Closing-in sectional material mounting structure matched with door leaves of different specifications

A technology of closing profile and installation structure, which is applied in the direction of windows/doors, building components, sealing devices, etc., can solve the problems of affecting the overall appearance, poor versatility, large closing, etc., and achieves various installation types, convenient installation, and increased friction. force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

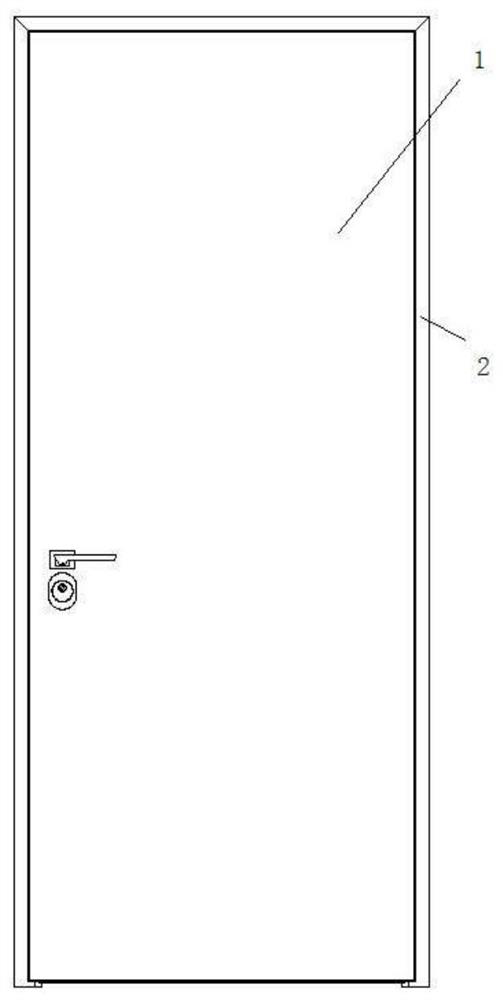

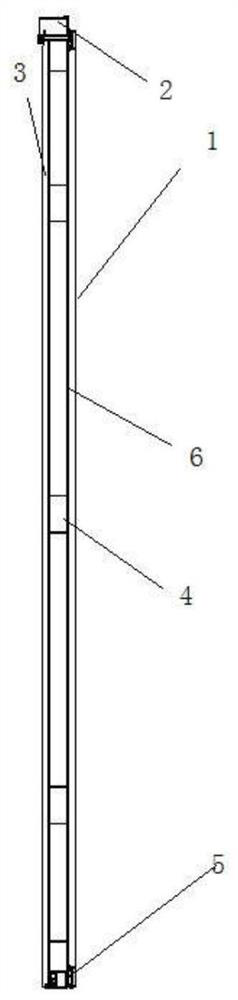

[0061] The invention provides a closing profile installation structure for door leaves of different specifications. Through the corresponding closing profiles, it can be installed with different doors. is the narrowing effect.

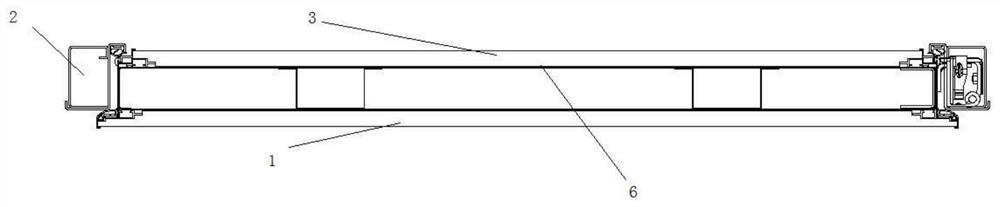

[0062] As the installation structure of closing profiles for door leaves of different specifications in this application, the specific closing profiles are as follows:

[0063] The large panel closing profile 7 of the large panel closing profile installation structure is as follows: Figure 37 The main body 7-1 of the closed profile of the large panel, the supporting plate of the closed profile of the large panel 7-3, the baffle plate 7-4 of the closed profile of the large panel and the sealing strip placement port 7-6 of the closed profile of the large panel are shown. The profile main body 7-1 and the outer side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com