Wetting component for hydrophilic urinary catheter

A urinary catheter and hydrophilic technology, which is applied in the field of wetting components of hydrophilic urinary catheters, can solve problems such as the adhesion between the surface of the catheter and the packaging bag, the patient's inability to use it quickly, and the overflow of wetting fluid on the coating surface. To achieve full utilization, reduce the chance of adhesion, improve the effect of convenience and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

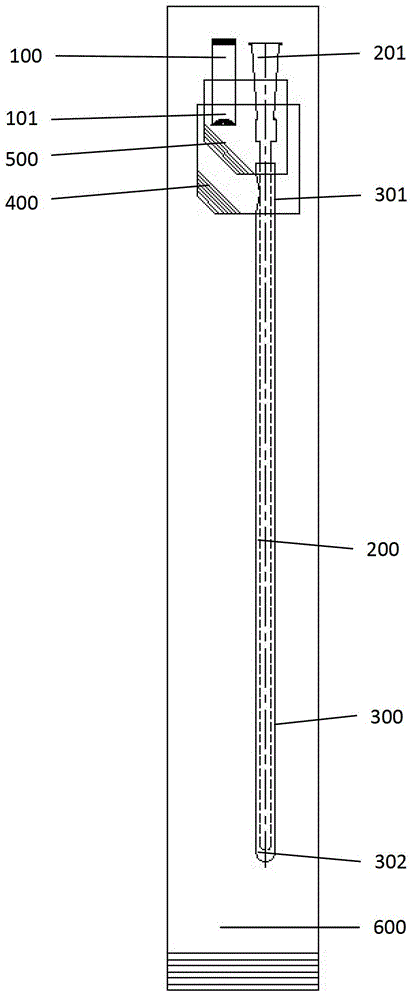

[0030] like figure 1 Shown is the first embodiment of the present invention, the wetting assembly of the hydrophilic urinary catheter includes a wetting fluid reservoir 100 , a hydrophilic urinary catheter 200 and an outer sleeve 300 , the wetting fluid reservoir 100 , Both the hydrophilic urinary catheter 200 and the outer sleeve 300 are placed in the outer package 600 to form a whole. The wetting liquid in the wetting liquid container 100 is water or physiological saline, sterilized by high pressure steam, and packaged aseptically. The outer packaging 600 is made of flexible material that can penetrate gas, and the outer packaging 600 can permeate ethylene oxide gas, so that the entire internal components can be sterilized, thereby reducing the cost of disinfection, transportation and storage.

[0031] The insertion part of the hydrophilic urinary catheter 200 is accommodated in the outer sleeve 300, and the inner diameter of the outer sleeve 300 is slightly larger than the...

no. 2 example

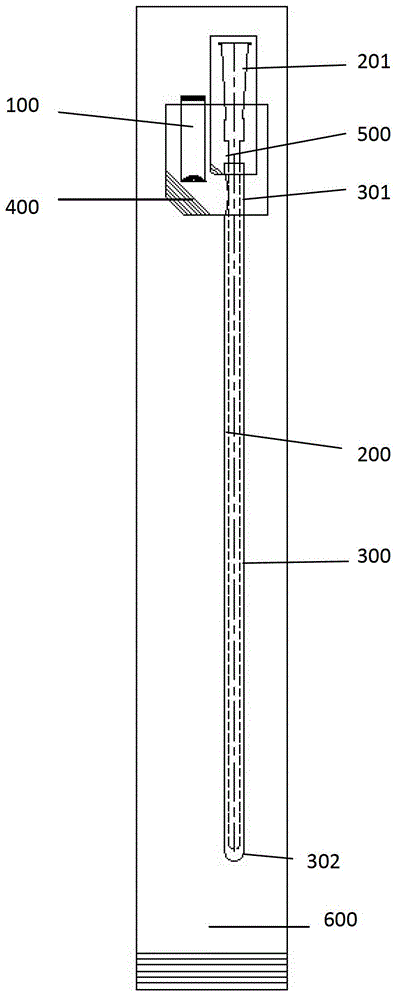

[0035] like figure 2 Shown is the second embodiment of the present invention, the difference between this embodiment and the above-mentioned first embodiment is that: the wetting fluid reservoir 100 is partially accommodated in the connecting device 400, and the hydrophilic catheter connector 201 is completely Received in the sheath 500 , the wetting fluid reservoir 100 is connected to the outer sleeve 300 through the connection device 400 . The proximal end 301 of the outer sleeve in the connecting device 400 has a top opening and a side opening. The usage method of this embodiment is the same as that of the above-mentioned first embodiment, so it will not be described in detail.

Embodiment approach

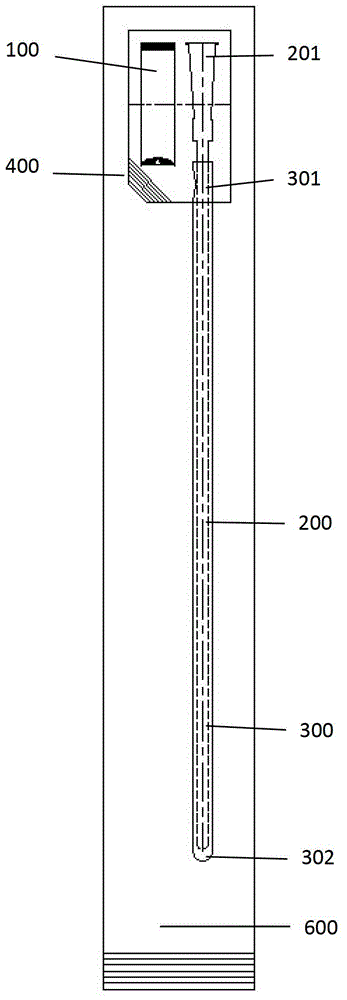

[0037] like image 3 Shown is the third embodiment of the present invention, the difference between this embodiment and the above-mentioned first embodiment is: the wetting fluid reservoir 100 and the hydrophilic catheter connector 201 are all accommodated in the connecting device 400, connected The proximal end 302 of the overtube within the device 400 opens a top opening and a side opening.

[0038] When in use, keep the outer packaging 600 intact, apply preset conditions to the wetting liquid reservoir 100 by hand, the discharge port 101 of the wetting liquid reservoir will rupture, and the wetting liquid will be quickly discharged to the connecting device 400, and the wetting liquid will pass through The side opening of the proximal end 301 of the outer sleeve enters the gap between the inner wall of the outer sleeve 300 and the hydrophilic coating on the outer wall of the hydrophilic urinary catheter 200, and the hydrophilic coating is wetted to lubricate the hydrophilic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com