Process for quickly curing and drying negative green plate

A rapid curing and raw plate technology, applied in the direction of lead-acid battery electrodes, etc., can solve the problems of long cycle, high process production cost, and low efficiency of curing chamber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0088] Specific embodiments of the present invention will be described in detail below.

[0089] A process for rapid solidification and drying of a negative raw electrode plate, comprising the following program steps:

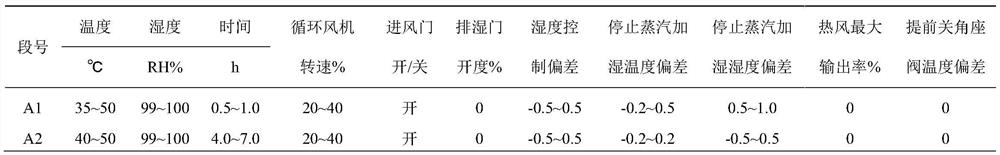

[0090] (1) Curing constant temperature and high humidity maintenance stage, process parameters:

[0091]

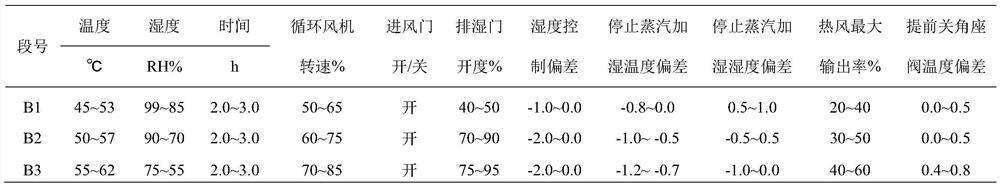

[0092] (2) In the stage of curing temperature rise and dehumidification at a constant speed, the parameters of the process program:

[0093]

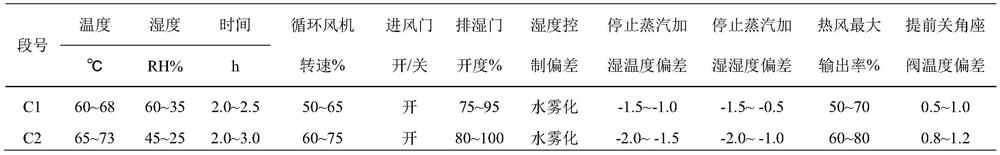

[0094] (3) In the stage of curing temperature rise and rapid dehumidification, process parameters:

[0095]

[0096] (4) In the stage of drying, heating and rapid dehumidification, process parameters:

[0097]

[0098] (5) Drying high temperature rapid enhancement stage, process parameters:

[0099]

[0100] (6) Drying and cooling fast and stable stage, process parameters:

[0101]

[0102] Fast curing drying program data comparison table

[0103]

[0104] The above-mentioned embodiments ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com