Structure for reducing melt wrappage adhesion of crust breaking chips

A technology of shelling hammer head and bag structure, which is applied in the field of electrolytic aluminum production and processing, can solve the problems that cannot be solved, such as sticking to the bag, hindering the alumina blanking, affecting the anode current density and anode current distribution, etc., so as to reduce the chance of sticking to the bag , maintain stable operation, reduce the temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

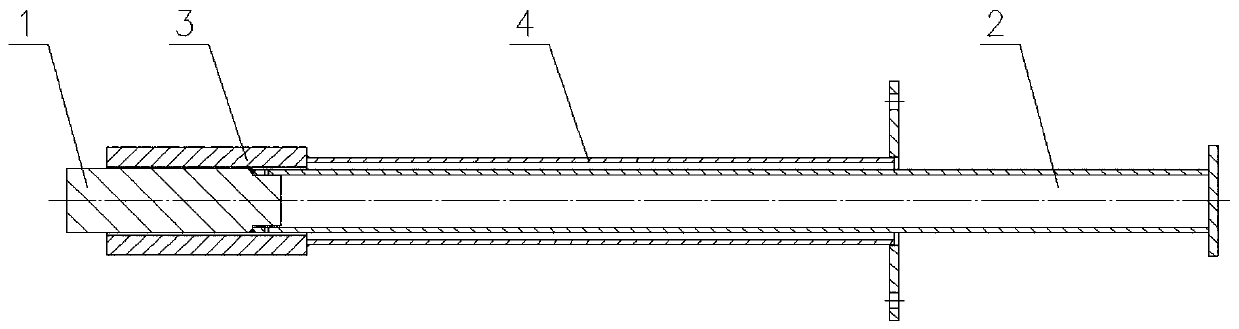

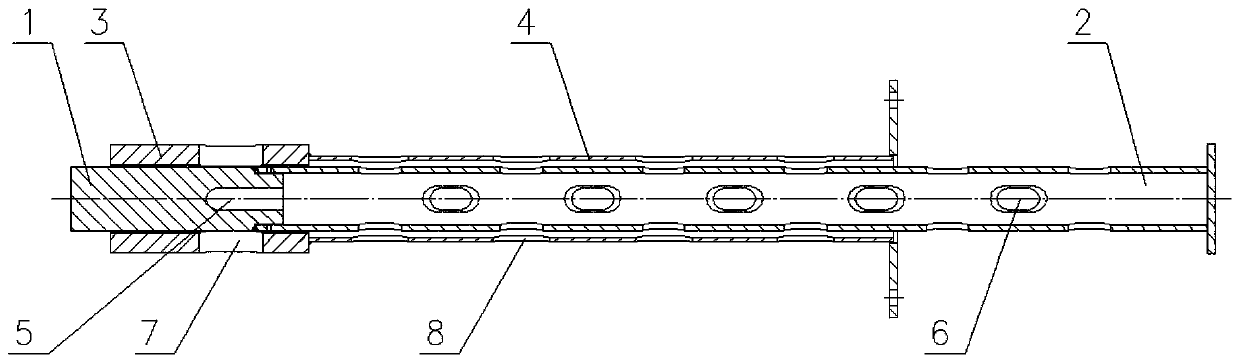

[0014] The present invention is specifically described below in conjunction with accompanying drawing, as figure 1 , figure 2 As shown, a structure for reducing the sticking of the shelling hammer head includes a shelling hammer head 1, a hammer shaft 2, a scraper 3, a casing 4, a cross notch 5, a hammer shaft hole 6, a scraper hole 7, and a casing Hole 8: Shelling hammer head 1 is connected with hammer shaft 2 to form one body, there are scraper 3 and casing 4 set between shelling hammer head 1 and hammer shaft 2, and said scraper 3 and casing pipe 4 are integrated The specific structure is as follows: the shelling hammer head 1 is provided with a cross notch 5 near the end of the hammer rod 2, and the axially equal division of the hammer rod 2 is provided with hammer rod holes 6, and the hammer rod holes 6 are arrayed along the circumference It is arranged in the circumferential direction of the hammer rod 2; the scraper 3 is also provided with a scraper hole 7, and the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com