A kind of short fiber for lead-acid battery plate

A technology of lead-acid batteries and short fibers, which is applied in the direction of lead-acid batteries, battery electrodes, circuits, etc. It can solve the problems of high waste rate, large human injury, and low plate strength, so as to reduce waste, reduce floating powder, The effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The plate preparation process is as follows:

[0025] (1) Put lead powder and short fibers in a mixer, add sulfuric acid and water to form a lead paste suitable for coating boards through continuous stirring;

[0026] (2) Press the combined lead paste on the grid to coat the board;

[0027] (3) curing and drying; making positive and negative plates.

[0028] (4) In the electrolyte of dilute sulfuric acid, the positive plate is connected to the positive electrode of the power supply, the negative plate is connected to the negative plate of the power supply, and the lead paste substance on the positive plate is converted into PbO2-based activity by electrochemical methods. Substances, lead paste substances on the negative plate are transformed into active substances mainly composed of spongy lead.

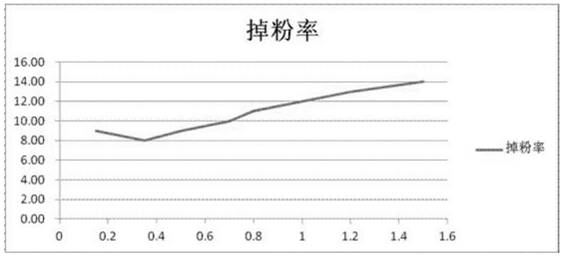

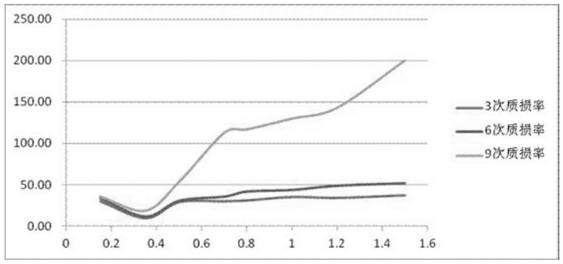

[0029] Drop test: Take the polar plates of each embodiment and comparative example respectively, number them, and weigh them. Make the polar plate parallel to the clean con...

Embodiment 6

[0063] Example 6: Choose 10 negative electrode raw plates, number them randomly, choose 0.35D for their single fineness, 2-3mm in length, and add 0.15% of the total mass of the lead paste. The result is as follows:

[0064]

[0065] Comparative example of this embodiment: choose 10 negative electrode raw plates, number them randomly, choose 1.5D for single fineness, 2-3mm in length, and add 0.15% of the total mass of the lead paste. The result is as follows:

[0066]

[0067] The index of embodiment 6 is obviously better than comparative example.

Embodiment 7

[0068] Embodiment 7: 5 pieces of negative electrode cooked plates are optional, randomly numbered, the single fiber fineness is selected as 0.35D, the length is 2-3mm, and the addition ratio is 0.2% of the total mass of the lead paste. The result is as follows:

[0069]

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com