Soft wiper

A boneless wiper and wiper blade technology, applied in vehicle cleaning, vehicle maintenance, transportation and packaging, etc., can solve the problems of difficult disassembly of wiper joints and uneven pressure of wiper blades, and achieve uniform pressure distribution and tight guarantee. fit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

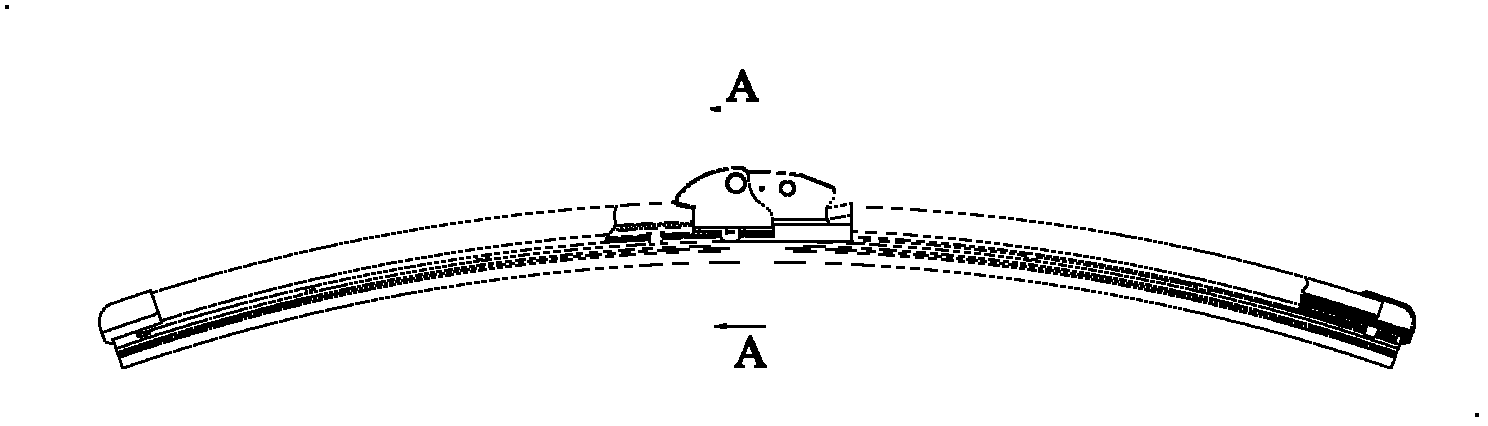

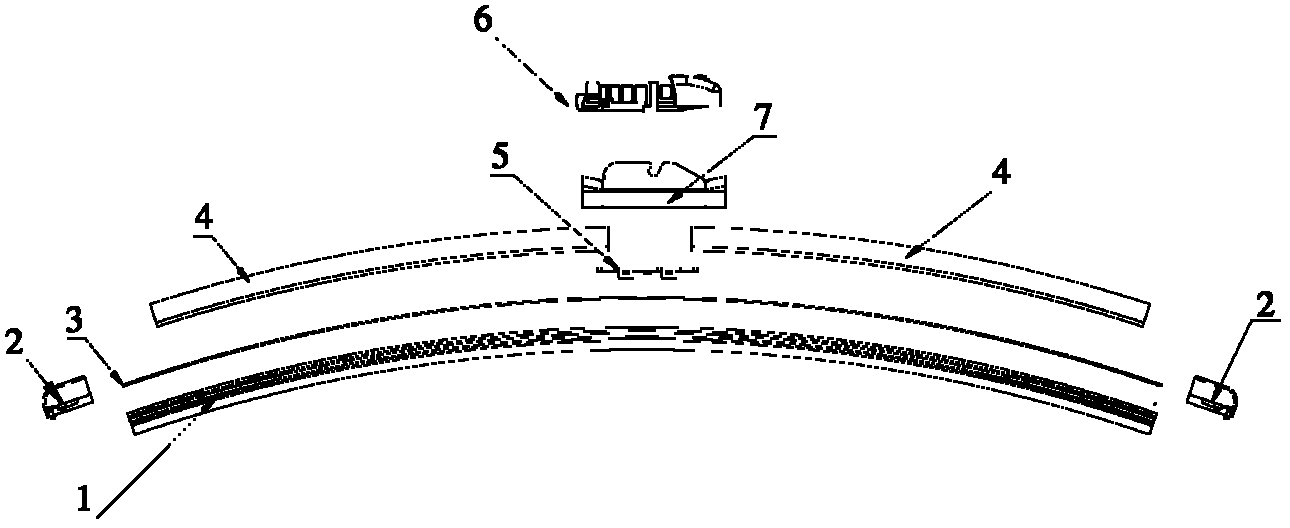

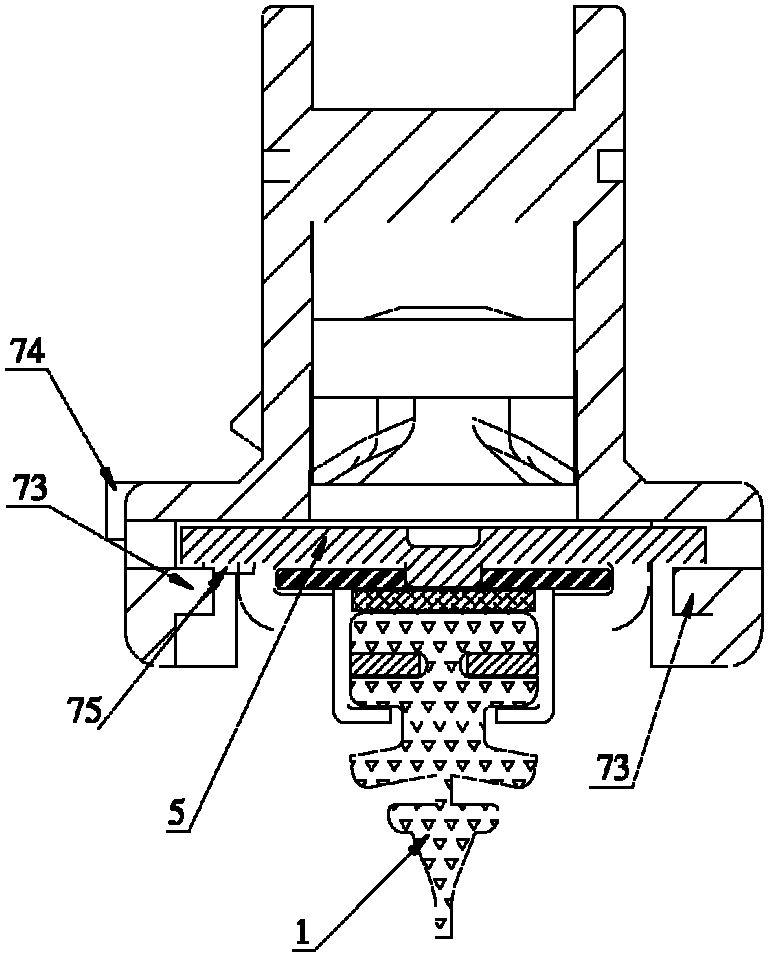

[0025] like figure 1 , figure 2 , image 3 As shown, the present invention includes a wiper blade assembly and a joint 7 for connecting a wiper arm, and the two are connected as a whole through a sheet-shaped connecting steel sheet 5 . Different transition joints 6 can also be installed on the joint 7 to adapt to various types of wiper arms, so as to realize the versatility of the wiper.

[0026] The wiper blade assembly adopts the existing technology, including the rubber strip 1, the elastic steel sheet 3 is fixed on the top surface of the rubber strip 1, and the sheet-shaped connecting steel sheet 5 is arranged in the middle of the rubber strip 1 and fixed on the elastic steel sheet 3, the left and right sides of the sheet-shaped connecting steel sheet 5 are respectively provided with left and right triangular sheaths 4, and the left and right triangular sheat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com