Patents

Literature

30results about How to "Reduce floating powder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for pretreating raw polar plates for internal formation

ActiveCN103035884AReduce floating powderNo pollution in the processLead-acid accumulator electrodesPretreatment methodPre treatment

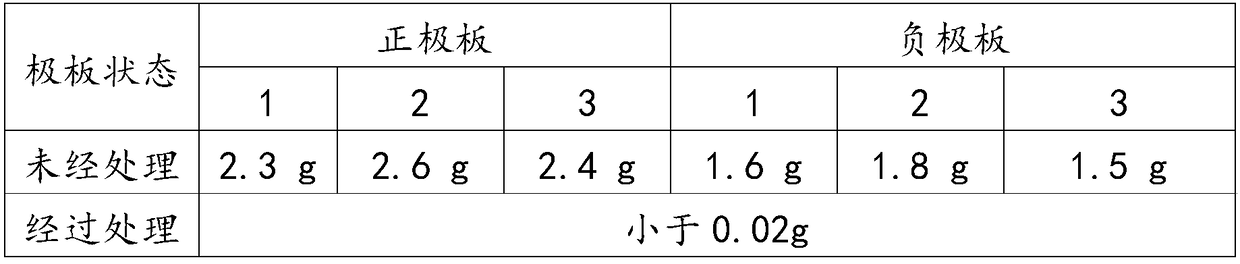

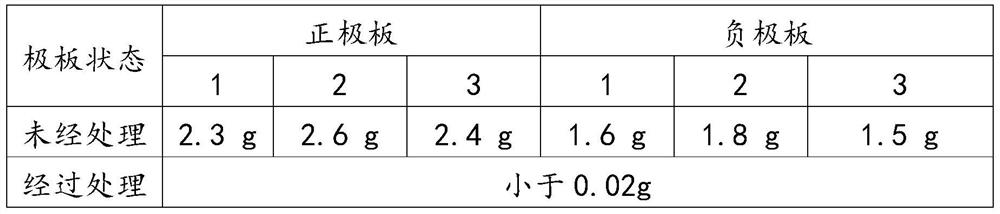

The invention discloses a method for pretreating raw polar plates for internal formation. The method comprises the following steps: (1), soaking the raw polar plates subjected to solidification and drying into dilute sulfuric acid with the density of 1.01 to 1.40 g / mL (at the temperature of 25 DEG C), wherein the soaking time of the positive plate is 20 to 80 minutes and the soaking time of the negative plate is 10 to 50 minutes; and (2), drying the soaked raw polar plates. By the pretreatment method, the raw polar plates are pretreated, the floating powder on the surfaces of the polar plates is obviously reduced, and dust pollution on a clamping board and a sheet wrapping board is basically avoided in the turnover process and the sheet wrapping process of the polar plates. By the pretreatment method, the temperature basically keeps at 30 to 35 DEG C after a battery is acidified, the battery temperature basically maintains to be 40 to 45 DEG C in the charging process, and advantages are brought to formation of the polar plates, so that bad hidden danger is reduced during the traditional internal formation production.

Owner:TIANNENG BATTERY GROUP

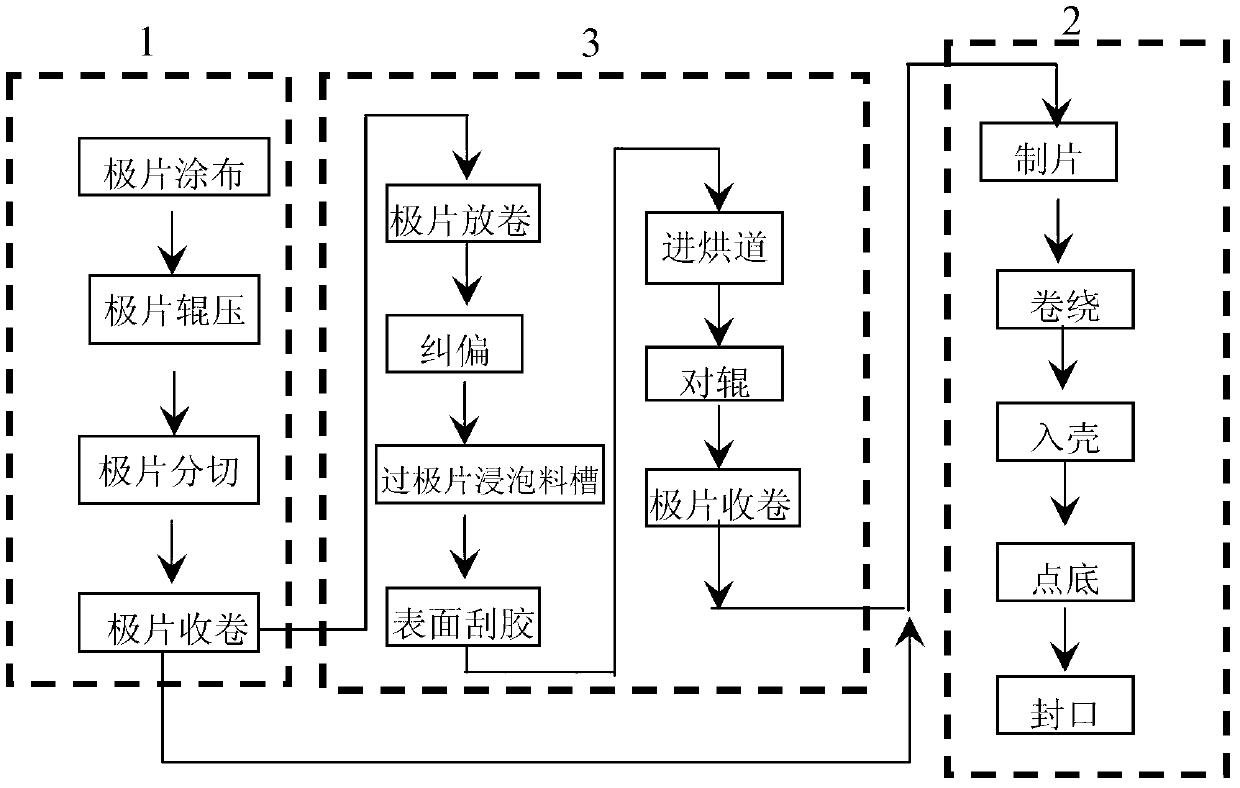

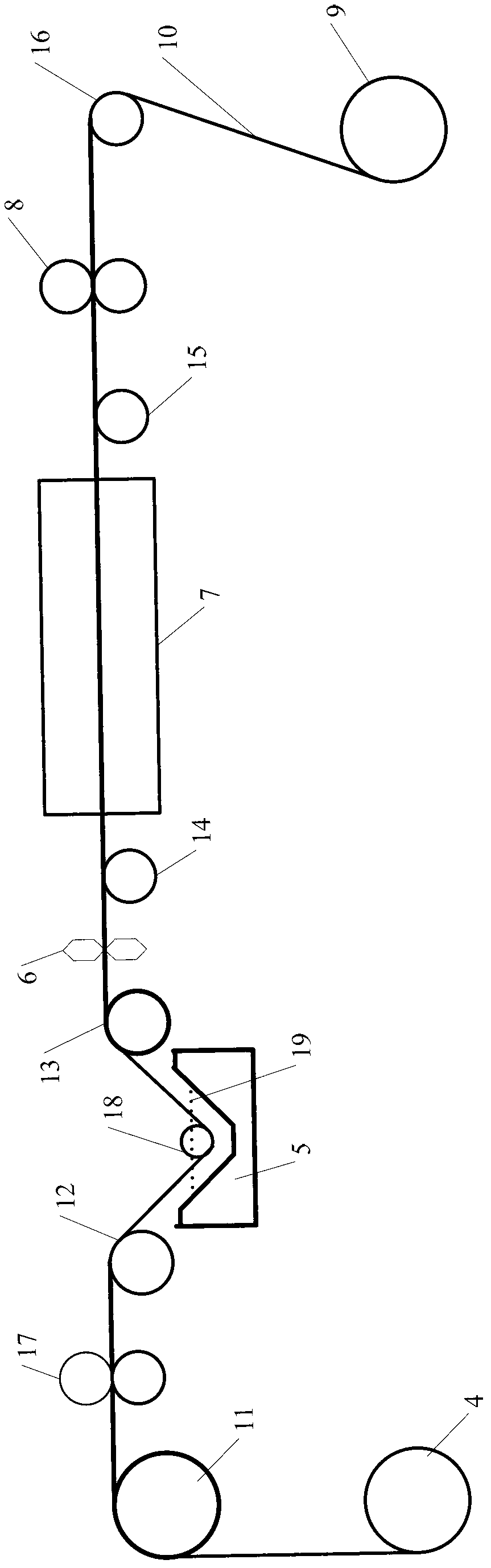

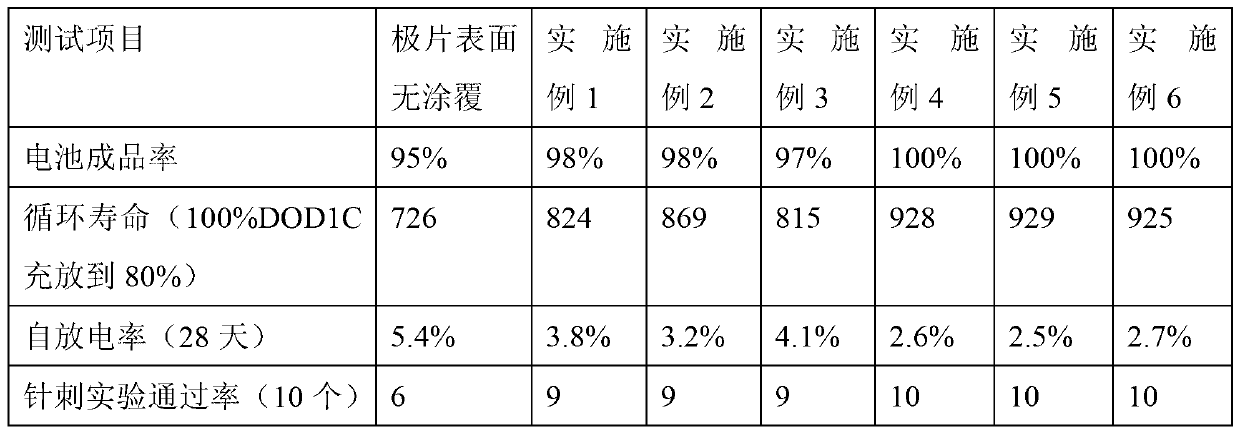

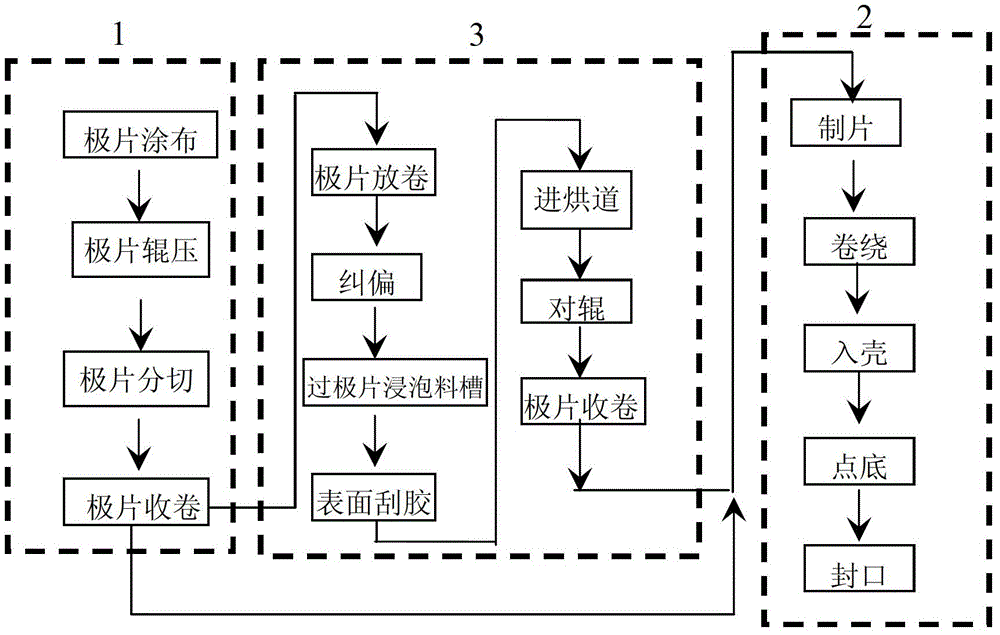

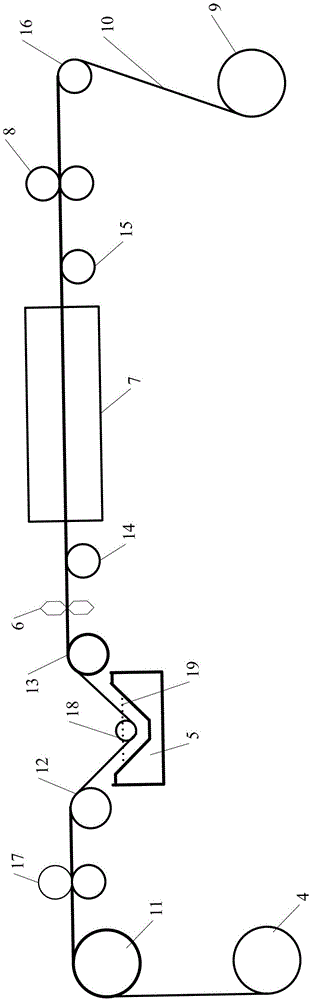

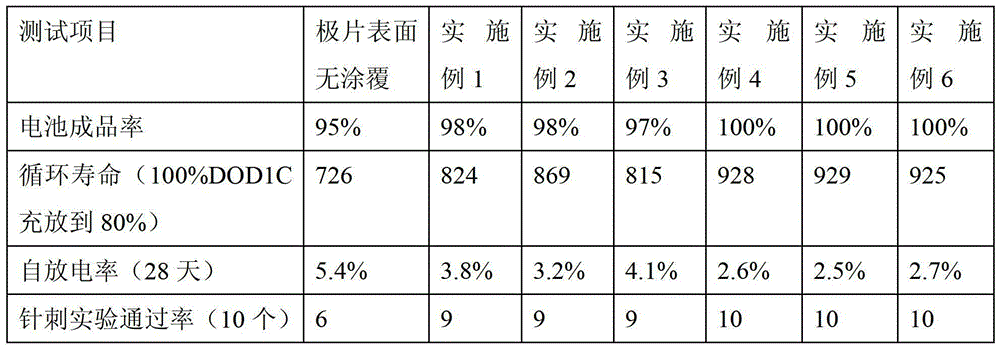

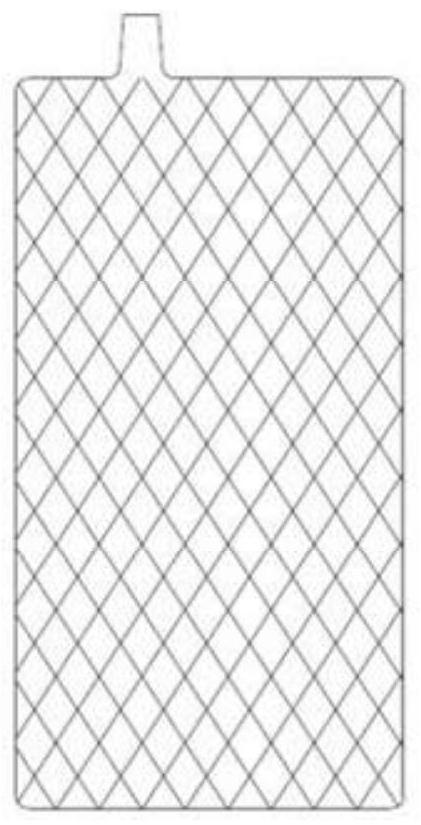

Lithium ion battery pole sheet making method and lithium ion battery pole sheet surface treatment device

InactiveCN103137945AImprove adhesionImprove cycle lifeCell electrodesElectrical batteryLithium electrode

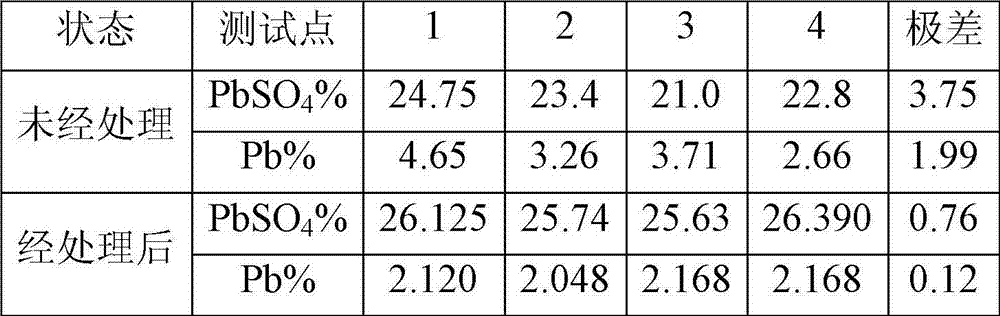

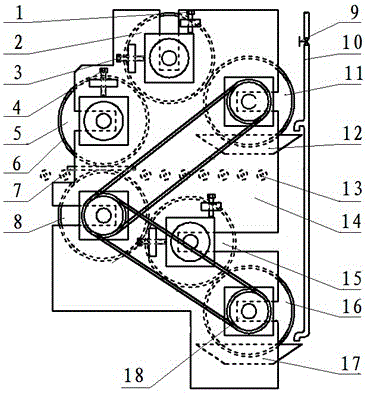

The invention discloses a lithium ion battery pole sheet making method. The method comprises: a pole sheet coating slitting operation; a pole sheet surface treatment operation comprising a step of immersing a coat-slitted pole sheet in an aqueous high-polymer treatment liquid, and a step of drying to obtain a high-polymer film on the surface of the pole sheet; and a made sheet packaging operation. The method which allows the pole sheet surface treatment operation to be increased and the high-polymer film to be formed on the surface of the pole sheet can effectively prevent the powder fall of the lithium ion battery pole sheet, reduce the floatation powder generated in the making process of a battery, improve the bonding force of active substances, and improve the comprehensive electrochemical performances of the lithium ion battery. The invention also discloses a surface treatment device of the lithium ion battery pole sheet. The device comprises, sequentially arranged, an unreeling wheel, a pole sheet immersion material tank, a spreading knife, a drying tunnel, roller machines and a reel wheel, and can automatically and efficiently complete the surface treatment of the pole sheet, so the industrialized continuous production is convenient.

Owner:湖南三迅新能源科技有限公司

Preparation method of lead storage battery green plate for reducing dusting powder

ActiveCN104466086AReduce dehydrationReduce floating powderElectrode manufacturing processesLead-acid accumulator electrodesDusting powdersSilicon oxide

The invention discloses a preparation method of a lead storage battery green plate for reducing dusting powder. The preparation method successively comprises a gypsum mixing process, a gypsum daubing process and a solidifying and drying process, wherein the gypsum daubing process comprises a daubing section, an acid leaching and rolling section and a surface dry treatment section, and an acid leaching solution is prepared from the following components in parts by weight: 12.5-22 parts of 90-95% vitriol, 1-5 parts of fumed silica, 0.5-1 part of lauryl sodium sulfate and 72-86 parts of water. The method disclosed by the invention is simple in operation and is applicable to a positive electrode and a negative electrode, the diachylon water loss of the green plate is reduced under the condition of not increasing processes, and the dehydrating rate is reduced from original 1% to less than or equal to 0.8%; the possibility of diachylon adhesion between pole plates is reduced, the dusting powder on the surface of the pole plate is lowered, and the loss rate of weight of the pole plate is lowered from 0.5-1% to 0-0.4%.

Owner:ZHEJIANG TIANNENG BATTERY JIANGSU

A kind of manufacturing method of high-rate type lithium-ion battery negative pole piece

The present invention discloses a manufacturing method of a high-rate type lithium-ion battery negative electrode sheet, comprising the following steps: taking artificial graphite, carbon black, carboxymethyl cellulose, and styrene-butadiene rubber emulsion, drying and cooling under vacuum conditions, and Carboxymethyl cellulose is poured into deionized water and stirred to dissolve, and then carbon black, artificial graphite and styrene-butadiene rubber emulsion are poured into the dissolved solution to make a slurry; the slurry is coated on the surface of aluminum foil, and the deionized Dry the ionized water after volatilization; add polyvinylpyrrolidone to anhydrous ethanol and stir and dissolve to make a solution; coat the solution on the pole piece coated with slurry, bake and cool the pole piece under vacuum condition, and roll the pole piece Pressed into a negative electrode sheet. The pole piece prepared by the method of the invention has the characteristics of less floating powder, smooth and burr-free surface of the pole piece, good high-rate discharge performance and high reliability, and the operation method is simple and easy, and the qualified rate of battery assembly is high. Lithium-ion batteries are suitable for power tools and electric bicycles.

Owner:无锡市明杨新能源股份有限公司

Special environment-friendly electrostatic spraying primer for bathrooms and construction method thereof

InactiveCN106634483AImprove adhesionStrong adhesionAnti-corrosive paintsBuilding material handlingAcrylic resinPolyamide

The invention relates to a special environment-friendly electrostatic spraying primer for bathrooms and a construction method thereof. The primer comprises the following raw materials in parts by weight: 60-90 parts of unsaturated polyester resin, 15-35 parts of organic-silicon-modified acrylic resin, 5-15 parts of environment-friendly adsorbent, 2-6 parts of nano silicon dioxide, 1-5 parts of nano titanium dioxide, 1-5 parts of nano calcium carbonate, 5-15 parts of diatomite, 2-8 parts of talcum powder, 10-20 parts of titanium white, 2-10 parts of antirust pigment, 2-5 parts of zinc stearate, 2-6 parts of hydroxyethyl methyl cellulose, 1-2 parts of fumed silica, 0.1-0.5 part of polyamide wax, 0.2-0.8 part of defoaming agent, 0.5-2 parts of leveling agent and 2-10 parts of styrene. The special environment-friendly electrostatic spraying primer for bathrooms can satisfy the construction requirements of electrostatic spraying, has the capacity of adsorbing stinky matters in the bathroom, and has the advantages of excellent moisture resistance, excellent weather resistance and excellent stability.

Owner:TIANCHANG JINLING ELECTRONICS

Preparing method of water system capacitor battery positive electrode

InactiveCN106848207AImprove conductivityHigh mechanical strengthAlkaline accumulator electrodesNickel accumulatorsCapacitanceCarbon black

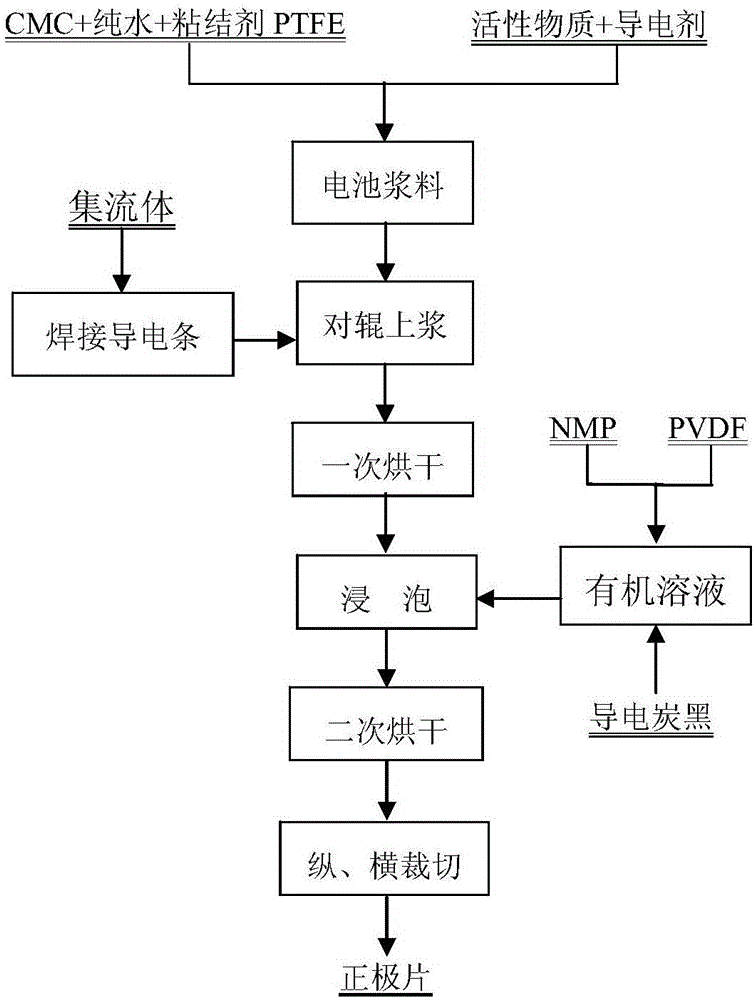

The invention belongs to the technical field of power batteries and nickel-metal hydride batteries thereof, in particular to a preparing method of a water system capacitor battery positive electrode. The method comprises the steps of roll-welding the current collector used by the positive electrode to conductive strips in advance in the horizontal direction, then making the current collectors soak in battery size, conducting double-rolling sizing and the primary drying, pre-pressing and making the products soak in organic solution, conducting secondary drying, rolling to conduct forming, welding, cutting the products horizontally and vertically to make the positive electrode, wherein, the battery size is the mixture of CMC, conductive agent, adhesives, active substance and current collectors, the organic solution is the mixture of NMP, conductive carbon black and PDVF. According to the preparing method of water system capacitor battery positive electrode, the dense combination of the active substance and the current collectors is achieved, the preparation process is continuous and intelligentized. The conductivity of the electrode piece is hugely increased, at the same time, the mechanical strength of the electrode piece is increased. The produced positive electrode piece has a high mechanical strength, excellent flexibility and smoothness. The method can satisfy the ultrahigh current and ultrahigh power input and output requirements in the full service life cycle of the water system capacitor batteries.

Owner:淄博君行电源技术有限公司

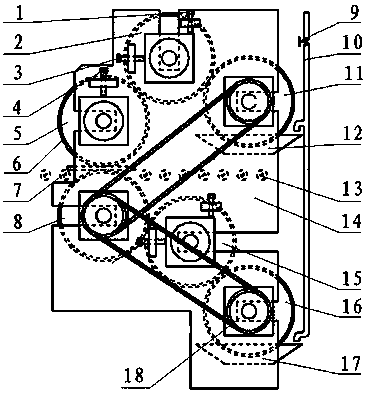

Environment-friendly material-saving device for sulfuric acid rolling of smeared unformed plates through rolling dipping of rich solution with barren solution

ActiveCN105938895ANo wasteReduce pollutionElectrode rolling/calenderingLead-acid accumulator electrodesEngineeringSulfuric acid

The invention discloses an environment-friendly material-saving device for sulfuric acid rolling of smeared unformed plates through rolling dipping of a rich solution with a barren solution. The device comprises an upper rolling dipping roll, a lower rolling dipping roll, an upper transfer roll, a lower transfer roll, an upper rolling roll, and a lower rolling roll, wherein the upper rolling dipping roll is rolled through an upper rolling dipping acid tank below the upper rolling dipping roll in a soaked manner, and the lower rolling dipping roll is rolled through a lower rolling dipping acid tank below the lower rolling dipping roll in a soaked manner; the upper rolling dipping roll and the lower rolling dipping roll are respectively in contact with the upper transfer roll and the lower transfer roll to transfer rolling; the upper transfer roll and the lower transfer roll are respectively in contact with the upper rolling roll and the lower rolling roll to transfer rolling; a gap is formed between the upper rolling roll and the lower rolling roll; an unformed plate delivery rollway is arranged in the gap; roll surfaces of the upper rolling dipping roll, the lower rolling dipping roll, the upper transfer roll, the lower transfer roll, the upper rolling roll and the lower rolling roll are all wrapped with acid-resistant and acid-absorbent roll cloth. When the unformed plates are rolled through the device, dripping of dilute sulfuric acid and lead mud is prevented, so that the acid rolling lead mud and the acid are not wasted, and a surface acid layer is thin and uniform.

Owner:TIANNENG GRP JIANGSU TECH

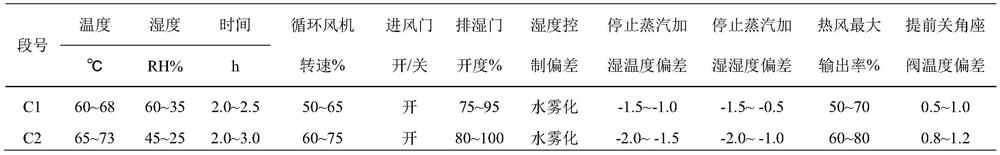

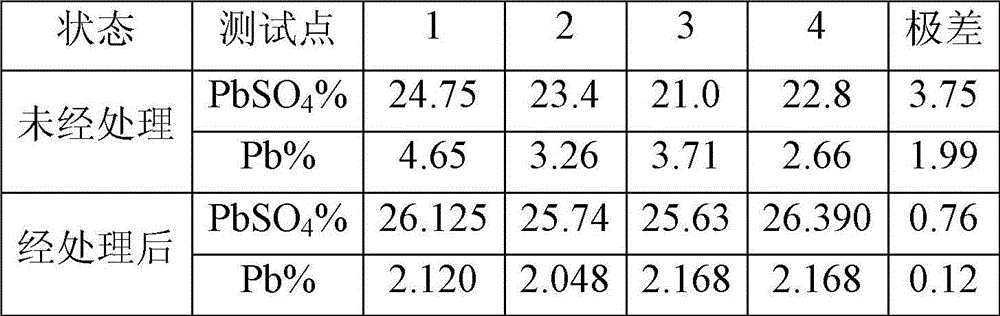

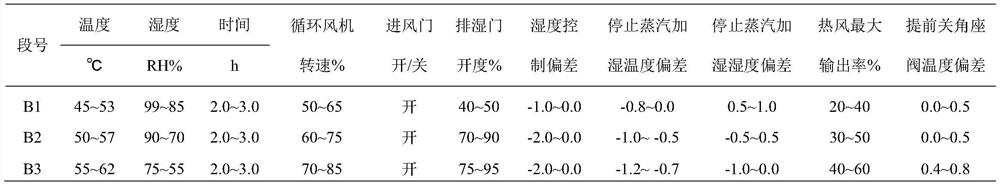

Process for quickly curing and drying negative green plate

ActiveCN111697202AUniform moistureSufficient humidityLead-acid accumulator electrodesLead carbonateManufacturing cost reduction

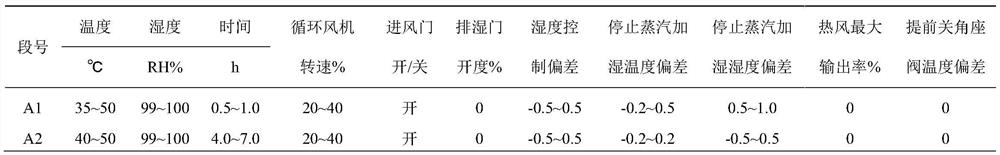

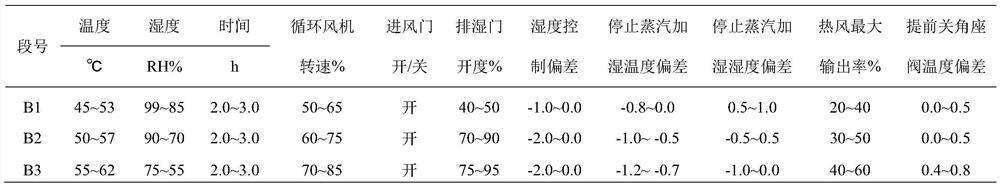

The invention belongs to the field of lead-acid storage batteries and particularly relates to a process for quickly curing and drying a negative electrode plate. The process at least comprises the following program steps of (1) a curing constant-temperature high-humidity maintaining stage, (2) a curing heating constant-speed dehumidifying stage, (3) a curing heating rapid dehumidifying stage, (4)a drying heating rapid dehumidifying stage, (5) a drying high-temperature rapid enhancing stage and (6) a drying cooling rapid strength stabilizing stage. According to the green polar plate cured anddried according to the process, the content of basic lead carbonate of the green polar plate is increased, the falling strength of the green polar plate is further improved, lead plaster looseness isreduced after falling, and the floating powder amount on a surface of the green polar plate is reduced, improvement of the strength of the green plate reduces a reject ratio of subsequent slicing andwrapping of the green plate. The process is advantaged in that the floating powder amount is small, lead powder flying dust in the subsequent polar plate production process is reduced, and environmental pollution is reduced, and the rapid curing and drying process can reduce the use amount of steam and electricity in the process, reduce curing and drying energy consumption and reduce manufacturingcost.

Owner:ZHEJIANG TIANNENG BATTERY JIANGSU +3

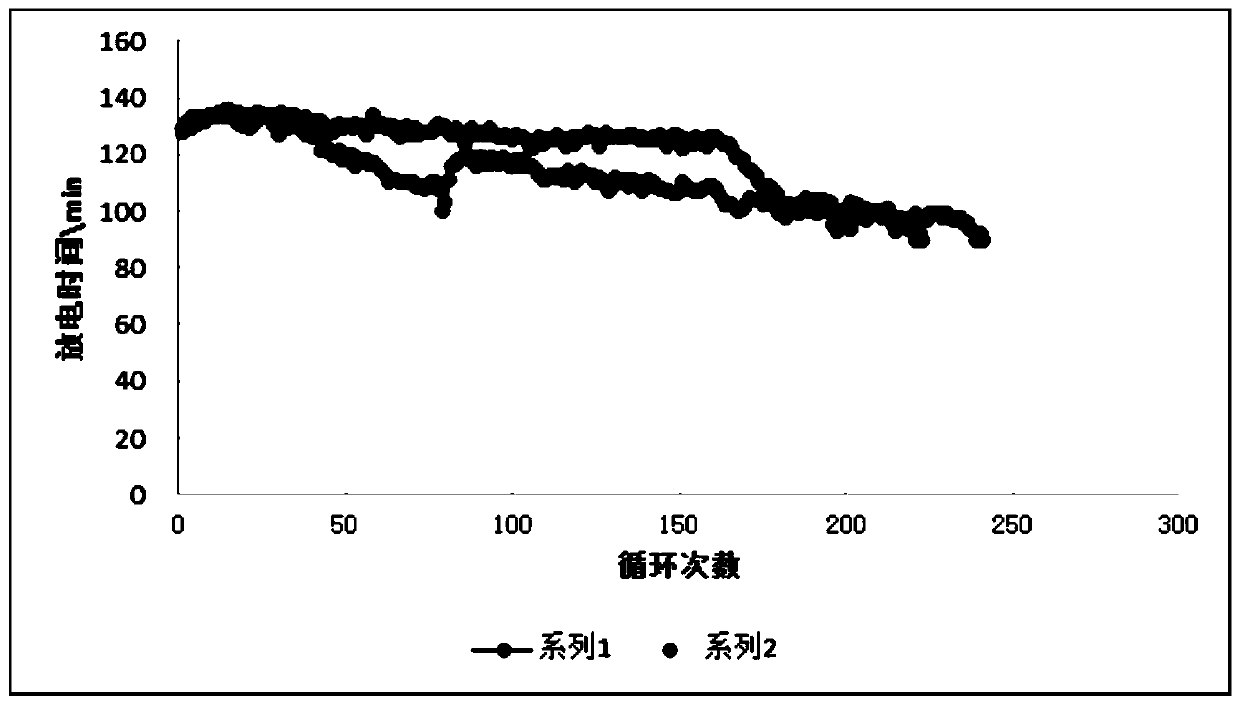

A kind of manufacturing method of high-rate type lithium-ion battery positive pole piece

InactiveCN102299298AReduce floating powderImprove reliabilityCell electrodesPolyvinylidene fluorideCarbon black

The invention discloses a method for making a positive pole piece of a high-rate lithium-ion battery, which is characterized in that it comprises the following steps: taking nickel-cobalt lithium manganese oxide, polyvinylidene fluoride, carbon black, and conductive graphite; baking under vacuum conditions , cooling; Pour polyvinylidene fluoride into N-methylpyrrolidone solution to make it fully dissolved, then pour carbon black, conductive graphite and nickel cobalt lithium manganate into the dissolved solution to make a slurry; the slurry Coated on the surface of aluminum foil, volatilize N-methylpyrrolidone in an oven and then dry; add polyvinylpyrrolidone to anhydrous ethanol to stir and dissolve to make a solution, and coat it on the pole piece with slurry, bake it in vacuum and cool it The pole piece is pressed into a positive pole piece with a rolling mill. The pole piece prepared by the method of the invention has the characteristics of less floating powder, smooth and burr-free surface of the pole piece, good high-rate discharge performance and high reliability, and the operation method is simple and easy, and the qualified rate of battery assembly is high. Lithium-ion batteries are suitable for power tools and electric bicycles.

Owner:无锡市明杨新能源有限公司

Method for pretreating raw polar plates for internal formation

ActiveCN103035884BReduce floating powderNo pollution in the processLead-acid accumulator electrodesPretreatment methodPre treatment

The invention discloses a method for pretreating raw polar plates for internal formation. The method comprises the following steps: (1), soaking the raw polar plates subjected to solidification and drying into dilute sulfuric acid with the density of 1.01 to 1.40 g / mL (at the temperature of 25 DEG C), wherein the soaking time of the positive plate is 20 to 80 minutes and the soaking time of the negative plate is 10 to 50 minutes; and (2), drying the soaked raw polar plates. By the pretreatment method, the raw polar plates are pretreated, the floating powder on the surfaces of the polar plates is obviously reduced, and dust pollution on a clamping board and a sheet wrapping board is basically avoided in the turnover process and the sheet wrapping process of the polar plates. By the pretreatment method, the temperature basically keeps at 30 to 35 DEG C after a battery is acidified, the battery temperature basically maintains to be 40 to 45 DEG C in the charging process, and advantages are brought to formation of the polar plates, so that bad hidden danger is reduced during the traditional internal formation production.

Owner:TIANNENG BATTERY GROUP

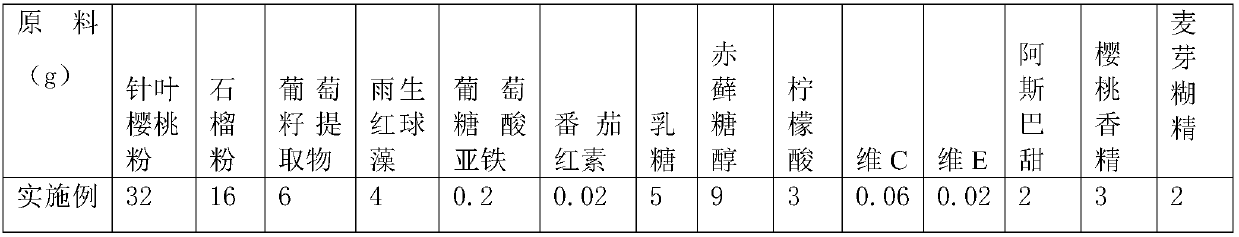

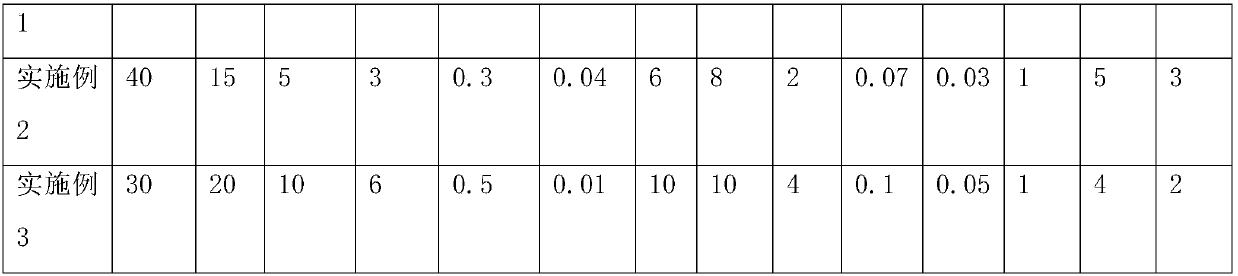

Solid beverage with skin whitening function, and preparation method thereof

PendingCN109527322AHas anti-oxidant and whitening functionsAntioxidant protectionFood ingredient functionsVitamin CLycopene

The invention discloses a solid beverage with a skin whitening function, and a preparation method thereof, and belongs to the technical field of solid beverages. The solid beverage comprises Acerola cherry powder, pomegranate powder, grape seed extract, Haematococcus pluvialis, ferrous gluconate, lycopene, lactose, erythritol, citric acid, vitamin C, vitamin E, aspartame, cherry essence and maltodextrin, and is obtained through mixing, high-pressure homogenization, dry granulation and sieving. The solid beverage has anti-oxidation and whitening functions, the raw materials are not oxidized inthe preparation process, and the high-pressure homogenization improves the roundness of the solid beverage, and makes the solid beverage be not prone to be crushed and have less dusting flour.

Owner:ZHEJIANG JIANFENG HEALTH TECH

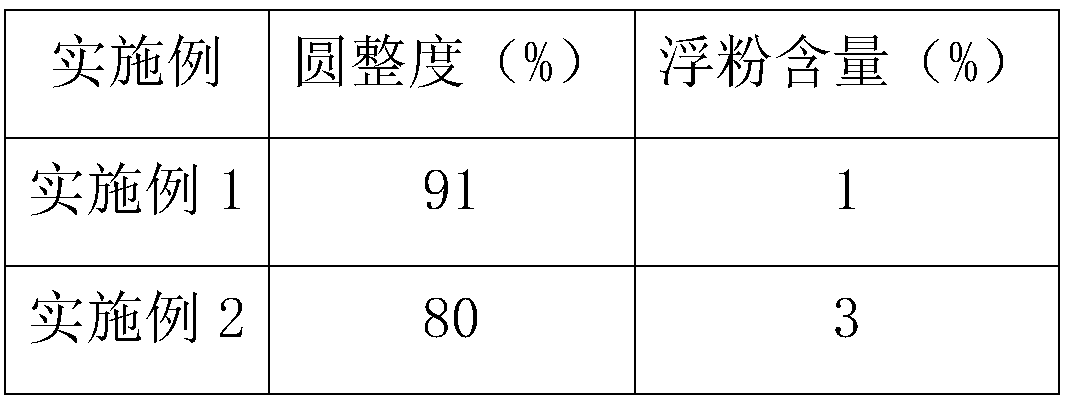

Glue solution for surface treatment of nickel-metal hydride (NI-MH) battery plate and gum dipping device

ActiveCN101984514BMix well without layeringImprove performanceAlkaline accumulator electrodesDusting powdersEngineering

Owner:江苏金赛尔电池科技有限公司

A lead-acid battery

ActiveCN107611443BExtend your lifeHigh initial capacityCell electrodesFinal product manufactureElectrolytic agentFiber

The invention discloses a lead-acid storage battery, which includes a pole plate, an electrolyte, a separator and a battery tank. The pole plate includes a grid and a lead paste, and the lead paste contains short fibers. It is characterized in that the short fibers The single fiber fineness is 0.15‑0.8D. The application of the present invention improves the strength of the pole plate, reduces the waste in the production process, increases the mechanical strength of the active material, prevents shedding, and improves the cycle performance; at the same time, it reduces the generation of floating powder, and can also increase the porosity of the positive plate and improve the performance of the battery. initial capacity.

Owner:SHANDONG JINKELI POWER SOURCES TECH

Method for preparing high-durability silicic acid storage battery

InactiveCN109786652ALess floating powder on the surfaceEasy to useElectrode manufacturing processesFinal product manufacturePower flowSilicic acid

The invention discloses a method for preparing a high-durability silicic acid storage battery comprising the steps of selecting a negative constant plate groove; feeding the plate charged with a negative constant method; at the end, performing current discharge for 0.5h at the last stage, grooving the plate, and directly drying the same without washing. The plate produced by the method provided bythe invention has less surface floating powder on the surface, and the floating powder can be reduced by about 20%, thereby improving the service performance and service life of the battery and improving the production environment of the employee.

Owner:马仲起

Highlight for cosmetics and preparation method thereof

ActiveCN113712832AHigh glossEasy to useCosmetic preparationsBody powdersAluminium oxidesMaterials science

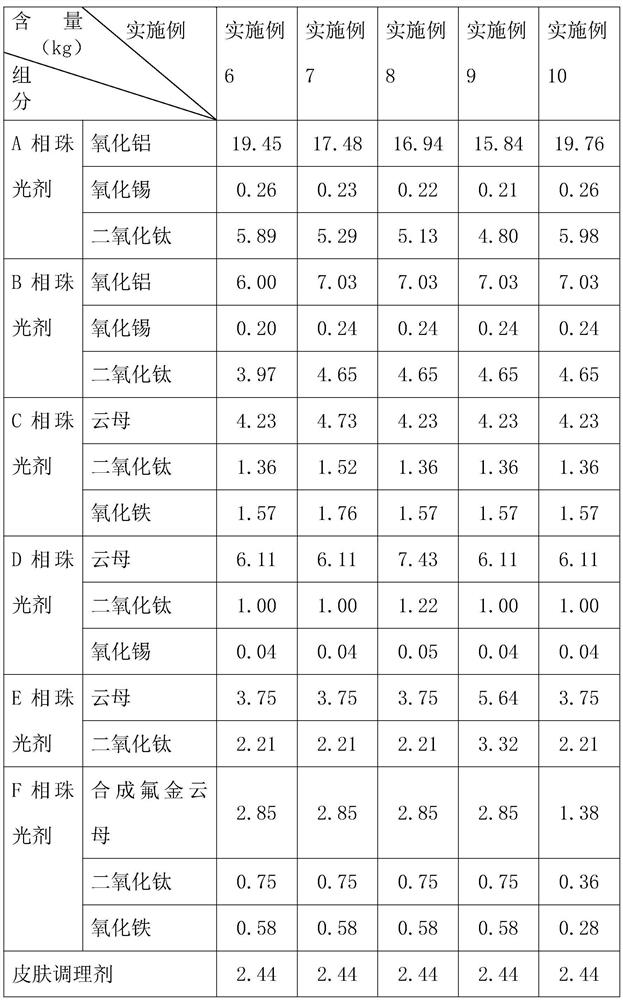

The invention relates to the field of cosmetics, and particularly discloses a highlight for cosmetics and a preparation method thereof. The highlight for cosmetics is prepared from the following components in percentage by mass: 18.85-27% of A-phase pearling agent, 8-16.15% of B-phase pearling agent, 5-11% of C-phase pearling agent, 4-9% of D-phase pearling agent, 4-8.5% of E-phase pearling agent, 2-6% of F-phase pearling agent and the balance other assistants, totaling 100%; the A-phase pearling agent is a mixture of aluminum oxide, tin oxide and titanium dioxide, wherein the aluminum oxide, tin oxide and titanium dioxide respectively account for 57-79%, 1-6% and 20-37% of the total amount of the A-phase pearling agent; and the B-phase pearling agent is a mixture of aluminum oxide, tin oxide and titanium dioxide. The highlight has favorable fitness and glossiness.

Owner:JOTM DAILY CHEM HANGZHOU CO LTD

An environment-friendly and energy-saving smear raw plate rich liquid rolling dipping lean liquid rolling sulfuric acid device

ActiveCN105938895BNo wasteReduce pollutionElectrode rolling/calenderingLead-acid accumulator electrodesMaterials scienceEnvironmentally friendly

The invention discloses an environment-friendly material-saving device for sulfuric acid rolling of smeared unformed plates through rolling dipping of a rich solution with a barren solution. The device comprises an upper rolling dipping roll, a lower rolling dipping roll, an upper transfer roll, a lower transfer roll, an upper rolling roll, and a lower rolling roll, wherein the upper rolling dipping roll is rolled through an upper rolling dipping acid tank below the upper rolling dipping roll in a soaked manner, and the lower rolling dipping roll is rolled through a lower rolling dipping acid tank below the lower rolling dipping roll in a soaked manner; the upper rolling dipping roll and the lower rolling dipping roll are respectively in contact with the upper transfer roll and the lower transfer roll to transfer rolling; the upper transfer roll and the lower transfer roll are respectively in contact with the upper rolling roll and the lower rolling roll to transfer rolling; a gap is formed between the upper rolling roll and the lower rolling roll; an unformed plate delivery rollway is arranged in the gap; roll surfaces of the upper rolling dipping roll, the lower rolling dipping roll, the upper transfer roll, the lower transfer roll, the upper rolling roll and the lower rolling roll are all wrapped with acid-resistant and acid-absorbent roll cloth. When the unformed plates are rolled through the device, dripping of dilute sulfuric acid and lead mud is prevented, so that the acid rolling lead mud and the acid are not wasted, and a surface acid layer is thin and uniform.

Owner:TIANNENG GRP JIANGSU TECH

Method for synthesizing inert composite electrode plate floating powder

InactiveCN109786650ALess floating powder on the surfaceEasy to useElectrode manufacturing processesLead-acid accumulator electrodesComposite electrodeSynthesis methods

The invention discloses a method for synthesizing an inert composite electrode plate floating powder. The synthesis method comprises the following steps of selecting a negative constant plate groove;feeding the plate charged and synthesizing the same with a negative constant synthesis method; at the end of the synthesis, performing current discharge for 0.5h at the last stage of the synthesis, grooving the plate, and directly drying the same without washing. The plate produced by the synthesis method provided by the invention has less surface floating powder on the surface, and the floating powder can be reduced by about 20%, thereby improving the service performance and service life of the battery and improving the production environment of the employee.

Owner:朱国宏

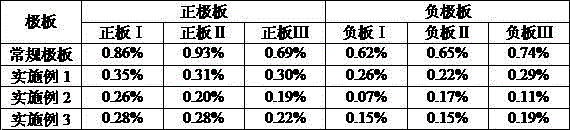

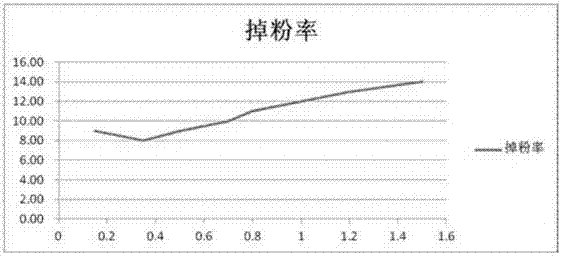

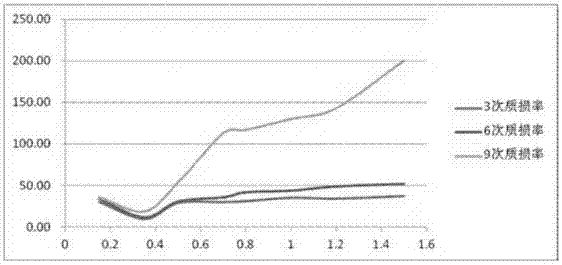

A method for manufacturing lead-acid storage battery plates that reduces the powder shedding rate on the surface of the plates

ActiveCN107732161BIncrease capacityInhibition of problems such as poor formation effectLead-acid accumulator electrodesElectrolytic agentElectrical battery

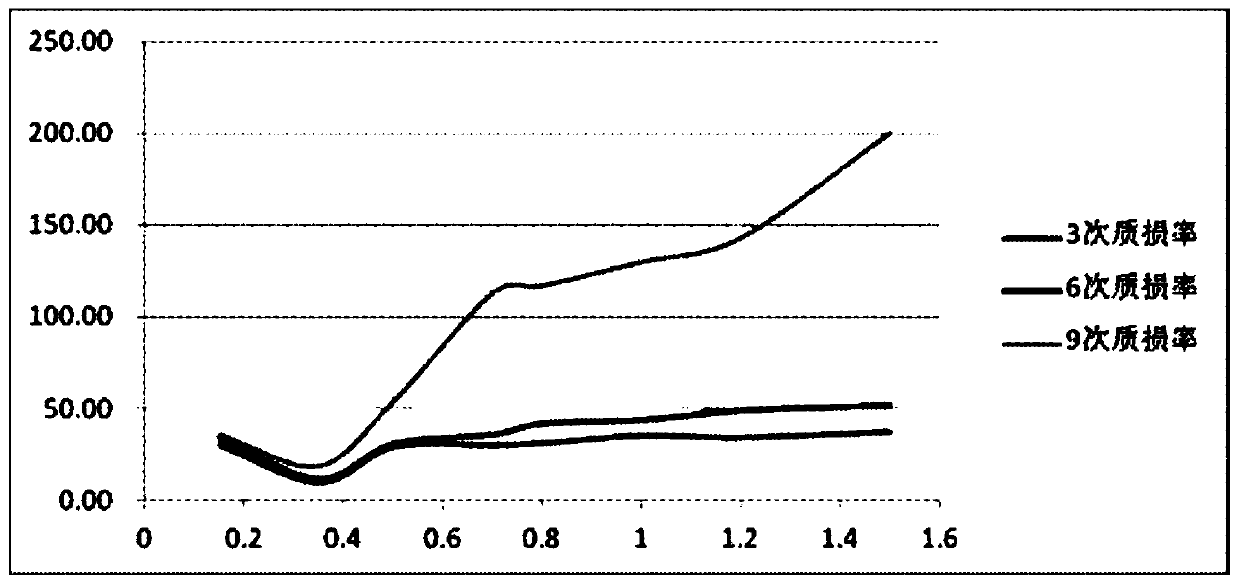

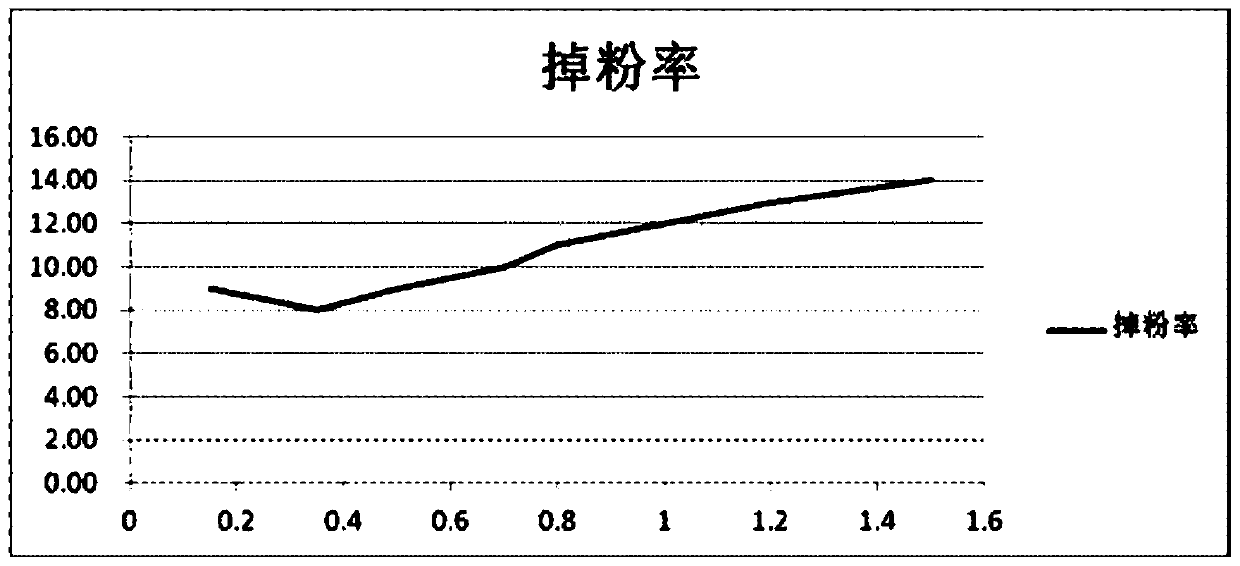

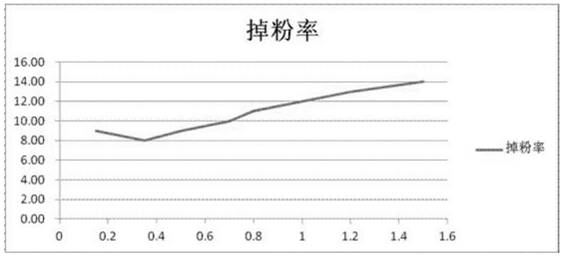

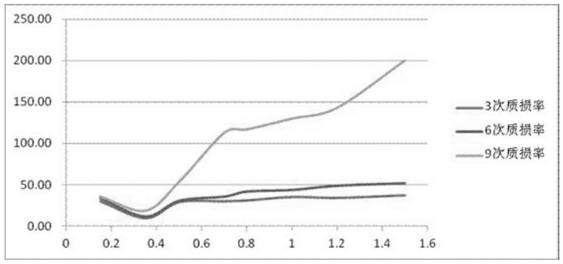

The invention discloses a lead storage battery electrode plate production method for reducing the powder shedding rate of the surface of an electrode plate. The lead storage battery electrode plate production method comprises: making a paste, and coating or spraying the surface of an electrode plate, wherein the paste making comprises adding an electric conduction binder and controlling an acid adding rate and a temperature so as to change the structure of the lead paste, and during the coating or the spraying, the active substance on the surface of the electrode plate is connected by using apolymer sol, such that the floating powder during the sheet brushing can be reduced by improving the binding force between the electrode plate surface and the coating, the problems of low battery capacity, subsequent short circuit and the like due to the floating power during the formation can be easily solved, and the polymer sole is dissolved into the electrolyte through the polymerization reaction along with the temperature increase when the electrode plate is assembled into the battery and filling formation is performed so as to effectively improve the poor formation effect caused by the too high temperature in the battery at the initial stage of the acid mixing.

Owner:CHAOWEI POWER CO LTD

Preparation method and surface treatment device of lithium ion battery pole piece

The invention discloses a lithium ion battery pole sheet making method. The method comprises: a pole sheet coating slitting operation; a pole sheet surface treatment operation comprising a step of immersing a coat-slitted pole sheet in an aqueous high-polymer treatment liquid, and a step of drying to obtain a high-polymer film on the surface of the pole sheet; and a made sheet packaging operation. The method which allows the pole sheet surface treatment operation to be increased and the high-polymer film to be formed on the surface of the pole sheet can effectively prevent the powder fall of the lithium ion battery pole sheet, reduce the floatation powder generated in the making process of a battery, improve the bonding force of active substances, and improve the comprehensive electrochemical performances of the lithium ion battery. The invention also discloses a surface treatment device of the lithium ion battery pole sheet. The device comprises, sequentially arranged, an unreeling wheel, a pole sheet immersion material tank, a spreading knife, a drying tunnel, roller machines and a reel wheel, and can automatically and efficiently complete the surface treatment of the pole sheet, so the industrialized continuous production is convenient.

Owner:湖南三迅新能源科技有限公司

A kind of preparation method of lead-acid storage battery raw electrode plate reducing floating powder

ActiveCN104466086BImprove bindingSmall particle sizeElectrode manufacturing processesLead-acid accumulator electrodesDusting powdersFumed silica

The invention discloses a preparation method of a lead storage battery green plate for reducing dusting powder. The preparation method successively comprises a gypsum mixing process, a gypsum daubing process and a solidifying and drying process, wherein the gypsum daubing process comprises a daubing section, an acid leaching and rolling section and a surface dry treatment section, and an acid leaching solution is prepared from the following components in parts by weight: 12.5-22 parts of 90-95% vitriol, 1-5 parts of fumed silica, 0.5-1 part of lauryl sodium sulfate and 72-86 parts of water. The method disclosed by the invention is simple in operation and is applicable to a positive electrode and a negative electrode, the diachylon water loss of the green plate is reduced under the condition of not increasing processes, and the dehydrating rate is reduced from original 1% to less than or equal to 0.8%; the possibility of diachylon adhesion between pole plates is reduced, the dusting powder on the surface of the pole plate is lowered, and the loss rate of weight of the pole plate is lowered from 0.5-1% to 0-0.4%.

Owner:ZHEJIANG TIANNENG BATTERY JIANGSU

Formation method for improving floating dust on surface of negative electrode plate

InactiveCN109755677ALess floating powder on the surfaceEasy to useFinal product manufactureSecondary cells charging/dischargingOceanographyWater washing

The present invention discloses a formation method for improving floating dust on a surface of a negative plate. The formation method comprises the following steps that a constant negative polar platetank is selected; the polar plate is placed into the tank in a charged state and formation is carried out with a constant negative formation method; when the formation is terminated, discharging is performed for 0.5 h with the current in the last formation stage, and the polar plate is taken out of the tank and is directly dried without water washing. The polar plate produced by the formation method of the invention has less floating dust on the surface; the floating dust can be reduced by about 20%, thereby the service performance of a battery is improved, the service life of the battery isprolonged, and the production environment of an employee is also improved.

Owner:张志炜

Silicate storage battery with high stability

InactiveCN109755678ALess floating powder on the surfaceEasy to useFinal product manufactureSecondary cells charging/dischargingEngineeringElectrical and Electronics engineering

The invention discloses a silicate storage battery with high stability. A formation method comprises the following steps of selecting a constant negative pole plate groove; allowing a pole plate to enter the groove in a live-line way, and performing formation by a constant negative formation method; and discharging for 0.5 hours with a current at the last stage of formation, taking out the pole plate of the groove, and directly drying without washing. A few amount of floating powder is generated on a surface of the pole plate generated by the formation method, the flowing powder can be reducedby about 20%, so that the service performance of the battery is improved, the service lifetime of the battery is prolonged, and the production environment of staff is also improved.

Owner:张志炜

Lead acid battery pole plate

PendingCN107394119AHigh strengthReduce floating powderLead-acid accumulator electrodesPorosityElectrical battery

The invention discloses a lead acid battery pole plate. The lead acid battery pole plate comprises grids and lead plaster. The lead plaster contains short fiber and is characterized in that the single fiber fineness of the short fiber is 0.15-0.8 D. By using the lead acid battery pole plate, the pole plate intensity is increased, waste loss during a production process is reduced, the mechanical strength of the active substance is increased, shedding can be prevented, and the cycle performance is increased; at the same time, generation of the floated powder is reduced, the positive plate porosity is increased, and primary capacity of a battery is increased.

Owner:SHANDONG JINKELI POWER SOURCES TECH

A kind of rapid solidification and drying process of negative raw electrode plate

ActiveCN111697202BUniform moistureSufficient humidityLead-acid accumulator electrodesLead carbonateManufacturing cost reduction

Owner:ZHEJIANG TIANNENG BATTERY JIANGSU +3

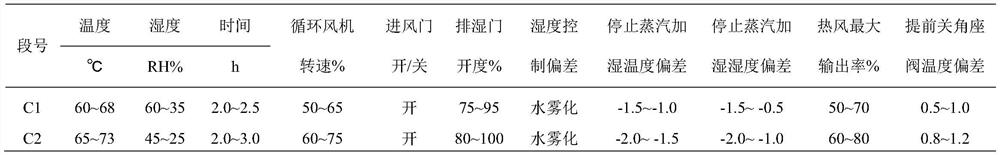

Method for container formation of unformed plate for power battery

ActiveCN108767199AImprove performanceReduce floating powderLead-acid accumulator electrodesPower batteryElectrical battery

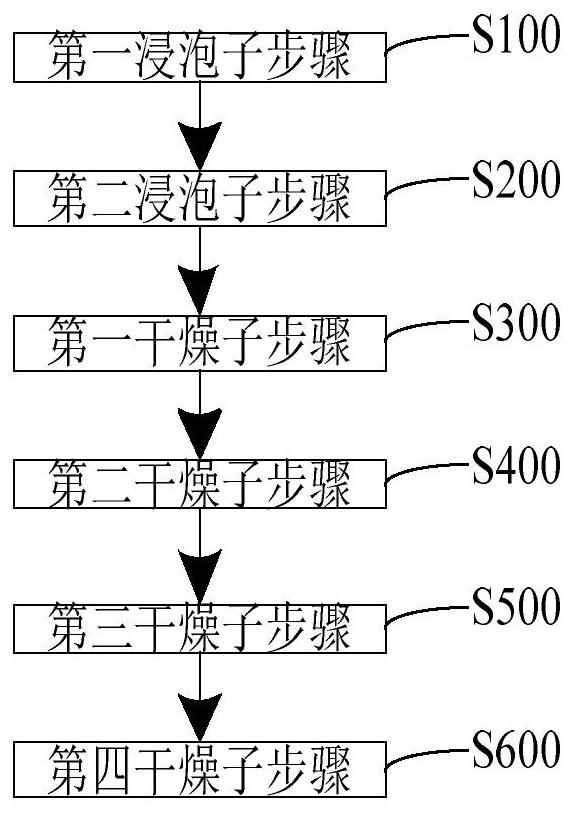

The invention discloses a method for container formation of an unformed plate for a power battery. The method comprises the following steps: 1, immersing: immersing a cured unformed plate: 1) carryingout a first immersion sub-step: immersing the cured unformed plate in a silica colloid-containing diluted sulfuric acid electrolyte having a density of 1.05-1.20 g / ml; and 2) carrying out a second immersion sub-step: immersing the immersed unformed plate obtained after the first immersion sub-step in a silica colloid-containing diluted sulfuric acid electrolyte having a density of 1.25-1.40 g / ml;and 2, drying: drying the immersed unformed plate obtained after the immersion step. The floating powder of the plate processed through the method is obviously reduced, and the performances of a battery assembled by using the processed plate are further improved.

Owner:ANHUI LEOCH BATTERY TECH

A kind of short fiber for lead-acid battery plate

ActiveCN107403934BHigh strengthReduce floating powderLead-acid accumulatorsCell electrodesPhysical chemistrySingle fiber

The invention discloses a short fiber used for lead-acid storage battery plates. The short fiber comprises a plurality of organic fibers with a length of 6mm or shorter, and the single fiber fineness ranges from 0.15 to 0.8D. The short fiber is capable of increasing plate strength, reducing loss in production process, increasing active substance mechanical strength, preventing shedding, improving cycling performance, reducing generation of floating powder, increasing positive plate porosity, and increasing initial capacity.

Owner:SHANDONG JINKELI POWER SOURCES TECH

Plate producing method effectively improving floating powder pollution of negative electrode plate

InactiveCN109786651ALess floating powder on the surfaceEasy to useElectrode manufacturing processesFinal product manufactureEngineeringPollution

The invention discloses a plate producing method effectively improving floating powder pollution of a negative electrode plate. The method comprises the following steps of selecting a negative constant plate groove; feeding the plate charged with a negative constant method; at the end, performing current discharge for 0.5h at the last stage, grooving the plate, and directly drying the same withoutwashing. The plate produced by the method provided by the invention has less surface floating powder on the surface, and the floating powder can be reduced by about 20%, thereby improving the serviceperformance and service life of the battery and improving the production environment of the employee.

Owner:马仲起

A method for internalizing a power battery into a green plate

ActiveCN108767199BImprove performanceReduce floating powderLead-acid accumulator electrodesPower batteryElectrolytic agent

The invention discloses a method for internalizing a power battery into a green electrode plate, which comprises the following steps: a soaking step for soaking the cured green electrode plate, at least including: a first soaking sub-step: soaking the cured green electrode plate The plate is soaked in dilute sulfuric acid electrolyte with colloidal silica added at a density of 1.05-1.20 g / ml; the second soaking sub-step: soaking the green electrode plate soaked in the first soaking sub-step in a density of 1.25-1.40 g / ml dilute sulfuric acid electrolyte with colloidal silica added; the drying step is used to dry the raw plate after soaking in the soaking step. The floating powder of the electrode plate treated by this method is obviously reduced, and the performance of the assembled battery is further improved.

Owner:ANHUI LEOCH BATTERY TECH

Lead-acid storage battery positive plate circular water cleaning process

InactiveCN109772800AReduce floating powderReduce generationFinal product manufactureLead-acid accumulator electrodesTime rangeEnvironmental engineering

The invention discloses a lead-acid storage battery positive plate circular water cleaning process. The lead-acid storage battery positive plate circular water cleaning process is characterized by comprising the following steps that after a negative plate is charged, grooving is carried out, after grooving, the plate is cleaned in 1-2# washing ponds, in the 1-2# washing ponds, circular tap water is used, the washing time ranges from 5 min to 10 min, in a 3# washing pond, pure water is used for carrying out immersing for three to five minutes, calcium carboxymethylcellulose is added in the purewater, the mass percent ranges from 2 to 6%, and after the calcium carboxymethylcellulose is completely dissolved in pure water, an air pipe is used for carrying out aeration for one to three minutes. The water washing method is simple, operation is easy, the floating powder on the surface of the negative plate obtained after water washing is reduced by about 47%, and the difficulty and the treatment cost of environment-friendly treatment of brush plates can be reduced.

Owner:李彤

Washing method for reducing floating powder on surface of positive plate

InactiveCN102806213AReduce floating powderReduce generationCleaning using liquidsCarboxymethyl celluloseEngineering

The invention discloses a washing method for reducing floating powder on the surface of a positive plate. The method is characterized by comprising the following steps of after forming and charging the positive plate, grooving the positive plate; washing the positive plate in a 1# washing tank and a 2# washing tank after finishing grooving the positive plate, wherein circulating tap water is used in the 1# washing tank and the 2# washing tank, and the washing time is 5 to 10 minutes; and soaking the positive plate for 3 to 5 minutes with purified water in a 3# washing tank, wherein 2 to 6 mass percent of carboxymethyl cellulose is added into the purified water, and after the carboxymethyl cellulose is completely dissolved in the purified water, aerating the plate for 1 to 3 minutes by using an air tube. The washing method is simple and easy to operate, the floating powder on the surface of the positive plate is reduced by about 47 percent, and the difficulty and treatment cost of environment-friendly treatment on a brushing plate are reduced.

Owner:JIANGSU LEOCH BATTERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com