Patents

Literature

86results about How to "Reduce the chance of sticking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

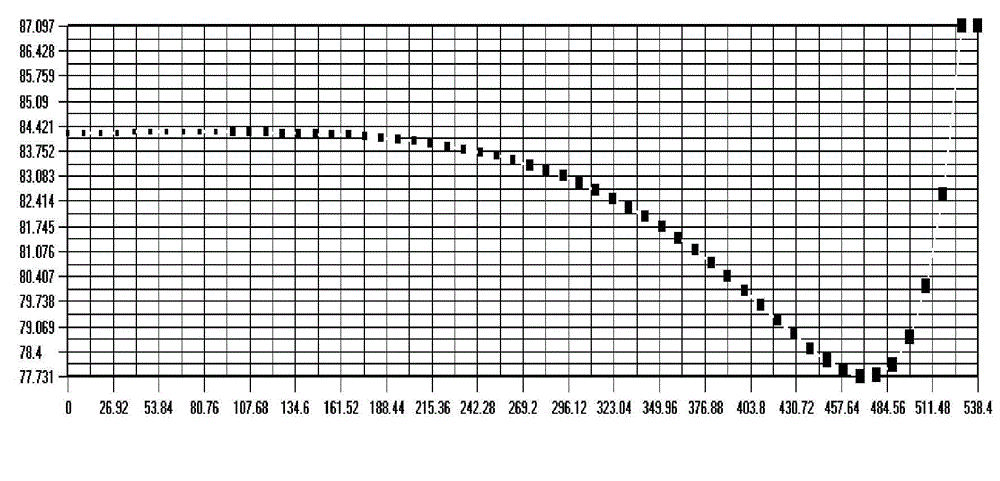

Method for implementing middle phase zero division zero sum by control protection switch

ActiveCN101505052AReduce bouncingReduce the chance of stickingEmergency protective circuit arrangementsOvervoltageElectricity

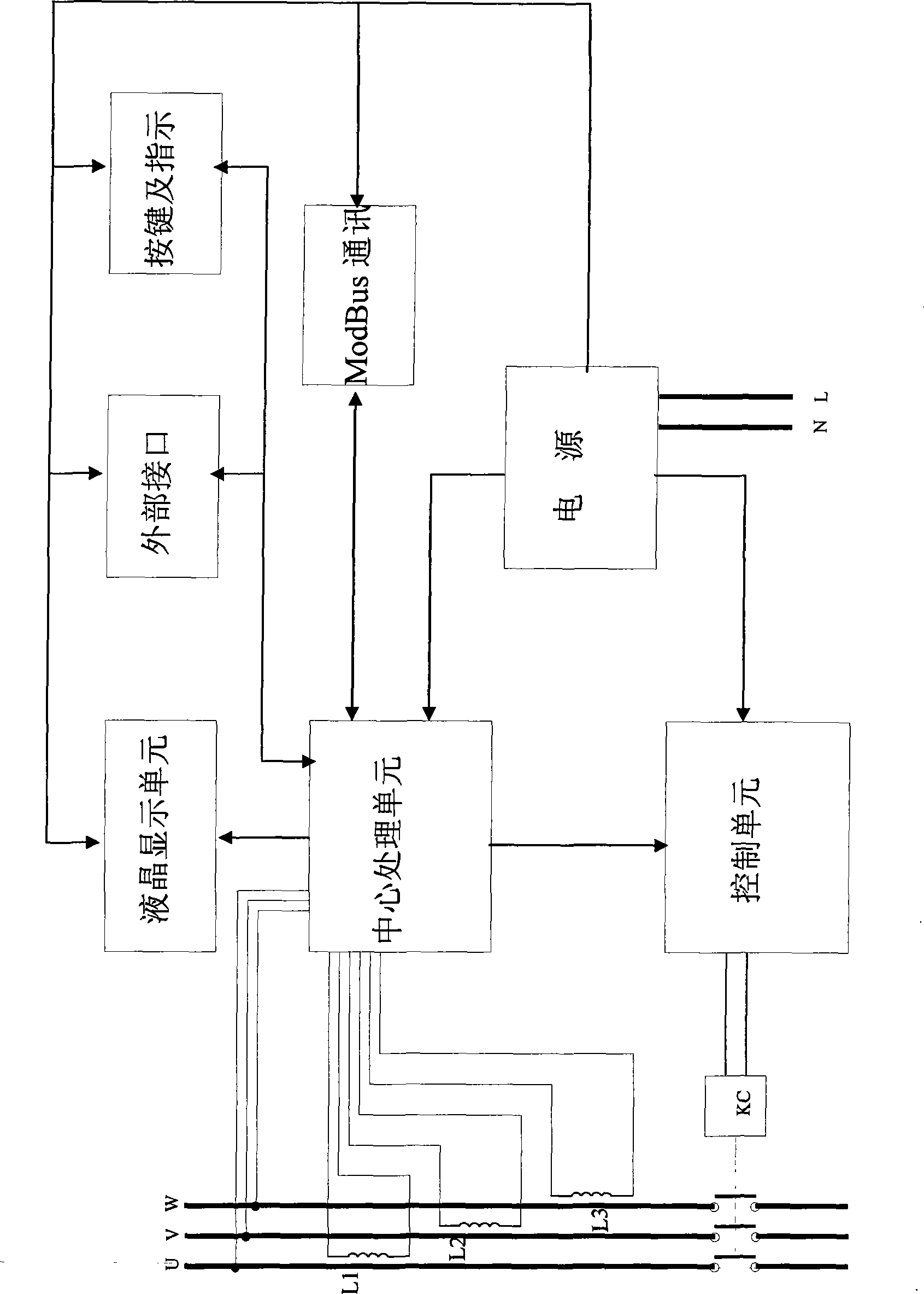

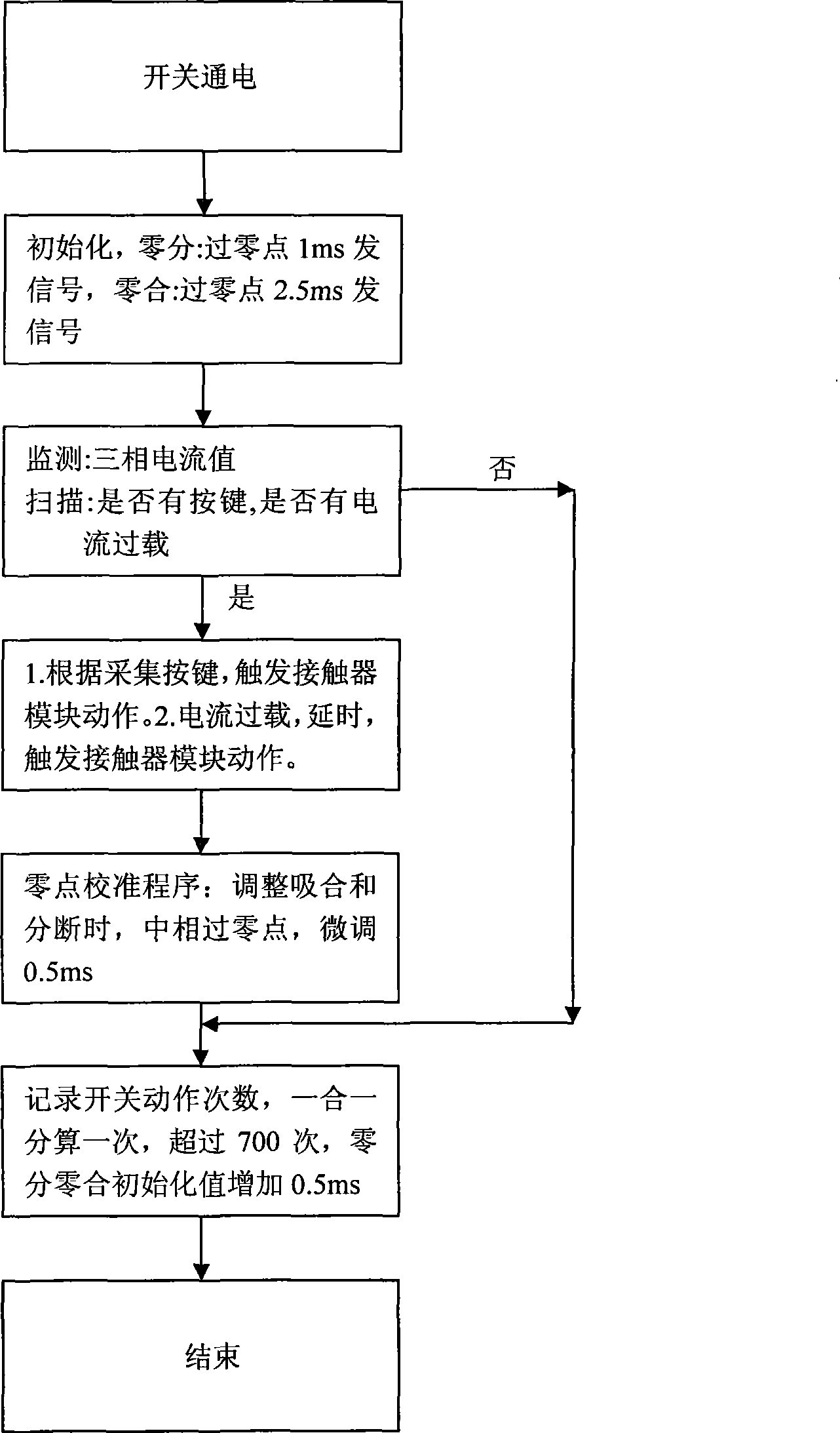

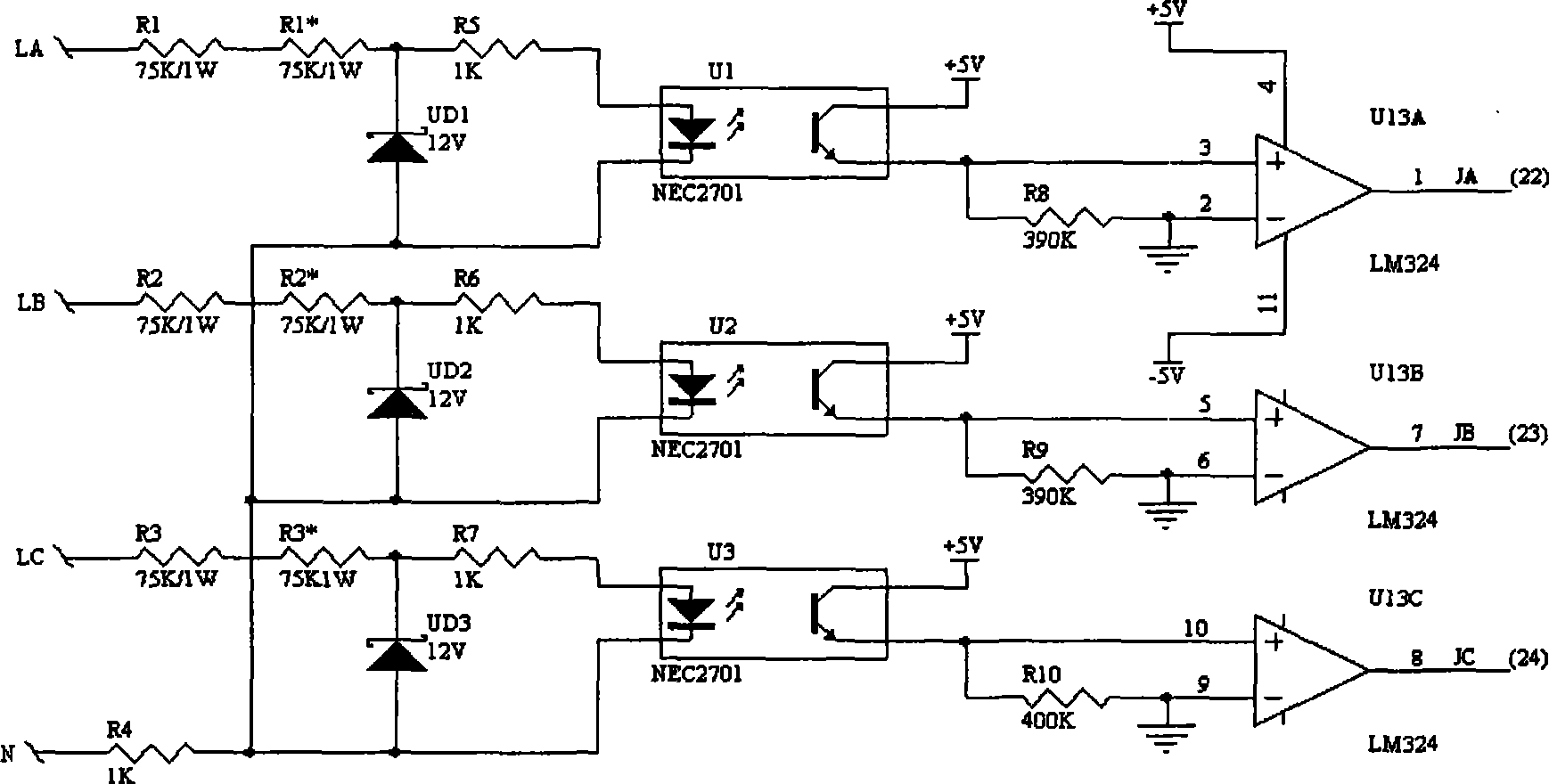

The invention relates to the technical field of motor control, in particular to a method for realizing medium phase zero-breaking and zero-closing by a control protection switch. The control protection switch is a carrier to realize the method, and comprises a central processing module and a contactor module. The method is characterized by comprising the following steps that: a main CPU singlechip of the central processing module acquires a voltage signal through a voltage signal acquisition circuit, and acquires a current signal through a current signal acquisition circuit; then a three-phase electricity zero-crossing point period is compared with electrified closing mechanical time and power off breaking mechanical time of the contactor module; and a closing or breaking signal after judgment is sent so as to close or break the contactor module of the control protection switch on the medium phase zero point of the three-phase electricity. The method is a simple and effective method for relieving the overvoltage and overcurrent impact, improves service life of the switch body, reduces abrasion of a contactor material, and reduces consumption of noble metal resources.

Owner:天津北方恒业电气技术有限公司

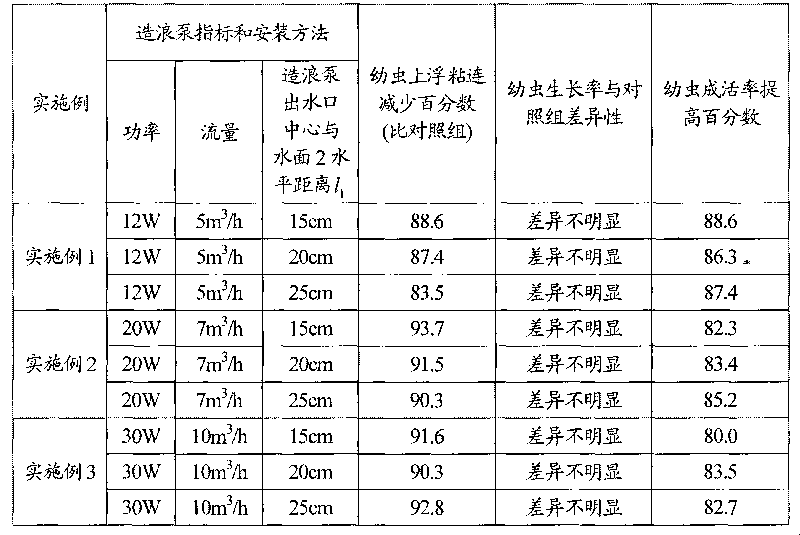

Method for preventing pinna pectinata larvae from floating upwards and adhering

ActiveCN101720704AGood waterproof performanceHigh dielectric strengthClimate change adaptationPisciculture and aquariaAdverse effectOffspring

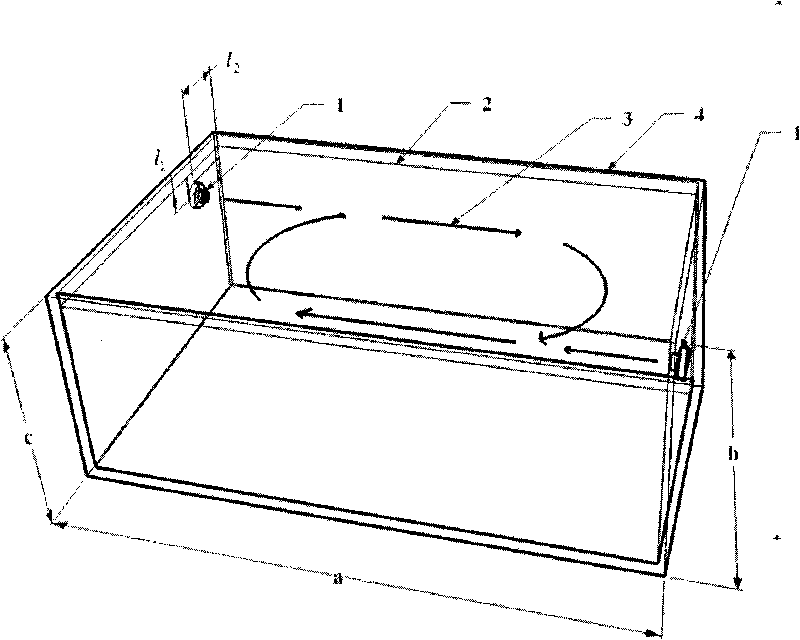

The invention relates to aquaculture bivalve offspring seed production, in particular to a method for preventing pinna pectinata larvae from floating upwards and adhering. Two wave-making pumps are arranged in a diagonal shape on the pond wall of a culture pond in a width direction; waves and water flows which are generated by the wave-making pumps are used for dispersing the pinna pectinata larvae so that the pinna pectinata larvae are uniformly distributed in the culture pond, thus the pinna pectinata larvae are prevented from floating upwards and adhering; 24 hours after pinna pectinata fertilized ovums are incubated into D-shaped larvae, when the D-shaped larvae float upwards and are adhered, the wave-making pumps are installed; the proper power of the wave-making pumps is 12-30 W, the proper flow rate is 5-10 m3 / h, the proper distance horizontally kept between the water outlet centers of the wave-making pumps and a water surface is 15-25 cm, and the proper distance between the water outlet centers of the wave-making pumps and the adjacent pond wall of the culture pond is 20-40 cm. The invention can reduce upward floating and adhesion ratio matched groups of the pinna pectinata larvae more than 80 percent, enhance the survival rate by 80 percent without obvious adverse effect on the growth of the larvae and achieve the culture density of the larvae by 4-5 / ml, thereby effectively enhancing the survival rate and the culture efficiency of the pinna pectinata larvae.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Water mist prevention UV (ultraviolet) gloss oil for gold card paper

InactiveCN102031717AQuality improvementImprove qualitySpecial visual effect coatingsEpoxyPhotosensitizer

The invention discloses water mist prevention UV (ultraviolet) gloss oil for gold card paper, which is prepared from the following raw materials in parts by weight: 40-60 parts of epoxy UV resin, 5-15 parts of amino active matter, 20-40 parts of 1.6-hexanedioldiacrylate, 4-10 parts of photosensitizer, 1-6 parts of nanometer metallic oxide and 0.2-2 parts of lubricating flatting agent. In the invention, the formula of the existing water mist prevention UV gloss oil is adjusted, the nanometer metallic oxide is added in, as the nanometer metallic oxide particles are minimum, refraction and reflection of light rays can not be affected, thereby solving the problem of glossiness of patterns on the gold card paper, increasing the scraping-resisting performance of a forming film and improving the quality of the water mist prevention UV gloss oil.

Owner:GUIZHOU RUODUN SCI & TECH DEV

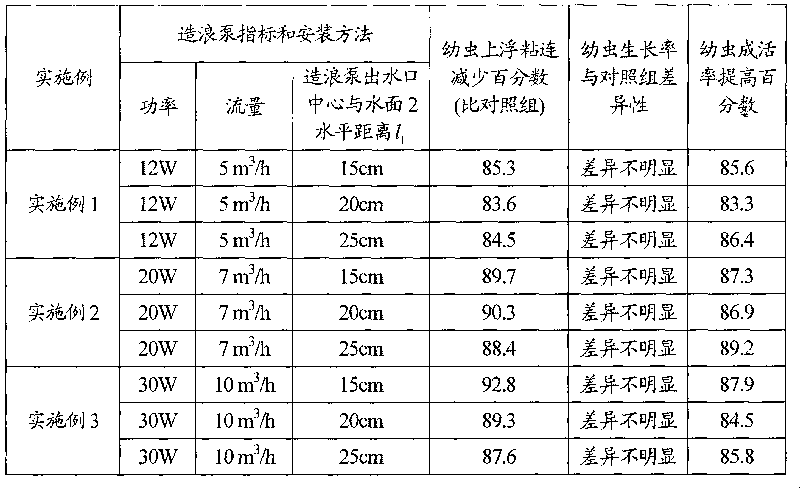

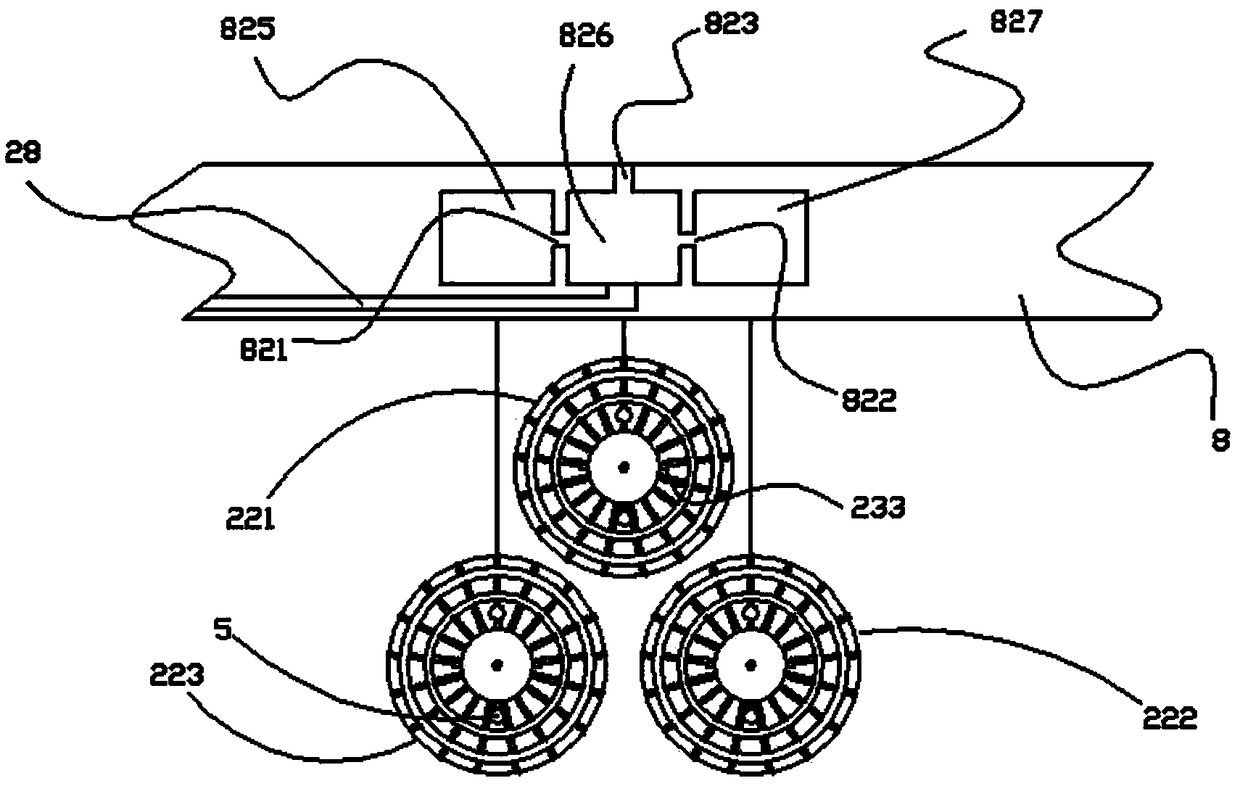

Quick charging method for battery management system with safety function

InactiveCN112406616AEnsure safetyReal-time monitoring of faultsCharging stationsElectric devicesBattery systemBattery cell

The invention provides a quick charging method for a battery management system with a safety function. According to the method, self-inspection is carried out on a battery system, the state of a quickcharging gun is sent to a vehicle control unit, the battery management system and a charging pile shake hands, carry out identification, and interact, a quick charging relay is closed, and the stateof the quick charging relay is sent to the vehicle control unit. In the charging process, if the battery breaks down, processing is carried out according to the fault level, and if the state of chargeof the battery reaches a set value, the battery management system receives an emergency power-off request sent by the vehicle control unit to disconnect the relay and judges whether the current on aloop is reduced to a specified value or not so as to ensure that the relay cannot be disconnected with load; and meanwhile, after the current drops for more than the specified time, the relay needs tobe disconnected in time no matter whether the current drops or not, so that the quick charging process is safer and more reliable, and the safety and reliability of the quick charging process are ensured.

Owner:DONGFENG MOTOR CORP HUBEI

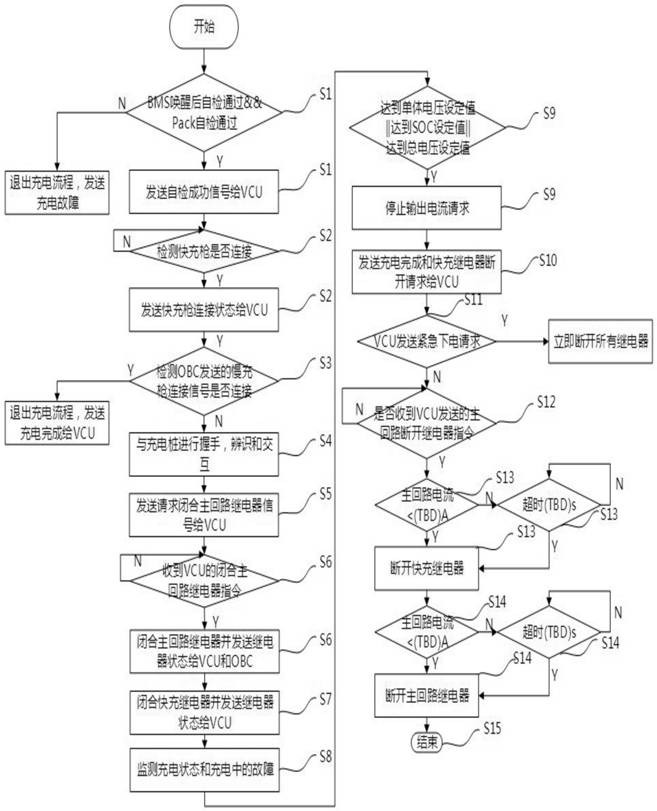

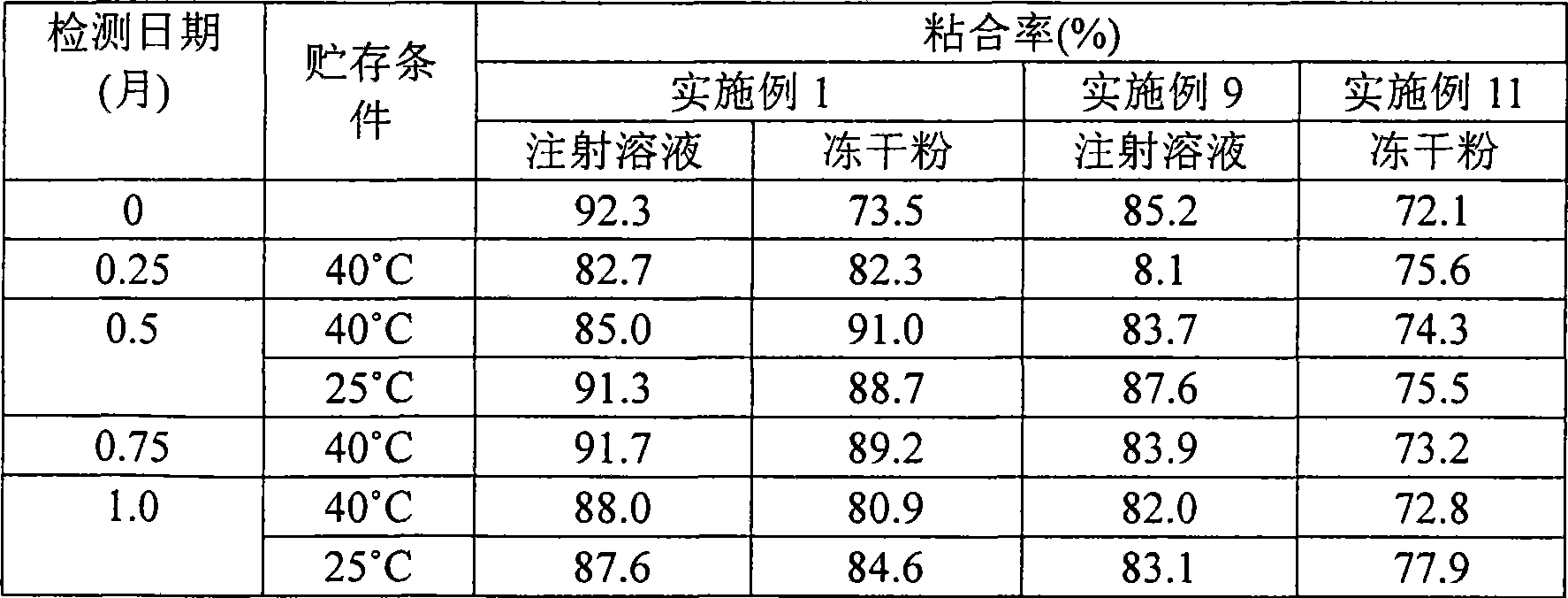

Gemcitabine hydrochloride or gemcitabine composition

InactiveCN101428035AExtended half-lifeSmall toxicityOrganic active ingredientsPowder deliveryGemcitabine HydrochlorideCurative effect

The invention belongs to the field of pharmacy, which discloses hydrochloric gemcitabine or gemcitabine composition. The composition comprises components in the following weight ratio: the ratio of hydrochloric gemcitabine or gemcitabine, polymer and protein is 0.1 to 20:0.00 to 50:0.00 to 20, wherein, the weight of polymer and protein is not zero at the same time. The composition can effectively prevent hydrochloric gemcitabine or gemcitabine from loosing the activity in vivo, and has the advantages of good stability, low toxicity and good efficacy.

Owner:常州安孚立德药业技术有限公司

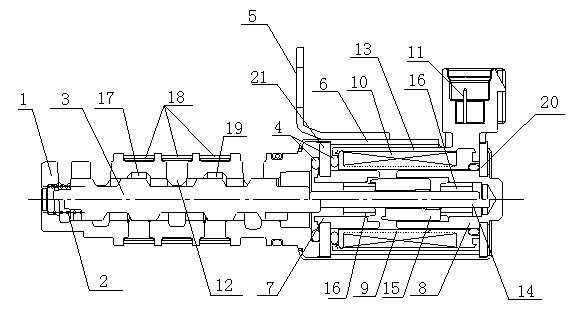

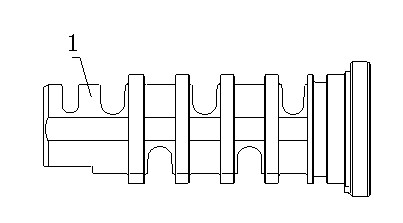

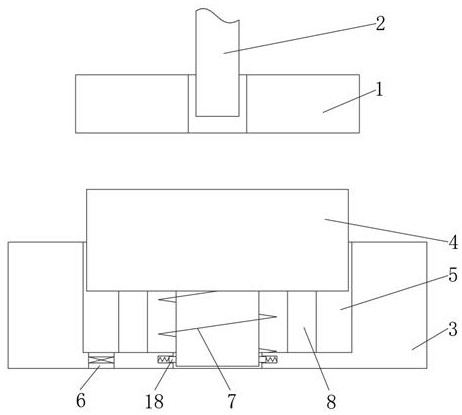

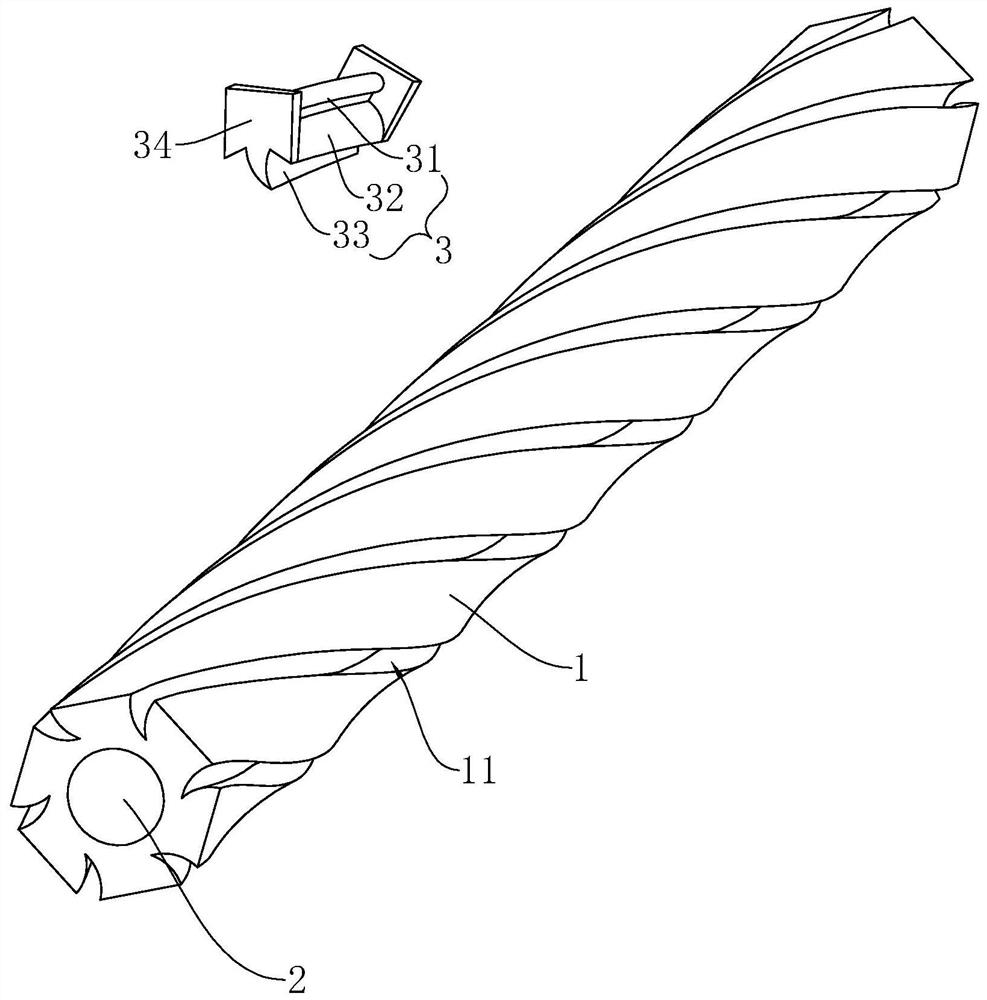

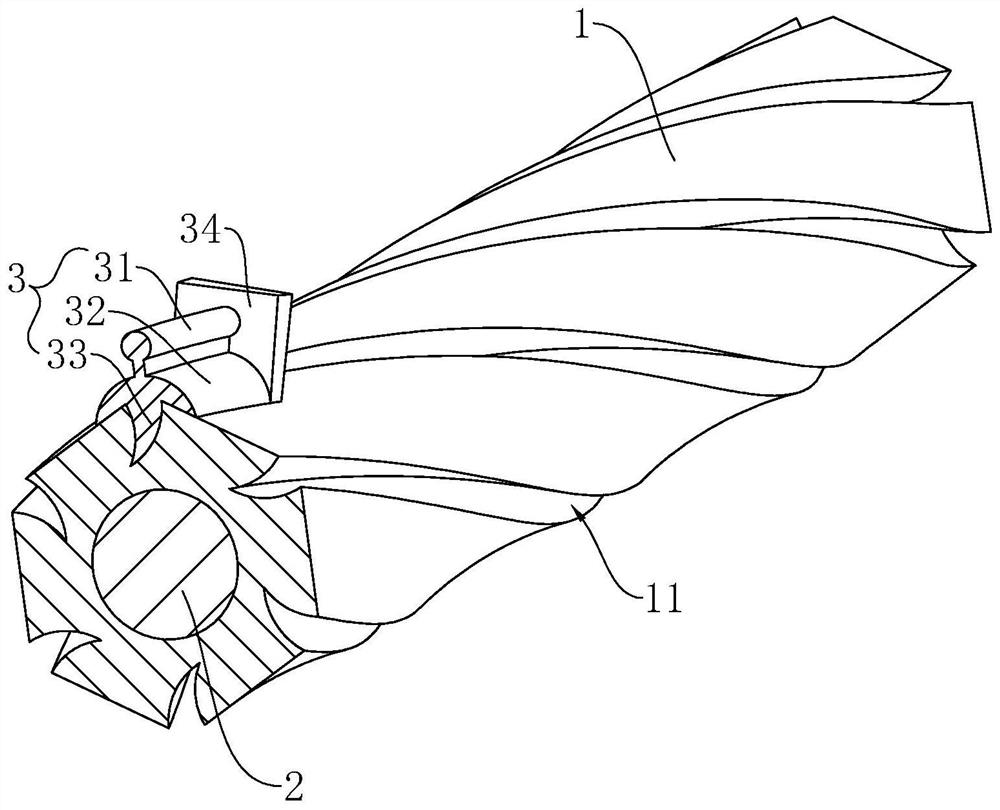

Large-flow continuous variable valve timing (CVVT) fuel control valve with filter screen

InactiveCN102003233AAdd filter functionHigh working reliabilityValve arrangementsDispersed particle filtrationForeign matterEntrance angle

The invention discloses a large-flow continuous variable valve timing (CVVT) fuel control valve with a filter screen. The large-flow CVVT fuel control valve with the filter screen comprises a valve bush component, a rear yoke iron component, a front yoke iron component, an iron core component, a winding component and an outer yoke sleeve component, wherein the valve bush component consists of a valve bush (1), a return spring (2), a valve core (3) and a ring; the valve bush (1) is provided with a fuel feed port (12), an entrance angle oil port (17) and a lag angle oil angle (19); and the fuel feed port (12), the entrance angle oil port (17) and the lag angle oil angle (19) are pressed into the filter screen (18) respectively. The large-flow CVVT fuel control valve with the filter screen controls the fuel flow to increase by 50 percent, improves the quick response time of a valve timing actuator, increases a filtering function of the filter screen, effectively protects foreign matters from entering the fuel control valve, guarantees that the valve core can slide in the valve bush freely, reduces the possibility of the clamping stagnation of the valve core, increases the working reliability of a valve timing system, reduces the requirements of a motor on the using environment and prolongs the service life of a product.

Owner:成都恒高机械电子有限公司

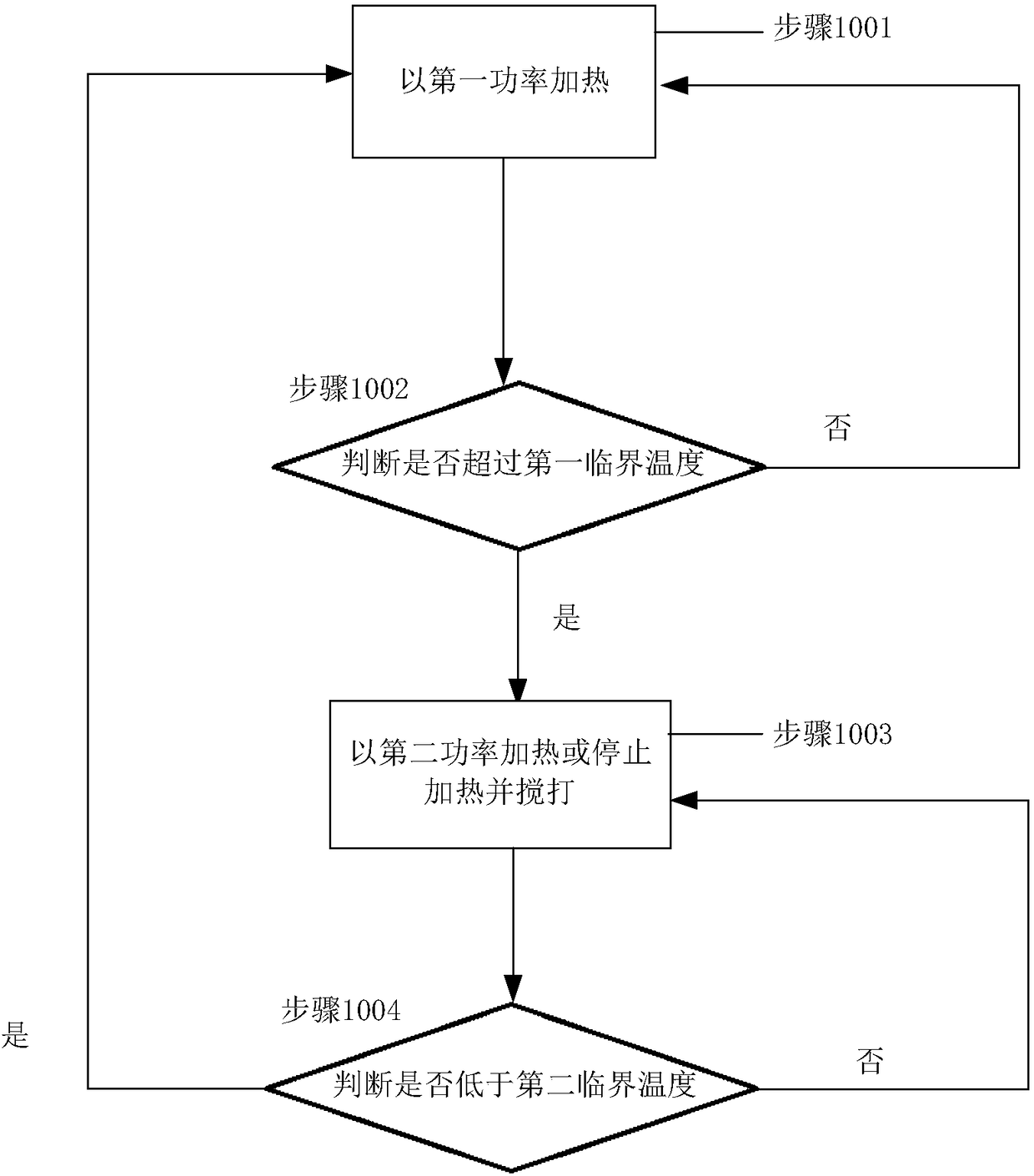

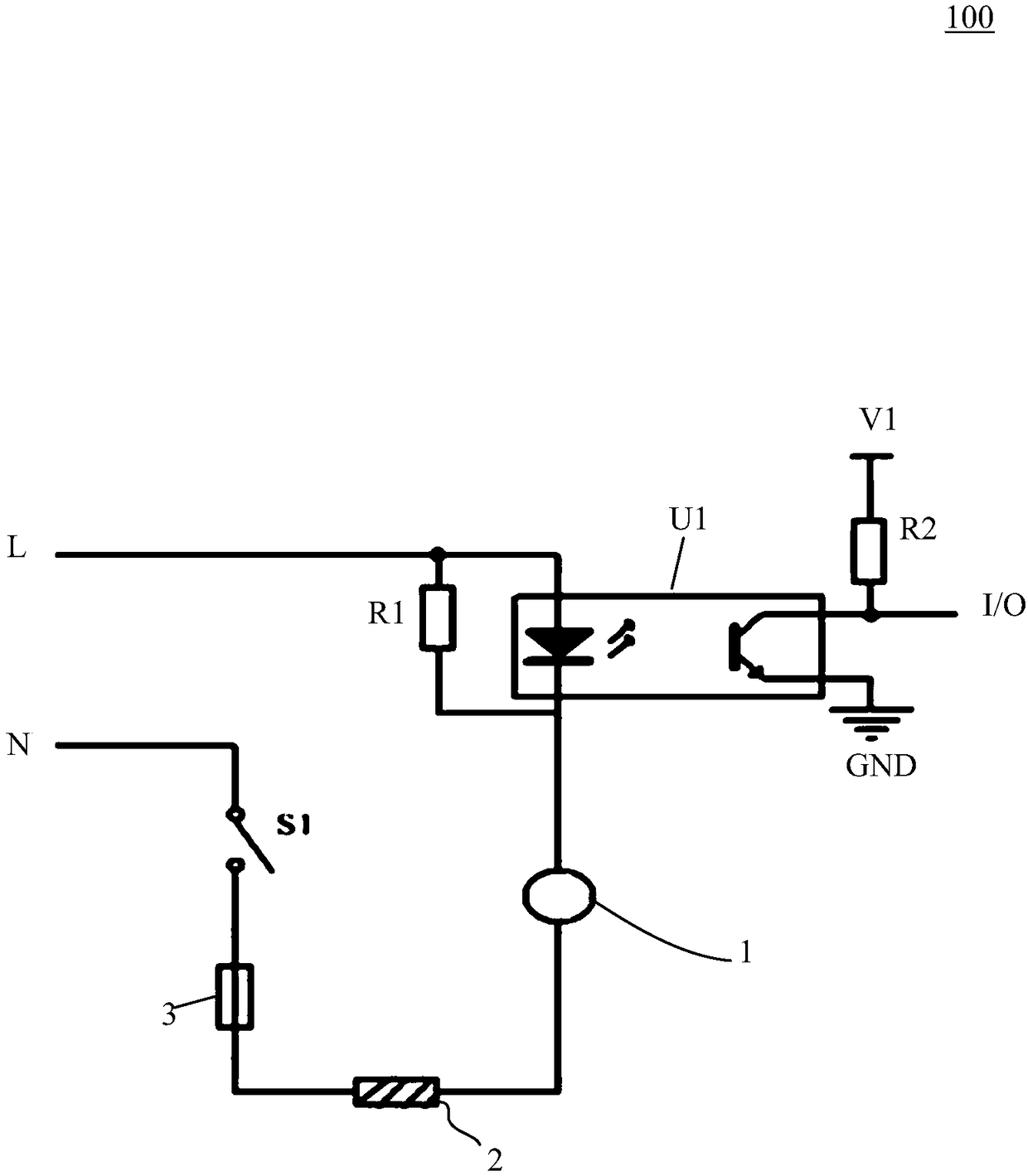

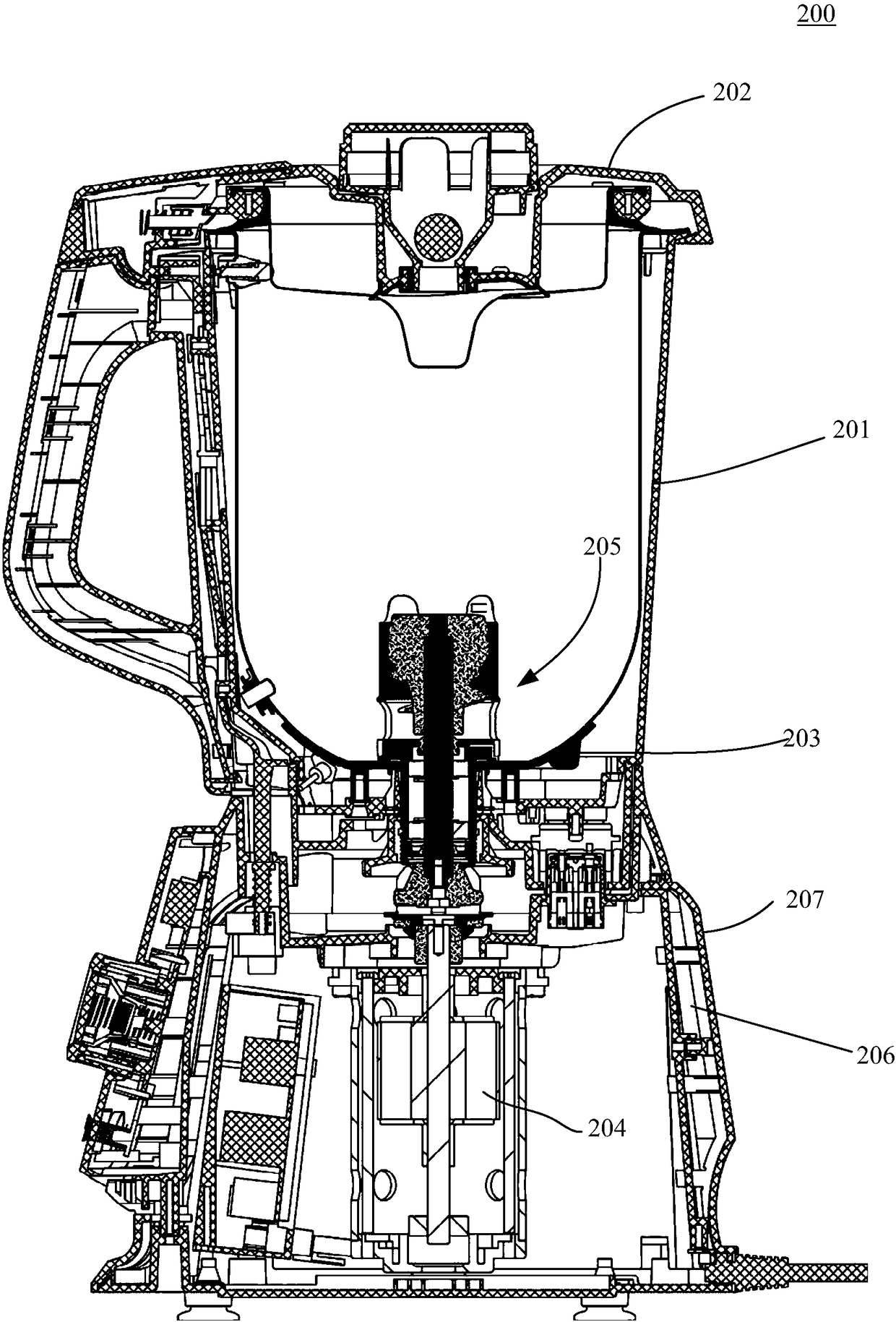

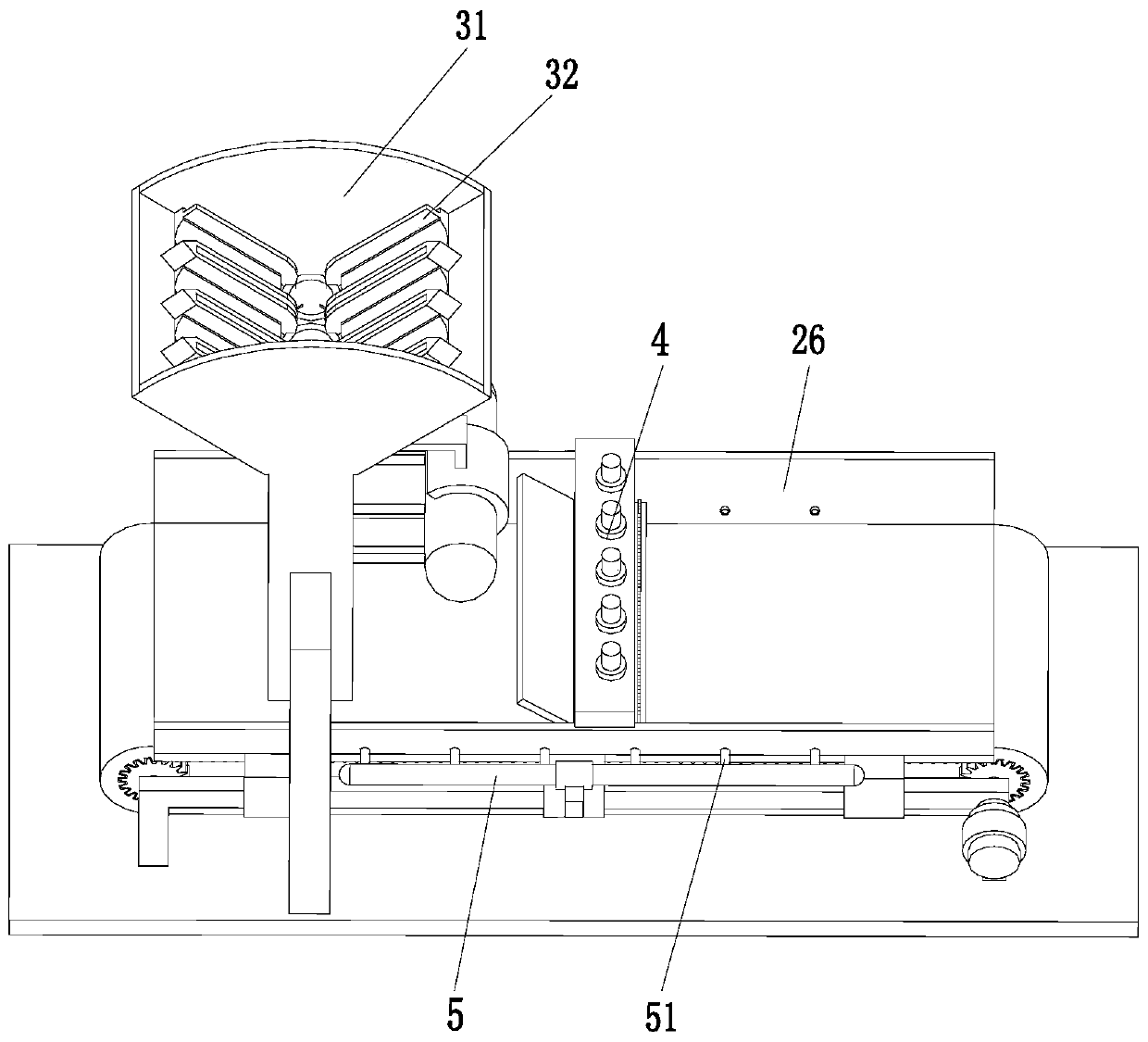

Food cooking method and food cooking machine

InactiveCN108113459AReduce the temperatureReduce the chance of stickingVessels with intergral heatingTime-controlled ignitorsProcess engineeringCooking methods

The invention provides a food cooking method. The method comprises the steps of step 1, heating foodstuff at a first heating power; step 2, determining whether or not the temperature of the foodstuffexceeds a first critical temperature, and if the situation that the temperature of the foodstuff exceeds the first critical temperature is determined, proceeding to step 3; step 3, heating the foodstuff at a second heating power which is lower than the first heating power or stopping heating the foodstuff, and whipping for a predetermined period of time. The food cooking method can effectively alleviate bottom paste phenomenons due to the fact that when the risk of the bottom paste is detected, whipping is started while a heating mode is changed.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

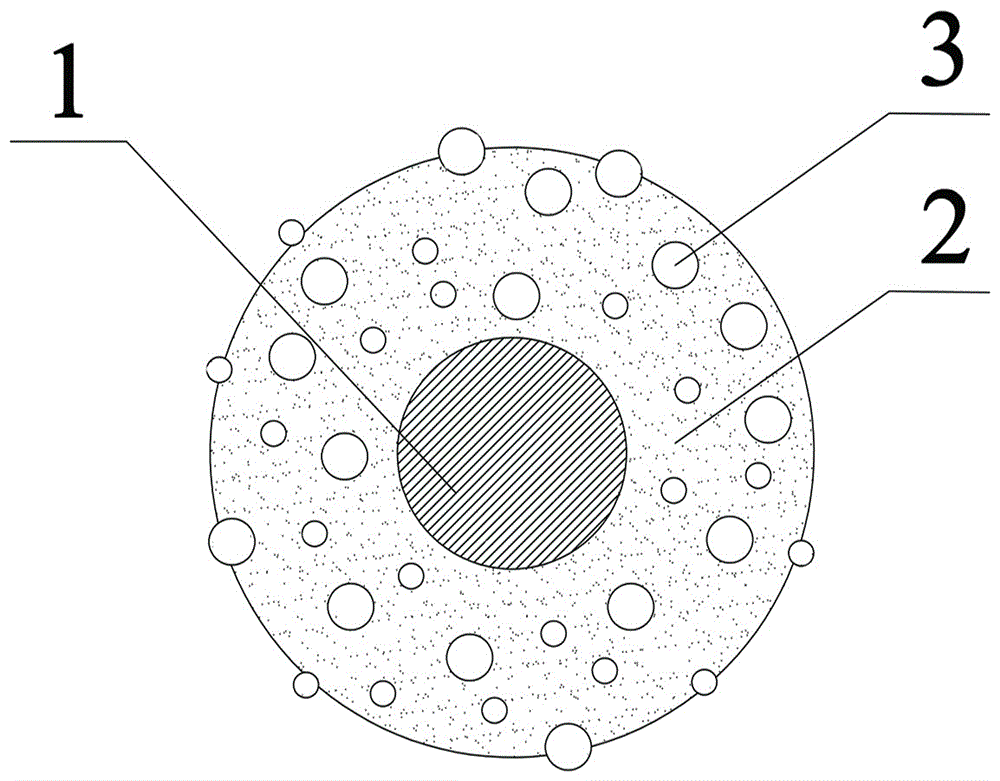

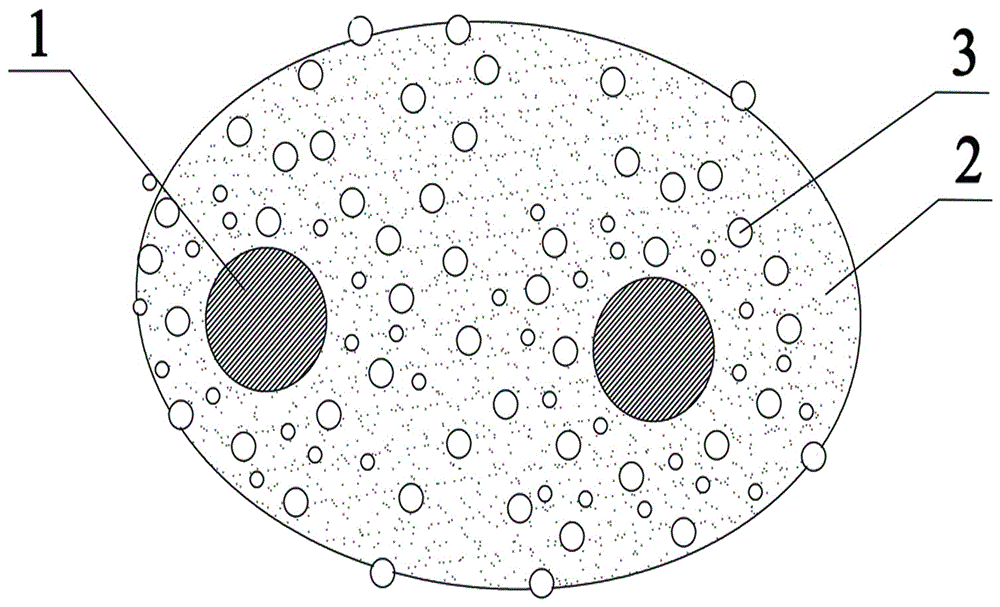

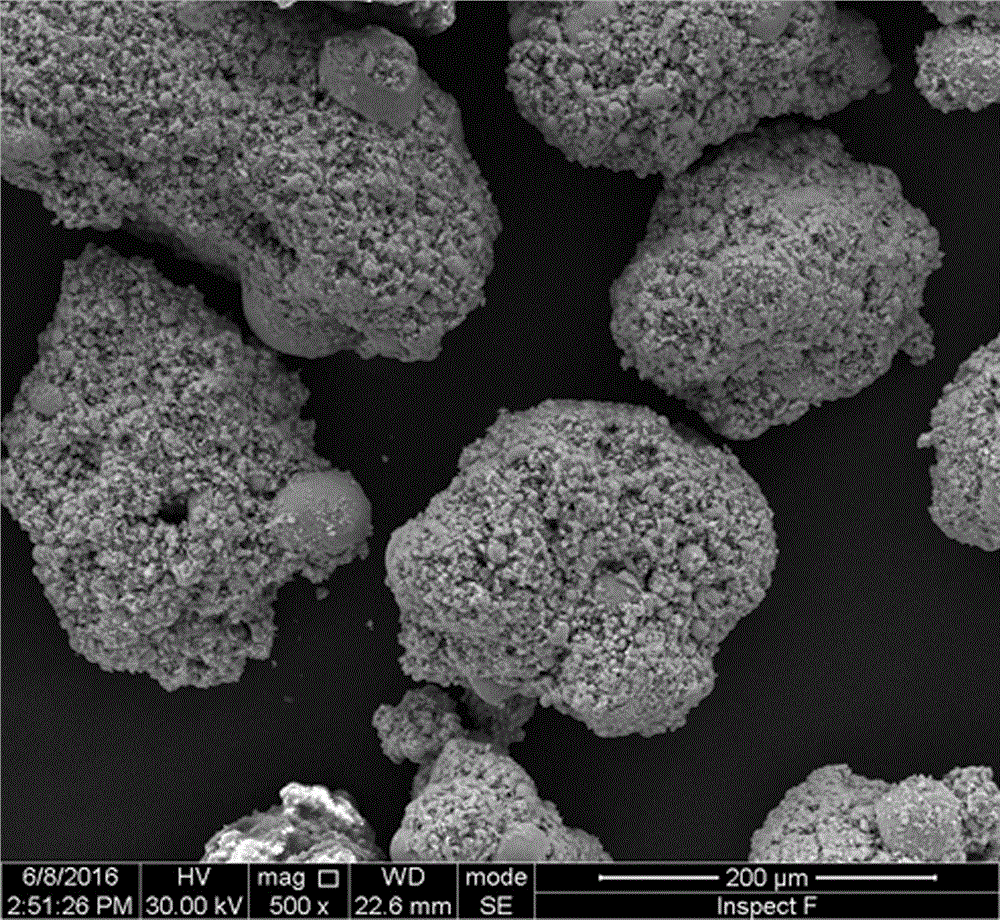

Magnetic grinding material and preparation method thereof

ActiveCN106753241AExtended service lifePreserve self-sharpeningOther chemical processesHot meltWork in process

Owner:ZHENGZHOU HONGJI ABRASIVE TECH CO LTD

Preparation method of lead storage battery green plate for reducing dusting powder

ActiveCN104466086AReduce dehydrationReduce floating powderElectrode manufacturing processesLead-acid accumulator electrodesDusting powdersSilicon oxide

The invention discloses a preparation method of a lead storage battery green plate for reducing dusting powder. The preparation method successively comprises a gypsum mixing process, a gypsum daubing process and a solidifying and drying process, wherein the gypsum daubing process comprises a daubing section, an acid leaching and rolling section and a surface dry treatment section, and an acid leaching solution is prepared from the following components in parts by weight: 12.5-22 parts of 90-95% vitriol, 1-5 parts of fumed silica, 0.5-1 part of lauryl sodium sulfate and 72-86 parts of water. The method disclosed by the invention is simple in operation and is applicable to a positive electrode and a negative electrode, the diachylon water loss of the green plate is reduced under the condition of not increasing processes, and the dehydrating rate is reduced from original 1% to less than or equal to 0.8%; the possibility of diachylon adhesion between pole plates is reduced, the dusting powder on the surface of the pole plate is lowered, and the loss rate of weight of the pole plate is lowered from 0.5-1% to 0-0.4%.

Owner:ZHEJIANG TIANNENG BATTERY JIANGSU

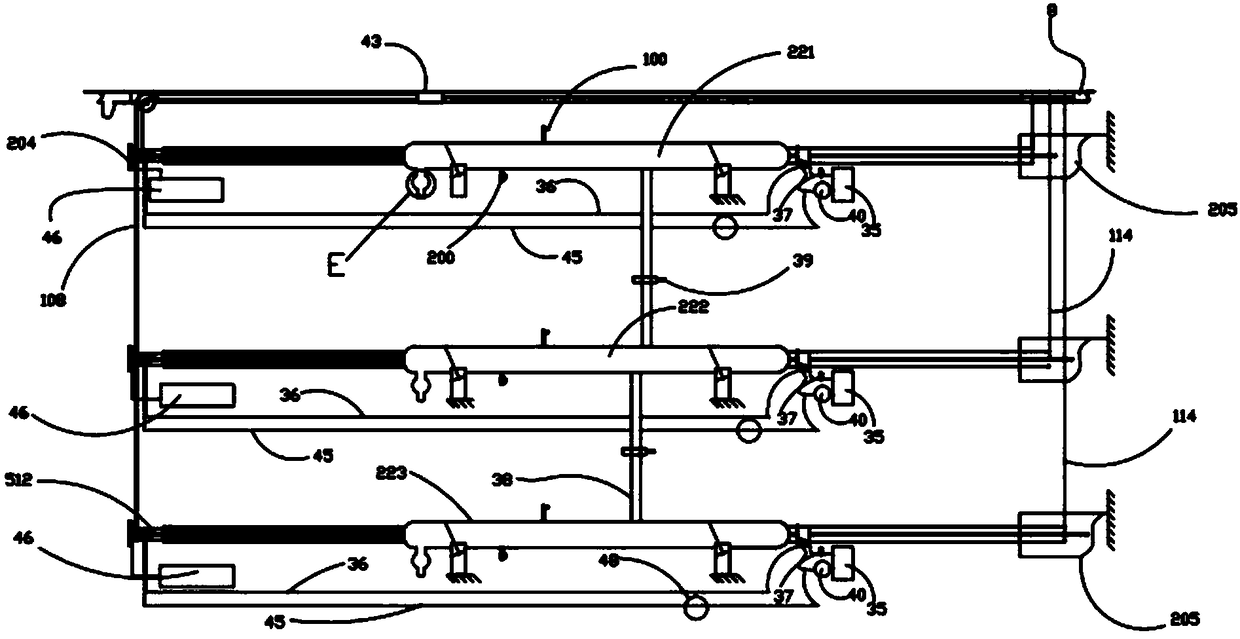

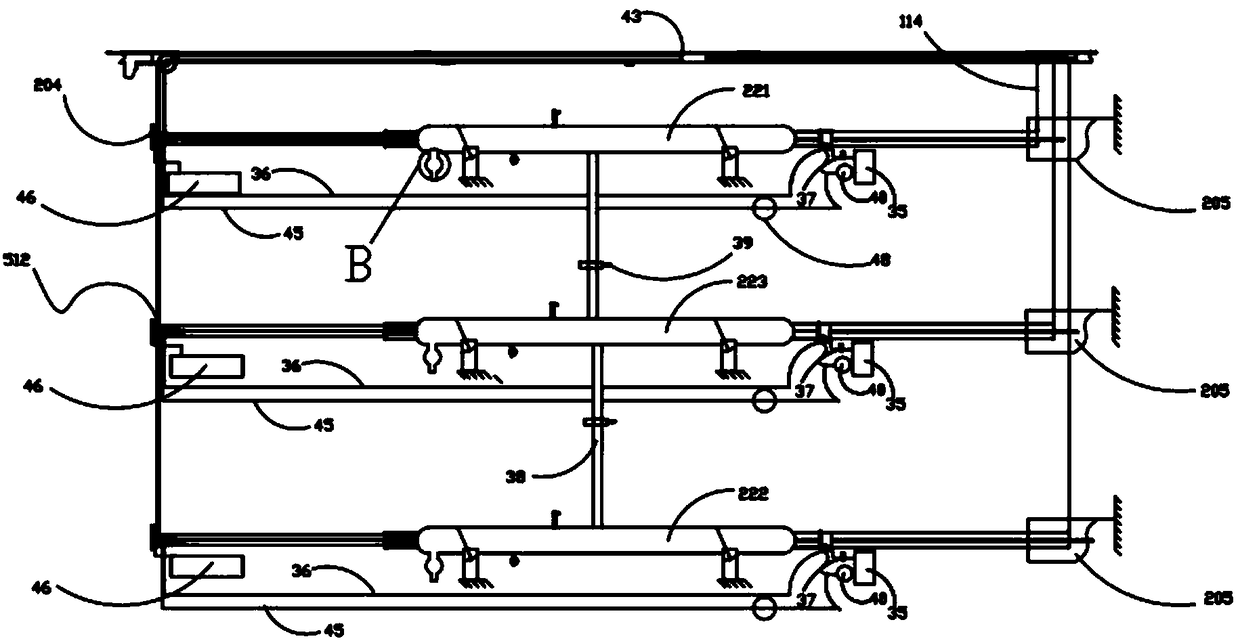

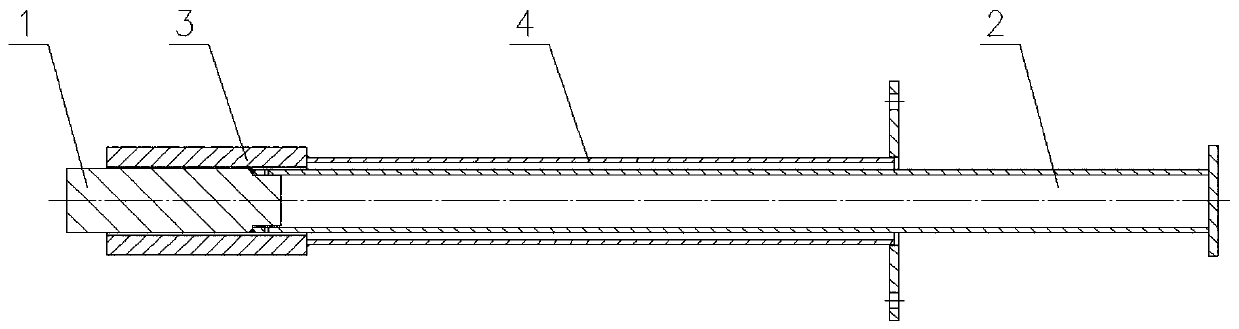

Steam catapult with parallel, series and separation functions

The invention discloses a steam catapult with parallel, series and separation functions. The steam catapult comprises a shell, an air storage tank and an ejection unit. The ejection unit comprises a desk, a sliding block tunnel, a sliding block, a low-pressure cavity shell, a tunnel pipe, a cylinder, piston sleeves, a tapered frame and stamping water cylinders. The in-out flow of the front and rear single-double three stamping water cylinders are controlled by three step control valves separately, one-way valves and a switch valve are installed in pistons, the pistons are divided into two parts including pistons I and pistons II, the pistons I and the pistons II are fastened by bolts separately, and sliding ways and piston sleeves, corresponding to the sides of the pistons I, are composedof sleeve fame beams and are connected with tapered frame hollow columns and penetrate out of front covers to be connected with bearing beams. When the weight of a carrier is specified, the steam catapult can calculate the exact movement value of corresponding parts, pull rods are arranged at the centers the end faces of the pistons II, and the pistons II are internally provided with shaft cores and shaft core pistons for common use of ejection and back stroke. The steam catapult with the parallel, series and separation functions has flexible operation, reliable performance, high speed, high efficiency and good air tightness, and the heat utilization rate is improved.

Owner:李广

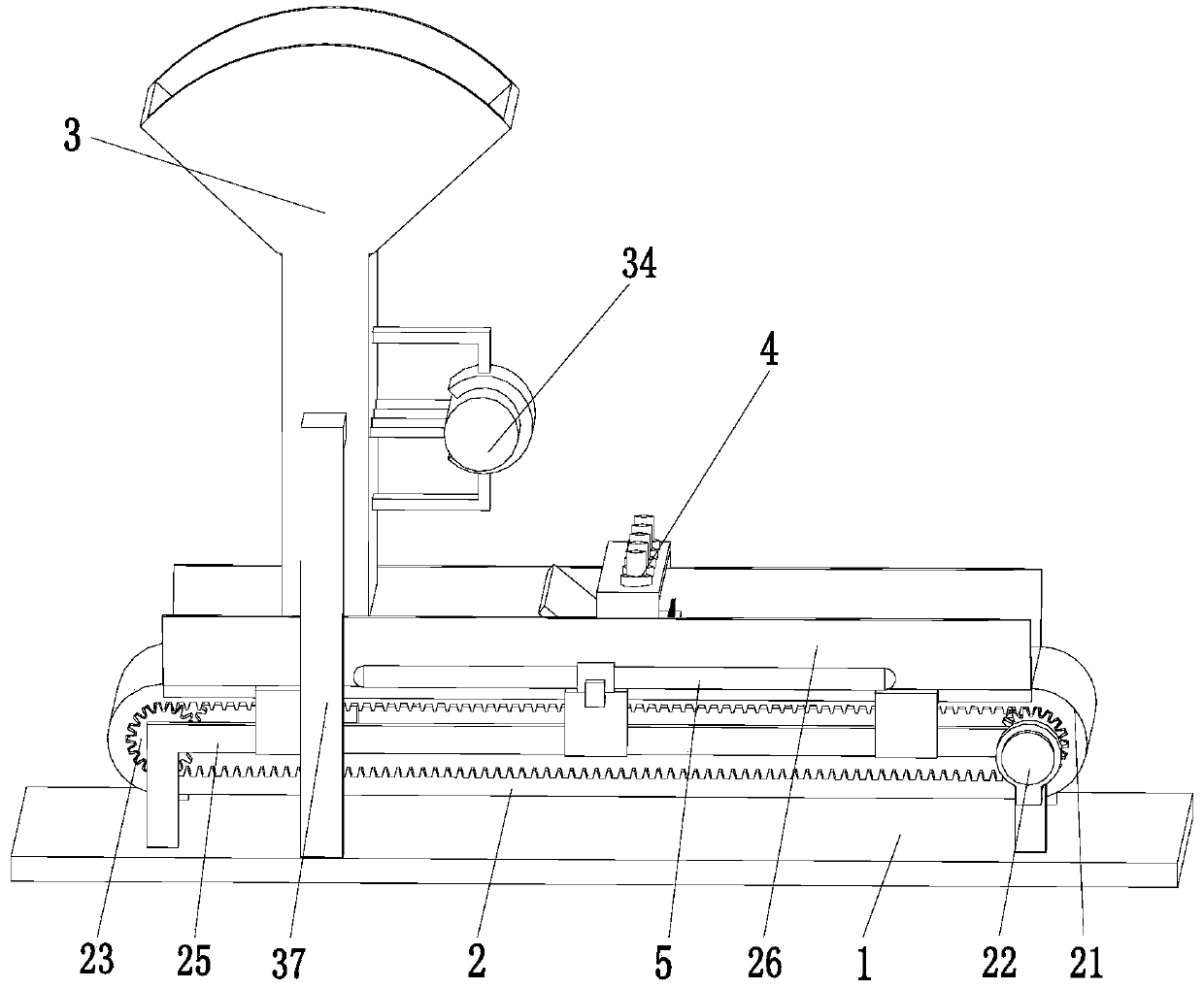

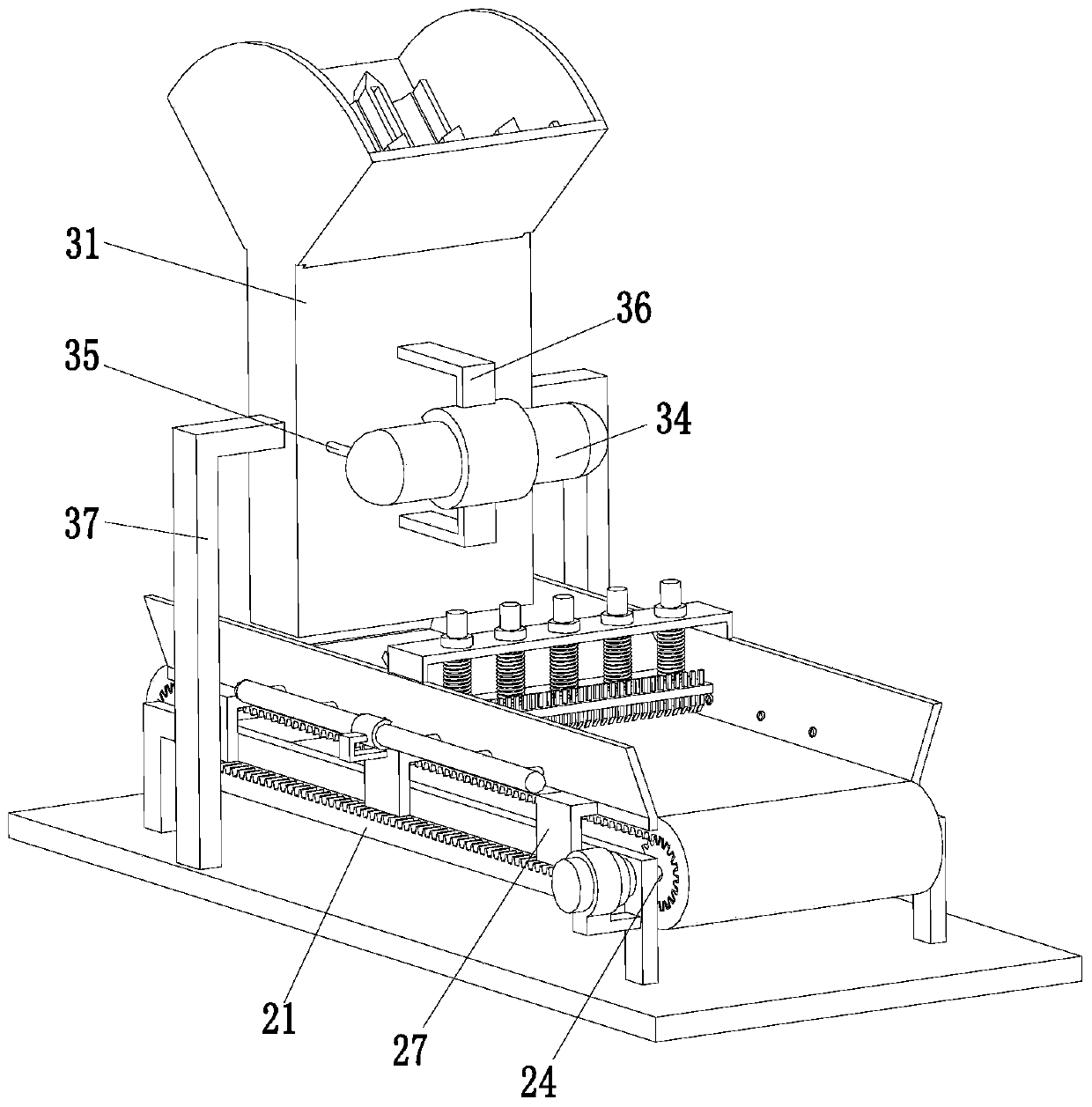

Polyethylene modified plastic pelleting processing preparation method

The invention relates to a polyethylene modified plastic pelleting processing preparation method. The plastic pelleting processing preparation method adopts a following plastic pelleting processing device, the plastic pelleting processing device comprises a bottom plate, a transmission mechanism, a cooling mechanism, a trowelling mechanism and an air cooling pump, and the cooling mechanism comprises a material feeding box, material feeding baffles, cooling pipes, an air pump, an air blowing pipe, an air pump support and a cooling support. The polyethylene modified plastic pelleting processingpreparation method adopting the plastic pelleting processing device comprises the following steps of S1, particle feeding; S2, falling cooling; S3, thorough cooling; and S4, even material spreading. By means of the polyethylene modified plastic pelleting processing preparation method, the problems in cooling treatment performed by existing plastic particle cooling equipment that plastic particlescannot make sufficient contact with cooling wind power to cause the poor cooling effect and the plastic particles have high adhesion rate in the cooling process to cause the low product quality can besolved.

Owner:广东恒真晟新材料科技有限公司

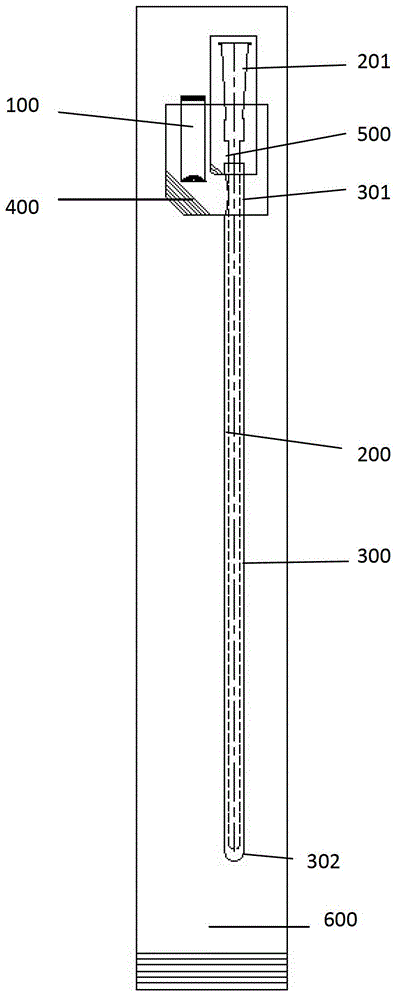

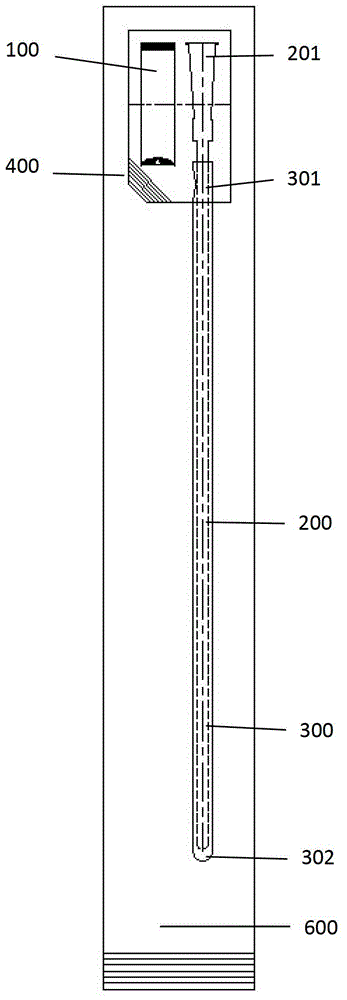

Body cavity drainage tube

ActiveCN109513096AAdequate drainageReduce inflammatory adhesionsMulti-lumen catheterHyperthermic perfusionGynecology

The invention discloses a body cavity drainage tube. The body cavity drainage tube comprises a main drainage tube, and further comprises a branch drainage tube A and N branch drainage tubes B; one endof the main drainage tube is communicated with one ends of the branch drainage tube A and the branch drainage tubes B respectively; the other ends of the branch drainage tubes B are closed; one ends,communicated with the main drainage tube, of the branch drainage tubes B are connected to the end part surface of the one end of the main drainage tube; the end part of the one end of the branch drainage tube A is located at the middle-lower part of the end part surface of the main drainage tube; the end parts of the one ends of the branch drainage tubes B are located at the middle-upper part ofthe end part surface of the main drainage tube in an equal arc distance or equidistance manner; and N is a natural number greater than or equal to 2. The body cavity drainage tube claimed in the invention can replace a traditional tubular drainage tube or a spiral multi-channel drainage tube, and is designed to be a sector-shaped multi-channel drainage tube, so generated blood or a diffusate in the operation area is fully drained, and inflammatory adhesion is reduced; and the body cavity drainage tube also can be used as a body cavity hyperthermia perfusion drainage tube, so body cavity hyperthermic perfusion chemotherapy can be fully carried out in the body cavity.

Owner:孙磊

Sunflower seeds with tomato flavor and processing method of sunflower seeds

The invention discloses sunflower seeds with a tomato flavor and a processing method of the sunflower seeds, and belongs to the technical field of food processing. The method involves the sunflower seeds with the tomato flavor, and processing raw materials comprise tomato sauce. The processing method of the sunflower seeds with the tomato flavor comprises the processing steps of weighing the raw materials including the tomato sauce, brine preparation, stewing, draining, drying and cooling. The sunflower seeds with the tomato flavor and the processing method of the sunflower seeds have the advantages that the tomato sauce is taken as the raw material to prepare the sunflower seeds, the processed sunflower seeds are delicious with slight sweetness and sour, can promote salivary secretion, reduce sweet greasy and greasy feelings and can prevent thirst, excessive internal heat and other problems caused by excessive intake of the sunflower seeds when the sunflower seeds are eaten. The sunflower seeds with the tomato flavor have an oral cavity drying coefficient less than 5.0, and are obviously superior to commercially available sunflower seeds.

Owner:CHACHA FOOD CO LTD

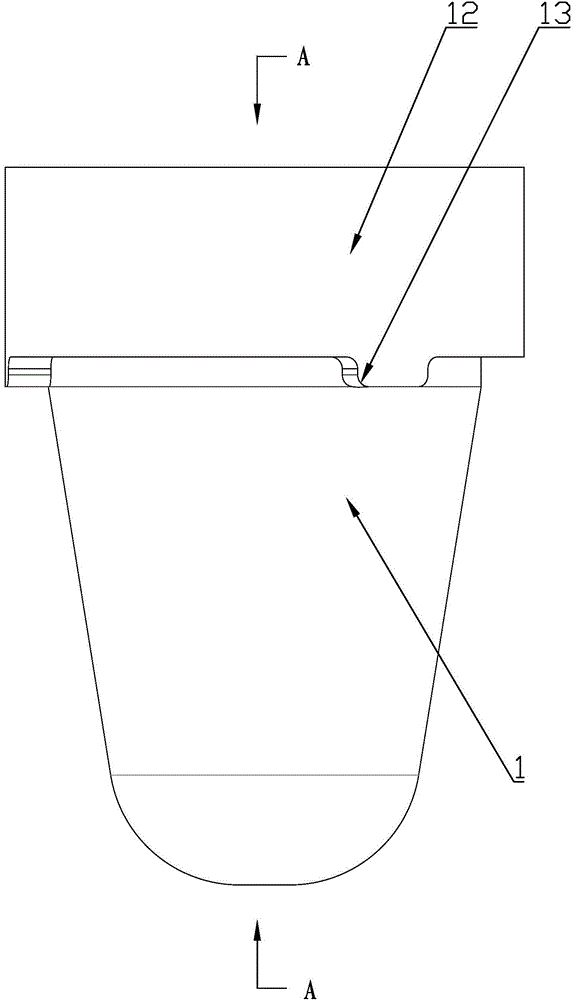

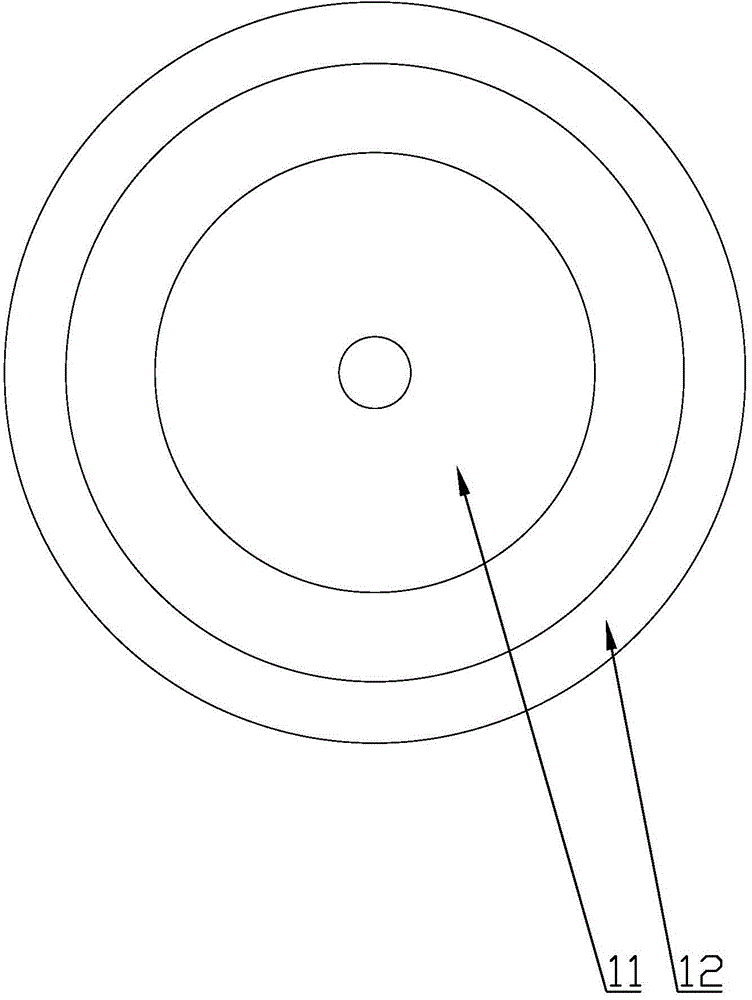

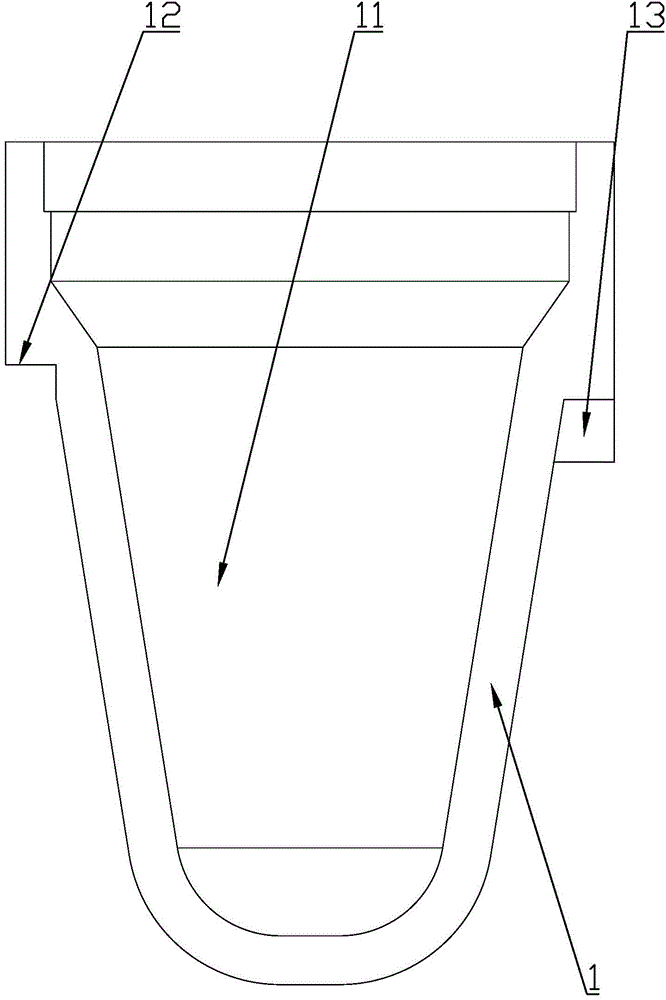

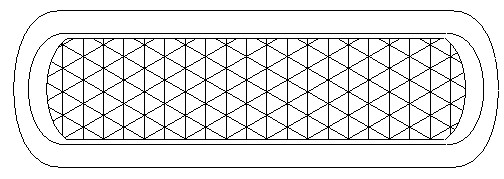

Reaction cup used for automatic chemical luminescence immunoassay instrument

ActiveCN104034880AReduce the chance of stickingEasy to sampleBiological testingEngineeringLuminescence

The invention relates to a reaction cup, and concretely discloses a reaction cup used for automatic chemical luminescence immunoassay instrument, the reaction cup comprises a cup body filled with a carrier, the profile of the cup body is in a conical shape with a gradually downward reduced diameter, an annular rectangular bench is arranged outside the cup rim of the cup body, at least three uniformly distributed circular-arc contact points are arranged at lower end of the annular rectangular bench; the bottom of a cup core space is an arc-shaped spherical surface, the upper part of the cup core space is a conical surface cooperated to the profile of the cup body, smooth transitioning is realized between the arc-shaped spherical surface and the conical surface; the reaction cup can employ a staked mode for storage; wherein the annular rectangular bench can clamp the reaction card in a reaction aperture of an incubation apparatus, at least three uniformly distributed circular-arc contact points are arranged at lower end of the annular rectangular bench, when the reaction cups are stakes, the contact area is little, so that the adhesion probability between the reaction cups while loading can be reduced.

Owner:郑州博赛生物技术股份有限公司

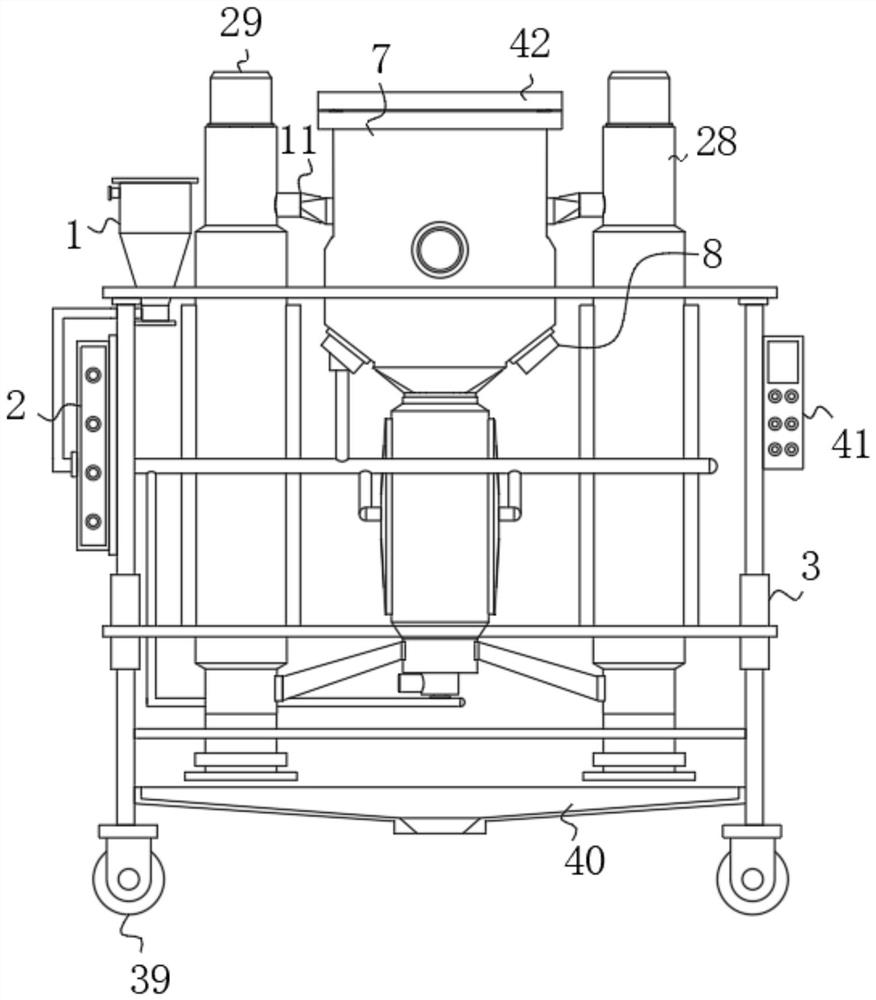

Drying equipment for production of hydroxypropyl methylcellulose

The invention discloses drying equipment for production of hydroxypropyl methylcellulose, and relates to the technical field of production of the hydroxypropyl methylcellulose. The drying equipment comprises a cyclone dust remover, a hot air supplying module and a support framework, wherein the circumferential sides of the cyclone dust remover and the hot air supplying module are fixedly connectedwith the support framework; and one end of an air inlet of the hot air supplying module fixedly communicates with the cyclone dust remover. The drying equipment also comprises a thinning mechanism, adrying main machine and two symmetrically-arranged drying auxiliary machine, wherein the circumferential sides of the thinning mechanism, the drying main machine and the two drying auxiliary machineare fixedly connected with the support framework; and one end of a discharging hole of each of the two drying auxiliary machines fixedly communicates with the thinning mechanism. According to the drying equipment for production of the hydroxypropyl methylcellulose disclosed by the invention, through design of the hot air supply module, the thinning mechanism, the drying auxiliary machines and thedrying main machine, the device can quickly and completely perform drying operations of the hydroxypropyl methylcellulose in an automatic manner, and when the device performs drying, a static type drying structure of a conventional drying device can be changed into a circulating type multi-time drying mechanism.

Owner:安徽森淼实业有限公司

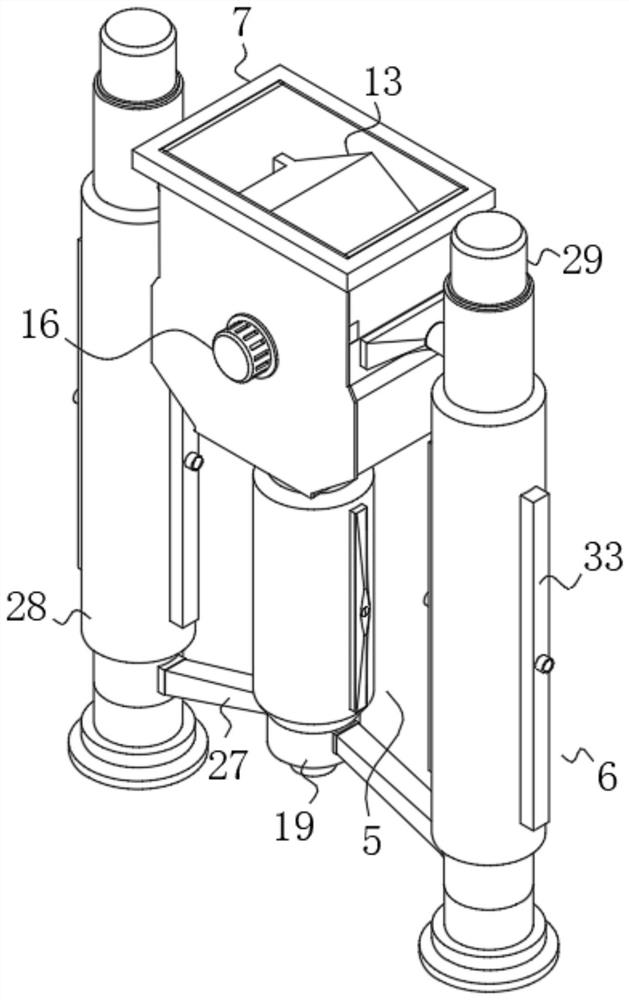

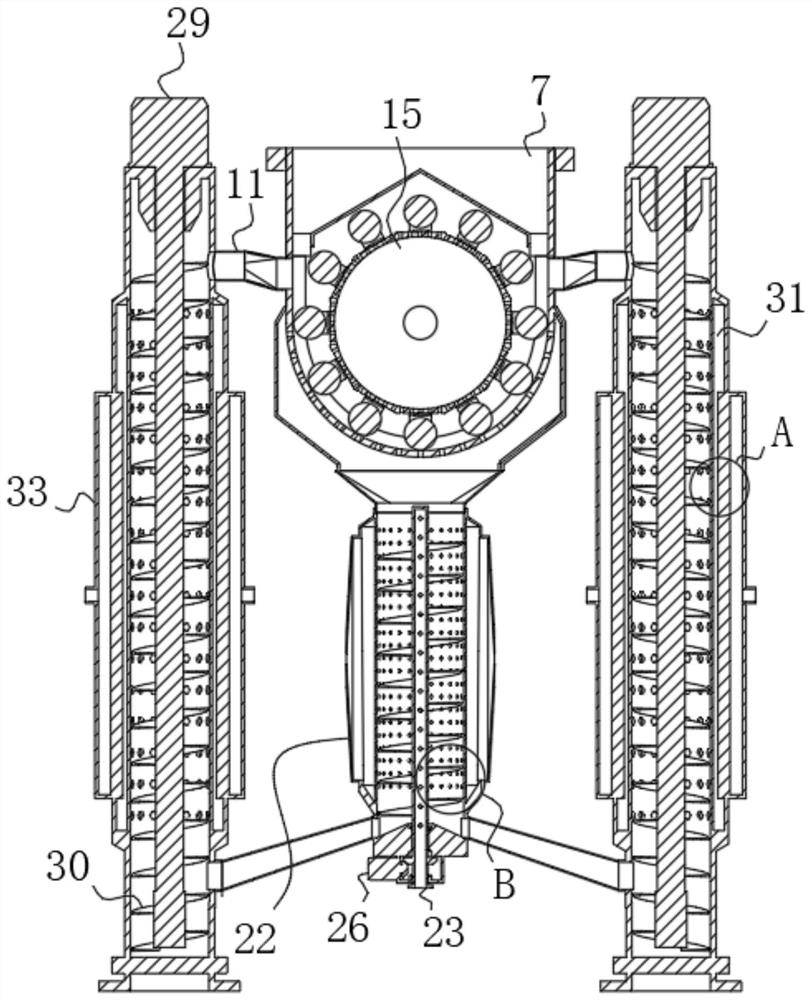

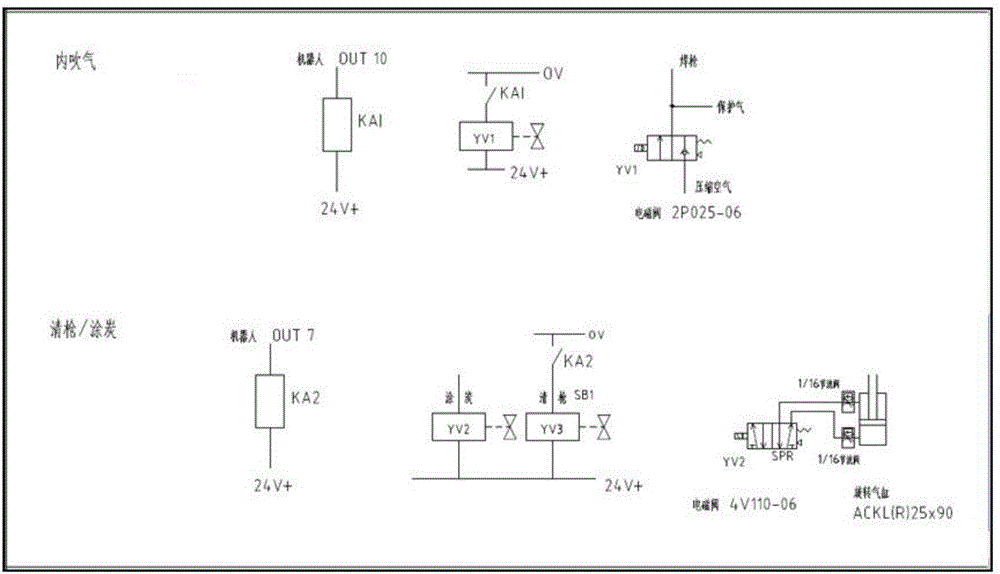

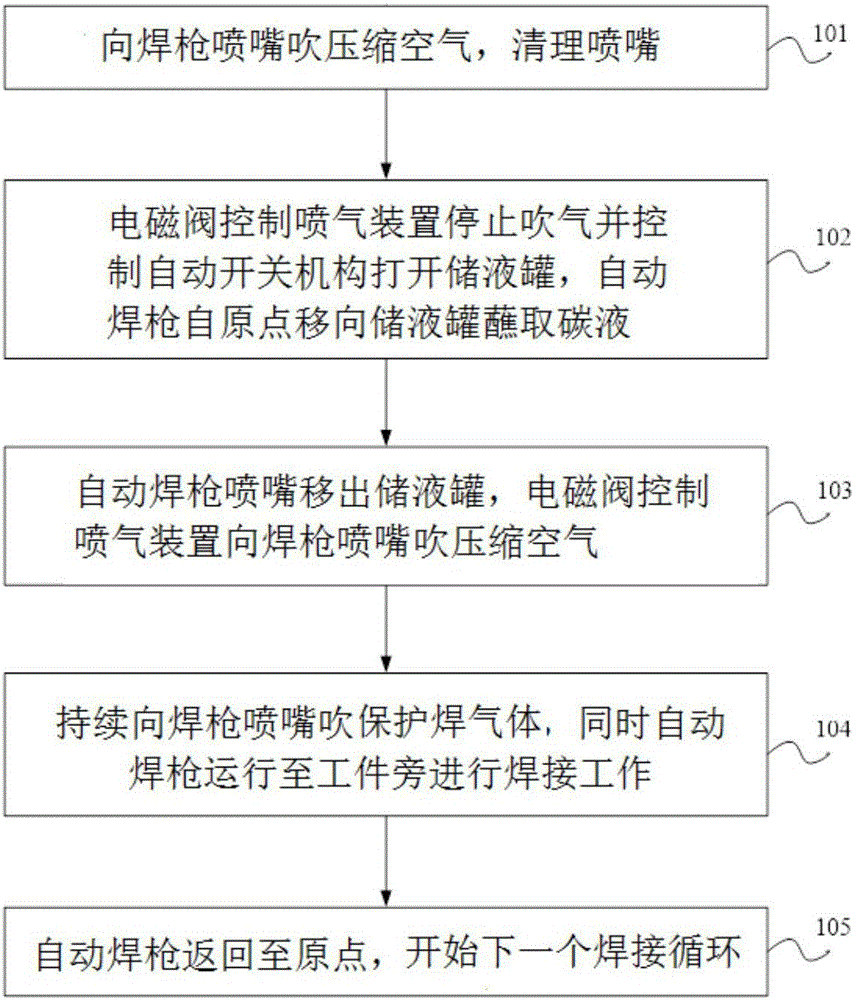

Anti-spatter welding method and system of automatic welding gun

InactiveCN106425059ANot easy to stickReduce chanceShielding gas supply/evacuation devicesSupport devices with shieldingSlagSpray nozzle

The invention discloses an anti-spatter welding method of an automatic welding gun. The anti-spatter welding method comprises the steps that high-pressure gas is sprayed to a spray nozzle of the welding gun, and the spray nozzle is cleaned; the spray nozzle of the welding gun is dipped in anti-spatter fluid; high-pressure gas and shielded welding gas are sprayed to the spray nozzle of the welding gun successively; and a workpiece is welded. Compared with the prior art, dipping of the anti-spatter fluid and gas blowing are combined, spattered molten drops can be isolated, the probability of adhesion between welding slag and the spray nozzle and adhesion between a contact tube and the inner wall of the contact tube is decreased, blockage of the spray nozzle and the contact tube of the welding gun is effectively avoided, and the purpose of preventing spatter of the spray nozzle and the contact tube of the welding gun is achieved; and in addition, a traditional gun cleaning device is not needed, the production cost is lowered, the service life of the contact tube is prolonged, the production time is saved, and high market value is achieved.

Owner:SHANGHAI FUJIYA HONGHU EXHAUST AIR SYST CO LTD

High-density PCB

InactiveCN102762030AIncrease the areaReduce solder fluxPrinted circuit assemblingElectrical connection printed elementsCentral line placementManufacturing engineering

The invention discloses a structure and a manufacturing method of a high- density PCB, and further discloses a DIP (Double In-line Package) LED display adopting the high-density PCB. The manufacturing method of the high-density PCB comprises the following steps: adjacent bonding pads are respectively mounted at the center line position deviated from welding holes, at which diversion pads are arranged. By adopting the method provided by the invention, pins are not adhered when the high-density PCB is subject to wave soldering and solder impact during manufacturing. The high-density PCB is suitable for large-scale industrial production and application.

Owner:秦玉成

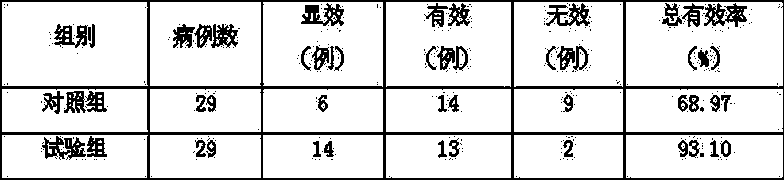

Pharmaceutical composition for treating tuberculous pleuritis and preparation method thereof

InactiveCN104189770AAlleviate malabsorption reactionsReduce adhesionAntibacterial agentsPlant ingredientsDiseaseShiny bugleweed

The invention discloses a pharmaceutical composition for treating the tuberculous pleuritis and a preparation method thereof. The pharmaceutical composition comprises active ingredients and pharmaceutically acceptable auxiliary materials. The active ingredients are prepared from the following Chinese herbal medicines: Chinese thorowax root, radix paeoniae alba, bighead atractylodes rhizome, fructus forsythiae, the fruit of Chinese magnoliavine, the fruit of Chinese wolfberry, purple bergenia rhizome, scutellaria baicalensis, buerger pipewort flower, platycodon grandiflorum, radix peucedani, the root of fangji, ramulus mori, plantago seed, poria cocos, hiraute shiny bugleweed herb, radix scrophulariae, rhizoma cimicifugae, sanguisorba officinalis and the like. The pharmaceutical composition enables pleural effusion to be sufficiently absorbed and meanwhile, can reduce the adverse reaction of absorption of the pleural effusion, shorten the course of the disease, reduce pleural adhesion, pleural thickening and chest pain and achieve the purpose of healing the tuberculous pleuritis.

Owner:强红枫

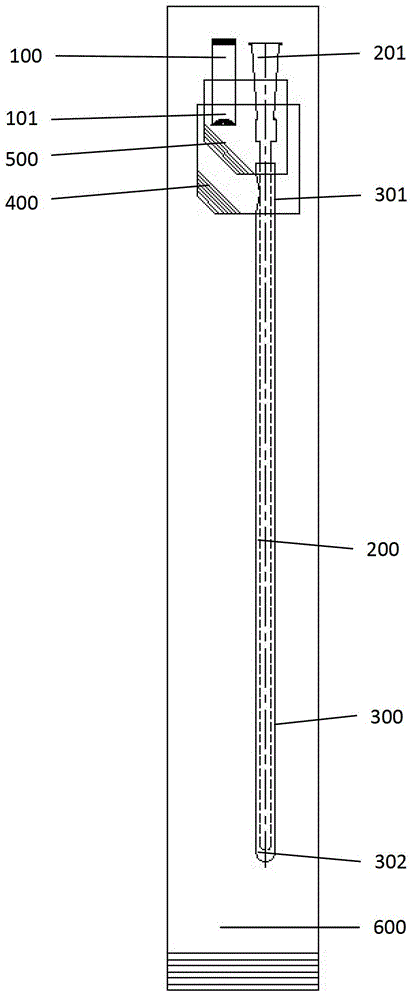

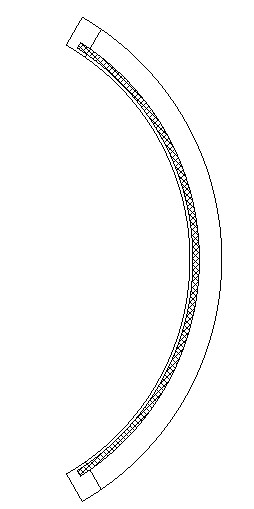

Wetting component for hydrophilic urinary catheter

ActiveCN103301551BPlay a protective effectReduce the chance of stickingWound drainsCatheterHydrophilic coatingUrinary catheter

Owner:张家港市沙工医疗器械科技发展有限公司

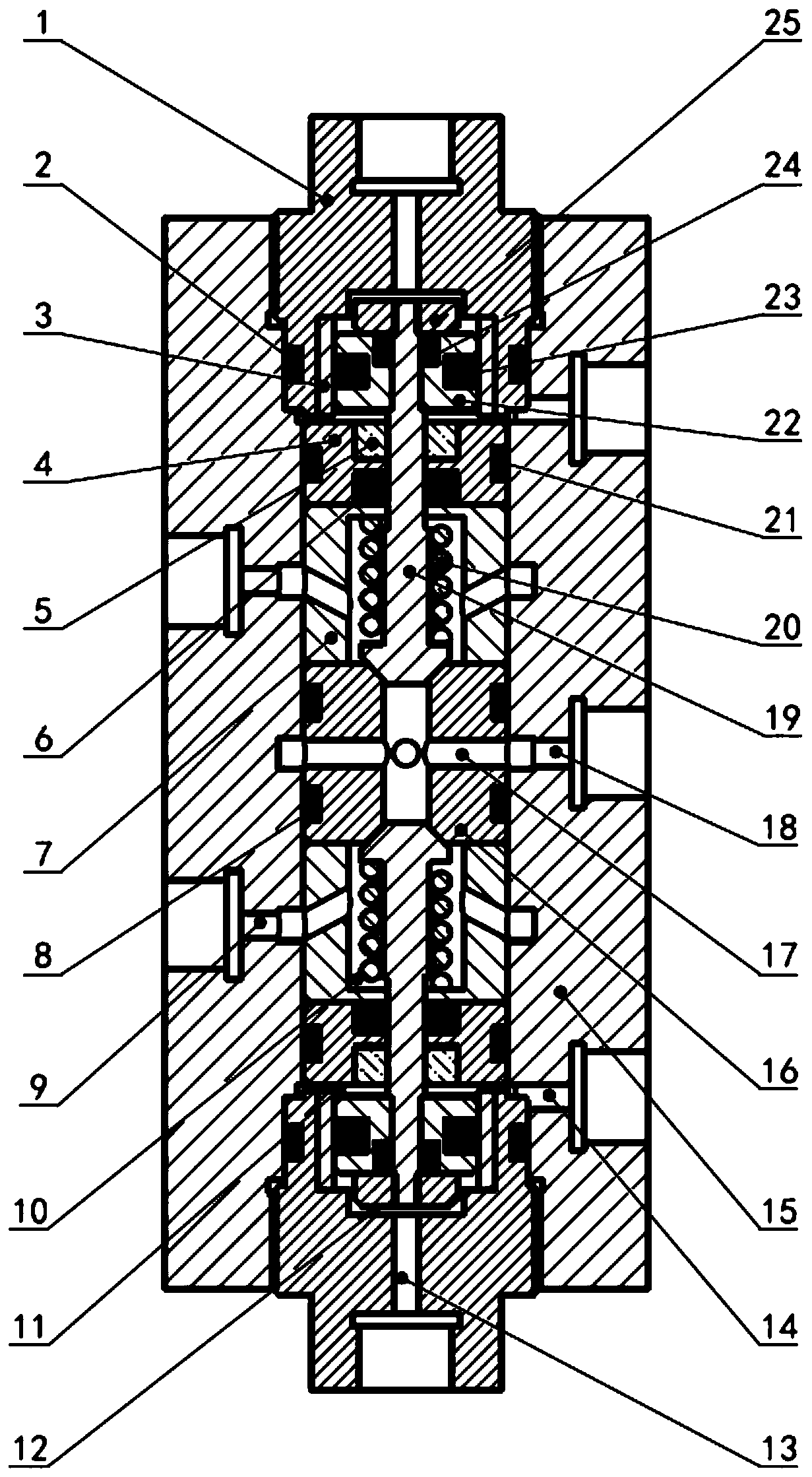

Compact pressure self-compensation total-sea-depth stop valve

ActiveCN110469698AHighly integratedSimple structureMultiple way valvesLift valveRemote controlSelf compensation

The invention discloses a compact pressure self-compensation total-sea-depth stop valve, and belongs to the relevant technical field of valve bodies. The compact pressure self-compensation total-sea-depth stop valve comprises two stop valve bodies which are oppositely arranged on the same valve body and are of the same structure. Each stop valve body comprises a stop valve screw plug assembly, a valve element assembly, an isolation pressure sheet assembly, a valve sleeve, a stop valve spring and a valve seat. The stop valve bodies are opened in a manner of being hydraulically driven, and therefore remote control can be achieved. Closing of the stop valve bodies is achieved through the force of the stop valve springs and hydraulic force generated by the area difference between the two sidesof the large end of the valve element assembly. The form of ceramic and stainless steel cooperation is adopted in cooperation between the valve element assembly and other parts, friction force in themotion process of the valve element assembly is effectively reduced, and meanwhile the possibility of jamming of the valve element assembly is reduced. The two oppositely-arranged stop valve bodies use the same valve seat in common, and the space utilization rate is increased. According to the compact pressure self-compensation total-sea-depth stop valve, the structure is simplified, the size isreduced, and then the complexity and cost of a buoyancy adjusting system of a submersible are reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

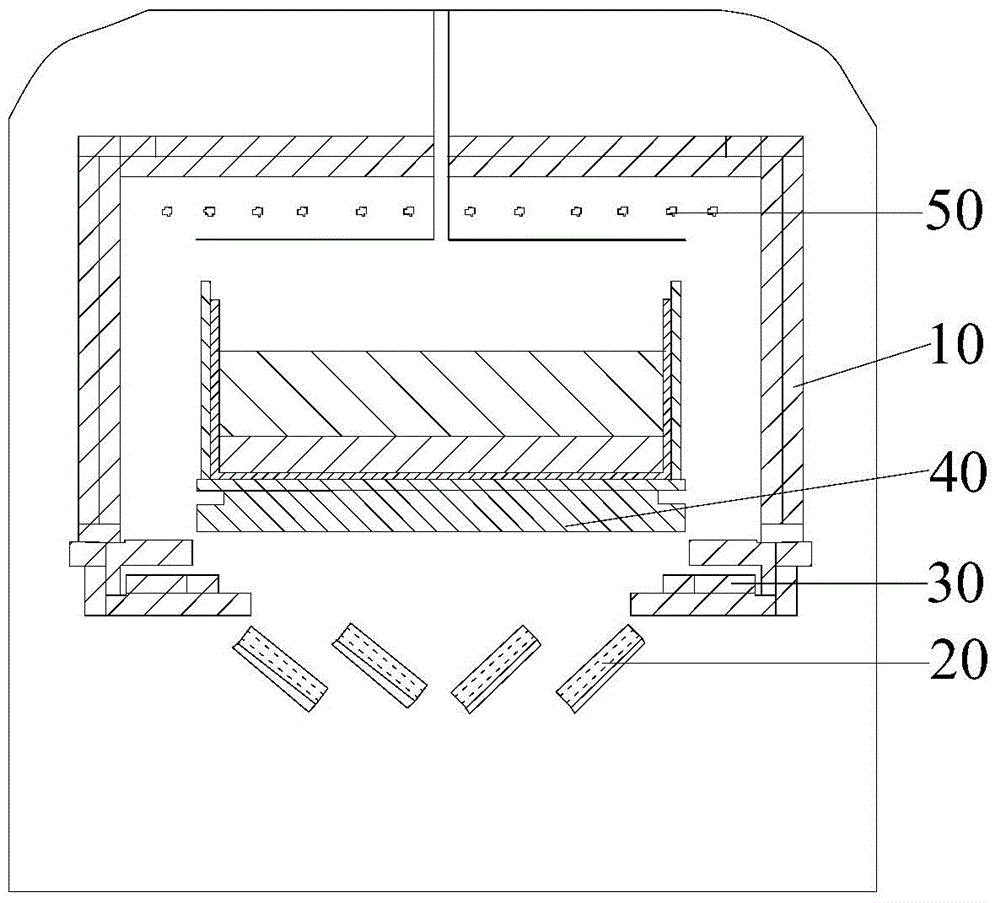

Preparation method of ingot furnace and silicon ingot

ActiveCN104451874AReduce thicknessIncrease cooling areaPolycrystalline material growthSingle crystal growth detailsThermal insulationIngot

The invention provides a preparation method of an ingot furnace and a silicon ingot. The ingot furnace comprises a thermal insulation cage, a plurality of louvers and baffle plates, wherein a window is formed in the bottom of the thermal insulation cage; the plurality of louvers are arranged below the window; holes which run through the louvers along the direction vertical to the thicknesses of the louvers are formed in the louvers; and the baffle plates are arranged in the thermal insulation cage and are arranged at the bottoms of two side walls of the thermal insulation cage. The heat radiating area of the louvers is increased when the louvers of the ingot furnace are opened, so that the heat radiating rate of the louvers is also increased and the crystal growth drive force at the late growth stage of the silicon ingot is improved. When the ingot furnace adopts a seed crystal process, the heat radiating rate of the bottom of the ingot furnace at a melting stage is increased, and the temperature of the bottom of the ingot furnace is lowered, so that the seed crystal is easy to reserve, and therefore, the quality of the prepared silicon ingot is improved. Meanwhile, the crystal growth drive force at the late growth stage of the silicon ingot is improved, so that the crystal growth rate at the late crystal growth stage is increased, the liquidity of silicon liquid is increased, further fractional condensation of impurities is reinforced, and the outturn percentage is further increased.

Owner:YINGLI GRP +2

Stamping device for manufacturing and processing aluminum alloy doors and windows

PendingCN114769420AImprove work efficiencyReduce heatShaping toolsStripping-off devicesEngineeringWaste material

The invention relates to the technical field of stamping equipment, and discloses a stamping device for manufacturing and processing aluminum alloy doors and windows, which comprises an upper clamping piece, a stamping head is arranged in the upper clamping piece, a main body is arranged below the upper clamping piece, a lower clamping piece is movably mounted in the main body, and the lower clamping piece is movably mounted in the main body. An air cavity is defined by the lower clamping piece and the main body together. Through the arrangement of the inclined plate and the discharging plate, when the lower clamping piece moves downwards, the supporting piece can push the inclined plate to contract, then the discharging plate is attached to the hole diameter of the discharging hole, then when the lower clamping piece moves upwards, the discharging plate is reset, the hole diameter of the discharging hole is increased, waste materials in the discharging hole are not prone to being clamped in the discharging hole, and the discharging efficiency is improved. And meanwhile, when the discharging plate is reset, the inclined plate can be driven to be reset, so that the inclined plate moves relative to the lower surface of the workpiece making contact with the inclined plate, the workpiece is rubbed and vibrated, and the workpiece is further promoted to be separated from the lower clamping piece.

Owner:江苏永铭汇门窗科技有限公司

Additive for coating used in public place

InactiveCN104098948ANovel antibacterial and antifungal effectGood antibacterial and antifungal effectAntifouling/underwater paintsSiccativesWeather resistancePublic place

The invention provides an additive for a coating used in a public place and relates to the technical field of coating additives. The additive comprises the following constituents in percentage by weight: 10-15 percent of nano-alumina, 15-20 percent of nano-silica, 8-10 percent of nano-zinc oxide, 5-10 percent of a drier and a solvent in balance amount, wherein the drier is one or two of zinc isoocatanoate and dibutyltin dilaurate; the solvent is one or more of butyl acetate, dimethyl carbonate and isopropanol. The additive provided by the invention has the advantages that the problems that the coating used in the public place is single in manufacturing function, cannot have good weather resistance, rapid drying performance, an anti-bacterial function and a self-cleaning function simultaneously, so that the problem that high public health security cannot be ensured is solved.

Owner:DRAGON FISH PAINT

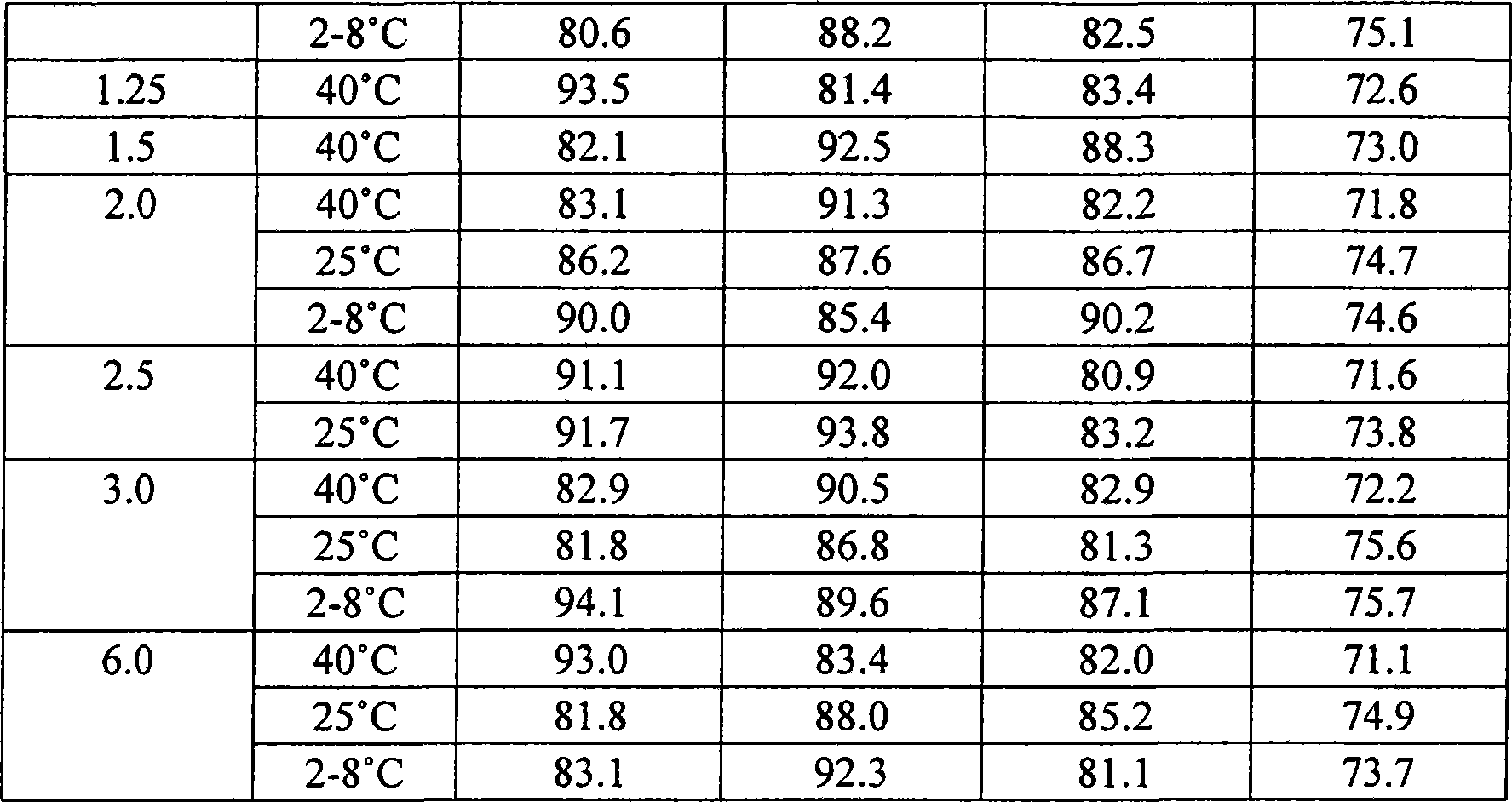

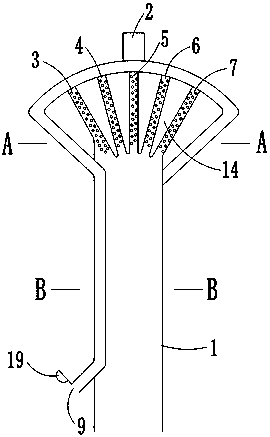

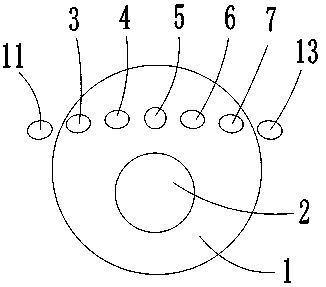

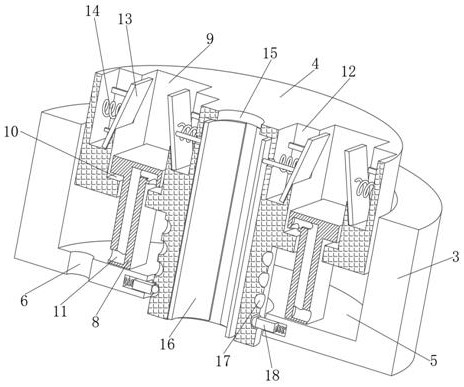

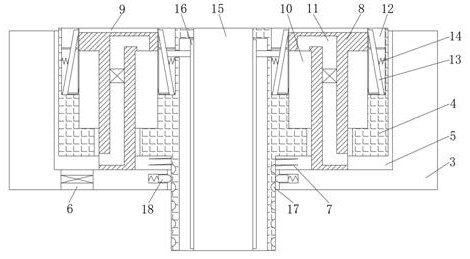

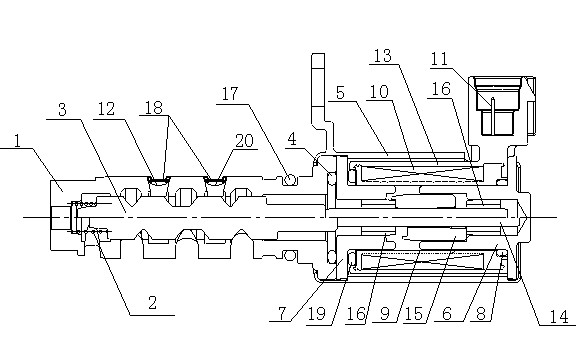

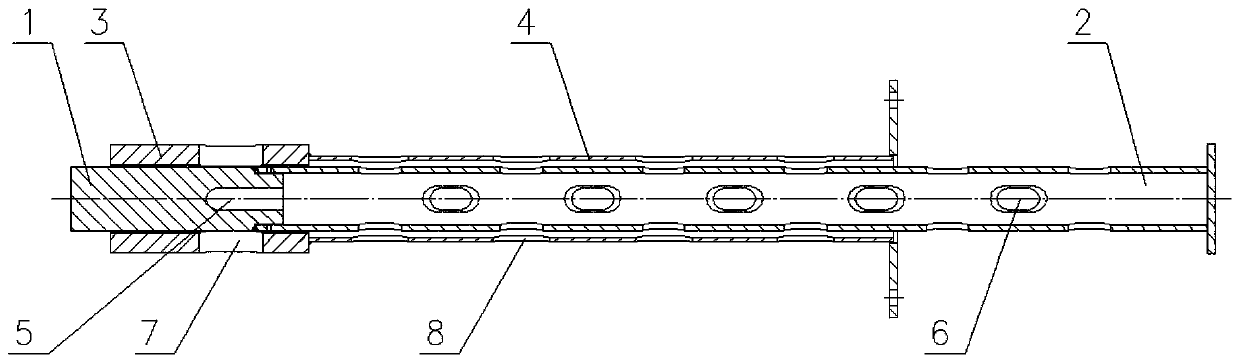

Continuously variable valve timing fuel control valve with filter screens

InactiveCN102061954AGuard against entryReduce the chance of stickingValve arrangementsMachines/enginesForeign matterVariable valve timing

The invention discloses a continuously variable valve timing fuel control valve with filter screens, which comprises a front yoke iron assembly, a rear yoke iron assembly, an iron core assembly, a valve sleeve assembly, an external yoke sleeve support (5), an inlet angle fuel port (12), a winding assembly (13), filter screens (18) and a lag angle fuel port (20), wherein the winding assembly (13), wherein the back yoke iron assembly and a rear ring (8) are arranged on the rear end of the external yoke sleeve support (5), and the rear end is fixed by riveting; the iron core assembly, the valve sleeve assembly, the front yoke iron assembly and a front ring (19) are arranged on the front end of the external yoke sleeve support (5), and the front end is fixed by riveting; the filter screens (18) are respectively installed in the inlet angle fuel port (12) and the lag angle fuel port (20) on a valve sleeve (1), and the valve sleeve is sheathed with an external ring (17). By applying the invention, foreign matter can be effectively prevented from entering the fuel control valve, the clamping stagnation of the fuel control valve is reduced, the working reliability of the valve timing system is ensured, and the service life of the fuel control valve is prolonged.

Owner:成都恒高机械电子有限公司

Polymer synthetic medical material for preventing postoperative celiac peritoneal adhesion

InactiveCN104027418AReduce exudationReduce hyperplasiaHydroxy compound active ingredientsSurgical drugsMentholAbdominal cavity

The invention relates to a polymer synthetic medical material for preventing postoperative celiac peritoneal adhesion. The polymer synthetic medical material comprises, by weight, 5-10 parts of berberine hydrochloride, 5-10 parts of menthol, 5-10 parts of hairyvein agrimony and 70-85 parts of polyethylene glycol.

Owner:周广刚

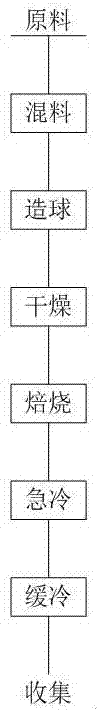

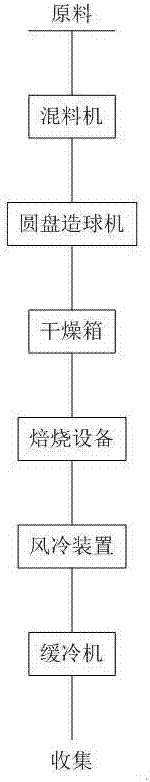

Device system for producing sintering-expanded haydite by red mud

PendingCN107353033ASave resourcesEnergy savingCeramic shaping plantsCeramic materials productionProcess engineeringEnergy consumption

The invention provides a device system for producing sintering-expanded haydite by red mud. The device system comprises a material mixing machine, a disk pelletizer, a drying device, a calcination device and a cooling device, wherein the disk pelletizer is connected with the material mixing machine; the drying device is connected with the disk pelletizer; the calcination device is connected with the drying device; the cooling device is connected with the calcination device for carrying out quenching processing on a pellet subjected to calcination to enable the surface of the pellet to be quickly solidified so as to prevent the pellet from being shrunk while the ceramic pellets are prevented from adhering. According to the device system, solid wastes are used as main raw materials, Fe2O3 resources in the red mud are used, Fe2O3 reacts with carbon to serve as gas forming agent to replace a situation that carbonate is traditionally taken as the gas forming agent, and resources are saved; in addition, the carbon can be used as the reducing agent of Fe2O3 in the pellet and also can be used as fuel for supplementing a heat source, and energy consumption is saved. The device system adopts an air cooling technology after materials are subjected to calcination, an adhesion rate between haydites can be lowered, and the finished product rate of a product is improved.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Applications of bovine bone peptide in preparation of drugs and food for treating and preventing osteoporosis

InactiveCN108066740AOvercoming problems with a weakened immune system that can cause more serious diseaseSmall side effectsHydrolysed protein ingredientsSkeletal disorderHormones regulationOsteoporosis treatment

The invention discloses applications of bovine bone peptide in preparation of drugs and food for treating and preventing osteoporosis, wherein the drugs and the food are particularly suitable for postmenopausal women. According to the present invention, the new applications of the bovine bone peptide are found by constructing osteoporosis animal models, wherein the osteoporosis treatment and prevention drugs and the osteoporosis treatment and prevention food prepared from the bovine bone peptide are safe, effective and reliable compared to hormones.

Owner:亿菩升(上海)生物科技有限公司

High-temperature lead-free solder wire and preparation method thereof

ActiveCN113441870AIncrease roughnessPrevent slidingWelding/cutting media/materialsSoldering mediaAlloySoldering

The invention relates to the field of brazing technologies, in particular to a high-temperature lead-free solder wire and a preparation method thereof. The problems that a lead-free solder wire is thin and soft, and is likely to slip when a worker holds the solder wire for soldering, and consequently the soldering efficiency of a workpiece is reduced are solved. The high-temperature lead-free solder wire comprises a shell made of tin alloy and an inner core made of soldering flux; and a plurality of spiral grooves are formed in the outer wall of the shell, and an anti-skid piece is arranged on the outer wall of the shell. The high-temperature lead-free solder wire has the advantages that the probability that the solder wire slips during soldering of workers is reduced, and the soldering efficiency is improved.

Owner:YIK SHING TAT SOLDER MFR KUNSHAN

Structure for reducing melt wrappage adhesion of crust breaking chips

InactiveCN111058060AReduce the temperatureReduce the chance of stickingEngineeringMechanical engineering

The invention discloses a structure for reducing melt wrappage adhesion of crust breaking chips. The structure comprises the crust breaking chips body, a hammer rod, a scraper, a sleeving, a cross-shaped notch, hammer rod holes, scraper holes and sleeving holes, wherein the crust breaking chips body and the hammer rod are connected into a whole, the crust breaking chips body is sleeved with the scraper, the hammer rod is sleeved with the sleeving, the scraper and the sleeving are arranged into a whole, and specifically, the cross-shaped notch is formed in the end part, close to the hammer rod,of the crust breaking chips body, the hammer rod holes are formed in the hammer rod in the axial direction at equal intervals, the hammer rod holes are formed in the circumferential direction of thehammer rod in a circumferential array mode, the scraper holes are further formed in the scraper, and the sleeving holes are formed in the sleeving. The structure for reducing the melt wrappage adhesion of the crust breaking chips has the advantages that flowing airflow can be fully utilized to cool the hammer rod of the chips body, the probability of the melt wrappage adhesion of the crust breaking chips body is effectively reduced, and stable operation of an electrolytic cell crust breaking and discharging system can be favorably maintained.

Owner:CHINA ALUMINUM INT ENG CORP +1

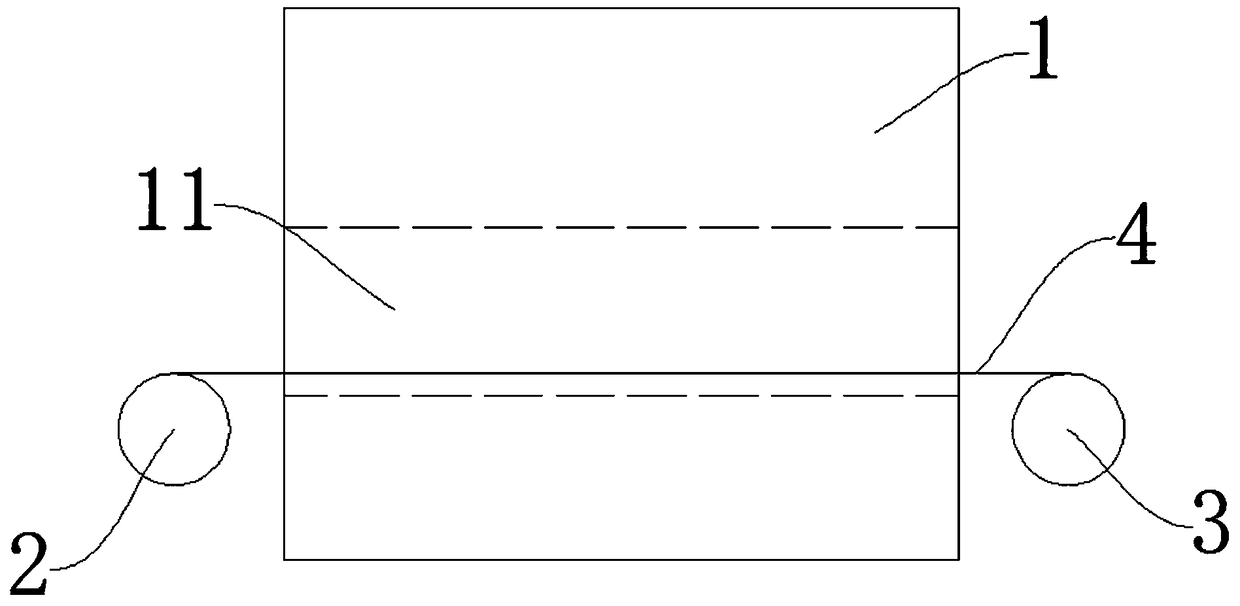

Making process of protective film used for ferrite sintering

Owner:绵阳北斗电子有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com