Underground diaphragm wall air bag type interface box and use method thereof

An underground continuous wall and interface box technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of waste, complicated operation, affecting the tightness of the interface, etc., to achieve convenient operation, wide range of use, improve material The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

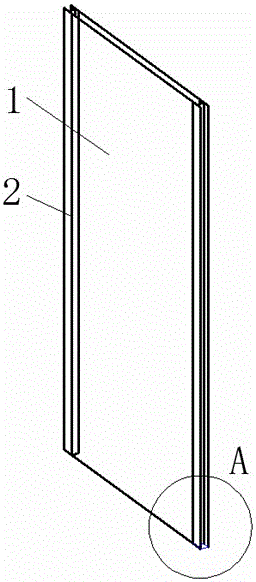

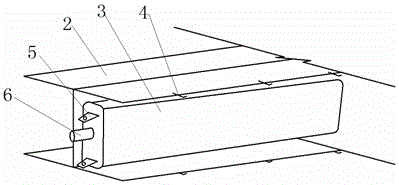

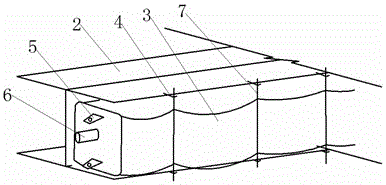

[0022] A method of using an interface box, comprising the following steps: (1) Processing of the airbag 3: the section of the airbag 3 is processed according to the size of the interface groove 2, the length of the airbag 3 is according to the length of the ground connection wall, and the upper end of the airbag 3 is welded and pumped Lifting handle 5, the cross-sectional size of the airbag 3 is slightly larger than the size of the interface groove 2, and the length of the airbag 3 is 1 meter longer than the ground connection wall; (2), steel bar processing: bind the steel bar according to the drawing of the ground connection wall to form the Reinforcement cage 1, weld the interface groove 2 on both sides of the reinforcement cage 1, and weld buckle fixing ribs 4 on the outside of the interface groove 2 according to the interval of 1.5 meters; (3), installation of airbag 3: for the inflated airbag 3. Place the upper end of the interface slot 2 in the interface slot 2, start to ...

Embodiment 2

[0024] A method of using an interface box, comprising the following steps: (1) Processing of the airbag 3: the section of the airbag 3 is processed according to the size of the interface groove 2, the length of the airbag 3 is according to the length of the ground connection wall, and the upper end of the airbag 3 is welded and pumped Pull out the handle 5, the section size of the airbag 3 is slightly larger than the size of the interface groove 2, and the length of the airbag 3 is 2 meters longer than the ground connection wall; (2), steel bar processing: bind the steel bar according to the drawing of the ground connection wall to form the Reinforcement cage 1, weld the interface groove 2 on both sides of the reinforcement cage 1, and weld buckle fixing ribs 4 on the outside of the interface groove 2 according to the distance of 2 meters; (3), installation of airbag 3: for the inflated airbag 3. Place the upper end of the interface slot 2 in the interface slot 2, start to infl...

Embodiment 3

[0026] A method of using an interface box, comprising the following steps: (1) Processing of the airbag 3: the section of the airbag 3 is processed according to the size of the interface groove 2, the length of the airbag 3 is according to the length of the ground connection wall, and the upper end of the airbag 3 is welded and pumped Lifting handle 5, the cross-sectional size of the airbag 3 is slightly larger than the size of the interface groove 2, and the length of the airbag 3 is 1 meter longer than the ground connection wall; (2), steel bar processing: bind the steel bar according to the drawing of the ground connection wall to form the Reinforcement cage 1, weld the interface groove 2 on both sides of the reinforcement cage 1, and weld buckle fixing ribs 4 on the outside of the interface groove 2 according to the distance of 2 meters; (3), installation of airbag 3: for the inflated airbag 3. Place the upper end of the interface slot 2 in the interface slot 2, start to in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com