Hidden wheel groove safety hub

A hidden, wheel groove technology, applied in the direction of wheels, rims, transportation and packaging, etc., can solve the problems of increasing the quality of wheels, having to use professional tools or machines, and stability effects, and achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

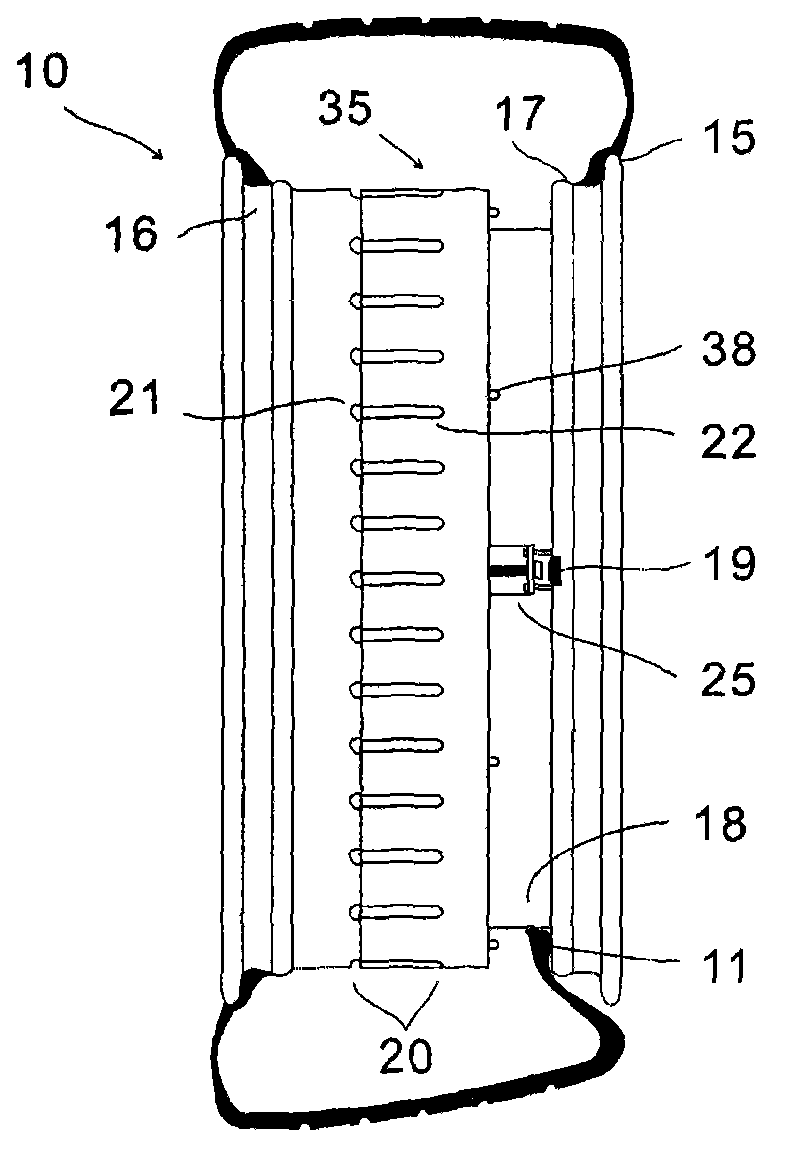

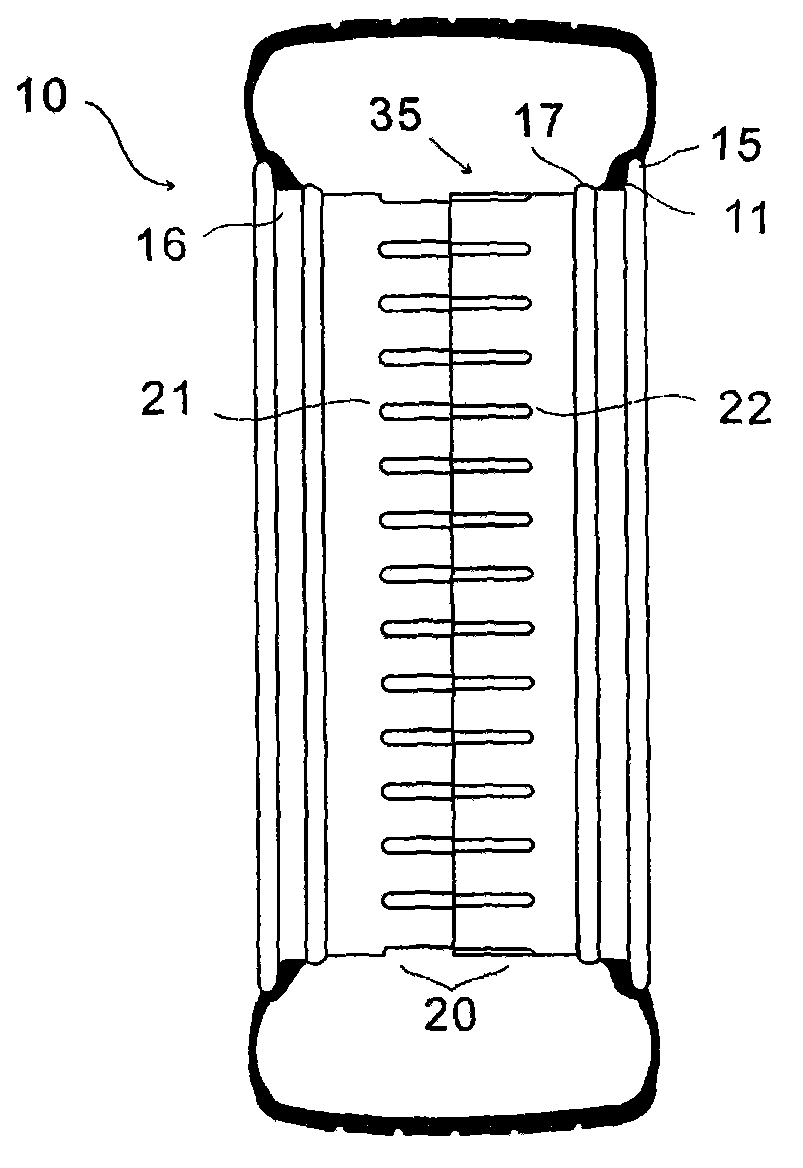

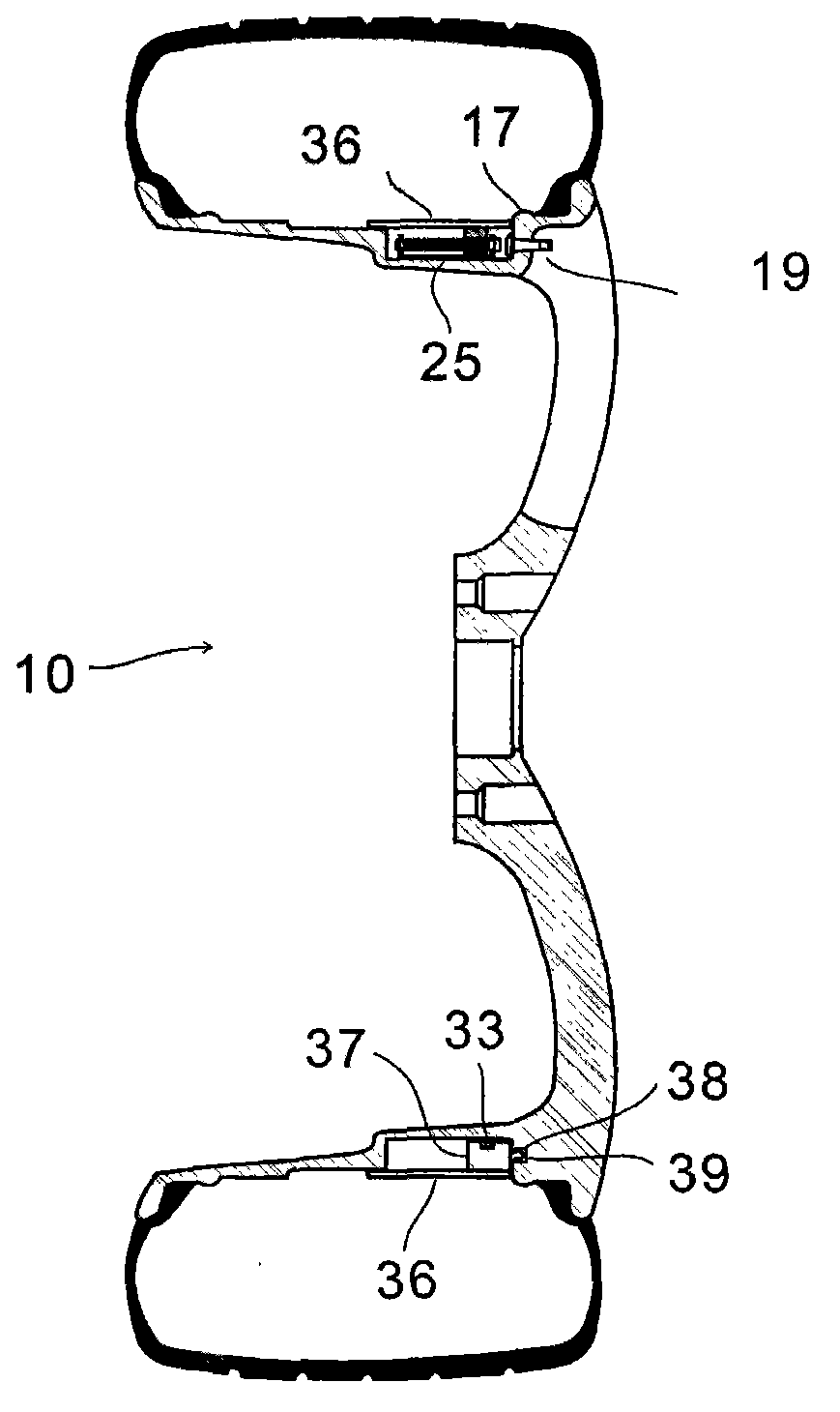

[0023] figure 1 It is a top view of the present invention in an unlocked state. A sliding ring lock 35 that can move left and right is set in the middle of the rim, and one end of the sliding ring lock 35 is provided with a plurality of positioning sliders 22, and these sliders form a plurality of concave-convex slide rails 20 with the groove slideways 21 on the corresponding wheel hubs. . In this way, the sliding ring lock 35 can slide left and right on the rim, and the sliding ring lock 35 is restricted from axially rotating.

[0024] The positioning slider 22 can be stamped on the annular metal ring 36, and can also be installed inside it. Groove slideway 21 just makes when hub casting or machining.

[0025] The other end of the sliding ring lock 35 is provided with a plurality of positioning rods 38, which correspond to the positioning holes 39 provided on the hub. When the sliding ring lock 35 is locked, the positioning rods 38 are inserted into the positioning holes 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com