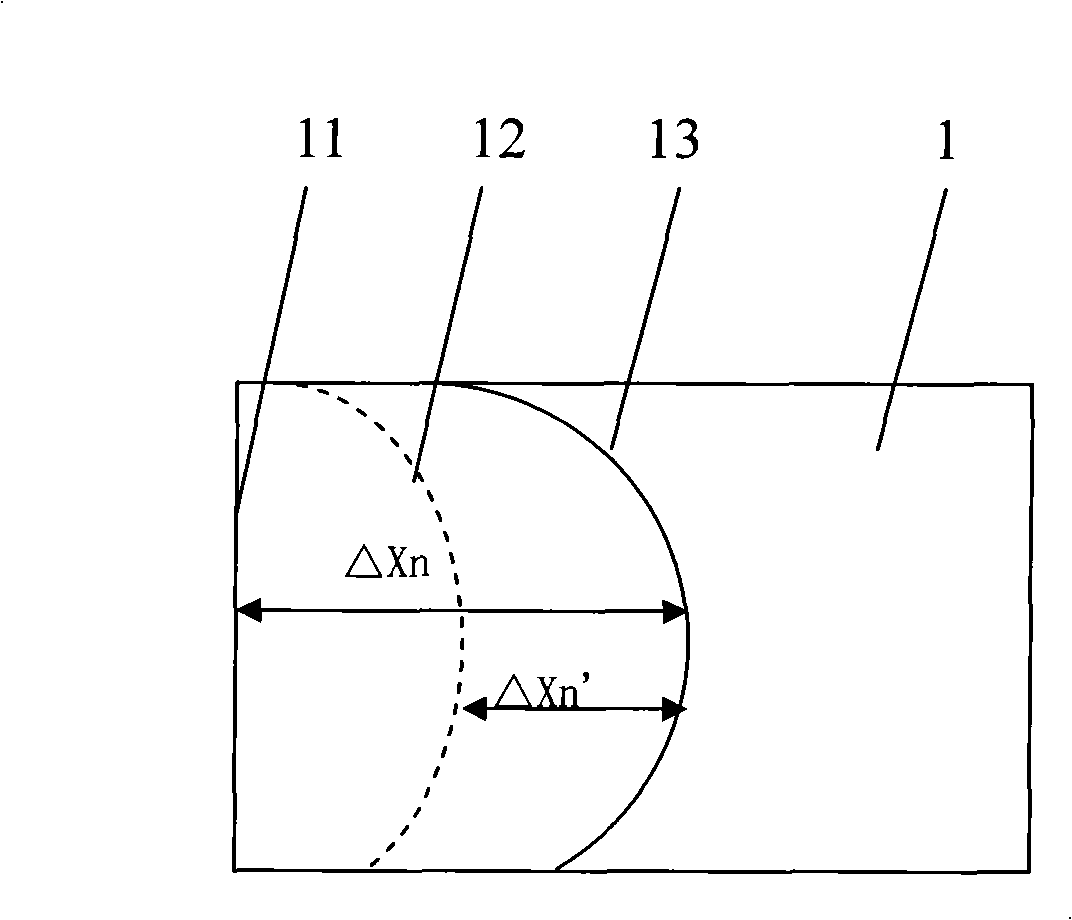

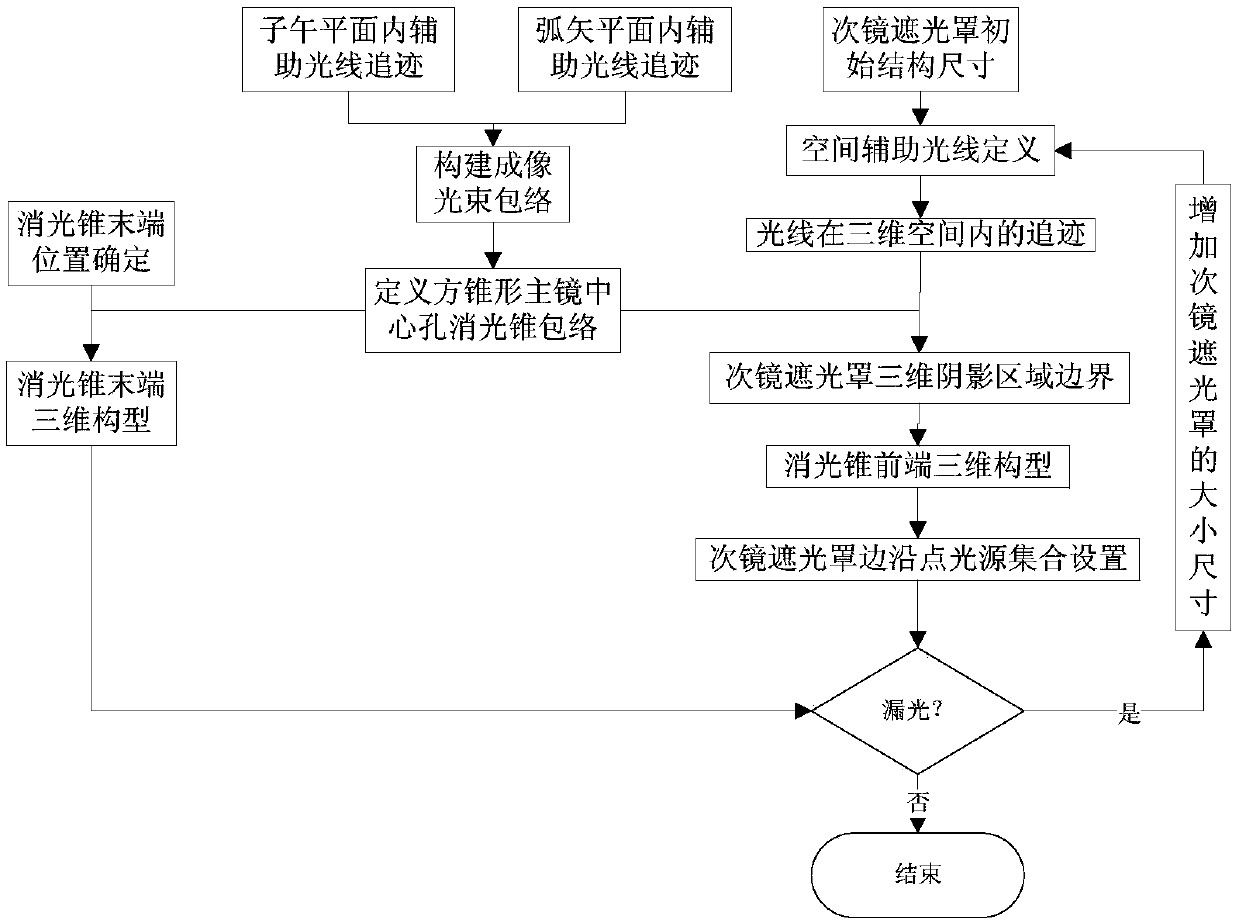

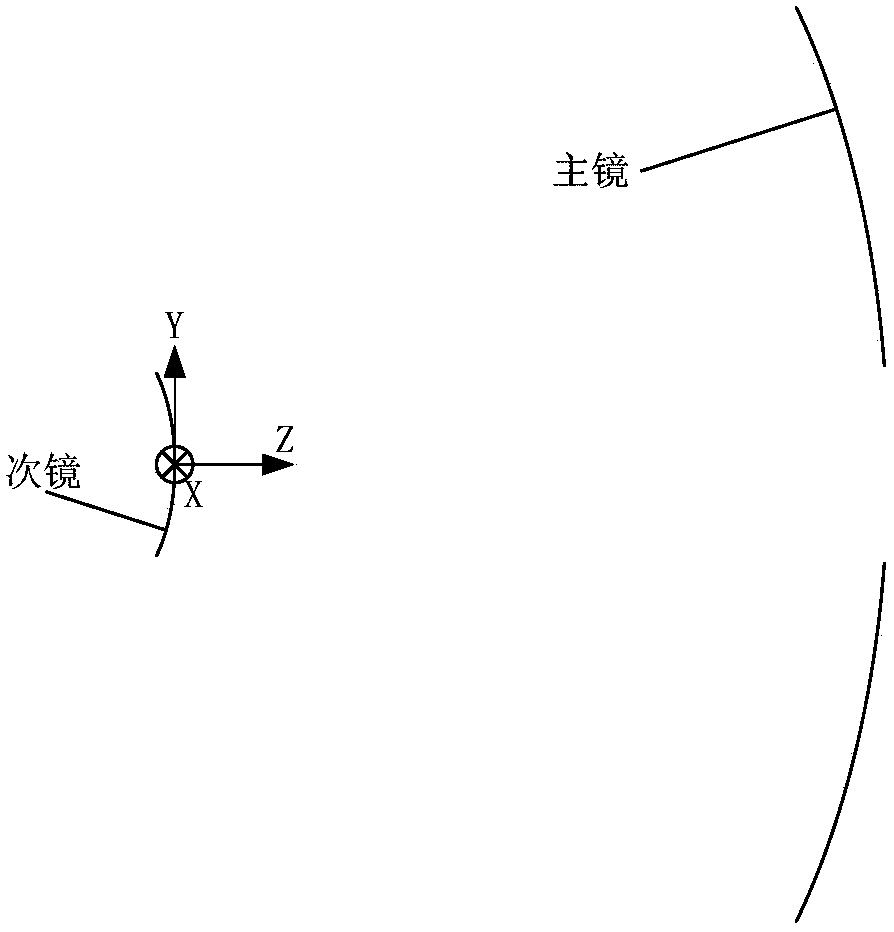

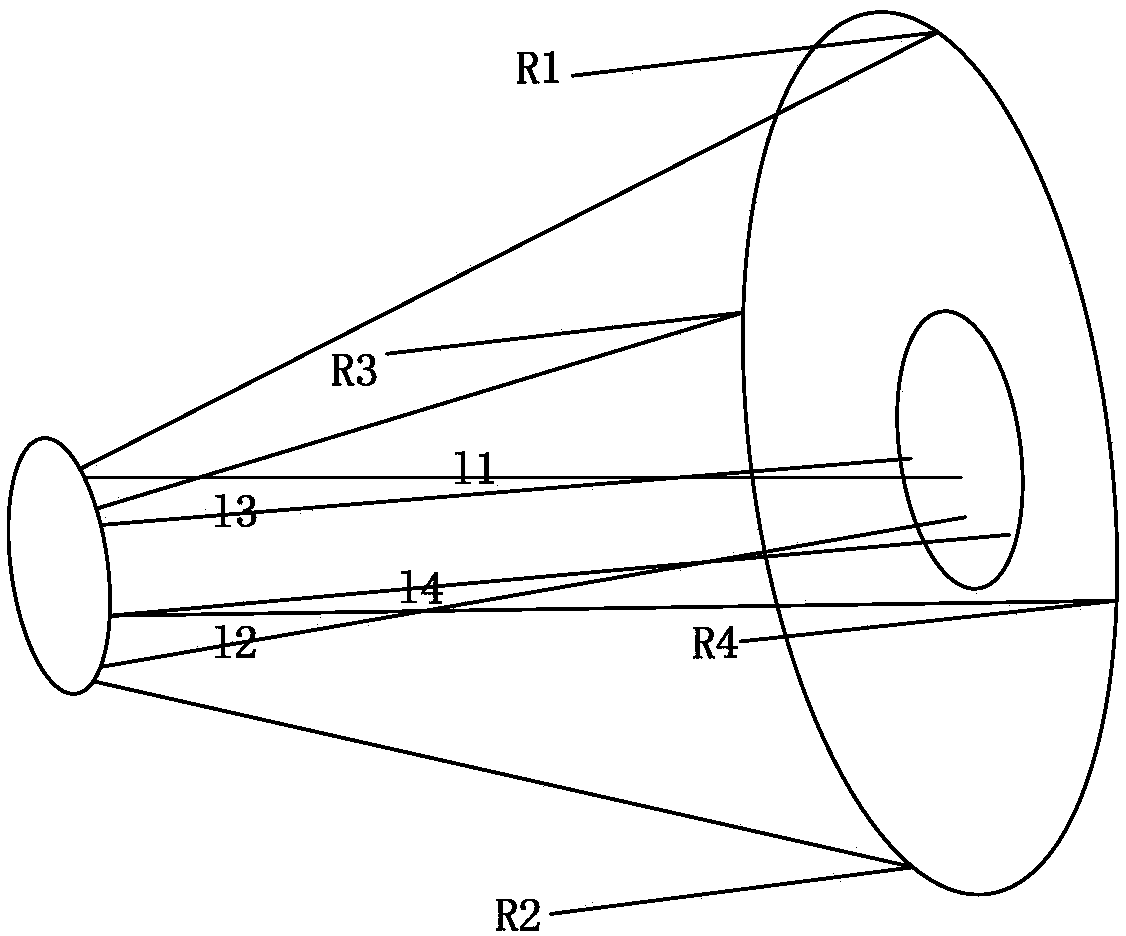

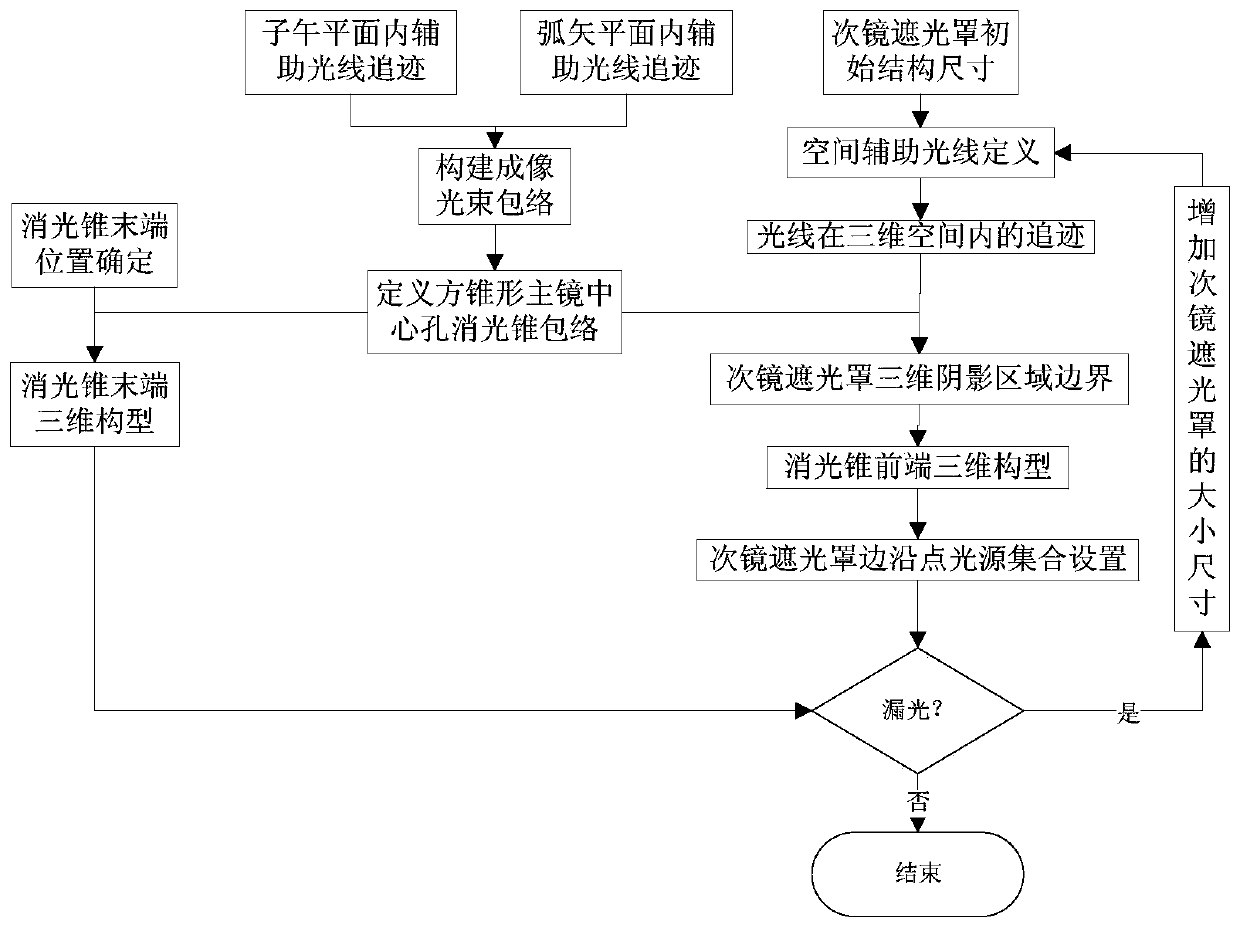

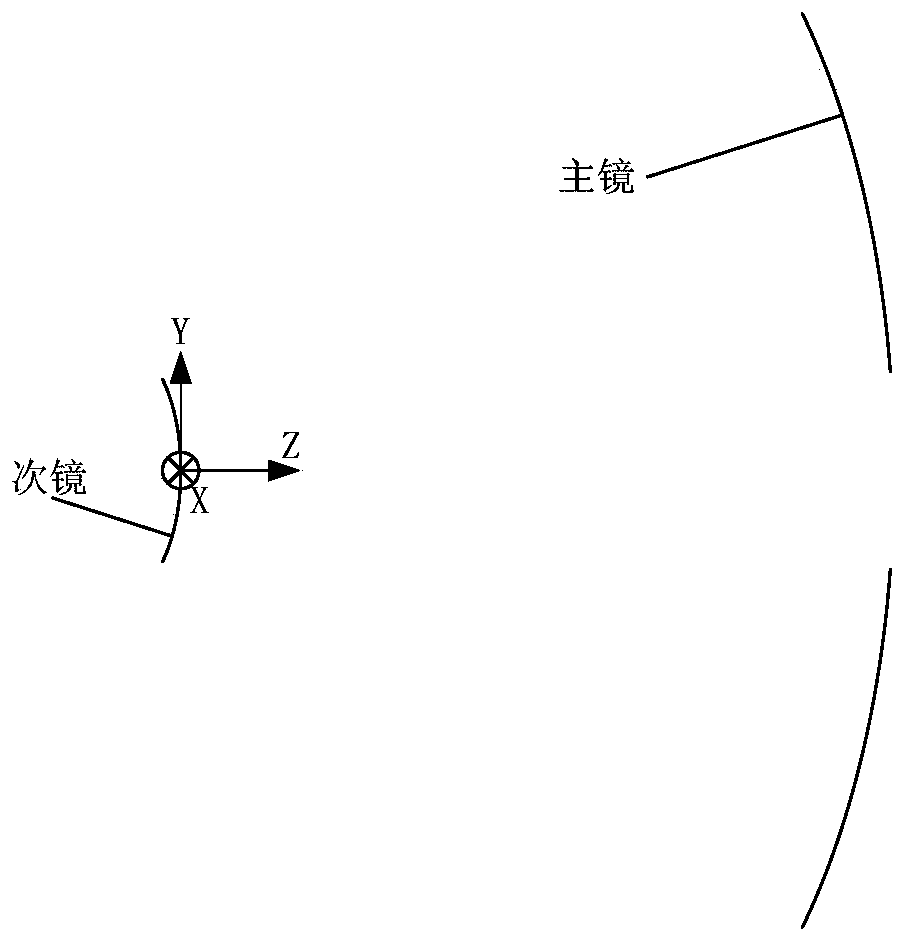

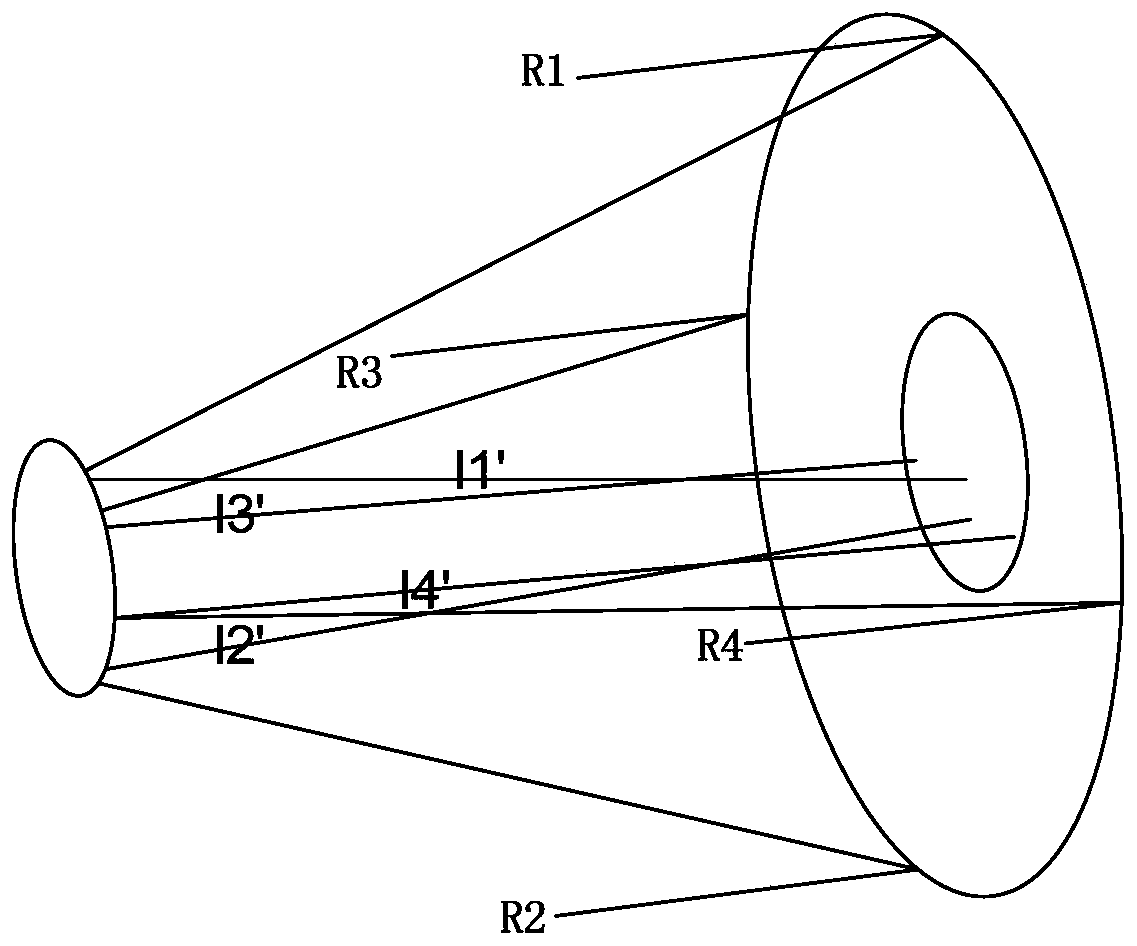

Space-ray-tracing-based method for designing secondary mirror hood and square-tapered extinction cone

ActiveCN107643595AOvercome each other's shortcomingsOvercome sizeOptical elementsExtinctionLens hood

The invention relates to a space-ray-tracing-based method for designing a secondary mirror hood and a square-tapered extinction cone. The method comprises: step one, establishing a Cartesian rectangular coordinate system used during a design process; step two, establishing auxiliary light in a meridian plane and a sagittal surface and carrying out calculation to obtain a boundary of a square-tapered main mirror central-hole extinction cone; step three, determining the position and configuration of the tail end of the square-tapered main mirror central-hole extinction cone; step four, definingan initial structure of a secondary mirror hood; step five, constructing a spatial auxiliary ray and carrying out calculation to obtain the position and configuration of the front end of a square-tapered extinction cone; step six, setting a point light source set at the edge of a conical surface, carrying out ray tracing, carrying out statistics of light source numbers with light leakage possibility, and increasing the size of the conical surface correspondingly; step seven, determining final spatial positions and three-dimensional configuration of the tail end and the front end of the square-tapered main mirror central-hole extinction cone; and step eight, carrying out calculation to obtain three-dimensional configuration of the secondary mirror hood.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

Hidden wheel groove safety hub

InactiveCN103895447ADoes not affect normal disassemblyWon't get out of controlRimsWheelsEngineeringBrake force

Owner:韩燕

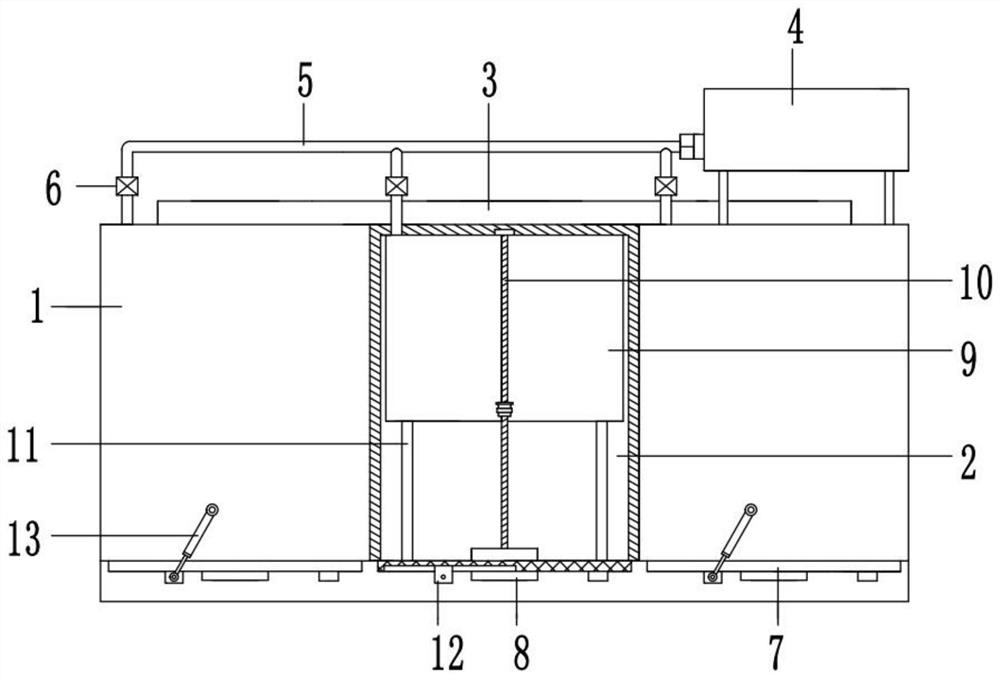

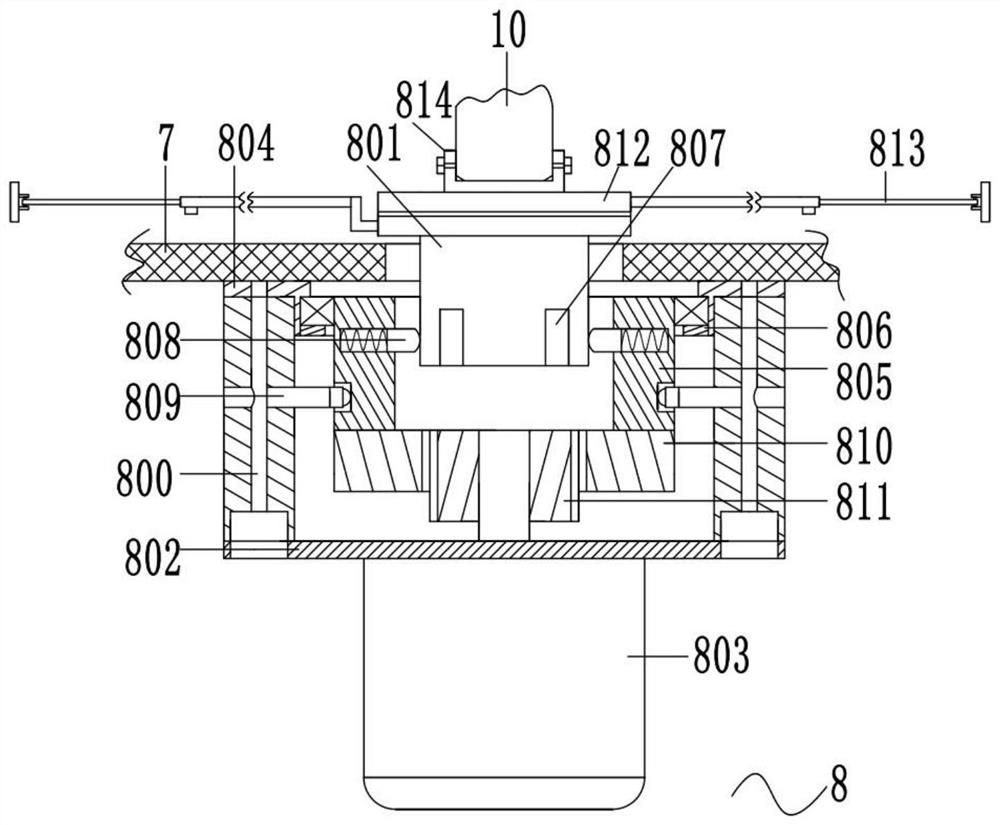

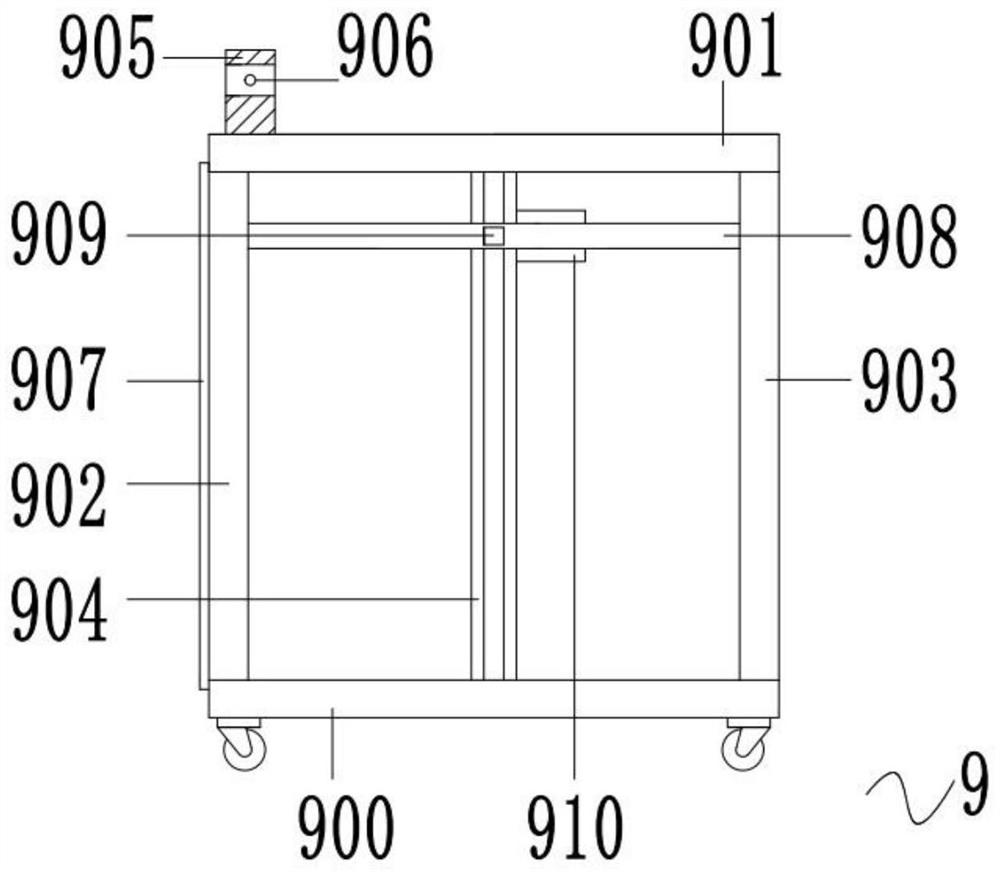

Vacuum brazing equipment of plate-fin heat exchanger and vacuum brazing method of vacuum brazing equipment

ActiveCN113369620AEasy to take outAvoid wastingHeat exchange apparatusMetal working apparatusEngineeringPush switch

The invention discloses vacuum brazing equipment of a plate-fin heat exchanger and a vacuum brazing method of the vacuum brazing equipment, and belongs to the technical field of heat exchanger machining. The vacuum brazing equipment of the plate-fin heat exchanger comprises a horizontally-arranged furnace body, vacuumizing equipment and a gas guide manifold; a plurality of heating cavities are uniformly arranged on the furnace body at intervals along the length direction; a button switch corresponding to the used heating cavity is utilized to enable an electromagnetic valve and the vacuumizing equipment to work; then, under the action of a second two-way timer, a heating device heats the working heating cavity; after work is finished, a heat insulation sealing door is opened through a reversing switch, and then a workpiece can be taken out of the heating cavity; the waste of time and resources for the overall heating of the furnace body is avoided; the working efficiency is increased; furthermore, because a high-temperature-resistant lead screw and a driving device are detachably connected, the high-temperature-resistant lead screw drives a material placing frame mechanism to move; workpieces can be conveniently taken out without going deep into a traditional furnace body; and the device is high in automation degree and has market popularization value.

Owner:ANHUI PROPELLENT HEAT TRANSFER TECH CO LTD

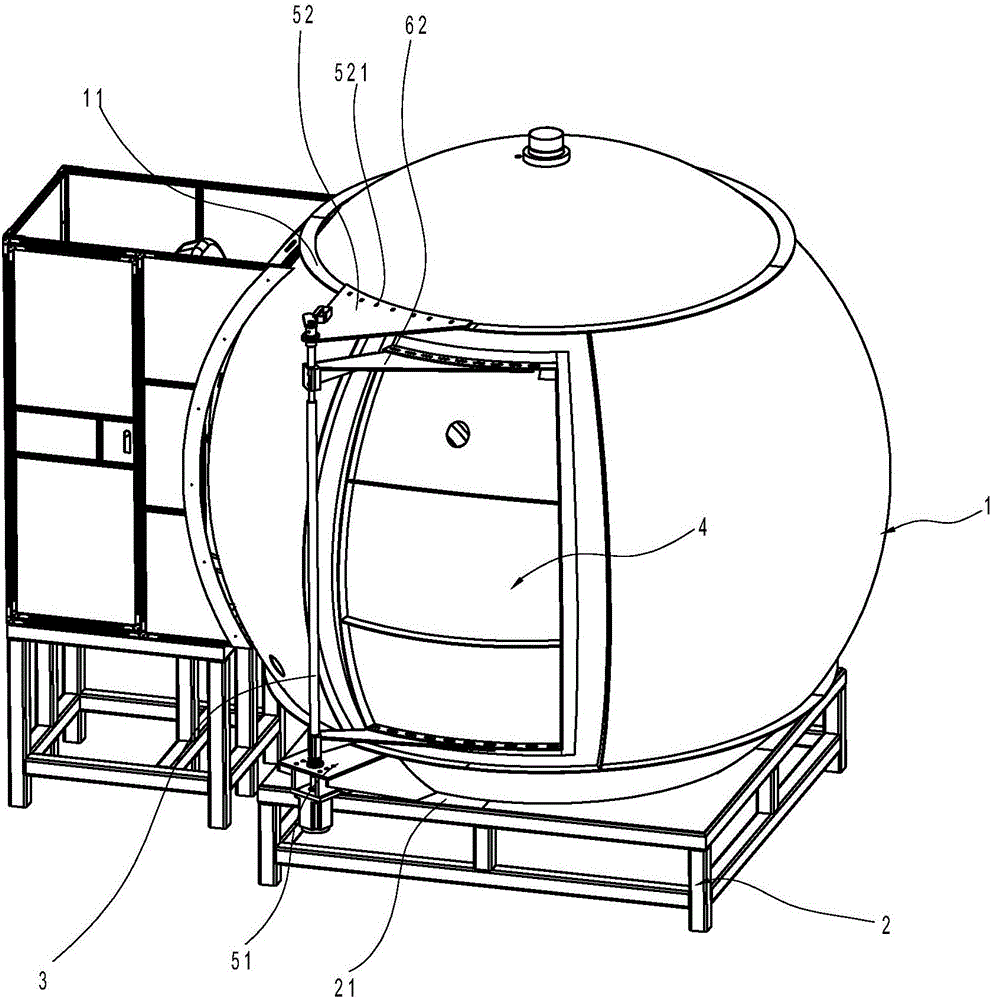

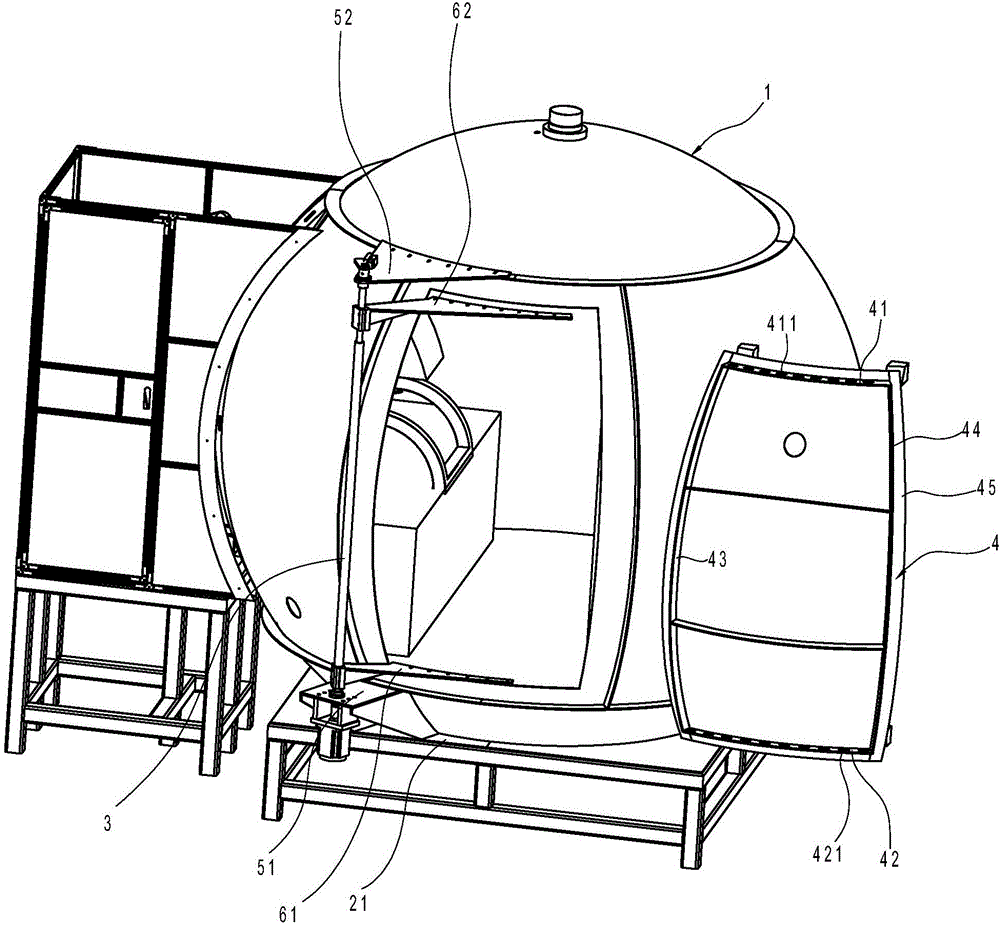

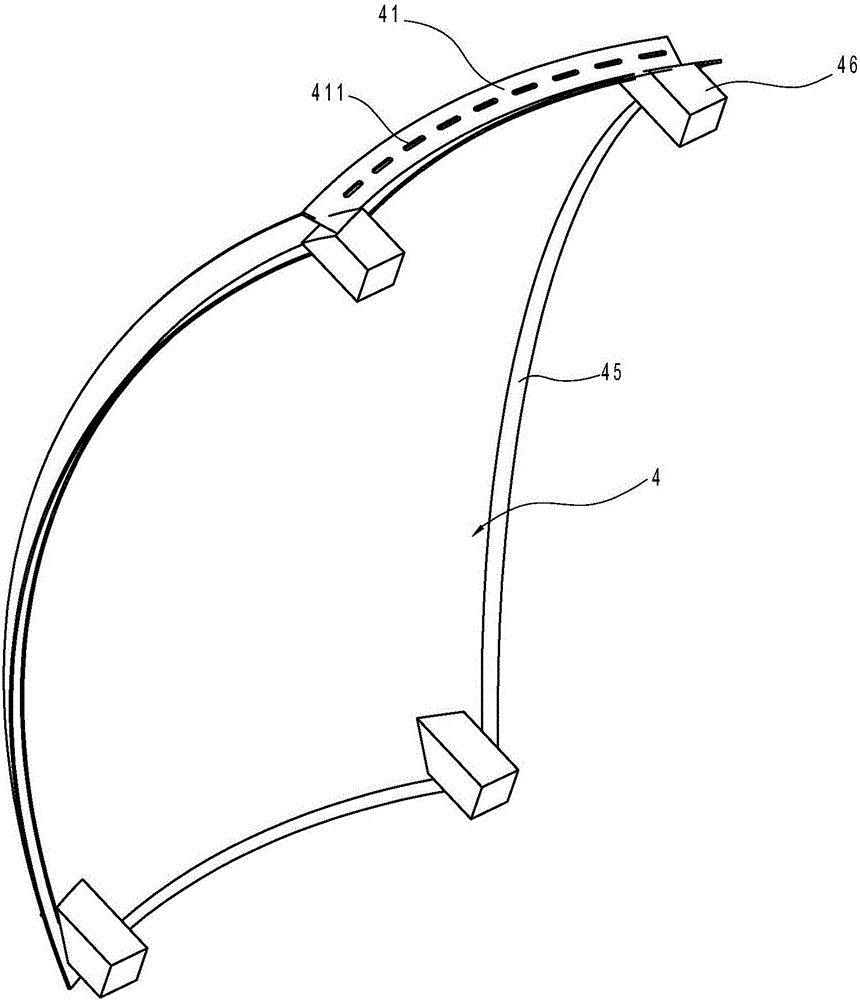

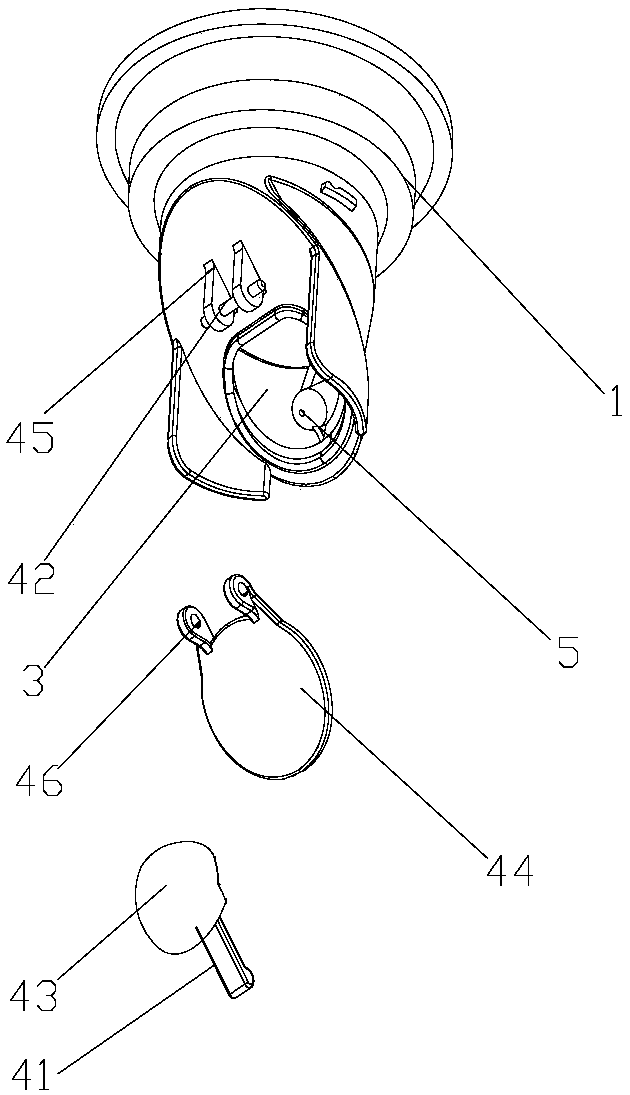

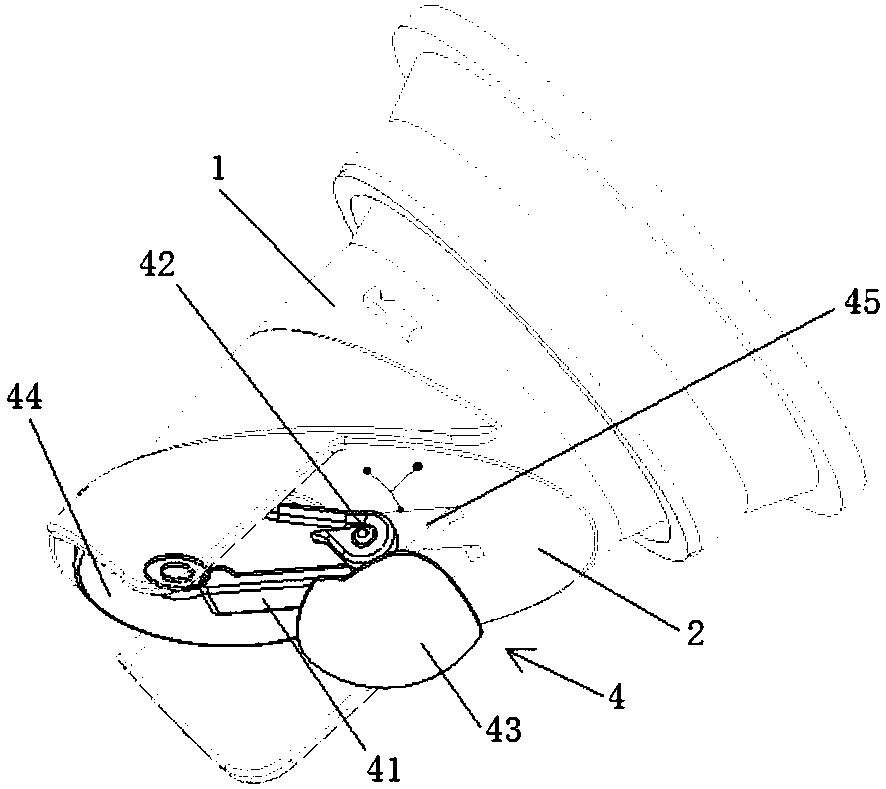

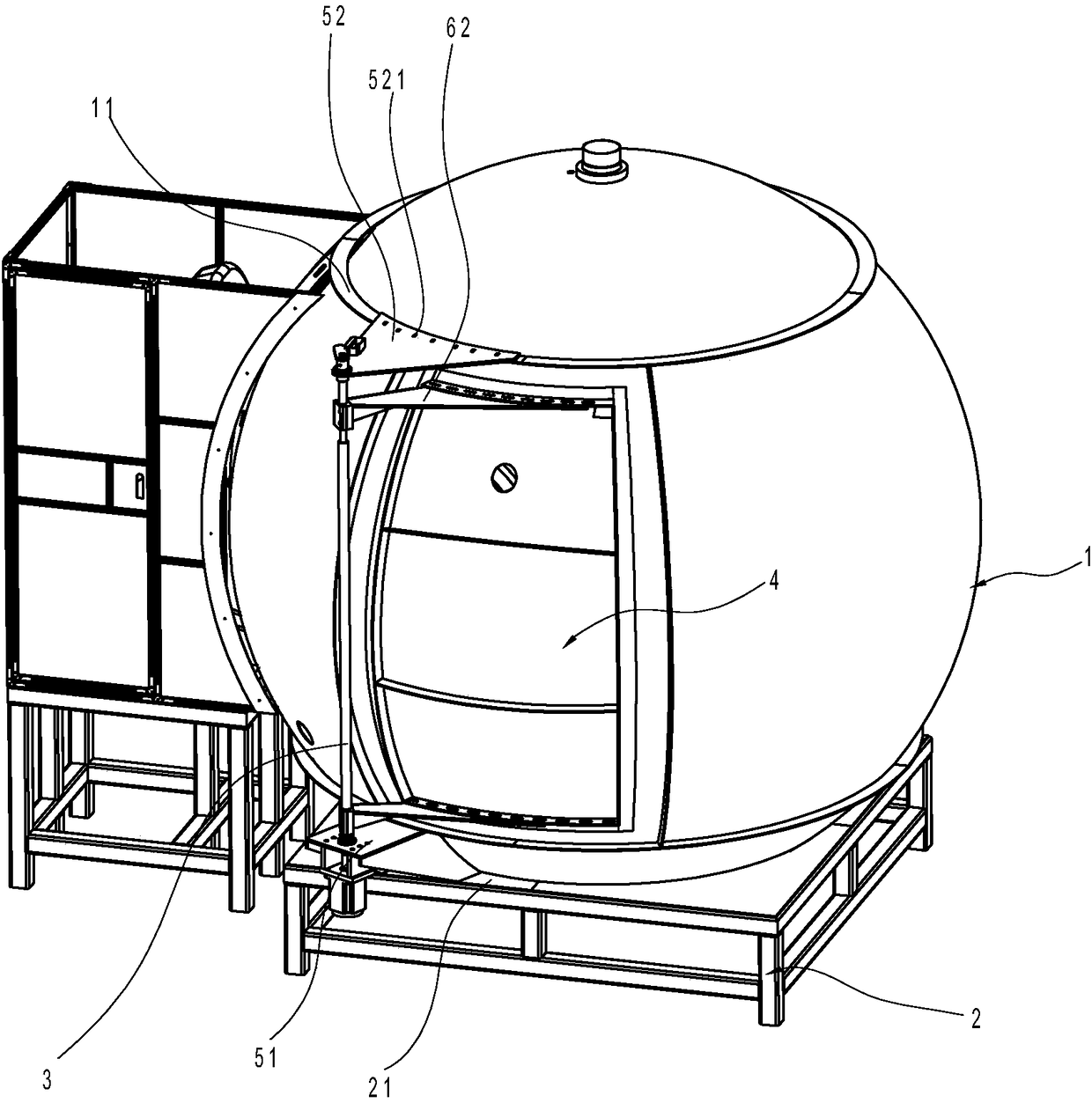

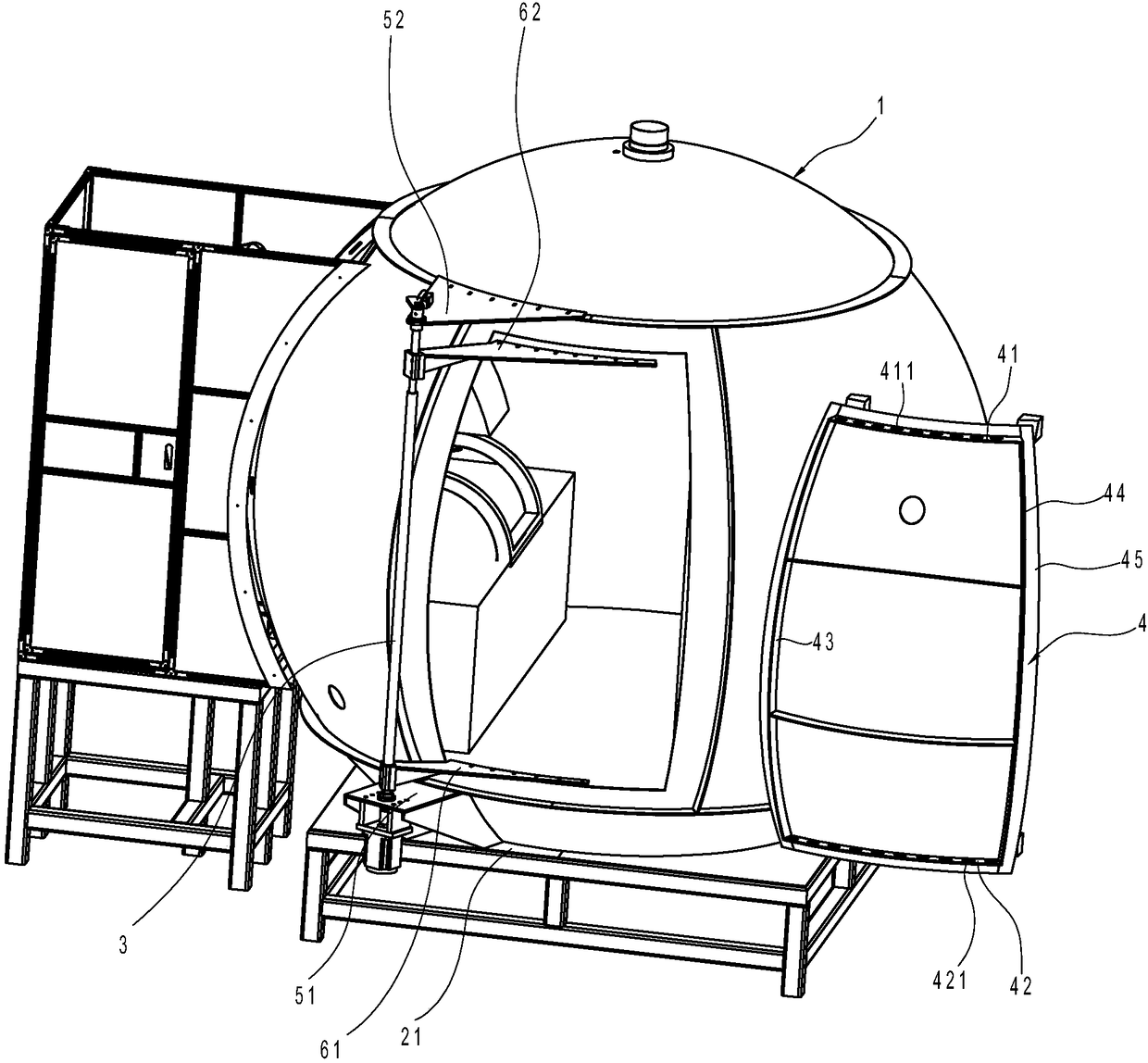

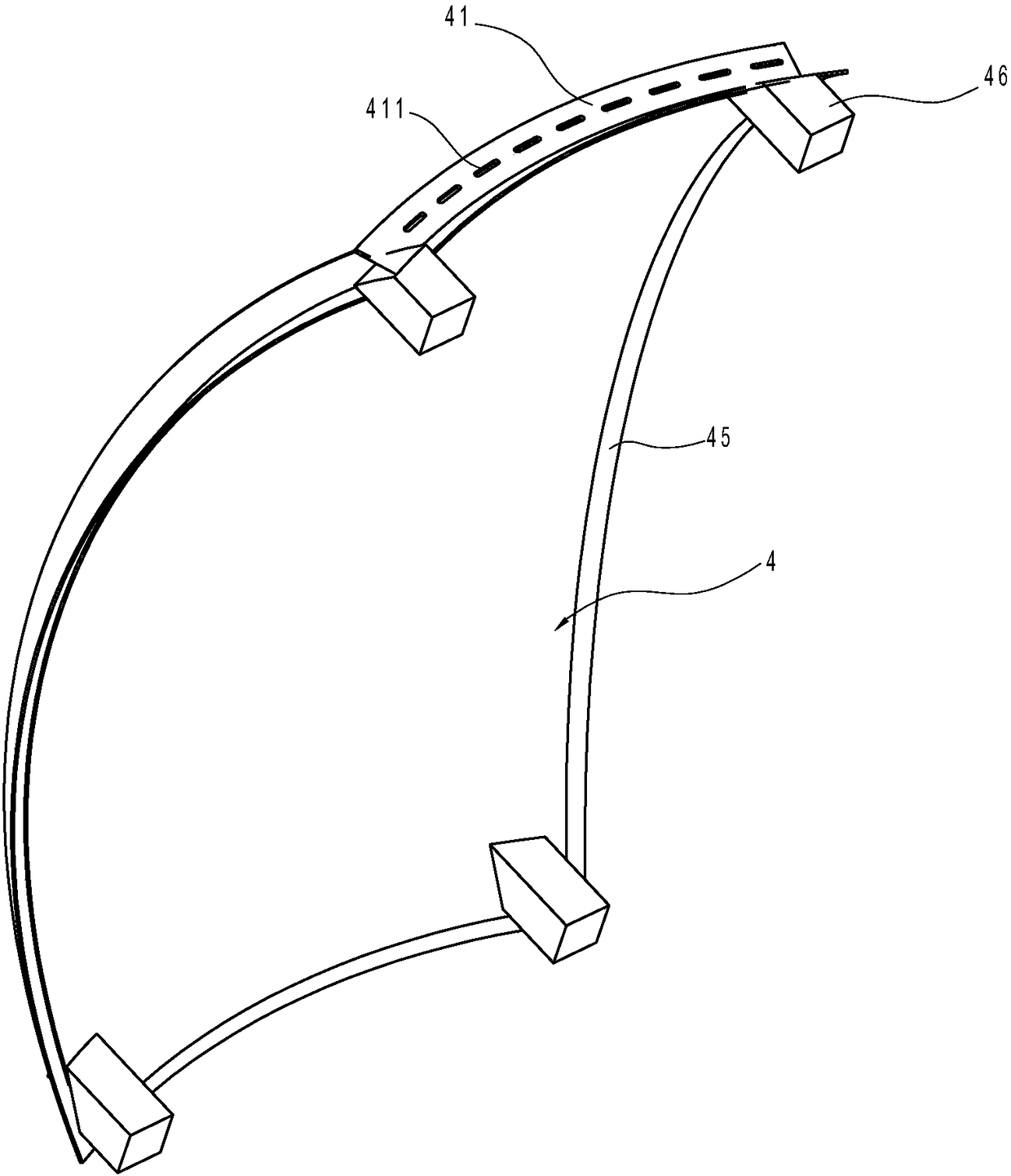

Cabin door mounting method

ActiveCN106334937AGuaranteed to be temporarily fixedGuaranteed to be verticalAssembly machinesMetal working apparatusEngineeringSpot welding

The invention discloses a cabin door mounting method. The method is characterized by comprising the following steps of: cutting a part of a cabin as a cabin door, and spot-welding the cabin door on the cabin; erecting a rotary shaft on a lower supporting plate and sleeving the upper end of the rotary shaft with an upper supporting plate; irradiating the rotary shaft by a first gradienter, wherein vertical glaze released by the first gradienter irradiates the surface of the rotary shaft, observing whether the projection of the vertical glaze released by using the first gradienter on the surface of the rotary shaft is located on a central line of the rotary shaft in the direction or not, if not, knocking on the upper supporting plate to correspond; arranging a second gradienter on one side of the first gradienter; and irradiating the rotary shaft by using the second gradienter, wherein vertical glaze released by the second gradienter irradiates the surface of the rotary shaft, observing whether the projection of the vertical glaze released by using the second gradienter on the surface of the rotary shaft is located on the central line of the rotary shaft in the direction or not, if not, knocking on the upper supporting plate to correspond.

Owner:浙江昇元姜氏健康科技有限公司

A maintenance-free full-proof floor drain

ActiveCN105625554BImplement active connectionAvoid easy accumulation problemsSewerage structuresFiberEngineering

The invention discloses a maintenance-free fully-preventive floor drain, comprising a hollow floor drain core, wherein a seal plate for spacing the upper and lower parts of the floor drain core is arranged in the floor drain core, a water outlet is arranged on the seal plate, a water retaining structure is arranged below the seal plate and comprises a lever, a rotating shaft used as a lever fulcrum, a clump weight arranged at one end of the lever and a water-retaining plate arranged between the water outlet and the other end of the lever, the water-retaining plate is in rotary connection with the rotating shaft and is used for seal fit with the water outlet, and the moment of the clump weight is greater than the moment of the water-retaining plate. The invention aims at providing the maintenance-free fully-preventive floor drain which is capable of thoroughly solving the problem of hair fiber accumulation, has good seal effect and prevents blow-by.

Owner:哈尔滨千奇环境技术有限公司

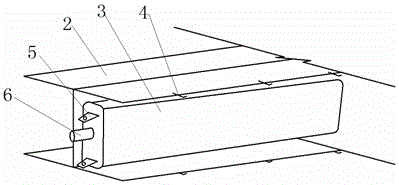

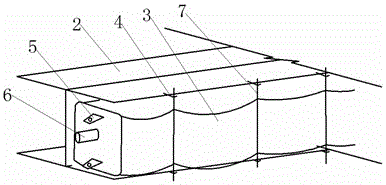

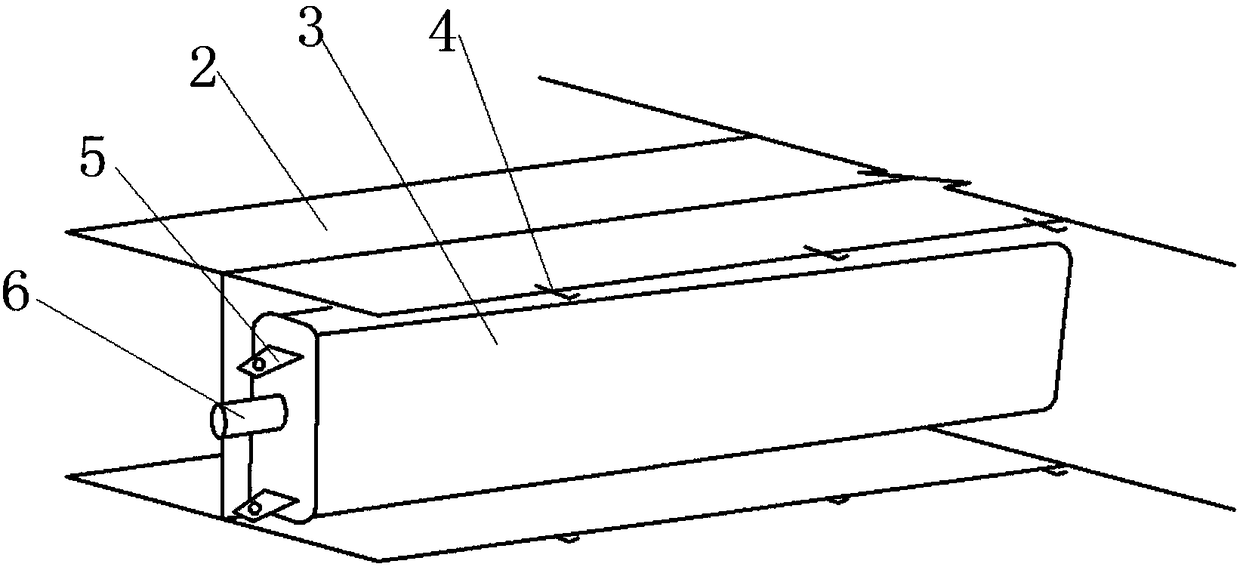

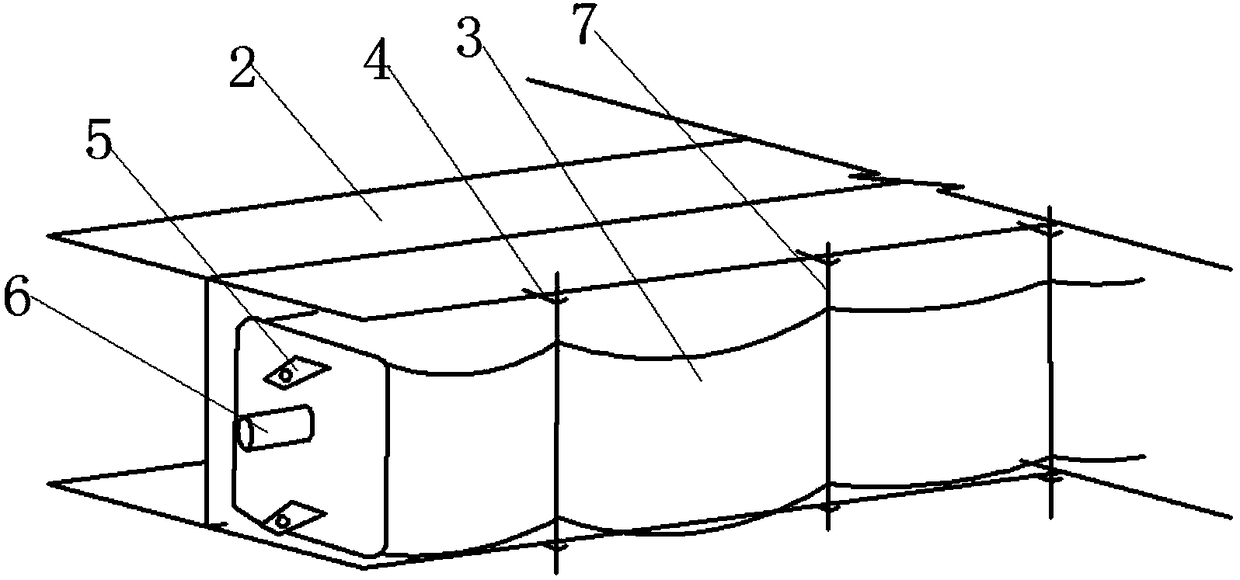

Underground diaphragm wall air bag type interface box and use method thereof

The invention discloses an underground diaphragm wall air bag type interface box and a use method thereof. The underground diaphragm wall air bag type interface box comprises an air bag, a reinforcement cage and fixing buckles, wherein interface grooves are formed in the two sides of the reinforcement cage; multiple buckle fixing ribs are arranged on the outer sides of the interface grooves; the air bag is located inside the interface grooves; the section of the air bag is rectangular; a charging connector is arranged at the upper end of the air bag; pulling-out lifting handles are arranged on the two sides of the charging connector; the fixing buckles are located inside the buckle fixing ribs; and the air bag and the fixing buckles are fixed to one another in a mutual squeezing mode. The use method comprises the first step of machining of the air bag, the second step of machining of reinforcing steel bars, the third step of installation of the air bag, the fourth step of sinking of the reinforcement cage and pouring of concrete, and the fifth step of pulling out of the air bag.

Owner:THE THIRD ENG CO LTD OF CCCC SECOND HIGHWAY ENG BUREAU

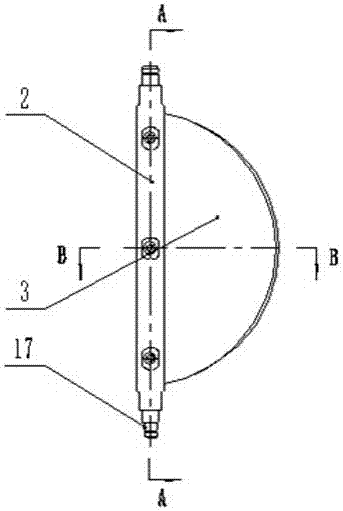

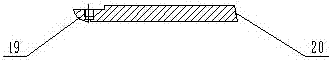

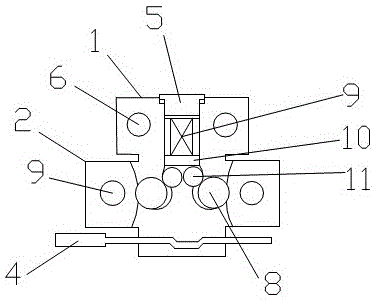

Explosion-proof diesel engine dual-fan air inlet shutoff device

ActiveCN107542582AAchieve closureReduce thrustEngine controllersMachines/enginesAir doorDiesel engine

The invention belongs to the technical field of explosion-proof diesel engine air inlet shutoff devices, and particularly relates to an explosion-proof diesel engine dual-fan air inlet shutoff device.The problems that an existing explosion-proof diesel engine air inlet shutoff device needs high acting force to shut off, the sealing effect is poor after shutting off, and serious air leakage is caused are solved. The explosion-proof diesel engine dual-fan air inlet shutoff device comprises a shell body and two rotating shafts symmetrically arranged in the shell body. Each rotating shaft is provided with an air door, and the air doors are each in a semicircle disk shape. According to the explosion-proof diesel engine dual-fan air inlet shutoff device, air inlet shutoff is achieved by using the function of air flow, the shutoff speed is high, the sealing effect is good, the motion is reliable, the structure is compact, the needed air cylinder force is small, and the explosion-proof dieselengine dual-fan air inlet shutoff device is ideal and can also be applied in the field of other pipeline airflow shutoff.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

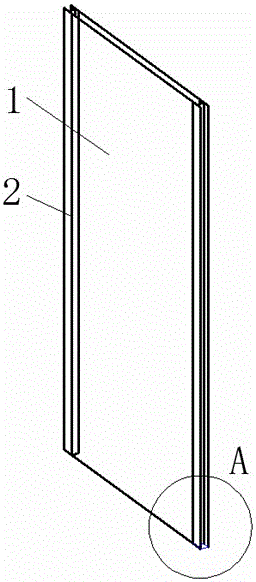

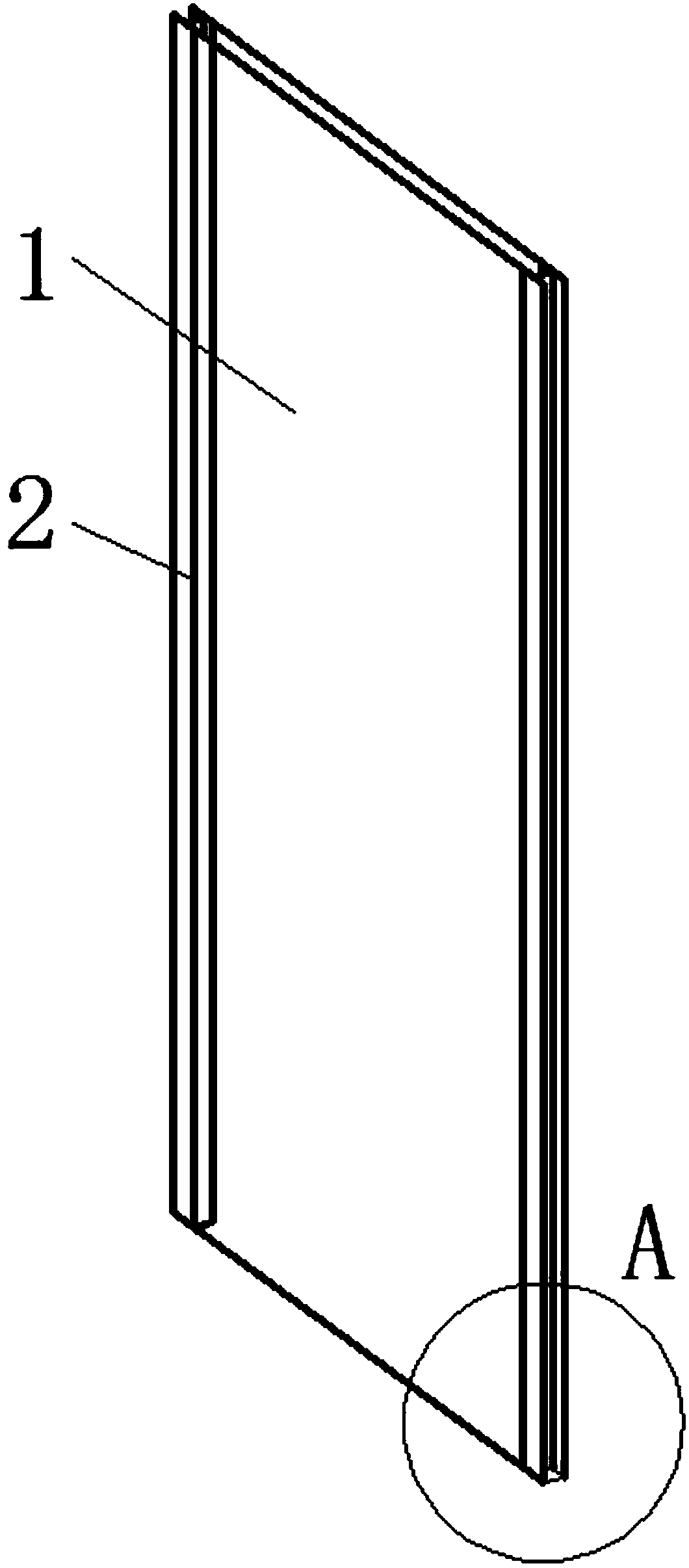

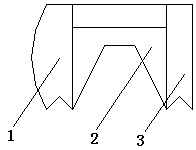

Stacked exterior wall with multilayer structure

InactiveCN105507453AEasy to assembleEnsuring Confined SpaceWallsThermal insulationMechanical engineering

The invention relates to a stacked exterior wall with a multilayer structure. The stacked exterior wall comprises a plurality of wallboards which are nested together from bottom to top to form the exterior wall. Each wallboard comprises an outer board, an inner board and a middle board, wherein the outer board and the inner board are positioned on two sides, the middle board is positioned between the outer board and the inner board, upper ends of the outer board and the inner board are provided with first clamping parts respectively, lower ends of the outer board and the inner board are provided with second clamping parts respectively, the first clamping parts and the second clamping parts can be matched in shape and tightly clamped together, the upper end of the middle board is provided with a trapezoidal head, the lower end of the middle board is provided with a trapezoidal groove higher than the trapezoidal head, and the trapezoidal head can be clamped in the trapezoidal groove. As each wallboard comprises an inner layer, a middle layer and an outer layer, the exterior wall can be assembled by stacking the wall boards layer by layer without structural distinguishing of each layer, so that convenience in assembly is achieved. In addition, the inner layers, the middle layers and the outer layers of the wall boards own form integral inner, outer and middle layer structures of the exterior wall, and functions of water resistance, thermal insulation and the like corresponding to each layer structure are unaffected.

Owner:SUZHOU FUTONG NEW MATERIALS & HIGH TECH

Underground Diaphragm Wall Airbag Type Interface Box and Using Method

The invention discloses an underground diaphragm wall air bag type interface box and a use method thereof. The underground diaphragm wall air bag type interface box comprises an air bag, a reinforcement cage and fixing buckles, wherein interface grooves are formed in the two sides of the reinforcement cage; multiple buckle fixing ribs are arranged on the outer sides of the interface grooves; the air bag is located inside the interface grooves; the section of the air bag is rectangular; a charging connector is arranged at the upper end of the air bag; pulling-out lifting handles are arranged on the two sides of the charging connector; the fixing buckles are located inside the buckle fixing ribs; and the air bag and the fixing buckles are fixed to one another in a mutual squeezing mode. The use method comprises the first step of machining of the air bag, the second step of machining of reinforcing steel bars, the third step of installation of the air bag, the fourth step of sinking of the reinforcement cage and pouring of concrete, and the fifth step of pulling out of the air bag.

Owner:THE THIRD ENG CO LTD OF CCCC SECOND HIGHWAY ENG BUREAU

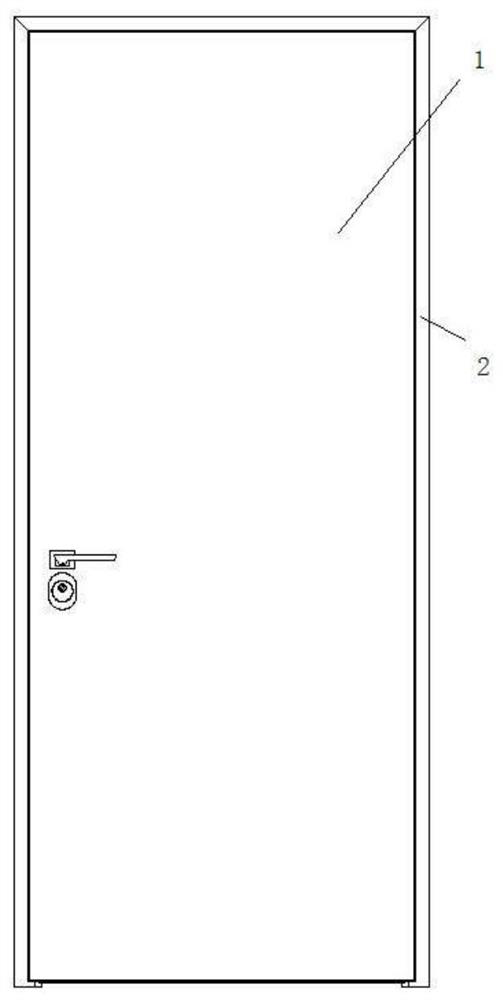

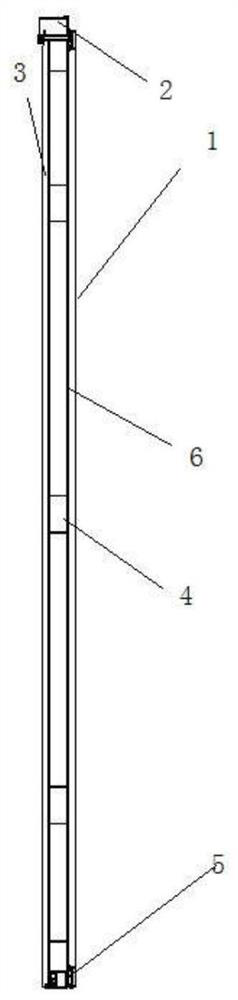

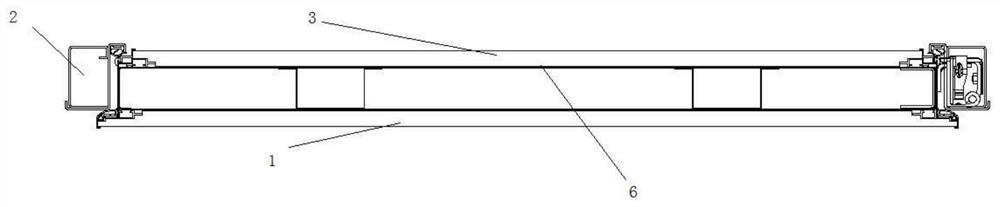

Closing-in sectional material mounting structure matched with door leaves of different specifications

PendingCN112627700AVersatileIncrease frictionSealing arrangementsMechanical engineeringSteel structures

Owner:NANJING GERUI GAITE DOOR IND CO LTD

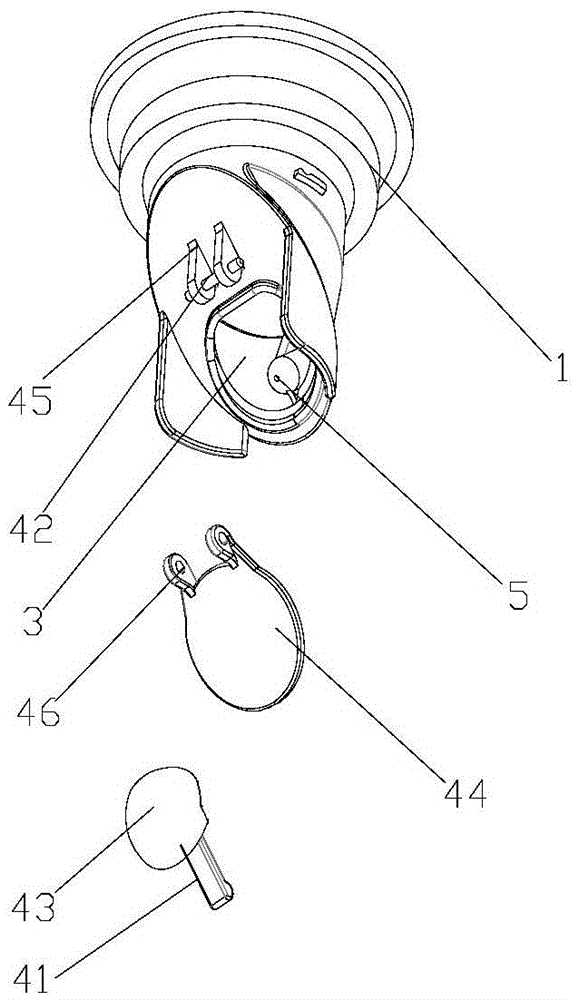

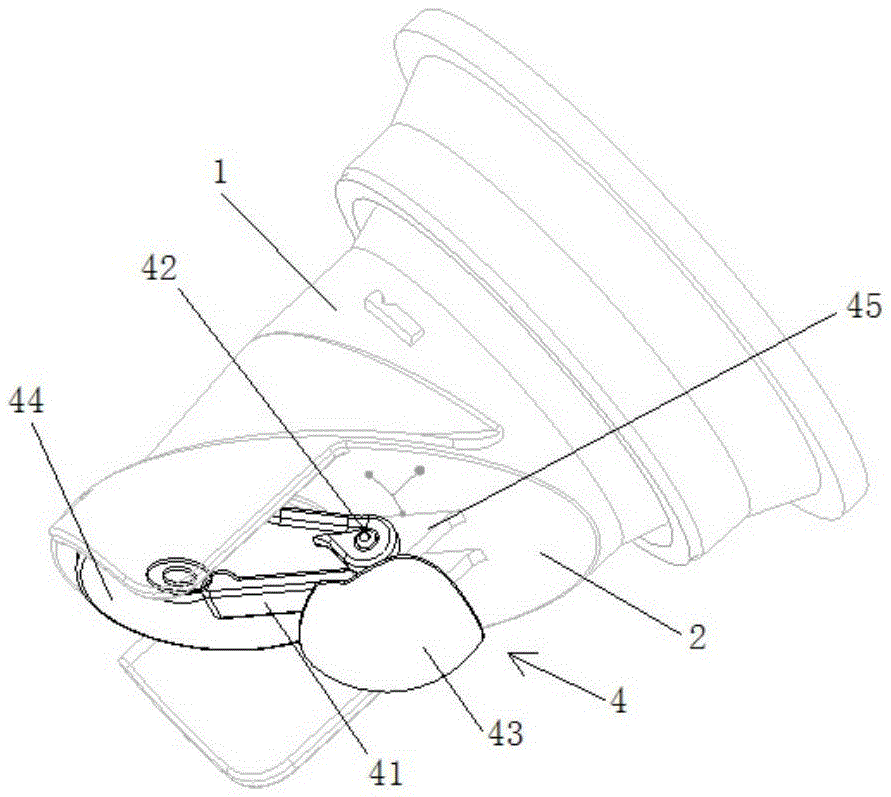

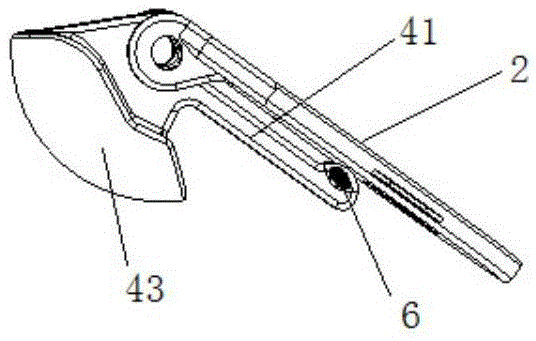

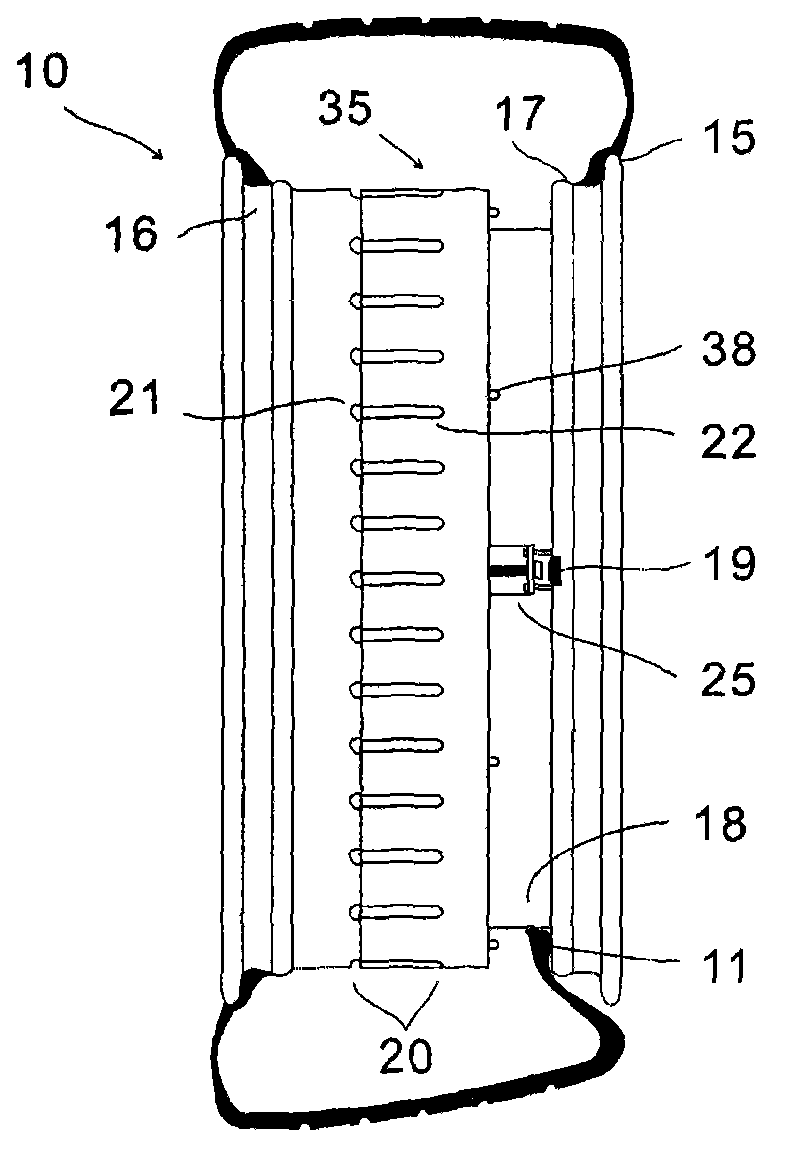

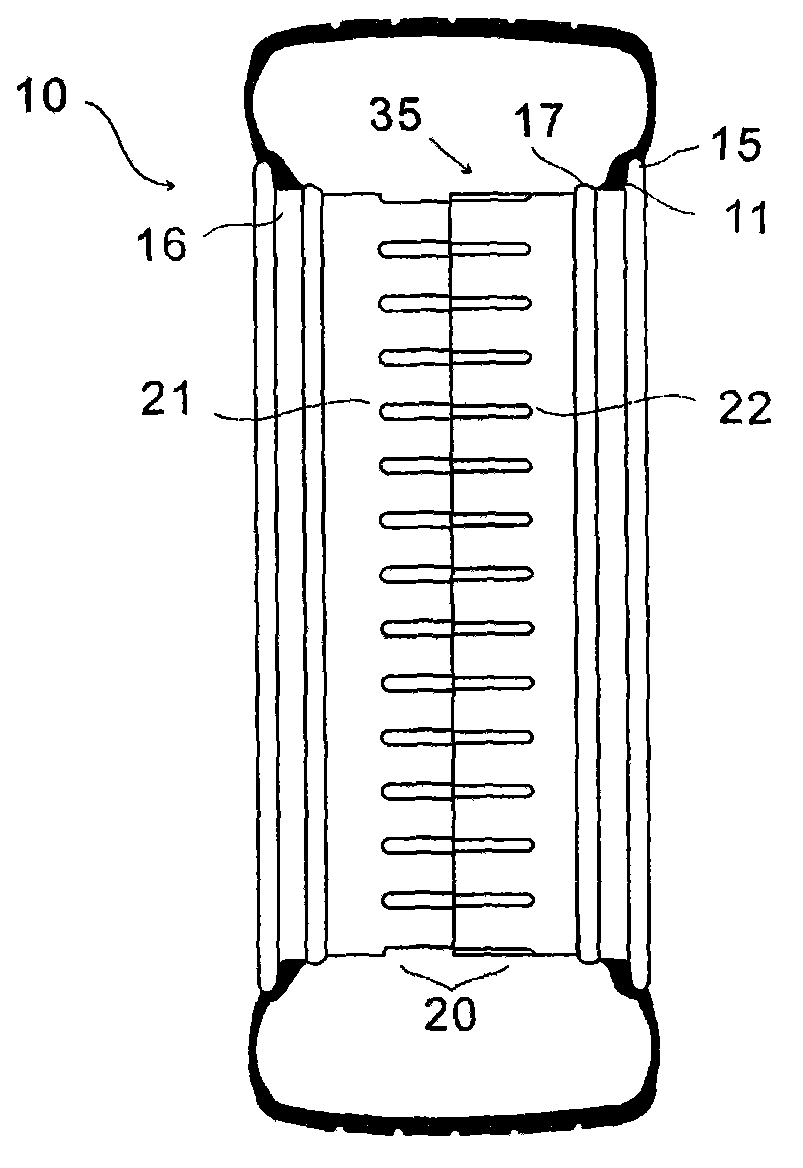

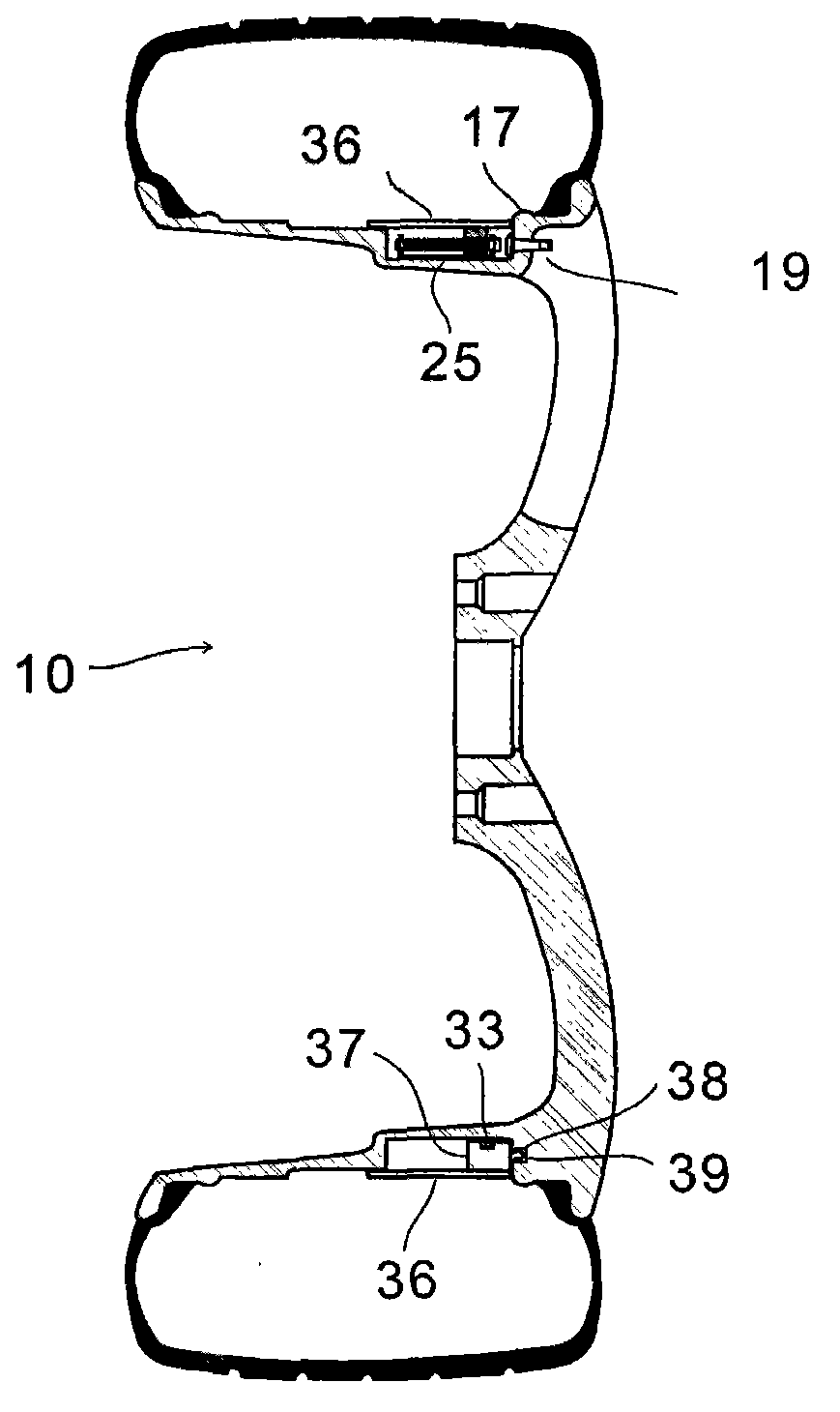

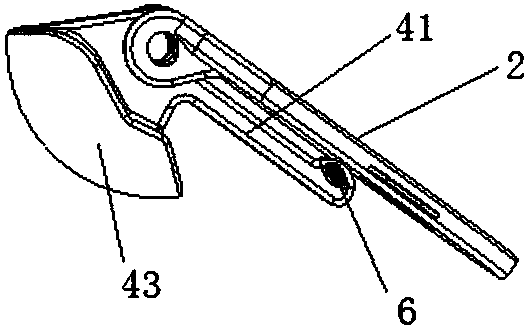

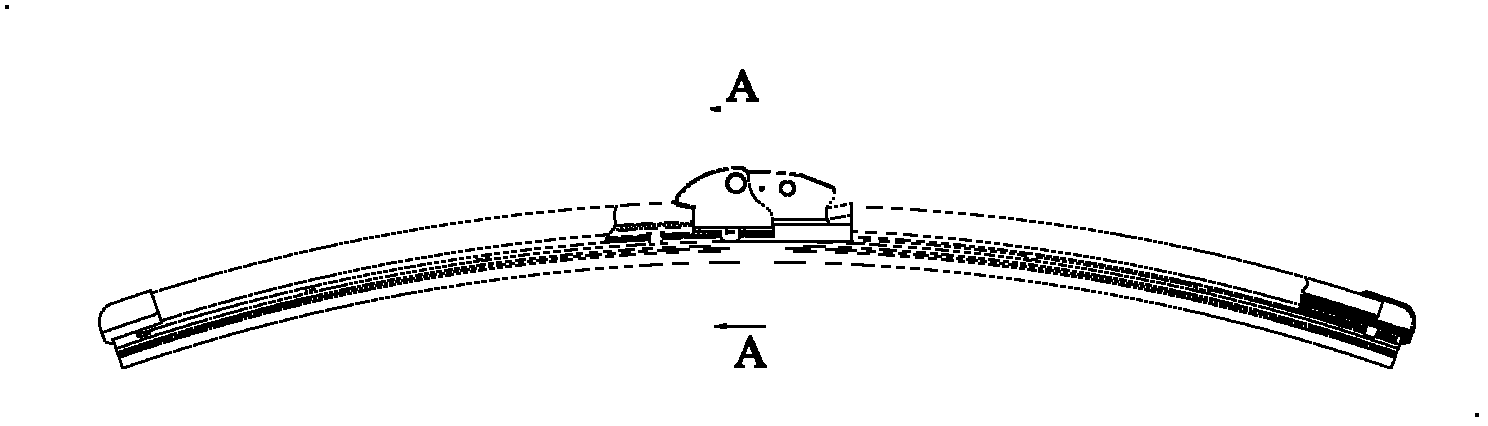

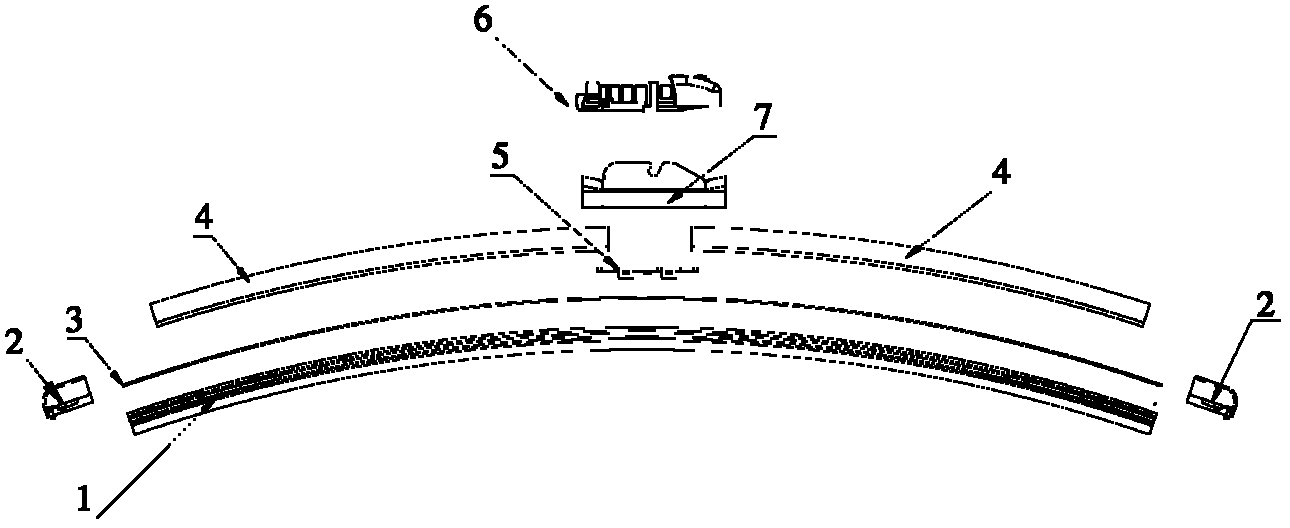

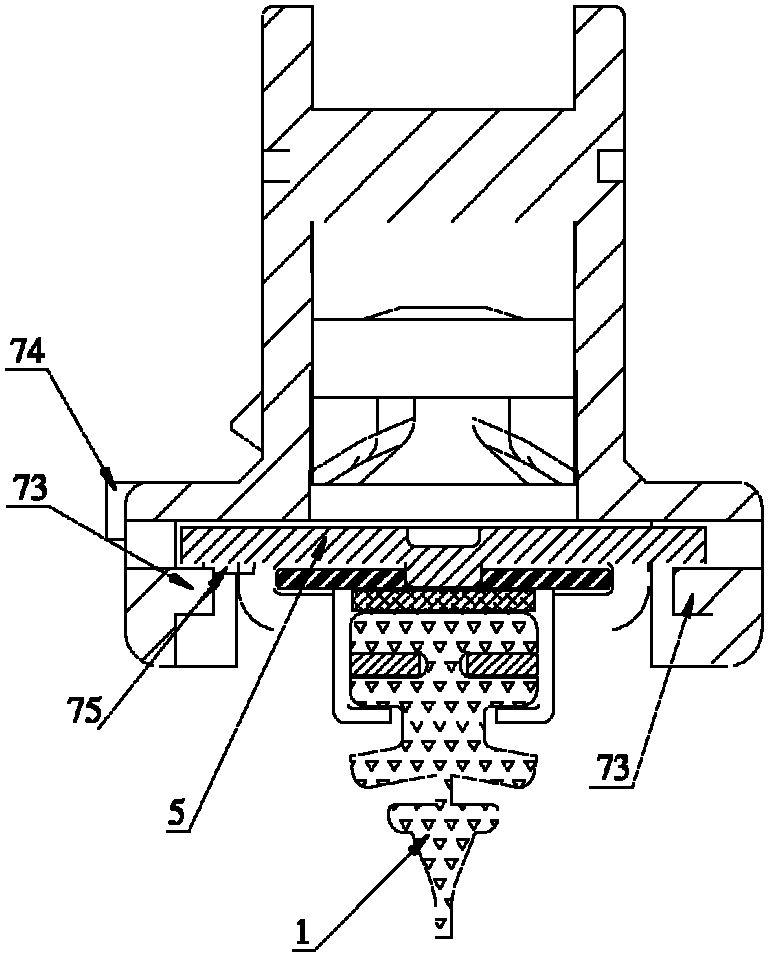

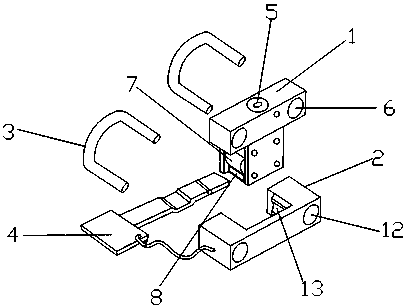

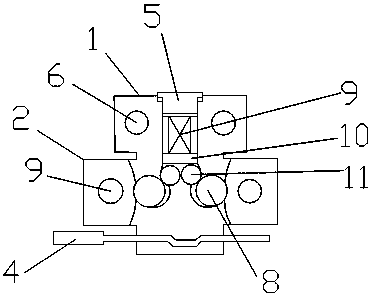

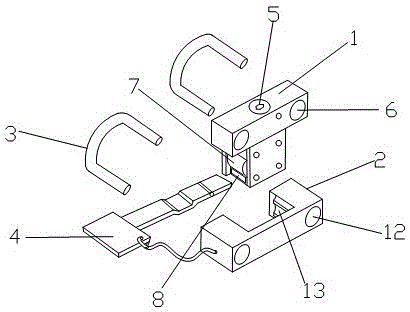

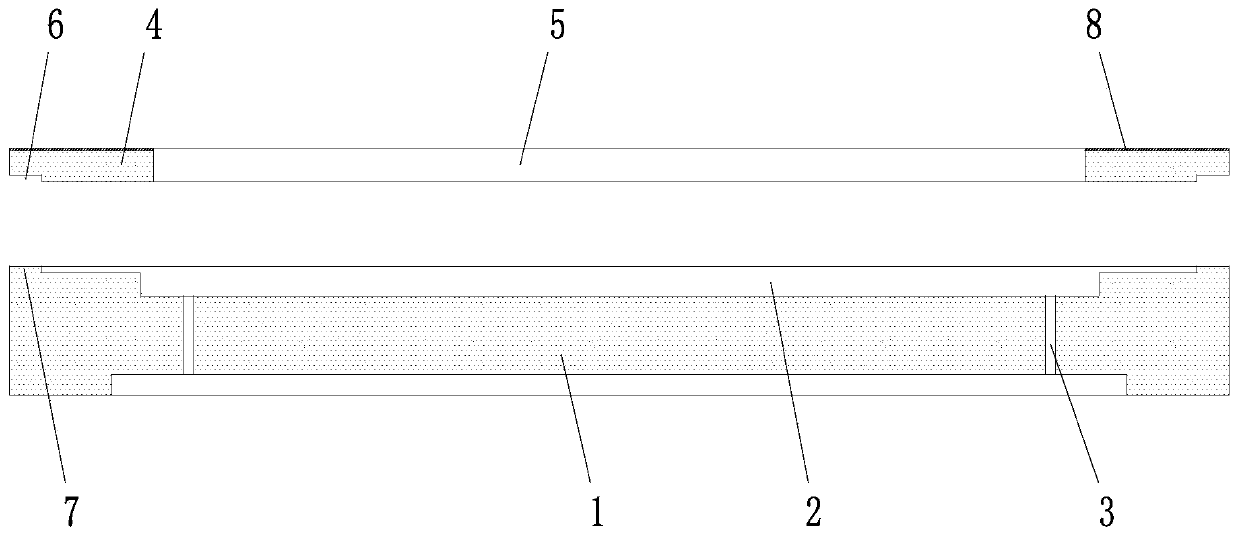

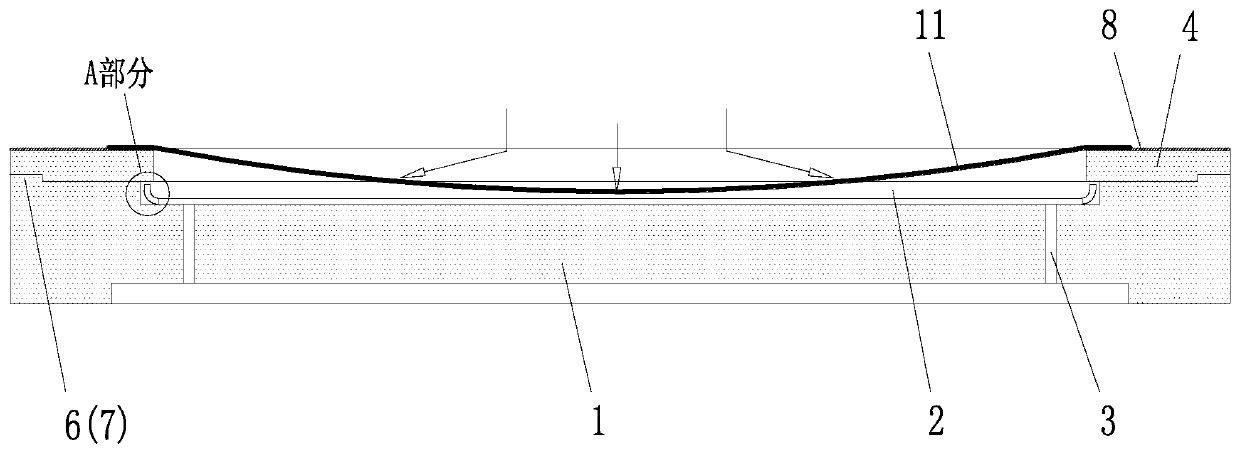

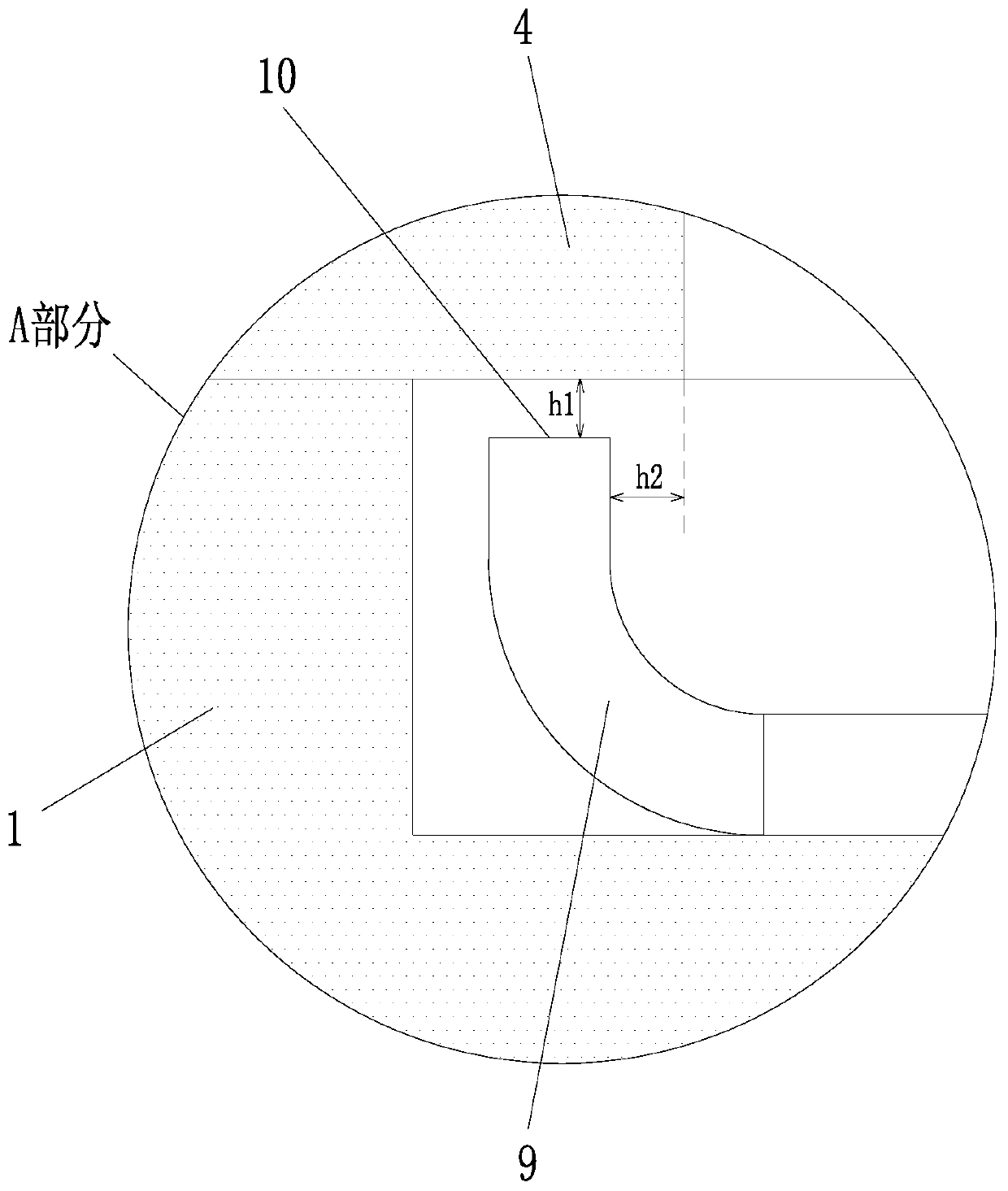

Soft wiper

A soft wiper comprises a blade assembly and a connector (7), both of which are incorporated by a connecting steel sheet (5). The connecting steel sheet (5) is provided with a number of projections (51, 52, 53). Two side walls (71) and a top wall (72) are provided at the lower connecting portion of the connector (7), and a number of strip projections (73) are provided on the inner surfaces of the two side walls (71). An opening communicated with the top wall (72) is provided on one side wall (71) of the lower connecting portion of the connector (7), and an elastic arm (74) is provided in the opening. A raised stop (75) is provided on the lower side of the elastic arm (74). The connecting steel sheet (5) is inserted and mounted in the gap between the strip projections (73) and the top wall (72). The fixation and the detachment of the connector (7) and the blade assembly are realized by sliding the connecting steel sheet (5) in the gap between the strip projections (73) of the two side walls (71) of the lower connecting portion of the connector and the top wall (72). Meanwhile, the pressure exerted by a wiper arm is transmitted to the blade assembly evenly through the connecting steel sheet (5), and it ensures the compact fit of the blade assembly and a front window shield.

Owner:NINGBO XINHAI AIDO AUTOMOBILE WIPER MFGCO

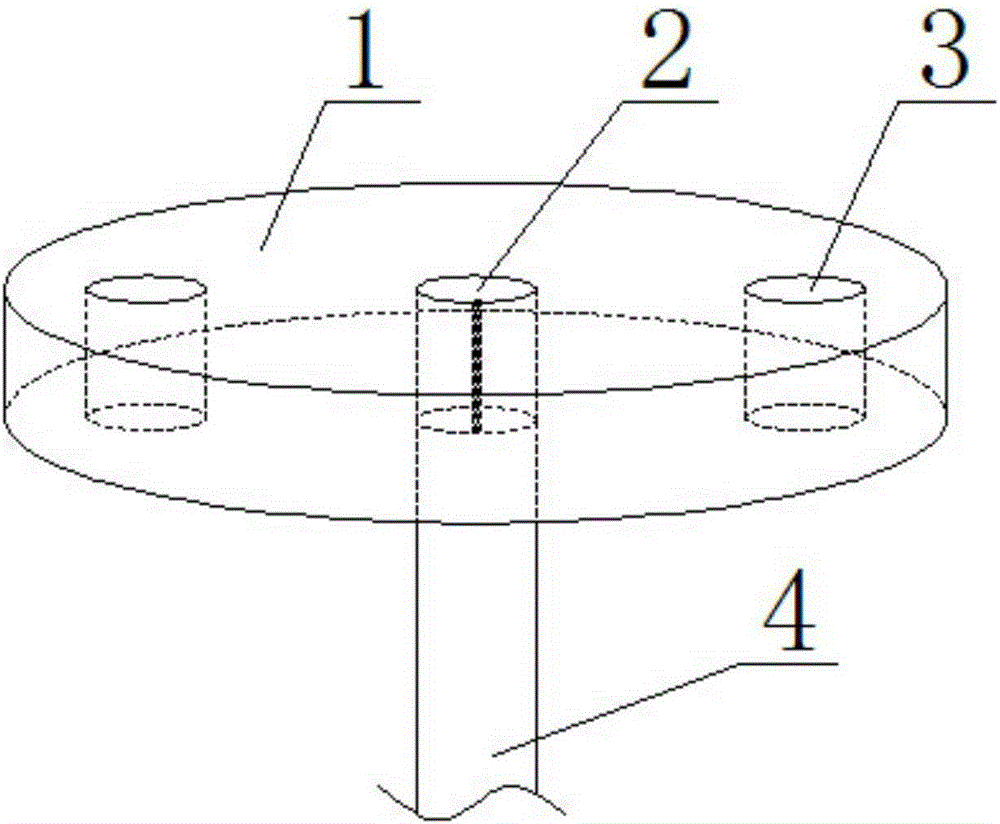

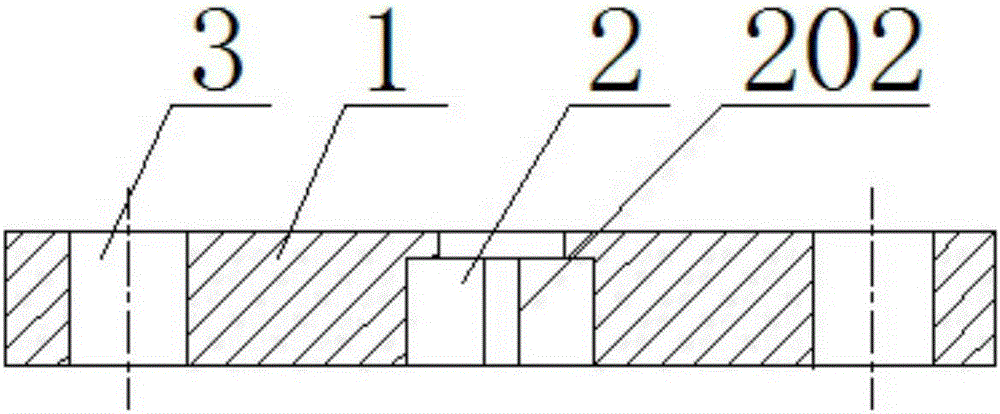

Tabletting middle mold structure of fluorine solzhenitsyn meglumine tablet production

The invention relates to a tabletting middle mold structure of fluorine solzhenitsyn meglumine tablet production. The tabletting middle mold structure of the fluorine solzhenitsyn meglumine tablet production comprises a middle mold platform and a transmission shaft. A connecting through hole is formed in the middle position of the middle mold platform, and a limiting clamping groove is formed in theconnecting through hole; two middle mold holes are formed in the two ends of the middle mold platform, and the transmission shaft comprises a shaft body and a limiting stair installed at the top end of the shaft body. The tabletting middle mold structure of the fluorine solzhenitsyn meglumine tablet production has the beneficial effects that by installing the limiting stair on the transmission shaft and the limiting clamping grooves in the middle mold holes, the close cooperation between the transmission and a middle mold device is effectively ensured, the middle mold is installed as a large-small passage structure, the position of the transmission shaft in the connecting through hole is effectively fixed, and the situationthat the pharmaceutical processing goes smoothly is ensured; and the structure is simple, the practicality is high, and the tabletting middle mold structure is suitable to promote and use in the field of the fluorine solzhenitsyn meglumine tablet production.

Owner:江苏海阔生物医药有限公司

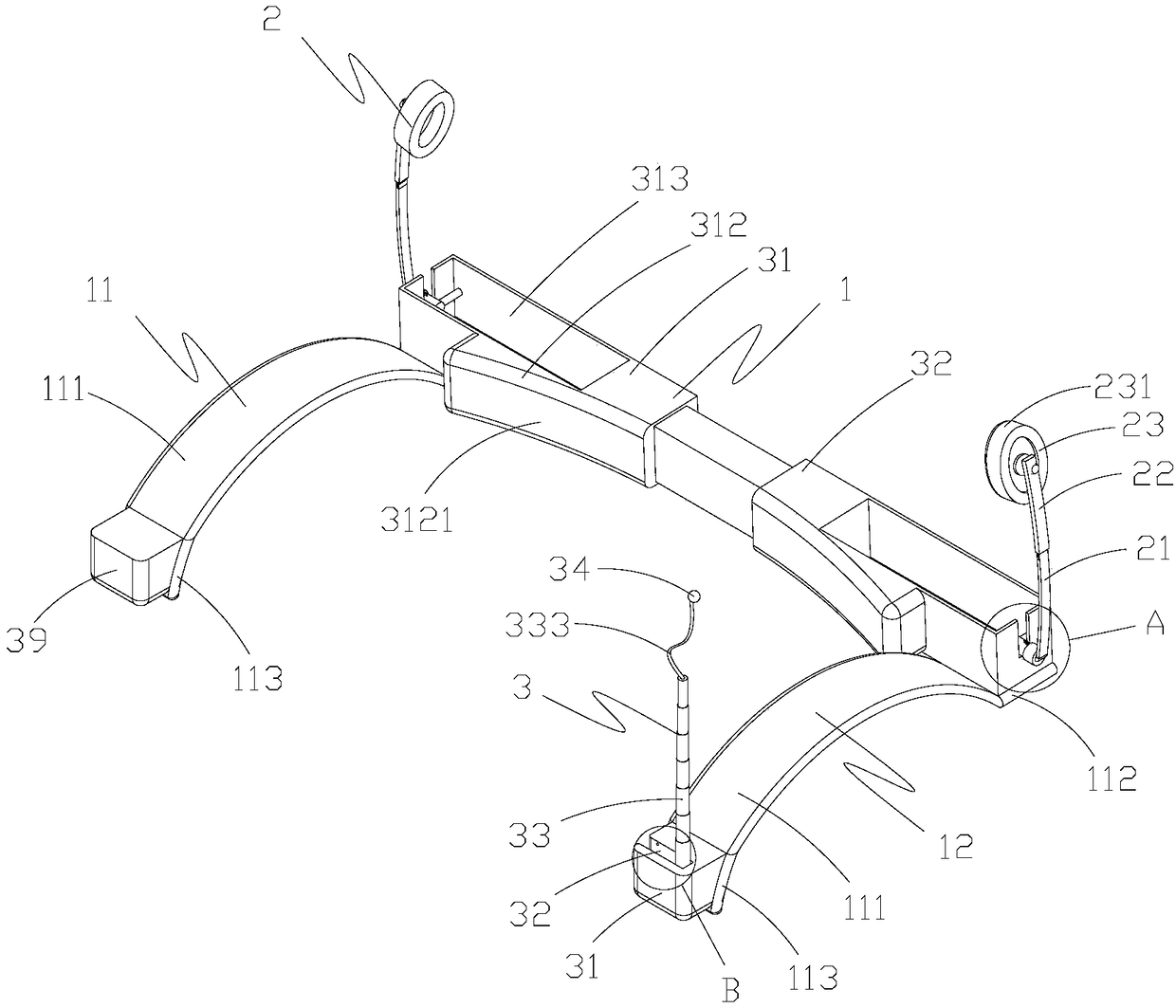

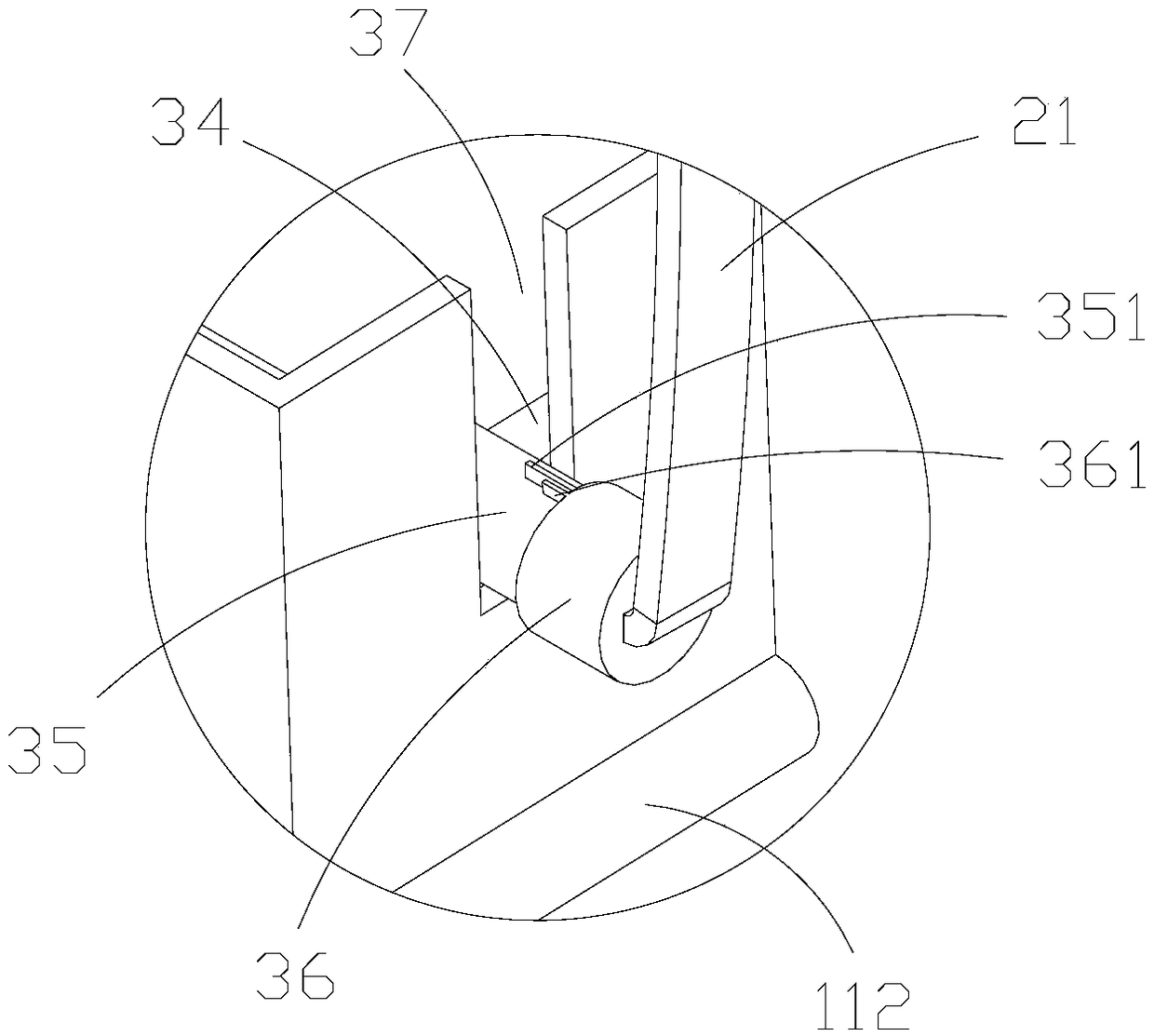

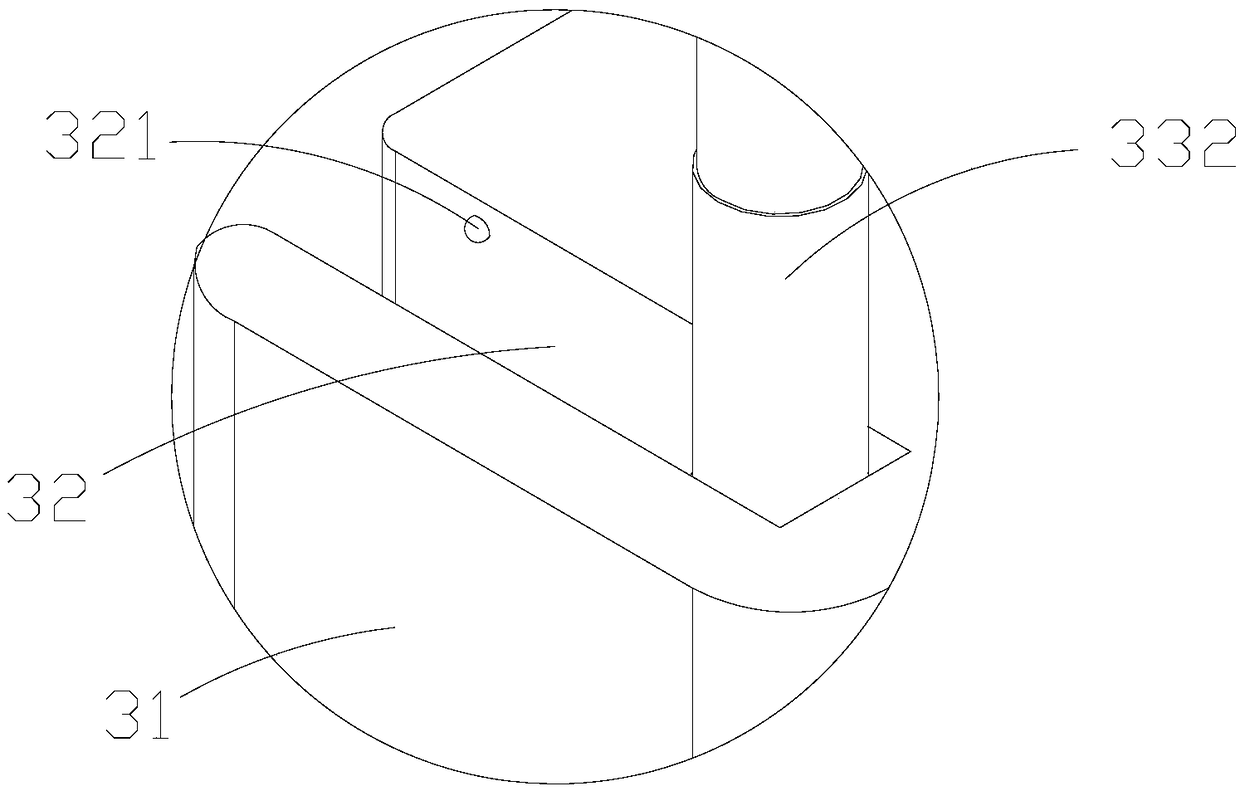

Comfortable-to-wear shoulder-mounted headset

The invention discloses a comfortable-to-wear shoulder-mounted headset, which comprise a support frame, a receiver portion arranged on the support frame and a microphone portion which can operate backand forth. The receiver portion comprises support bars that can operate back and forth, sleeve bars that can slide back and forth along the support bars and earmuffs arranged on the sleeve bars; theearmuff is detachably connected with a cushion; and the sleeve bar is in clearance fit with the earmuff through a universal component. According to the comfortable-to-wear shoulder-mounted headset inthe invention, the cushion is arranged so that the contact between the earmuffs and the ears is softer and the ears are not easy to be squeezed; the universal component is arranged so that the earmuffs can multi-directionally rotate relative to the sleeve bars; therefore, the earmuffs can be better fit around the ears of the user so as to adapt to users of different face types; as different face types can be adapted to, the pressure of the earmuffs to the ears is relatively uniform, thereby avoiding the problem of uncomfortable wearing due to excessive partial pressure.

Owner:杭州铭智云教育科技有限公司

Stacked multi-layer structure exterior wall

InactiveCN105507453BEasy to assembleWater resistance is not affectedWallsThermal insulationEngineering

The invention relates to a stacked exterior wall with a multilayer structure. The stacked exterior wall comprises a plurality of wallboards which are nested together from bottom to top to form the exterior wall. Each wallboard comprises an outer board, an inner board and a middle board, wherein the outer board and the inner board are positioned on two sides, the middle board is positioned between the outer board and the inner board, upper ends of the outer board and the inner board are provided with first clamping parts respectively, lower ends of the outer board and the inner board are provided with second clamping parts respectively, the first clamping parts and the second clamping parts can be matched in shape and tightly clamped together, the upper end of the middle board is provided with a trapezoidal head, the lower end of the middle board is provided with a trapezoidal groove higher than the trapezoidal head, and the trapezoidal head can be clamped in the trapezoidal groove. As each wallboard comprises an inner layer, a middle layer and an outer layer, the exterior wall can be assembled by stacking the wall boards layer by layer without structural distinguishing of each layer, so that convenience in assembly is achieved. In addition, the inner layers, the middle layers and the outer layers of the wall boards own form integral inner, outer and middle layer structures of the exterior wall, and functions of water resistance, thermal insulation and the like corresponding to each layer structure are unaffected.

Owner:SUZHOU FUTONG NEW MATERIALS & HIGH TECH

A production line for roller-coated color steel plates

InactiveCN102975019BGuaranteed uptimeGood molding effectOther manufacturing equipments/toolsRotary pressesProduction lineSurface roughness

Owner:LIAONING CHAOSHUO TOMA TECH STEEL PLATE PRINTING

Design method of secondary mirror hood and square cone extinction cone based on spatial ray tracing

ActiveCN107643595BDetermine the three-dimensional configurationGuaranteed to minimizeOptical elementsCENBOLExtinction

The invention relates to a space-ray-tracing-based method for designing a secondary mirror hood and a square-tapered extinction cone. The method comprises: step one, establishing a Cartesian rectangular coordinate system used during a design process; step two, establishing auxiliary light in a meridian plane and a sagittal surface and carrying out calculation to obtain a boundary of a square-tapered main mirror central-hole extinction cone; step three, determining the position and configuration of the tail end of the square-tapered main mirror central-hole extinction cone; step four, definingan initial structure of a secondary mirror hood; step five, constructing a spatial auxiliary ray and carrying out calculation to obtain the position and configuration of the front end of a square-tapered extinction cone; step six, setting a point light source set at the edge of a conical surface, carrying out ray tracing, carrying out statistics of light source numbers with light leakage possibility, and increasing the size of the conical surface correspondingly; step seven, determining final spatial positions and three-dimensional configuration of the tail end and the front end of the square-tapered main mirror central-hole extinction cone; and step eight, carrying out calculation to obtain three-dimensional configuration of the secondary mirror hood.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

Inner buckling joint of Teflon corrugated pipe and preparation method of inner buckling joint

ActiveCN113351457ACorrosion resistancePrevent leakageGeneral water supply conservationPretreated surfacesEpoxyPolymer science

The invention discloses an inner buckling joint of a Teflon corrugated pipe and a preparation method of the inner buckling joint. The preparation method comprises the following steps of processing 304 stainless steel to manufacture the buckling joint, and forming a plurality of small notches in the threaded surface of the buckling joint; degreasing the inner surface of the buckling joint in an alkaline degreasing agent, cleaning, drying and then carrying out sand blasting treatment; uniformly mixing and stirring fluorinated ethylene propylene, epoxy resin and isopropanol, adding nano silicon nitride and KH570, uniformly stirring, adding modified graphene oxide, uniformly stirring, coating on the inner surface of the buckling joint, and sintering to form a modified fluorinated ethylene propylene coating, thereby obtaining the inner buckling joint of the Teflon corrugated pipe, wherein the epoxy resin is prepared from 2', 5'-dihydroxybiphenyl-4-methanol and epichlorohydrin under the catalysis of sodium hydroxide, and the modified graphene oxide is prepared from dopamine modified graphene oxide. The prepared Teflon corrugated pipe inner buckling joint has the corrosion resistance and the sealing performance.

Owner:江阴市中鼎节能流体科技有限公司

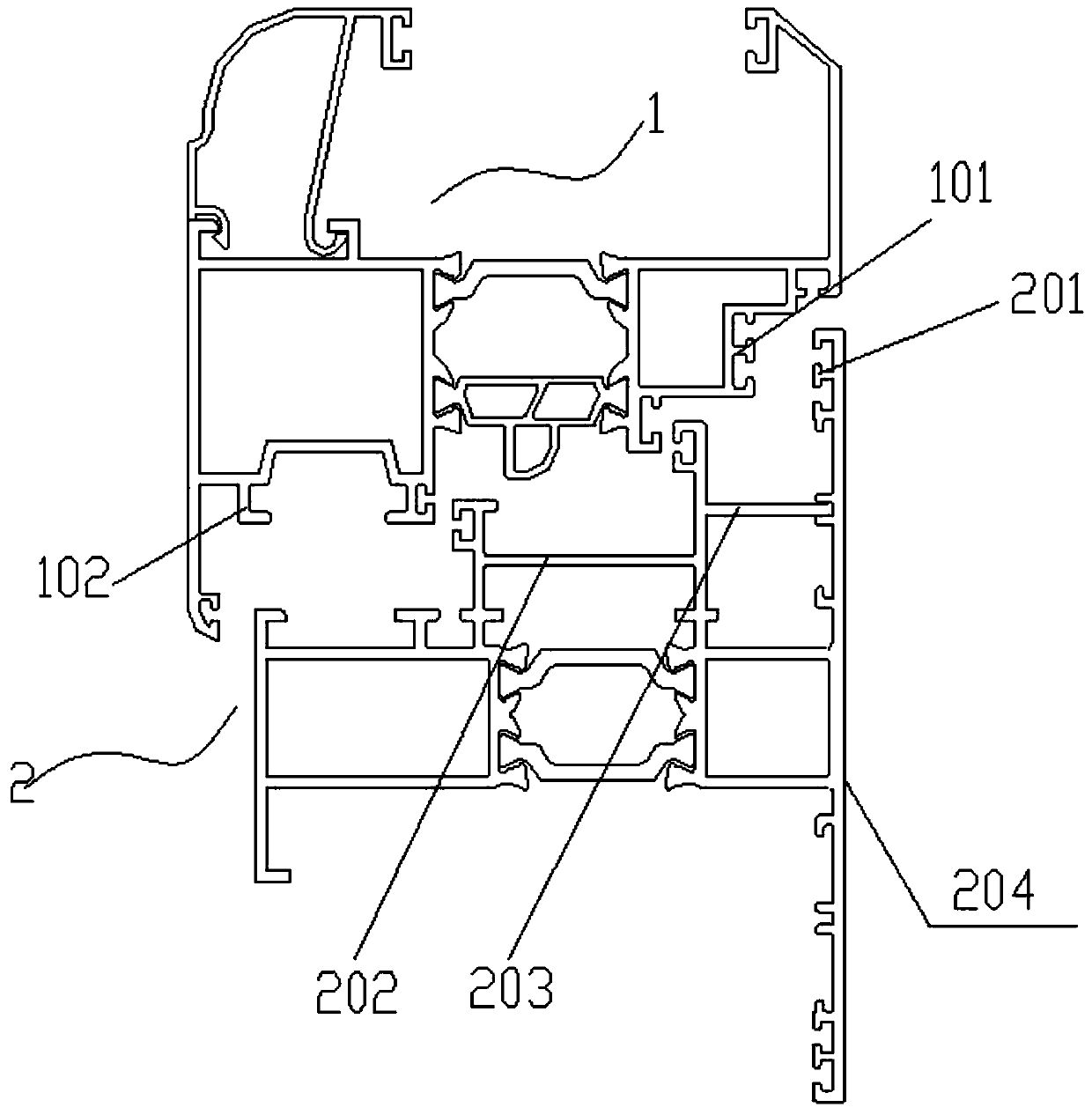

Windproof and soundproof drainage window

PendingCN110644899AIncreased occlusal contact pointsGuaranteed tightnessCorner/edge jointsNoise insulation doors/windowsSash windowLap joint

The embodiment of the invention discloses a windproof and soundproof drainage window which comprises a window frame and a window sash, wherein the window frame is disposed on the bottom of the windowsash; the window frame is connected to the window sash; and a drainage pipe is disposed at the window sash. The window is characterized by comprising a first lap joint structure, a second lap joint structure and a stair type structure, wherein the first lap joint structure is disposed on the window sash; the first lap joint structure is provided with multiple first grooves and multiple first raised parts; the second lap joint structure is disposed on the window frame, and the second lap joint structure is provided with multiple second grooves and multiple second raised parts; the multiple first grooves are in clamped fitting with the multiple second raised parts, and the multiple second grooves are in clamped fitting with the multiple first raised parts; the stair type structure is disposed on the window frame; the stair type structure comprises a first stair and a second stair; and the first stair and the second stair are provided with a clamping joint structure. The window disclosedby the invention is characterized by wind prevention, sound insulation and good sealing performance.

Owner:龙敏

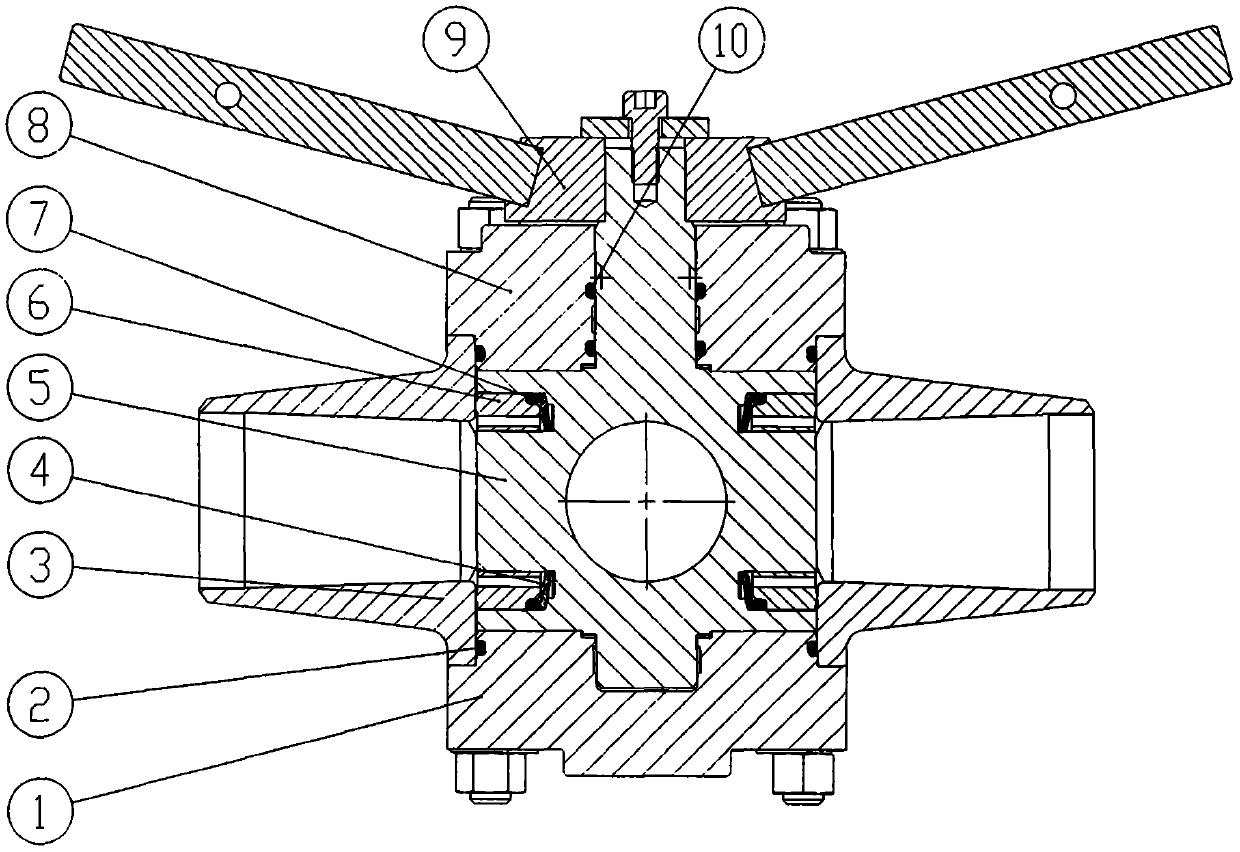

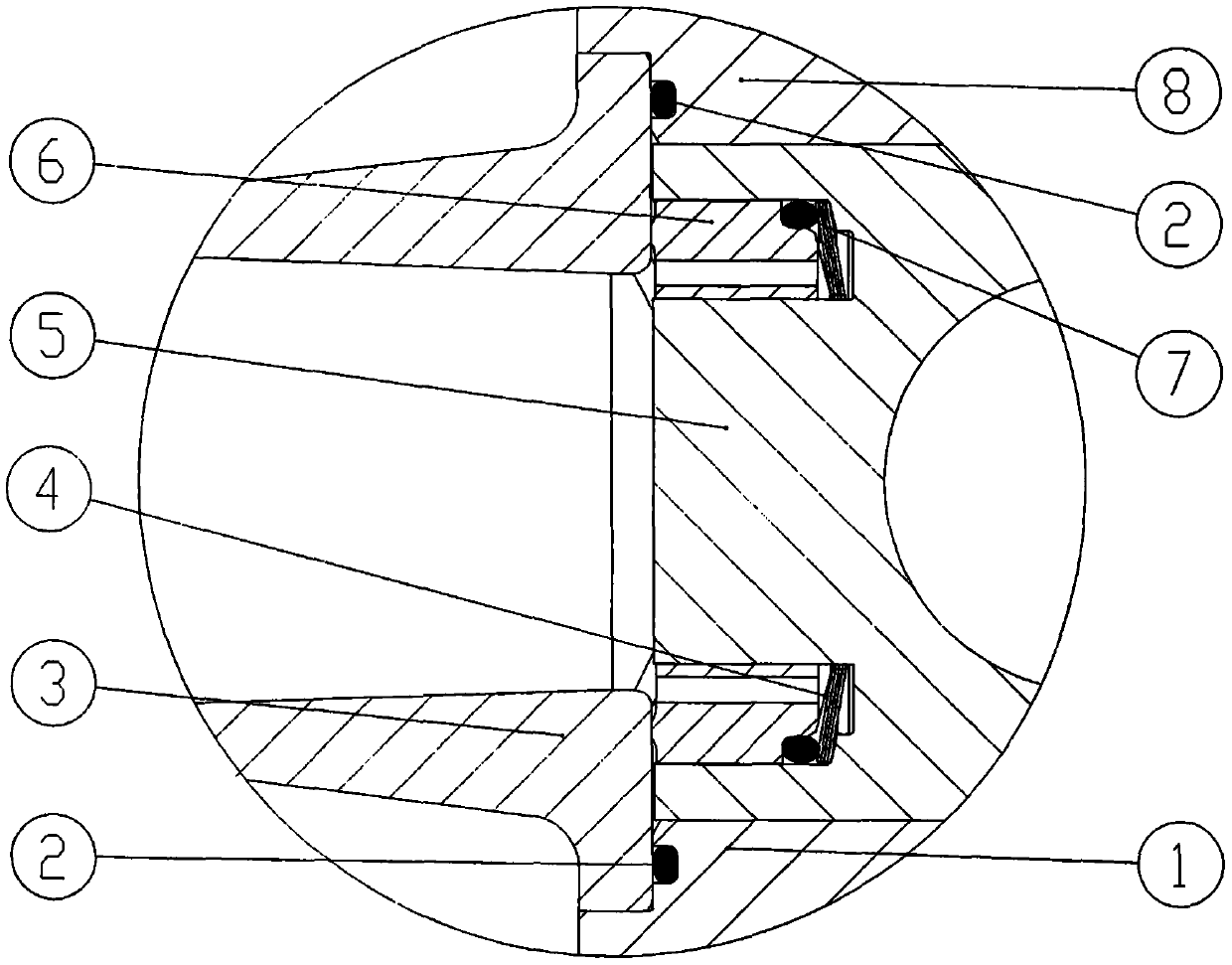

Spring-compensated movable valve seat plug valve

The invention relates to a spring-compensated movable valve seat plug valve, and is mainly used for fluid medium conveying pipes. The spring-compensated movable valve seat plug valve mainly includes avalve body, a plug cock, a spring washer, a valve seat, an upper valve cover, a lower valve cover, a sealing O-shaped ring and other components, a valve actuating mechanism is connected to the upperpart of the plug cock, a through hole is formed in the plug cock, the valve seat is mounted on the plug cock, the actuating mechanism drives the plug cock and the valve seat on the plug cock to do therotational motion in the valve body, the seat and the inner wall surface of the valve body form a sealing pair, and a circulating channel is opened or closed through the rotation. According to the spring-compensated movable valve seat plug valve, tight attaching of the sealing pair can be effectively ensured through the compensation force of a spring, the sealing performance is improved, the valve seat is designed to communicate with the medium through a circulating hole on the back face, through the asymmetric structure of the back face of the valve seat and the forced area of the sealing face, the forced area of the back face of the valve seat is greater than the sealing face area, the certain pressure difference is produced between the valve seat sealing face and the back face of the lave seat during working, and the pressure of the back face of the valve seat is greater than that of the sealing surface side, so that the media pressure is high, and the sealing performance is better.

Owner:HARBIN HBC VALVE

Liquid impact prevention device of equipment for gathering and transporting liquid-containing oil well head gas in desert oil field

PendingCN111827927AGuaranteed stabilityGuaranteed CorrosionWell/borehole valve arrangementsSealing/packingMining engineeringOil field

The invention discloses a liquid impact prevention device of equipment for gathering and transporting liquid-containing oil well head gas in a desert oil field. The liquid impact prevention device comprises an end cover and a built-in pressure relief valve arranged in the axial center of the end cover, wherein the outer end of the pressure relief valve is fixed to the outer end face of the end cover; the end cover is provided with a pressure relief passage and a pressure relief loop, an opening in one end of the pressure relief passage is formed in the side wall of the inner end of the end cover, an opening in the other end of the pressure relief passage is formed in the side wall of the outer end of the end cover, and the pressure relief passage is communicated or closed through the pressure relief valve; and two openings of the pressure relief loop are both formed in the inner end of the end cover, and the pressure relief valve is arranged on the pressure relief loop. According to the liquid impact prevention device, by reasonably designing the pressure relief valve, a valve element anti-tilting mechanism, a valve element spring, a valve element sealing structure and material selection, the pressure relief passage and the end cover, the destructive impact of a compressed gas-liquid mixed medium on a gathering and transporting equipment movement mechanism and a cylinder body is avoided, and liquid impact is avoided.

Owner:CHENGDU TIANCHEN COMPRESSORS MFG CO LTD

An explosion-proof diesel engine double-fan intake cut-off device

ActiveCN107542582BAchieve closureReduce thrustEngine controllersMachines/enginesCircular discDieseling

The invention belongs to the technical field of explosion-proof diesel engine air inlet shutoff devices, and particularly relates to an explosion-proof diesel engine dual-fan air inlet shutoff device.The problems that an existing explosion-proof diesel engine air inlet shutoff device needs high acting force to shut off, the sealing effect is poor after shutting off, and serious air leakage is caused are solved. The explosion-proof diesel engine dual-fan air inlet shutoff device comprises a shell body and two rotating shafts symmetrically arranged in the shell body. Each rotating shaft is provided with an air door, and the air doors are each in a semicircle disk shape. According to the explosion-proof diesel engine dual-fan air inlet shutoff device, air inlet shutoff is achieved by using the function of air flow, the shutoff speed is high, the sealing effect is good, the motion is reliable, the structure is compact, the needed air cylinder force is small, and the explosion-proof dieselengine dual-fan air inlet shutoff device is ideal and can also be applied in the field of other pipeline airflow shutoff.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

A tightly fitting mold clamp for injection molds

Owner:钟锋良 +1

Tightly fit injection mold locker

Owner:钟锋良 +1

A hatch door installation method

ActiveCN106334937BGuaranteed to be temporarily fixedGuaranteed to be verticalAssembly machinesMetal working apparatusEngineeringSpot welding

The invention discloses a cabin door mounting method. The method is characterized by comprising the following steps of: cutting a part of a cabin as a cabin door, and spot-welding the cabin door on the cabin; erecting a rotary shaft on a lower supporting plate and sleeving the upper end of the rotary shaft with an upper supporting plate; irradiating the rotary shaft by a first gradienter, wherein vertical glaze released by the first gradienter irradiates the surface of the rotary shaft, observing whether the projection of the vertical glaze released by using the first gradienter on the surface of the rotary shaft is located on a central line of the rotary shaft in the direction or not, if not, knocking on the upper supporting plate to correspond; arranging a second gradienter on one side of the first gradienter; and irradiating the rotary shaft by using the second gradienter, wherein vertical glaze released by the second gradienter irradiates the surface of the rotary shaft, observing whether the projection of the vertical glaze released by using the second gradienter on the surface of the rotary shaft is located on the central line of the rotary shaft in the direction or not, if not, knocking on the upper supporting plate to correspond.

Owner:浙江昇元姜氏健康科技有限公司

3D4R mobile phone shell jig

PendingCN110884109AAvoid air bubblesRealize the vacuum lamination processEngineeringMechanical engineering

The invention discloses a 3D4R mobile phone shell jig which comprises a jig body. A workpiece groove used for placing a mobile phone shell is formed in the upper portion of the jig body, a plurality of air holes are formed in the workpiece groove, the jig further comprises a cover plate used for holding a membrane material, a through hole is formed in the middle of the cover plate to enable the cover plate to form a ring-shaped structure, when the cover plate covers the upper portion of the jig body, the vertical projection of the inner ring of the cover plate covers at least the upper end face of the R-angle structure of the mobile phone shell, and a gap is reserved between the lower opening edge of the inner ring of the cover plate and the upper end face of the R-angle structure of the mobile phone shell. The jig has the advantages that the cover plate structure is additionally arranged on the laminating jig, the lamination mode is changed into gradual lamination from the middle to the periphery through ingenious structural improvement, the phenomenon that bubbles appear on the inner surface of the mobile phone shell after lamination is avoided, the tight lamination at the R-angle position of the mobile phone shell is particularly ensured, and the vacuum lamination process of the 3D4R mobile phone shell is really realized.

Owner:合肥市沛霖数控科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com