Tightly fit injection mold locker

A technology of injection mold and mold clamp, which is applied in the field of injection mold clamp to achieve the effect of preventing loss or potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

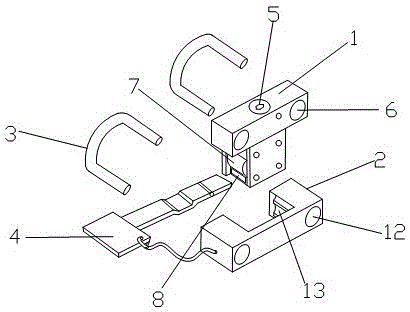

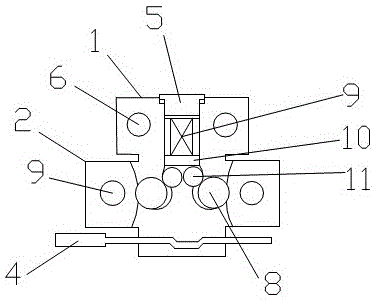

[0015] Refer to Figure 1-2 As shown, a tightly fitting injection mold clamping device includes a locking seat 1, a locking sleeve 2, a U-shaped fixing iron 3, and a safety strip 4. The locking seat 1 is provided with an adjusting bolt 5, an upper The round hole 6, the clamping wheel 7, and the clamping slot 8. The adjusting bolt 5 and the clamping wheel 7 are all embedded in the locking seat, and a butterfly spring 9 is arranged under the adjusting bolt 5. The butterfly spring 9 A top plate 10 is provided below, an internal roller 11 is provided below the top plate 10, and a rolling connection is formed between the internal roller 11 and the card wheel 7, and a cavity (not shown) is provided between the carden 7 and the locking seat 1 As shown), the locking sleeve 2 is provided with a lower circular hole 12 and a semicircular groove 13, and the semicircular groove 13 and the locking sleeve 2 are integrally formed, and the U-shaped fixing iron 3 is installed in the upper circul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com