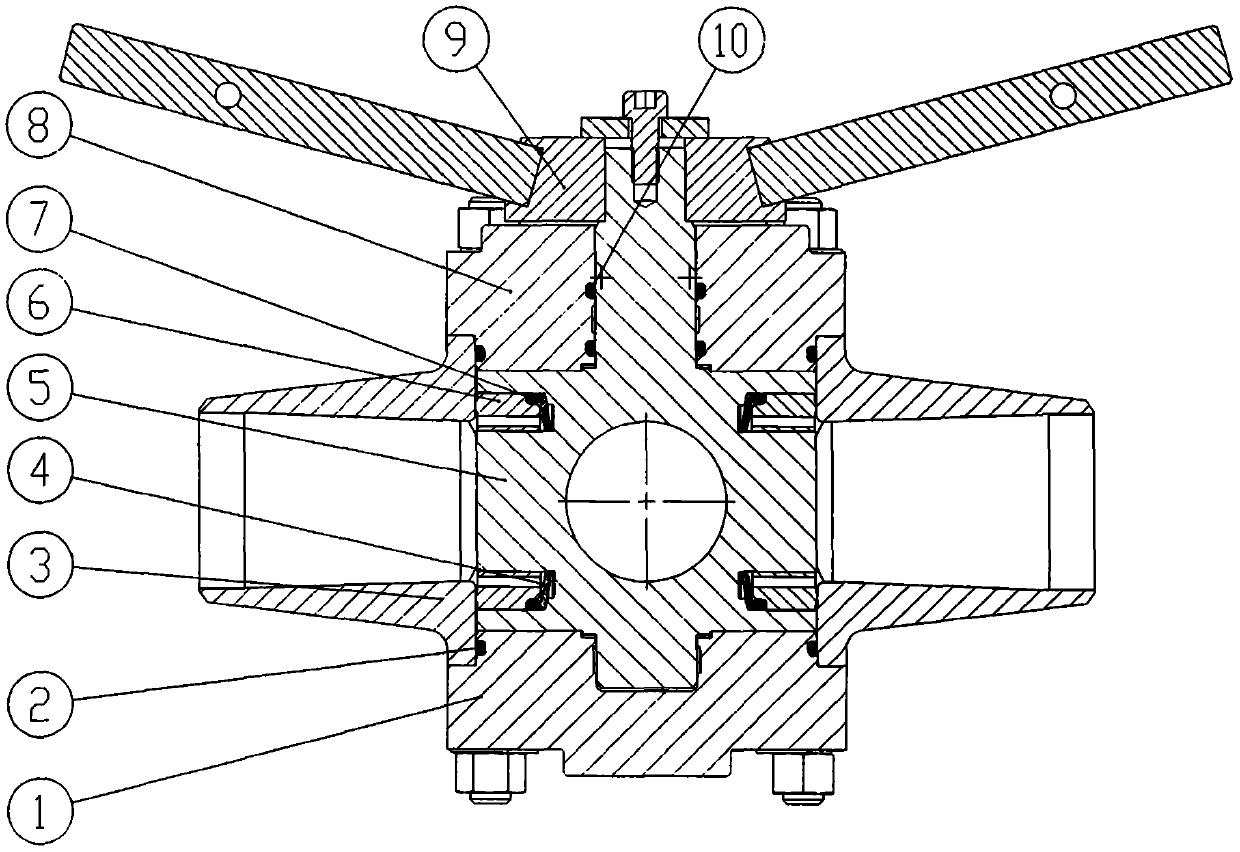

Spring-compensated movable valve seat plug valve

A technology of spring compensation and seat cock valves, which is applied in the direction of cocks, valve devices and engine components including cut-off devices, which can solve problems such as high-pressure leakage, achieve the effect of solving leakage problems and ensuring tight fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

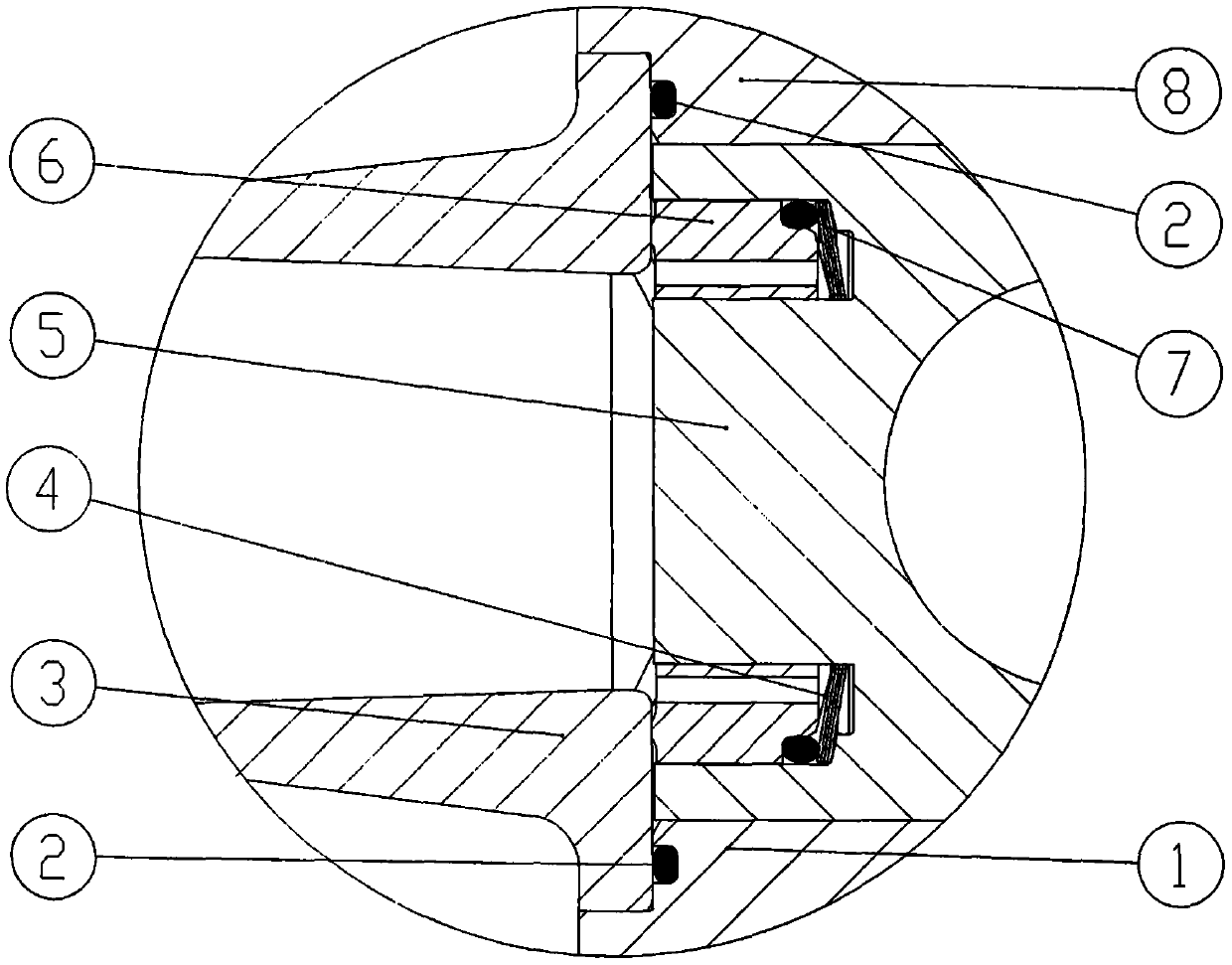

[0010] exist figure 1 In the illustrated embodiment, the valve is welded or otherwise mounted to the pipeline. When it is opened, the rotary actuator moves, and the actuator drives the cock to rotate. When the through hole on the cock communicates with the channel of the valve body, the valve opens and the medium circulates; when it is closed, the rotary actuator also moves, and the actuator drives the cock to rotate. When the cock is on When the valve seat rotates to the same axis as the valve body channel, the sealing surface of the valve seat and the wall surface of the inner cavity of the valve form a closed sealing pair, and the valve is closed to block the flow of the medium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com