A tightly fitting mold clamp for injection molds

A technology of injection molds and mold clamps, which is applied in the field of injection mold clamps to prevent losses or potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

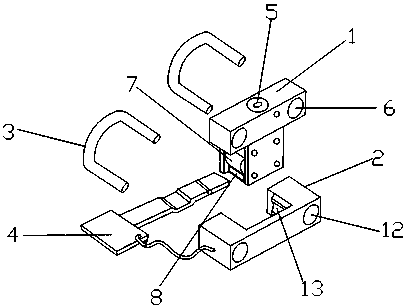

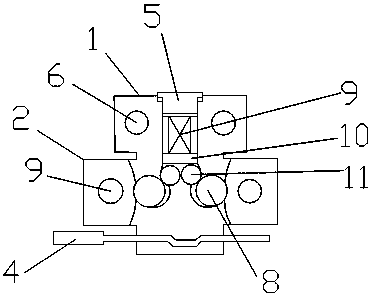

[0015] refer to Figure 1-2 As shown in the figure, a closely fitted mold clamp for injection molding includes a locking seat 1, a locking sleeve 2, a U-shaped fixing iron 3 and a safety bar 4, and the locking seat 1 is provided with an adjusting bolt 5, an upper The round hole 6, the card wheel 7 and the card groove 8, the adjustment bolt 5 and the card wheel 7 are all embedded in the locking seat, and a butterfly spring 9 is arranged below the adjustment bolt 5, and the butterfly spring 9 The bottom is provided with a top plate 10, and the bottom of the top plate 10 is provided with an internal roller 11, which is rollingly connected between the internal roller 11 and the card wheel 7, and a cavity (not shown) is provided between the card wheel 7 and the locking seat 1. As shown in the figure), the locking sleeve 2 is provided with a lower circular hole 12 and a semicircular groove 13, the semicircular groove 13 and the locking sleeve 2 are integrally formed, and the U-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com