Pipeline connection assembly and air conditioner with same

A technology for connecting components and connecting pipe fittings, which is applied in the direction of pipes/pipe joints/pipes, threaded connections, air conditioning systems, etc., which can solve the problems of complicated operation and troublesome maintenance of the connection between the evaporator and the connecting pipe, and achieve the improvement of refrigerant leakage. The effect of the tight road connection and the expansion of the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

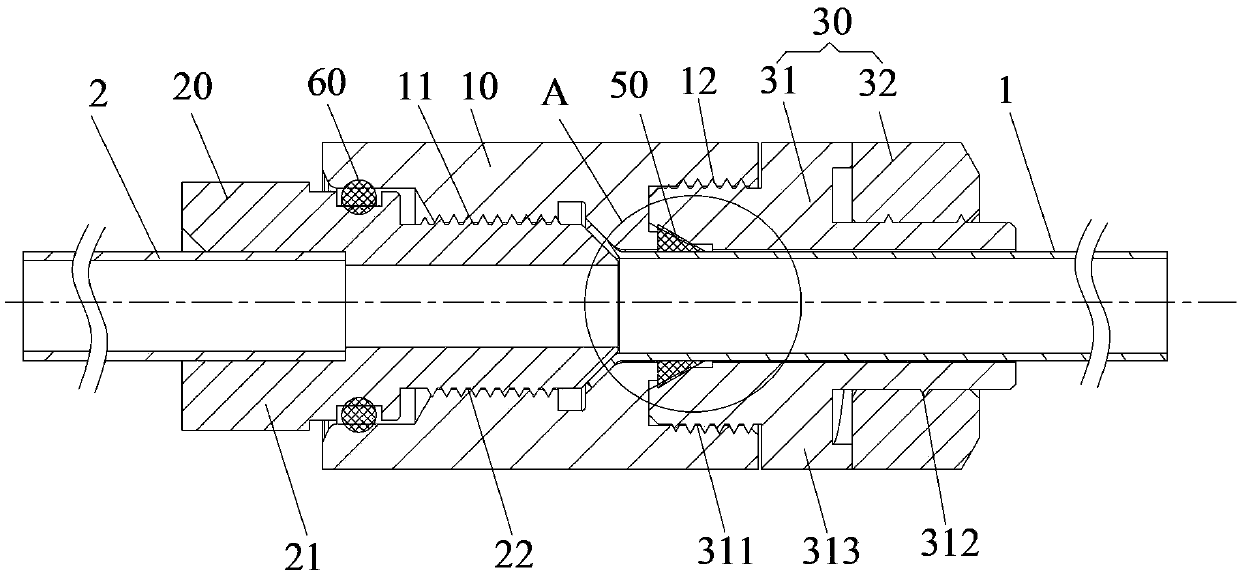

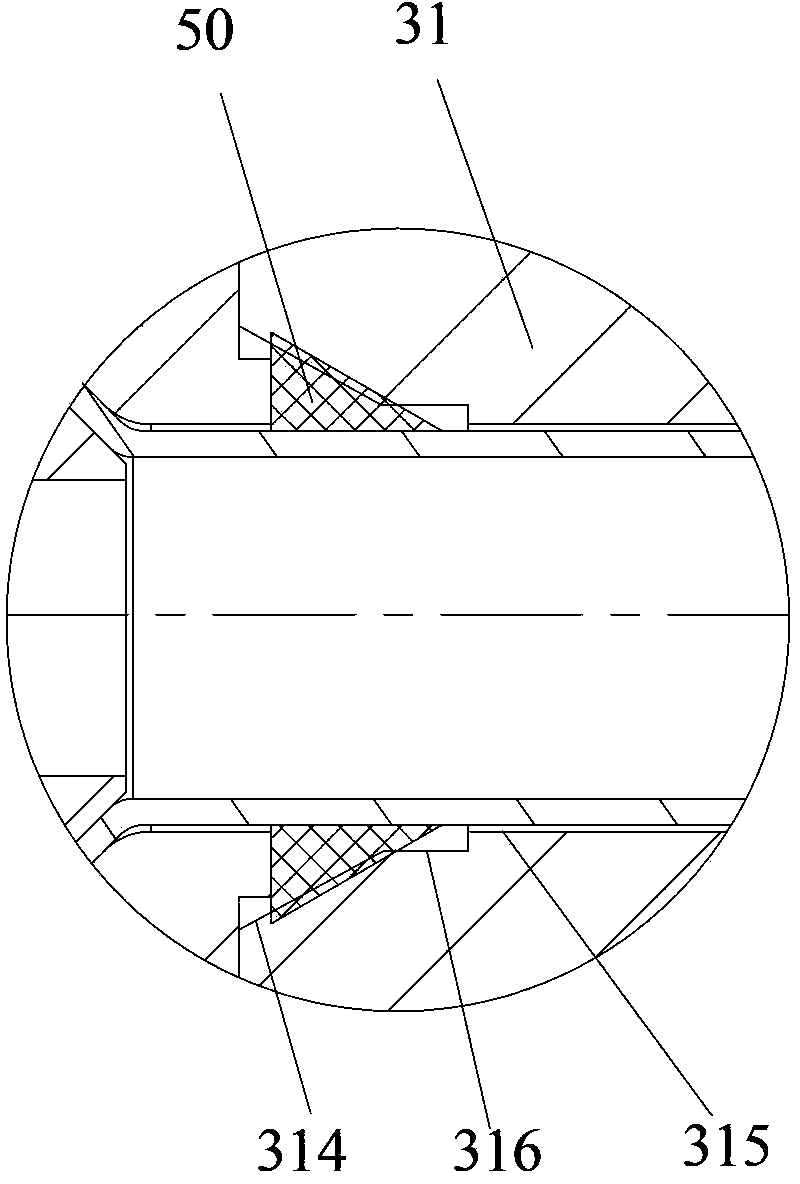

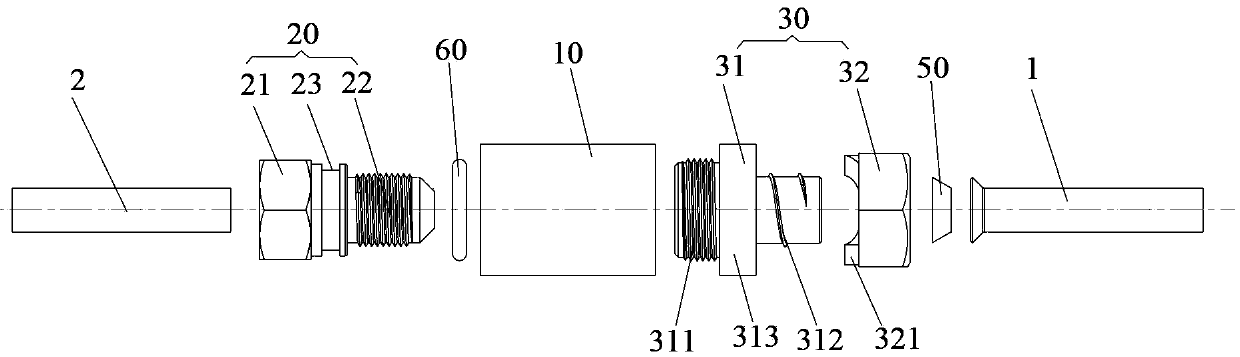

[0036] Such as Figure 1 to Figure 8As shown, the pipeline connection assembly of the first embodiment includes: a union nut 10 , a first pipe joint 20 and a second pipe joint 30 . The union nut 10 includes a first internal thread segment 11 at a first end and a second internal thread segment 12 at a second end, and the union nut 10 has a cylindrical outer surface, on which the first connected pipe 1 is mounted. The first pipe joint 20 includes a force application section 21 and a first external thread section 22, the force application section 21 is preferably a prism section, the first external thread section 22 is matched with the first internal thread section 11, and the second connected pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com