Explosion-proof diesel engine dual-fan air inlet shutoff device

A technology of explosion-proof diesel engine and cutting device, which is applied in mechanical equipment, engine control, machine/engine, etc., can solve problems such as hidden safety hazards, explosion-proof diesel engine cannot be stopped in an emergency, and the force is large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

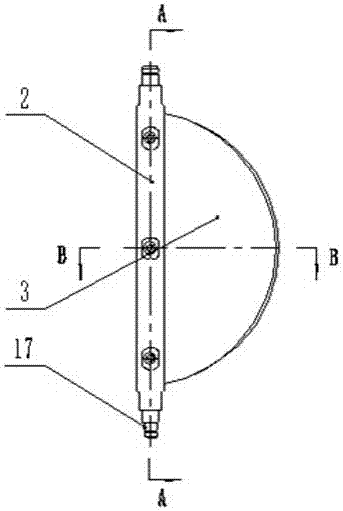

[0041] Example: figure 1As shown, it is a schematic view of the overall structure of the present invention, including a housing 1, a rotating shaft 2, a damper 3, an air sealing cushion 13, an air sealing block 29, a gear 5, a pull rod 6, a spring 7, a connecting rod I 8, a pin I 10, and a cylinder 11, support 12, protective cover 4, bolt I32, snap ring II36 are formed. Two rotating shafts 2, air sealing block 29, and gland 15 arranged symmetrically are installed inside the housing 1; a damper 3, air sealing cushion 13, and positioning pin 14 are respectively installed on each rotating shaft 2; the rectangular key at the end of the rotating shaft 2 Connecting rod Ⅰ8 and connecting rod Ⅱ9 are installed at 17 places; gear 5 is installed on the housing 1 and fixed by circlip Ⅰ25; pull rod 6 connects gear 5, connecting rod Ⅰ8 and connecting rod Ⅱ9 through pin shaft Ⅱ35, and spring 7 is installed on On the pull rod 6, the spring 7 is in the shortest state when the damper 3 is open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com