Patents

Literature

68results about How to "Continuous growth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

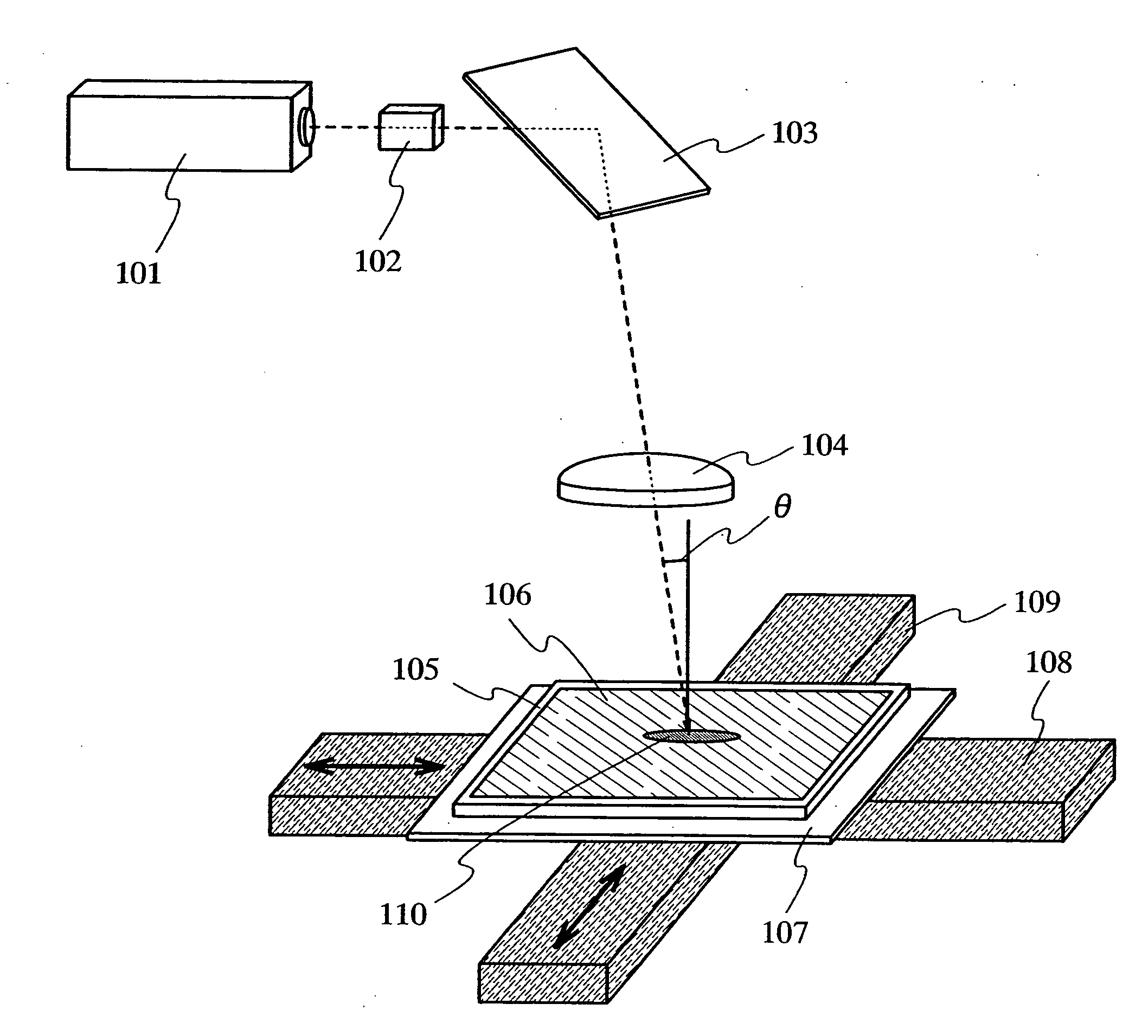

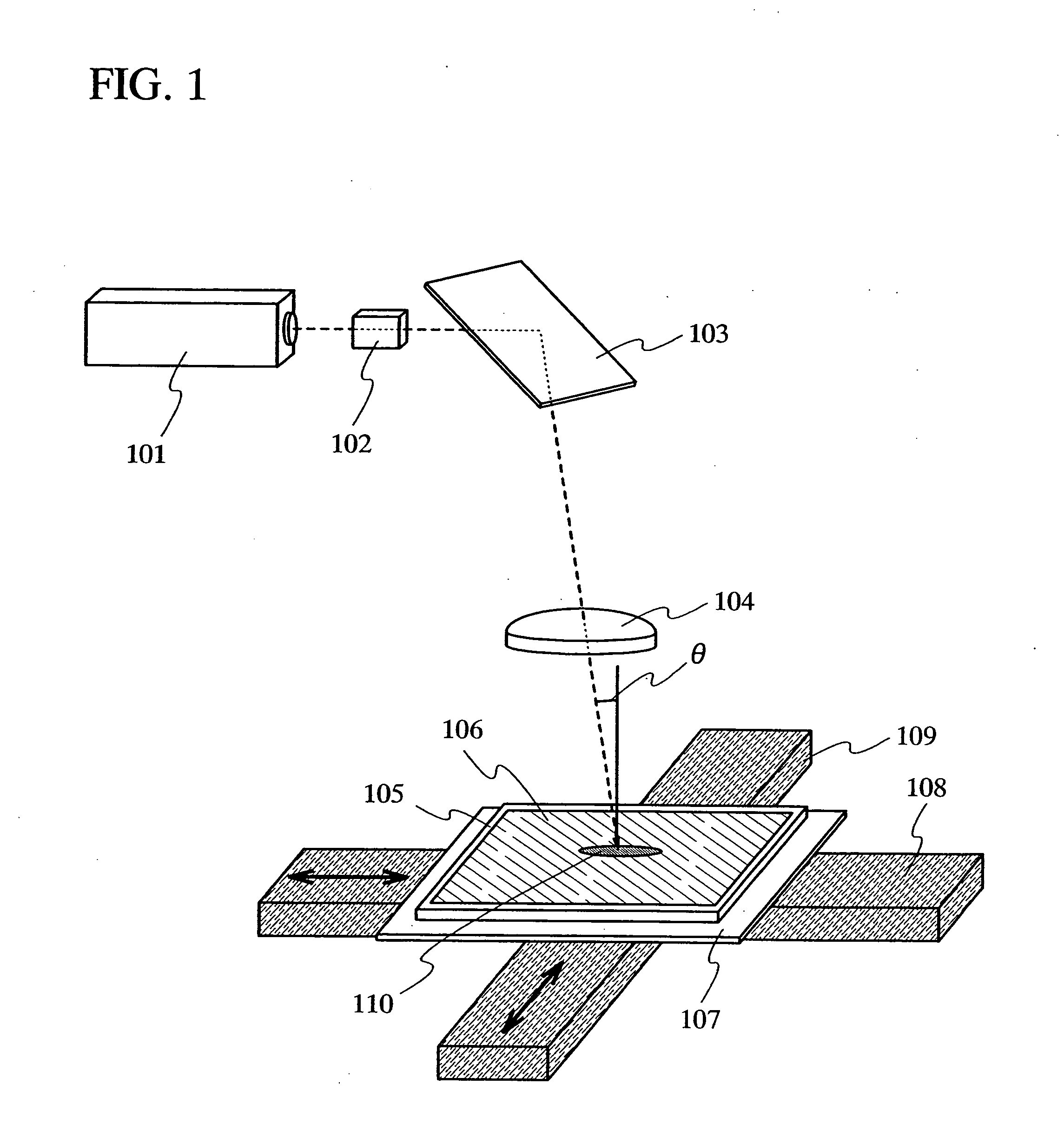

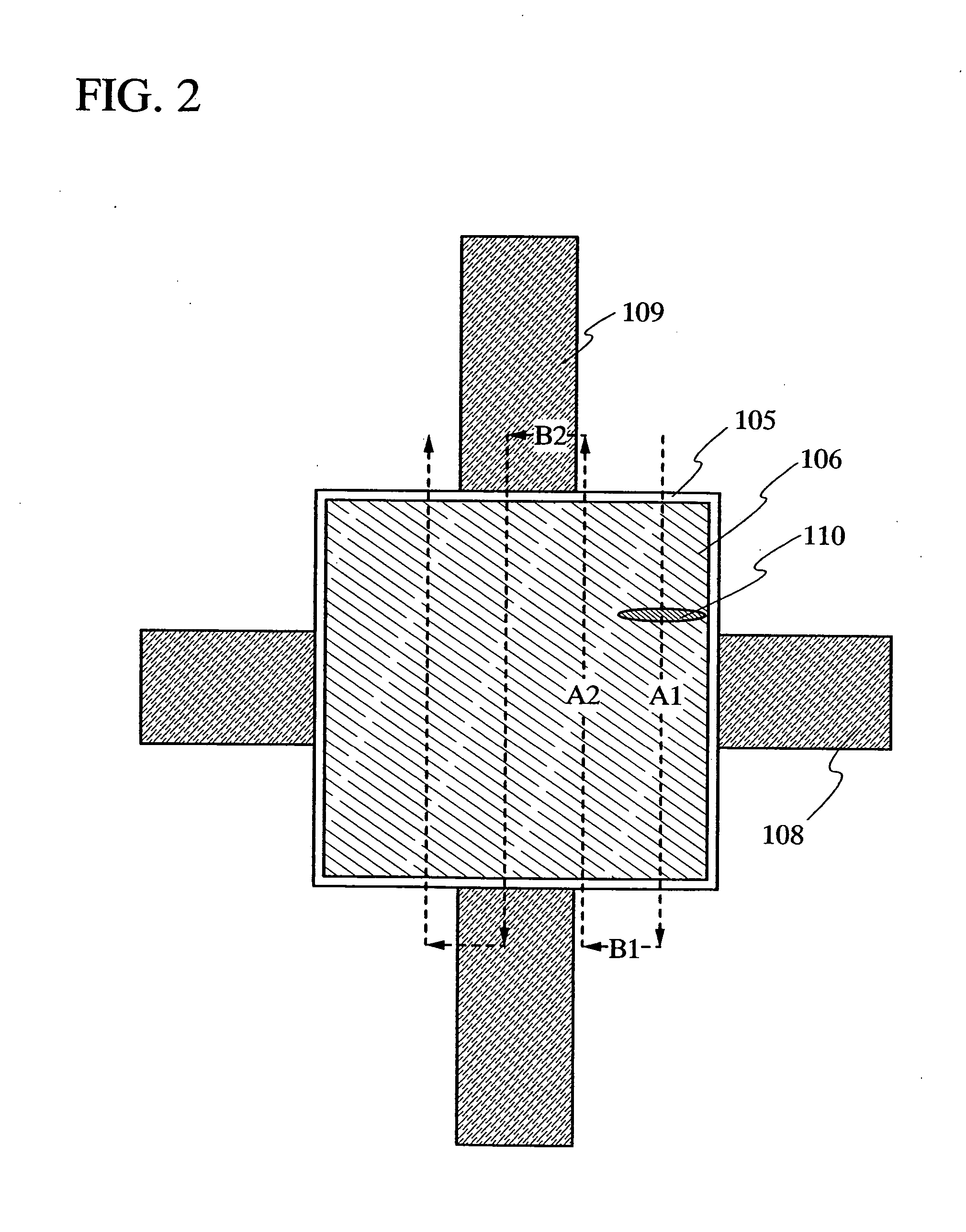

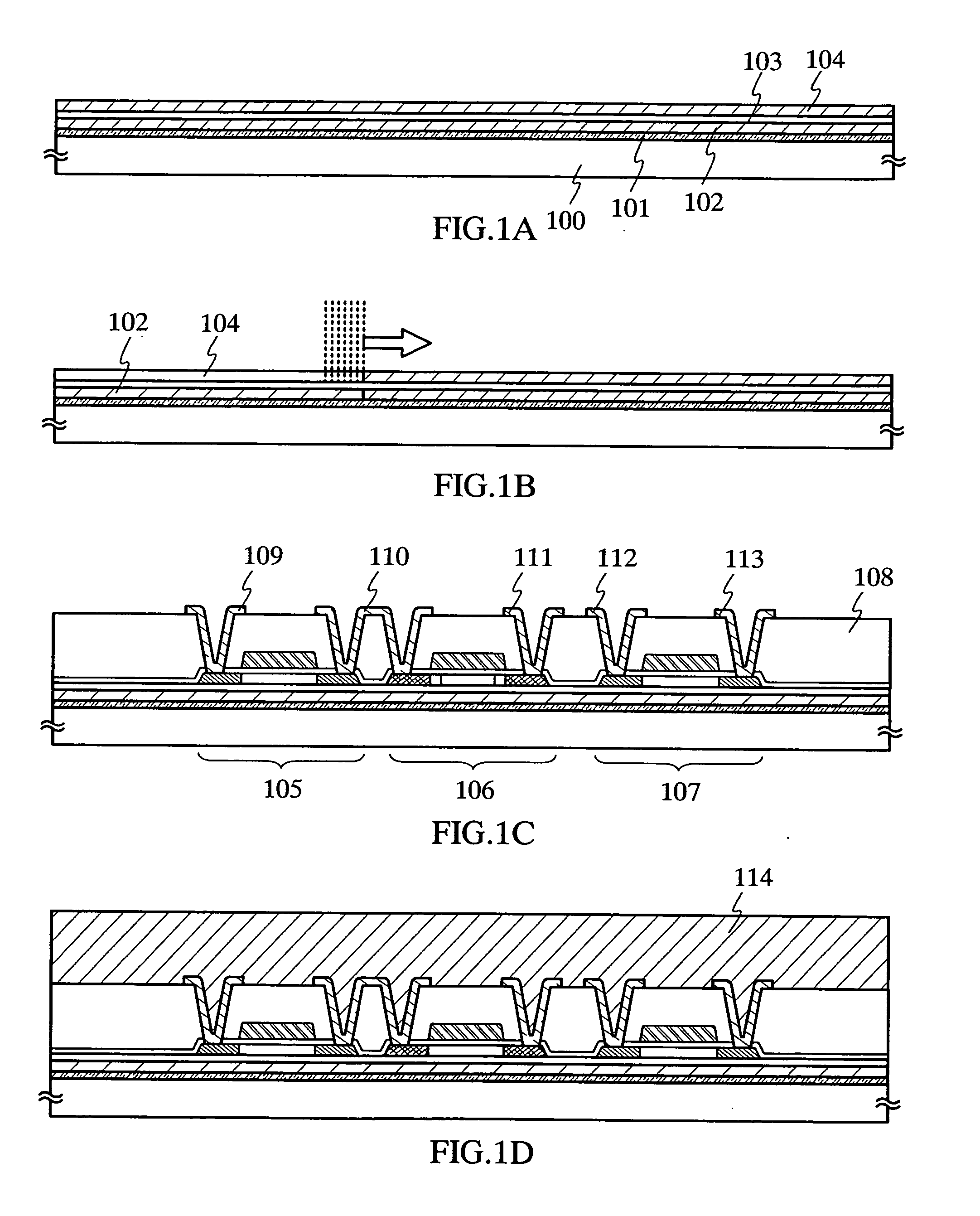

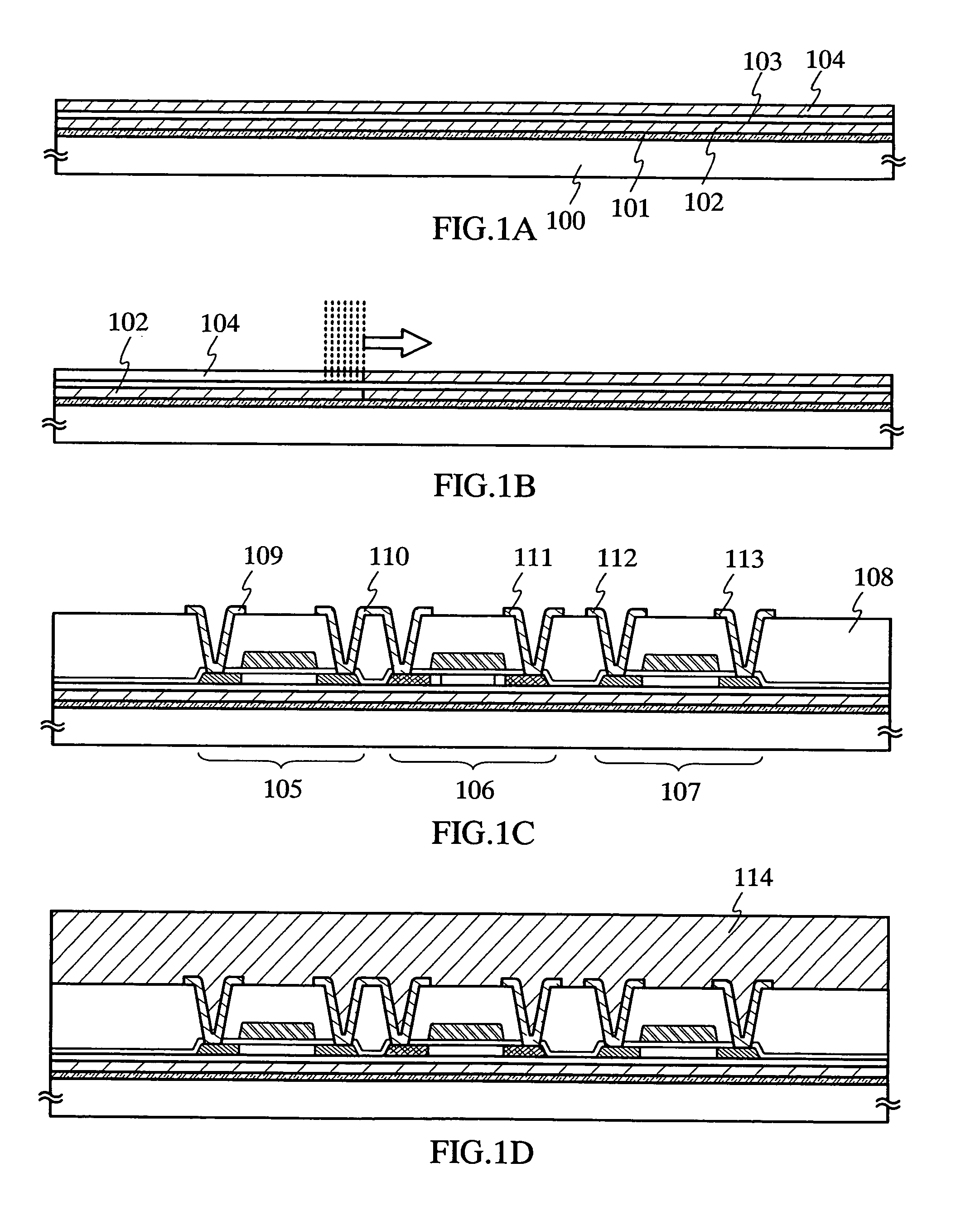

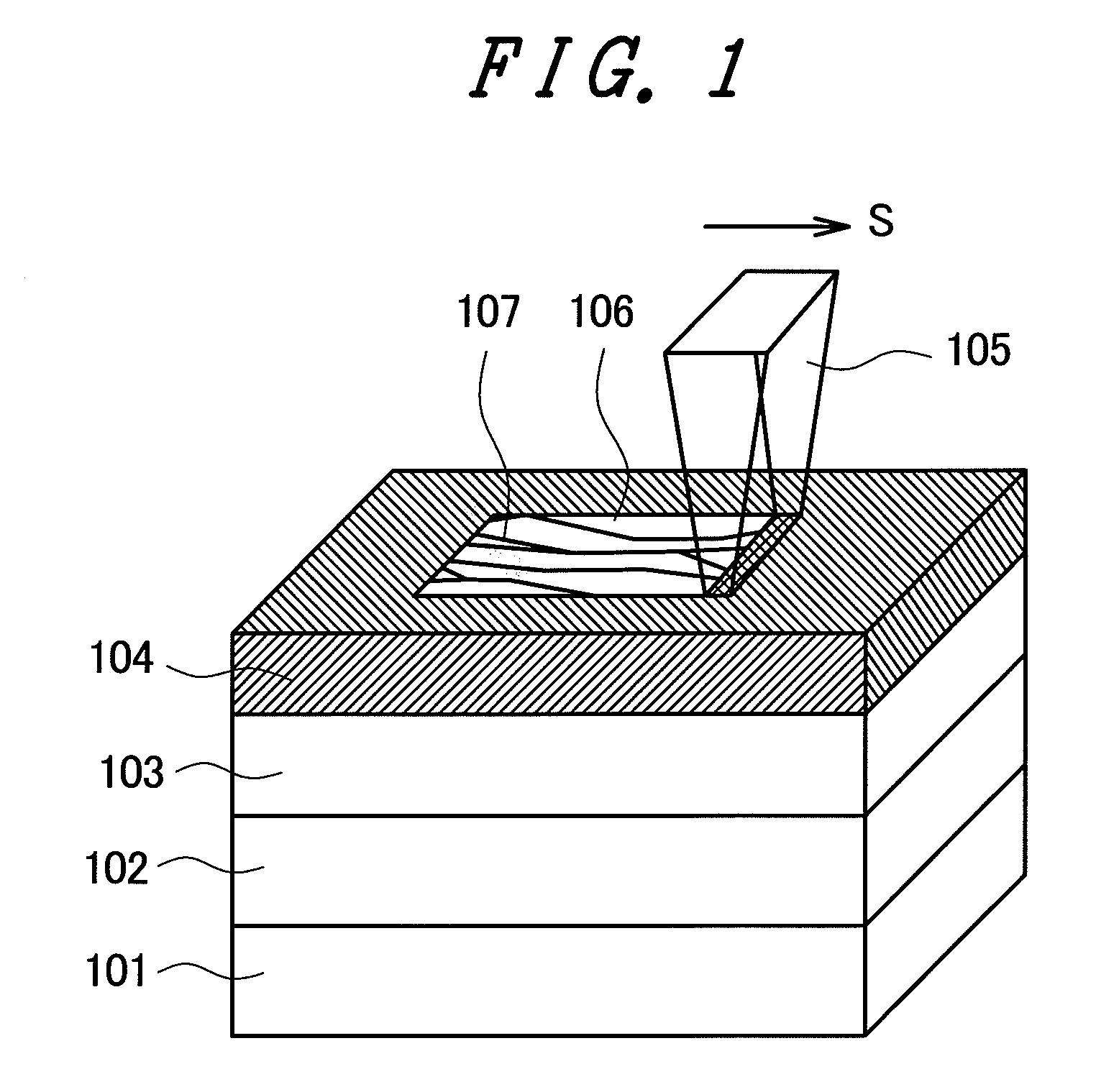

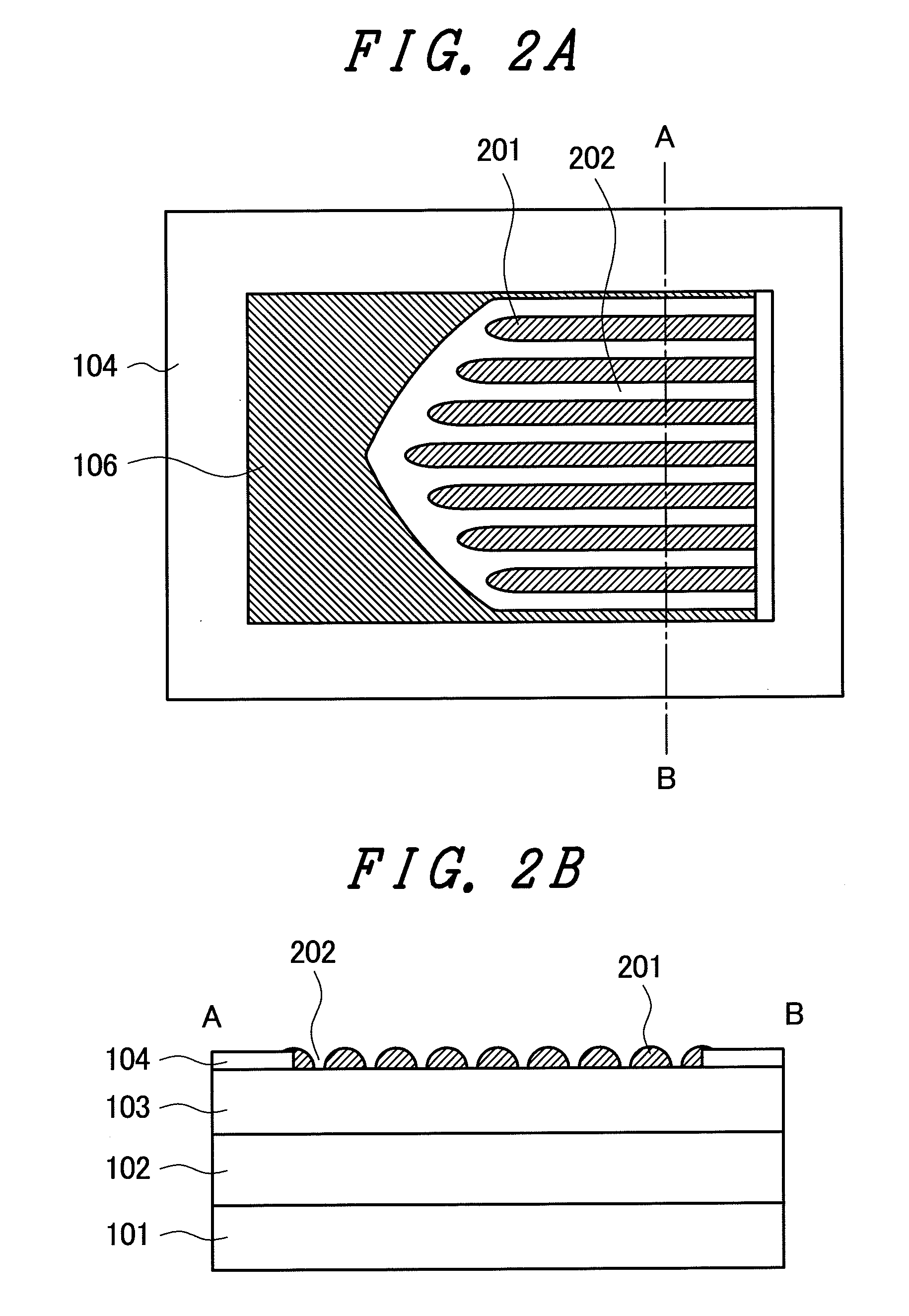

Laser irradiation apparatus, laser irradiation method and method for manufacturing semiconductor device

InactiveUS20050115930A1Decrease proportionFacilitate maintenanceLaser detailsSemiconductor/solid-state device manufacturingSingle crystalSemiconductor

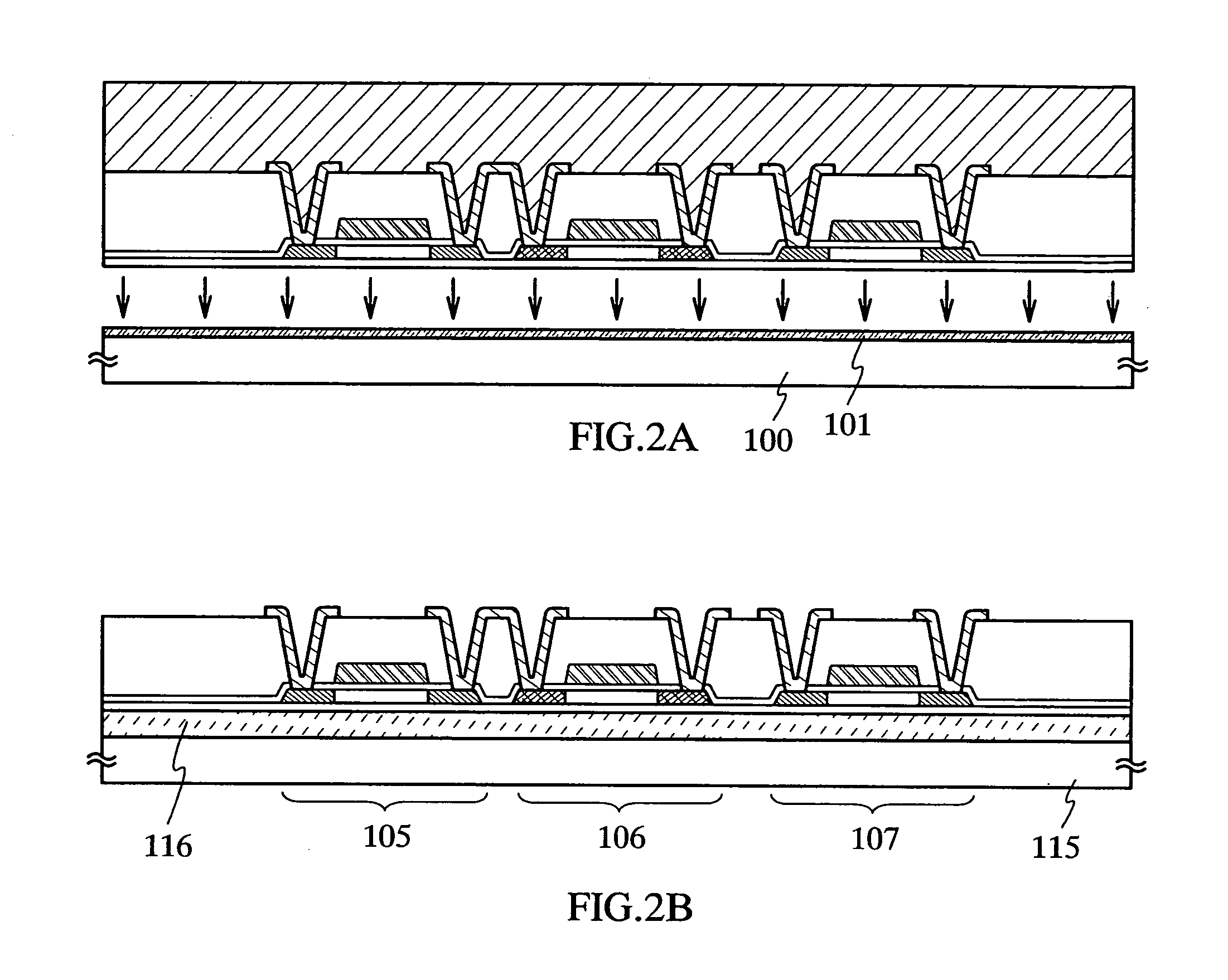

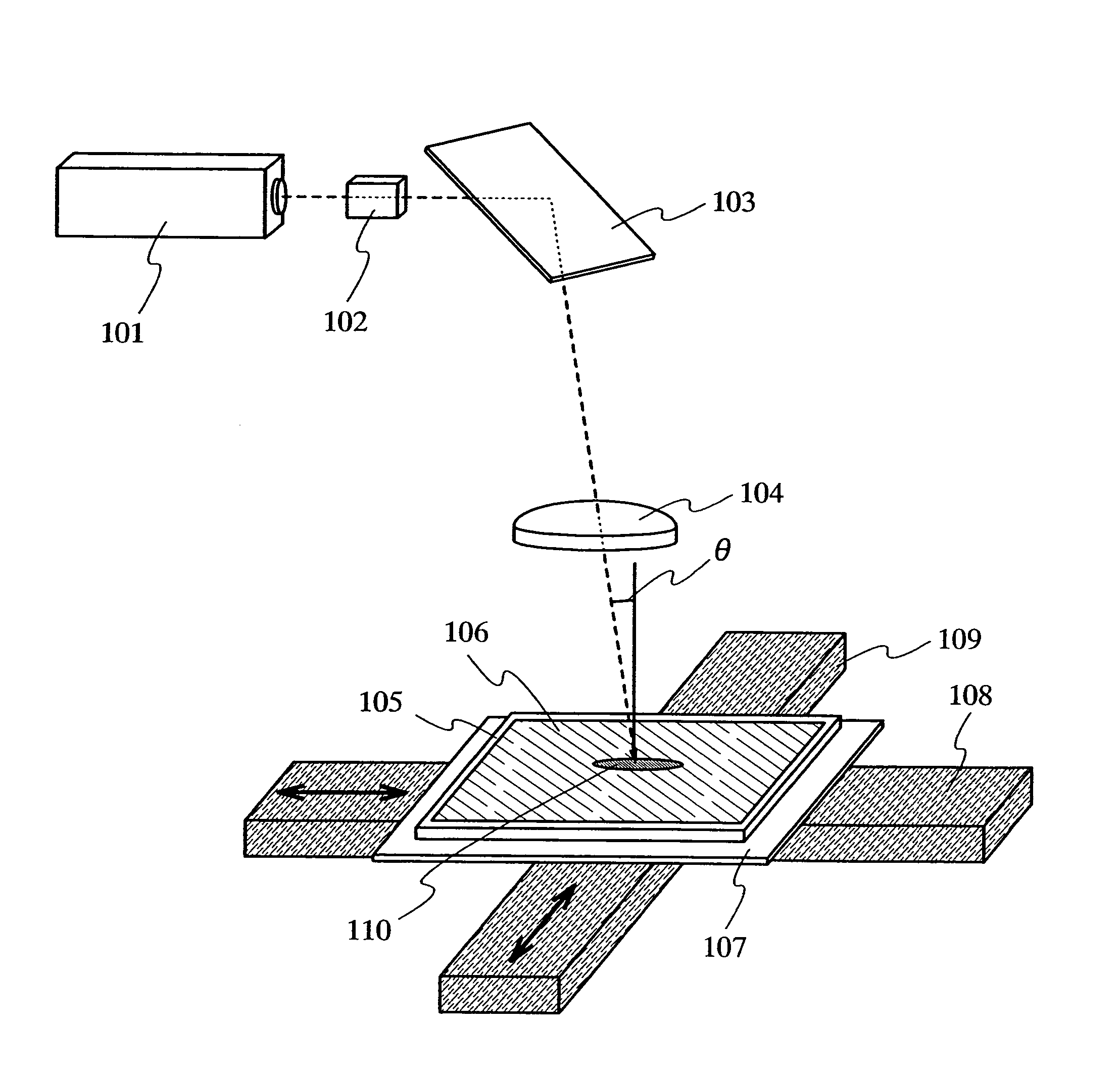

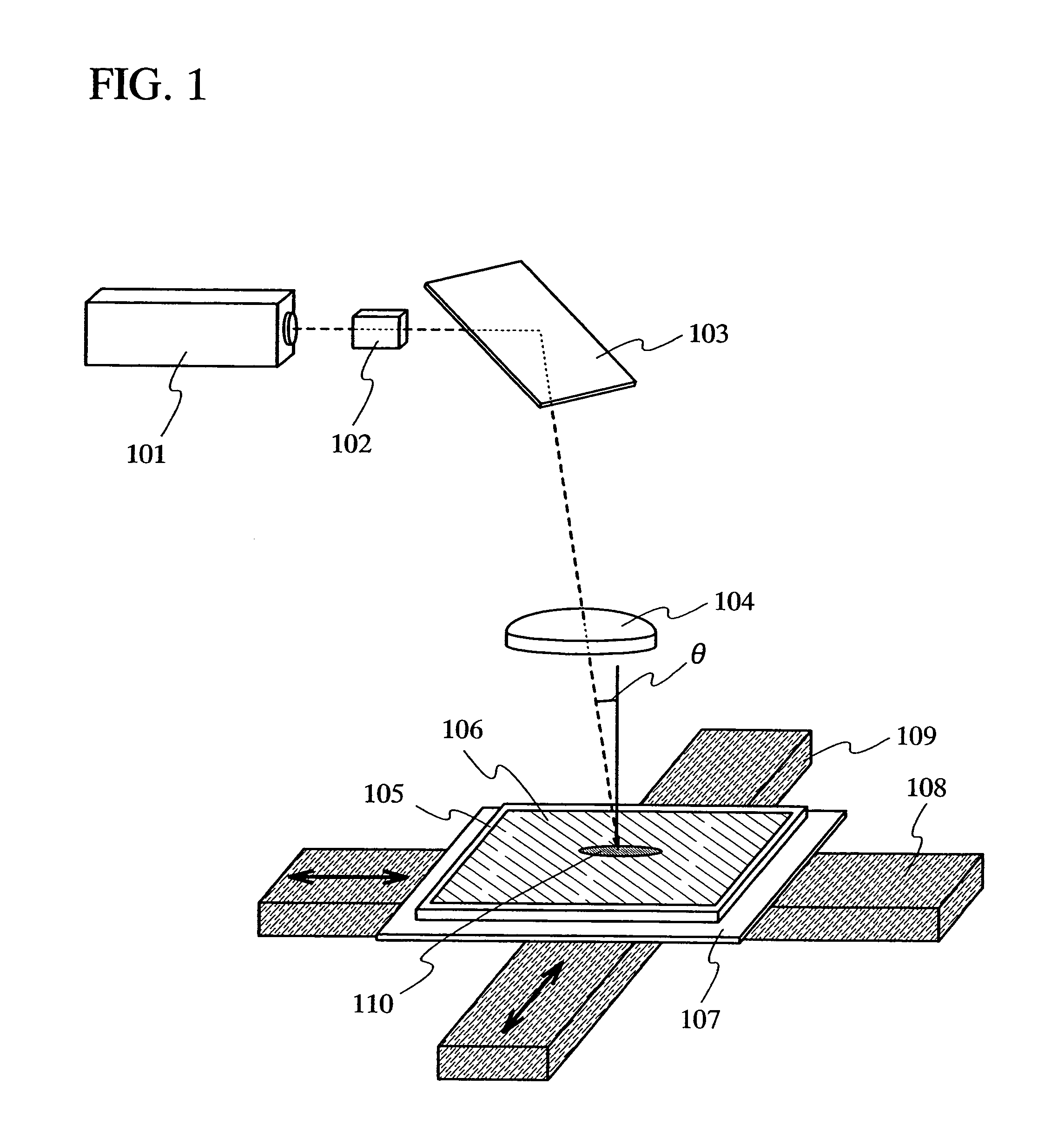

The object of the present invention is to provide a laser irradiation apparatus being able to enlarge the beam spot to a large degree compared with that of the CW laser, to suppress the thermal damage to the glass substrate, and to form an aggregation of crystal grains including a single crystal extending long in a scanning direction by growing the crystal continuously in the scanning direction. The laser irradiation of the present invention comprises a pulsed laser oscillator, a non-linear optical element for converting the wavelength of the laser light emitted from the pulsed laser oscillator, and an optical system for condensing the laser light whose wavelength is converted on a semiconductor film, wherein the pulsed laser oscillator has a repetition rate in the range of 10 MHz to 100 GHz.

Owner:SEMICON ENERGY LAB CO LTD

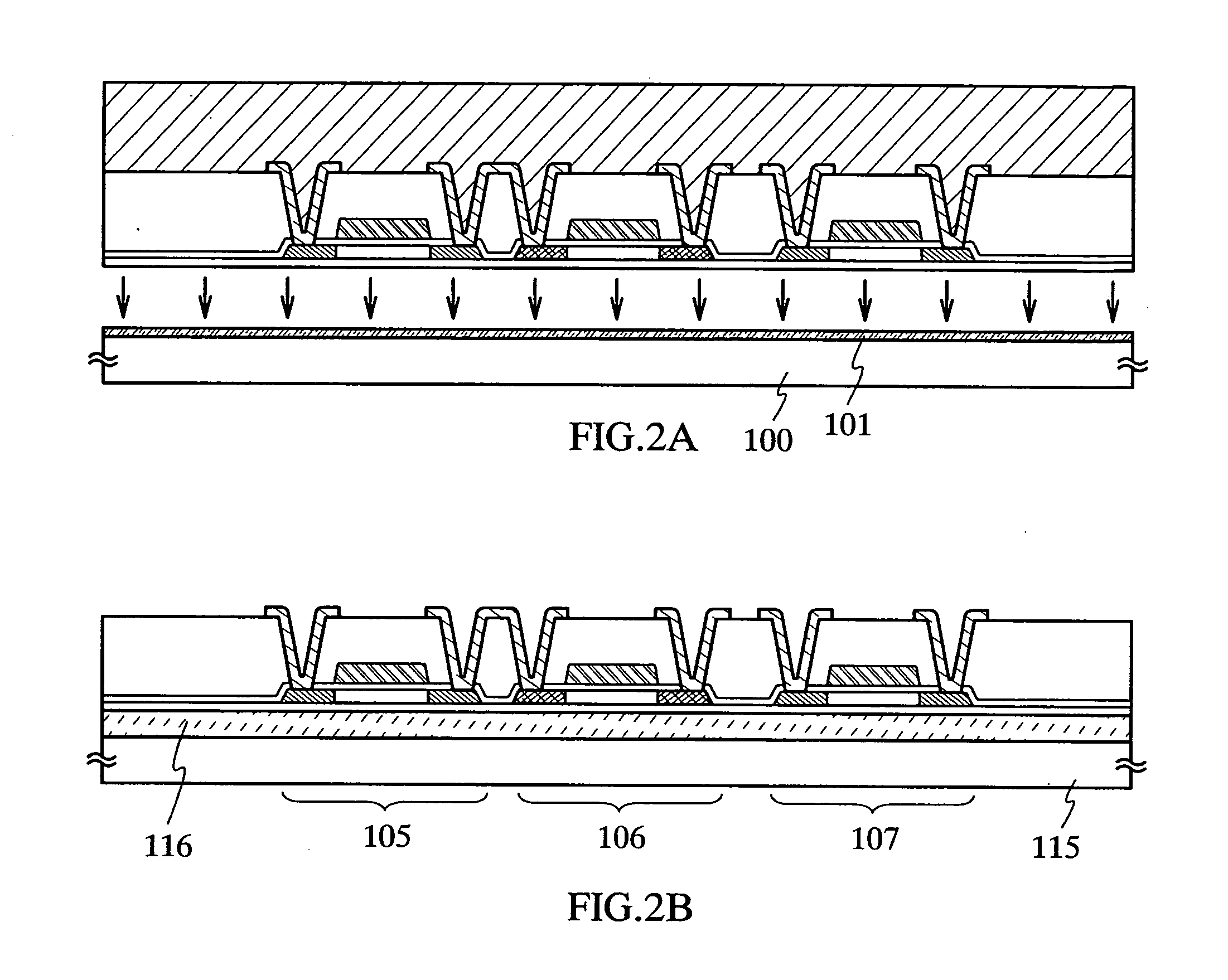

Method for manufacturing semiconductor device

InactiveUS20050214984A1Quick peelLower the volumeSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialThermal expansion

It is an object of the present invention to provide a method for manufacturing a semiconductor device, capable of keeping a peeling layer from being peeled from a substrate in the phase before the completion of a semiconductor element and peeling a semiconductor element rapidly. It is considered that a peeling layer tends to be peeled from a substrate because the stress is applied to a peeling layer due to the difference in thermal expansion coefficient between a substrate and a peeling layer, or because the volume of a peeling layer is reduced and thus the stress is applied thereto by crystallization of the peeling layer due to heat treatment. Therefore, according to one feature of the invention, the adhesion of a substrate and a peeling layer is enhanced by forming an insulating film (buffer film) for relieving the stress on the peeling layer between the substrate and the peeling layer before forming the peeling layer over the substrate.

Owner:SEMICON ENERGY LAB CO LTD

Method for manufacturing semiconductor device

InactiveUS7282380B2Quick peelLower the volumeSolid-state devicesSemiconductor/solid-state device manufacturingThermal expansionOptoelectronics

It is an object of the present invention to provide a method for manufacturing a semiconductor device, capable of keeping a peeling layer from being peeled from a substrate in the phase before the completion of a semiconductor element and peeling a semiconductor element rapidly. It is considered that a peeling layer tends to be peeled from a substrate because the stress is applied to a peeling layer due to the difference in thermal expansion coefficient between a substrate and a peeling layer, or because the volume of a peeling layer is reduced and thus the stress is applied thereto by crystallization of the peeling layer due to heat treatment. Therefore, according to one feature of the invention, the adhesion of a substrate and a peeling layer is enhanced by forming an insulating film (buffer film) for relieving the stress on the peeling layer between the substrate and the peeling layer before forming the peeling layer over the substrate.

Owner:SEMICON ENERGY LAB CO LTD

Laser irradiation apparatus, laser irradiation method and method for manufacturing semiconductor device

InactiveUS7551655B2Avoid thermal damageInhibit deteriorationLaser detailsSemiconductor/solid-state device manufacturingDevice materialLaser light

Owner:SEMICON ENERGY LAB CO LTD

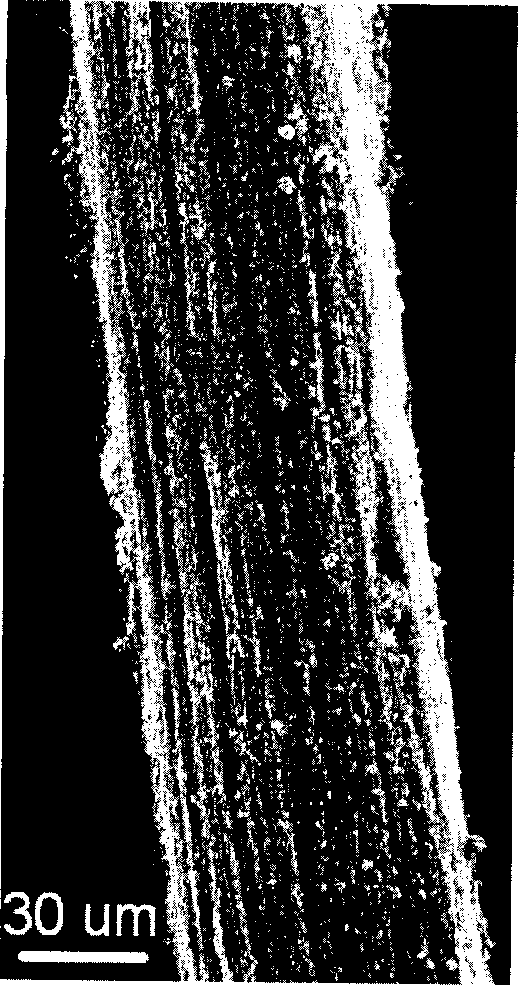

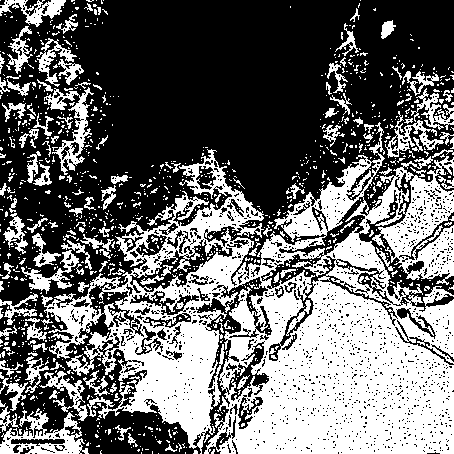

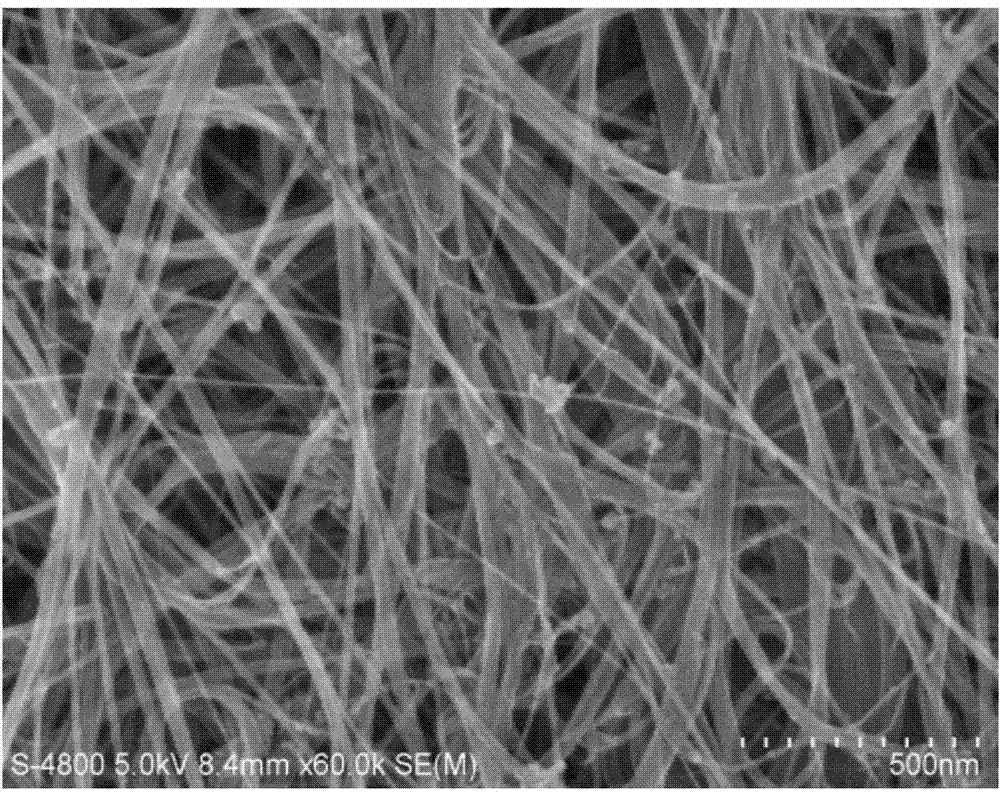

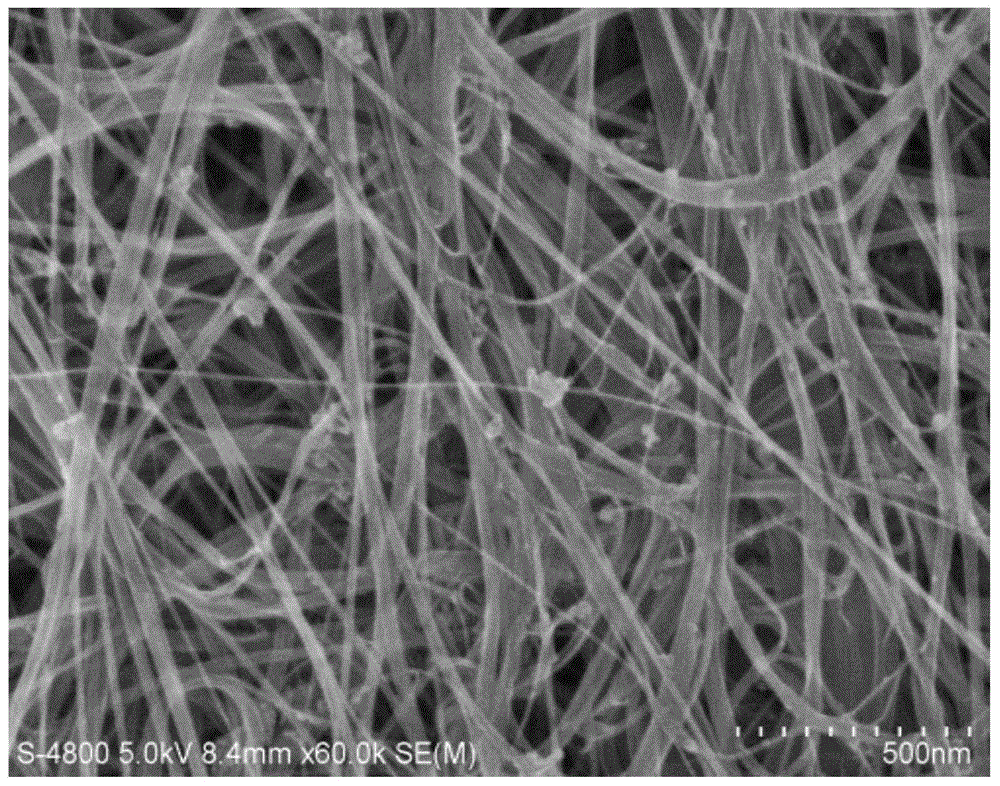

Process for directly synthesizing ultra-long single-wall continuous nano carbon tube

InactiveCN1365946AContinuous growthGrow straightMaterial nanotechnologyPolycrystalline material growthHydrogenFerrocene

A technological process for preparing ultra-long single-wall continuous nanometre carbon tubes by the vertical floating catalytic cracking method includes such steps as preparing reaction solution from n-hexane as carbon source, ferrocene as catalyst and thiophene as additive, introducing it in the form of vapour along with hydrogen gas into a reactor for catalytic cracking. Under specific technological parameters, ultra-long cord-shape single-wall nm carbon tube bundle can be obtained, the tubes have good orientation, their purity up to 85%, they are continuous and straight with length up to20 cm (length to diameter ratio greater than 108). The said method only needs one vertical electric furnace and no need of pre-reduction. Its advantages include good orientation performance, high purity, long length, simple operation and low cost.

Owner:TSINGHUA UNIV

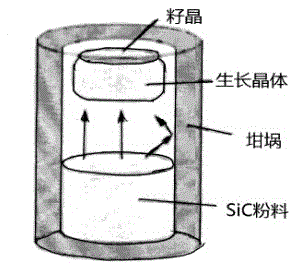

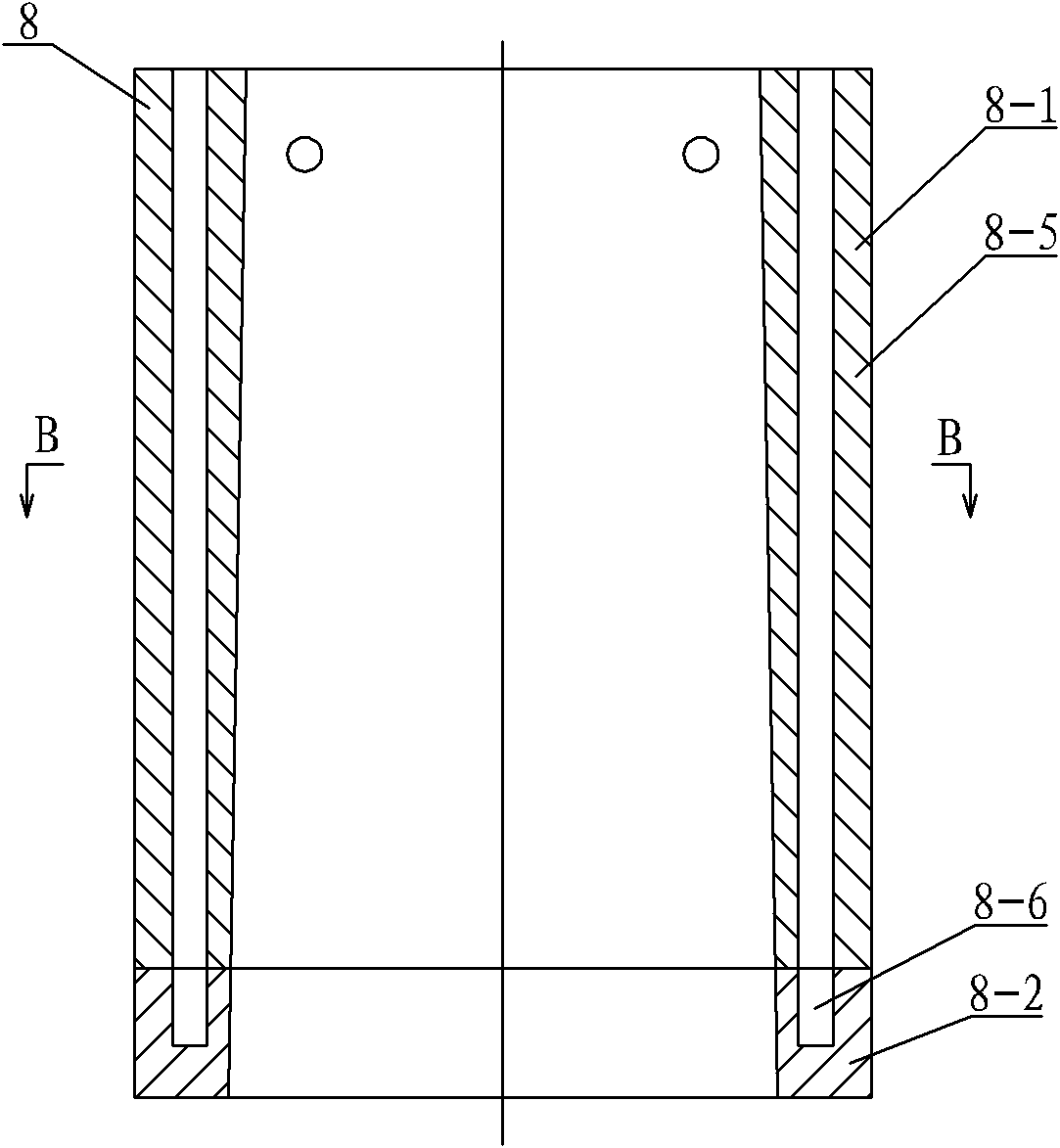

Continuous crystal growing method of silicon carbide single crystals

ActiveCN109234798AAchieve growthSingle crystal defect reductionPolycrystalline material growthFrom condensed vaporsPower qualitySilanes

The invention discloses a continuous crystal growing method of silicon carbide single crystals. The method is characterized in that silicon carbide single crystals are produced by using high-purity silicon carbide powder as raw materials by a physical vapor phase transporting method; in the silicon carbide single crystal production process, high-purity silane and carbon particles generating carbonization in high-purity silicon carbide powder react; high-purity silicon carbide powder is formed again to continuously supplement raw materials; the continuous growth of the silicon carbide single crystals is realized. In addition, the method is proceeded by using a crucible with double layer cavity walls, wherein open holes are formed in the side wall of the double layer cavity walls; the bottomcorner part of the cavity wall adopts circular arc design. The method has the important effects in the aspects of ensuring the continuous growth of large-size single crystals, inhibiting the siliconcarbide powder edge carbonization, improving the power quality, reducing the impurity content of the silicon carbide single crystals, improving the quantity of the silicon carbide single crystals andthe like.

Owner:SICC CO LTD

Rapid synthesis method of indium phosphide polycrystalline material and multi-tubular quartz phosphorus bubble thereof

InactiveCN102965734ASynthetic high purityContinuous growthPolycrystalline material growthSingle crystal growth detailsIndiumSynthesis methods

The invention discloses a rapid synthesis method of an indium phosphide polycrystalline material, which comprises the following steps of: (I) performing surface cleaning treatment on indium; (II) placing a multi-tubular quartz phosphorus bubble with phosphorus into a phosphorus source furnace; (III) placing the pre-designed thermal insulation system, heater, crucible with indium, phosphorus source furnace and seed crystal and B2O3 into a high-pressure single-crystal furnace hearth; (IV) vacuumizing the inside of the furnace and filling high-purity argon; (V) heating to vaporize phosphorus in the phosphorus bubble and injecting into indium melt, and reacting to generate indium phosphide; and (VI) growing crystal. The multi-tubular quartz phosphorus bubble comprises a quartz phosphorus container, at least two quartz phosphorus bubble tubes and a quartz cover. By adopting a multi-tubular quartz phosphorus bubble, the method disclosed by the invention realizes a rapid multi-tubular phosphorus injection synthesis technology, solves the problems of long synthesis time, non-uniform melt proportioning, impurity pollution and the like in the original technology, realizes rapid, efficient and high-purity synthesis of the indium phosphide material, and performs InP single crystal growth more easily.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

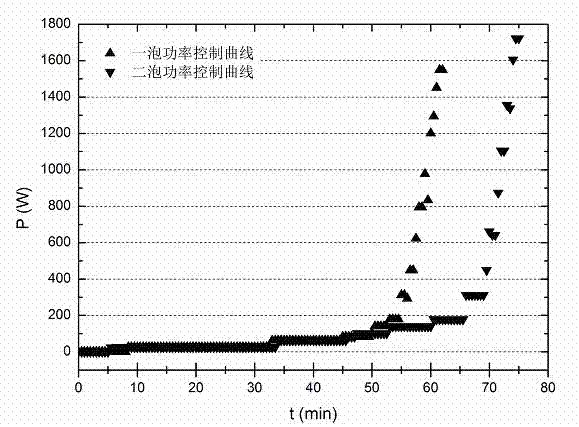

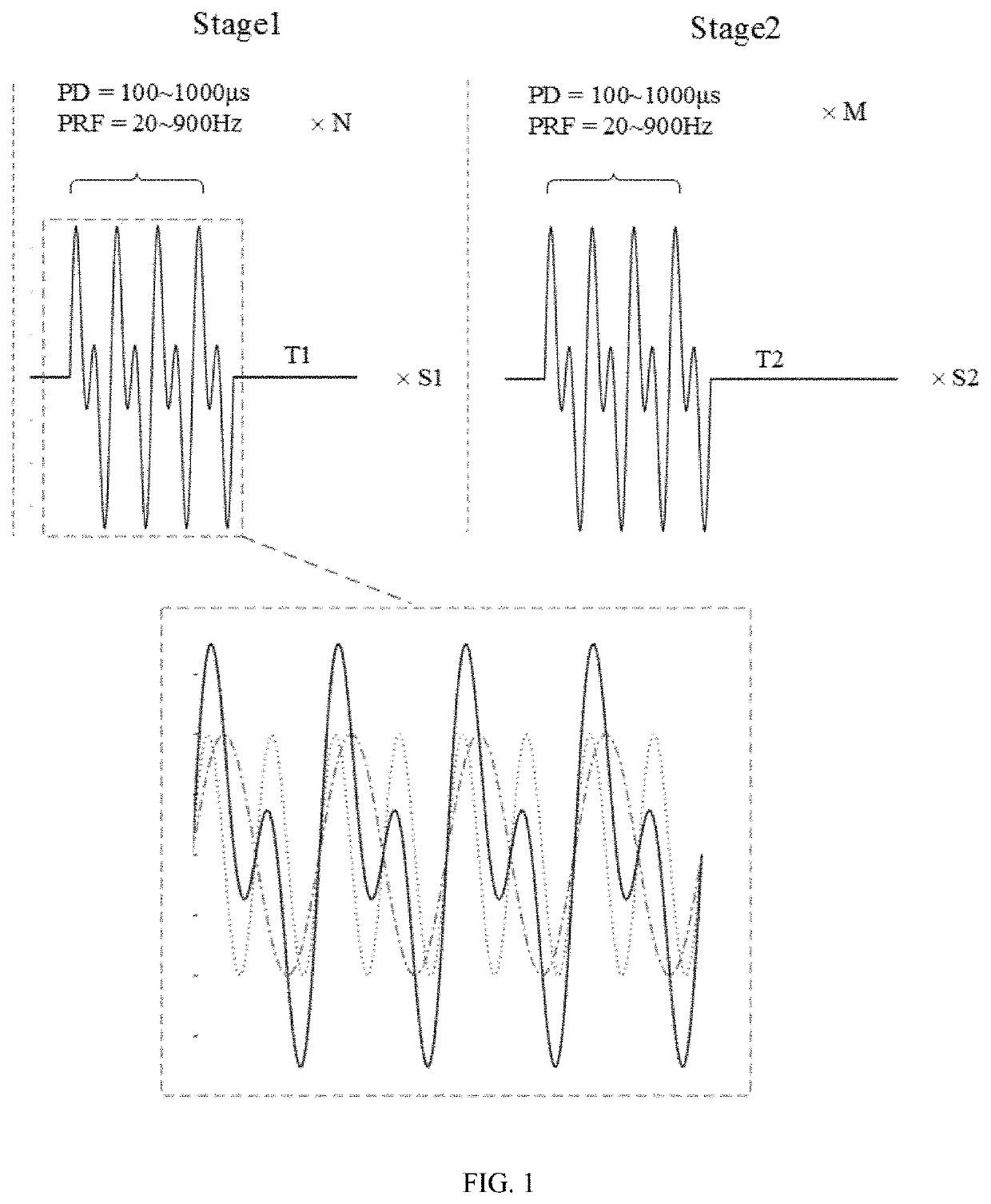

Method for controlling histotripsy using confocal fundamental and harmonic superposition combined with hundred-microsecond ultrasound pulses

ActiveUS10772646B2Preliminary homogenizationImprove treatment safetyUltrasound therapyDiagnosticsShock waveCavitation

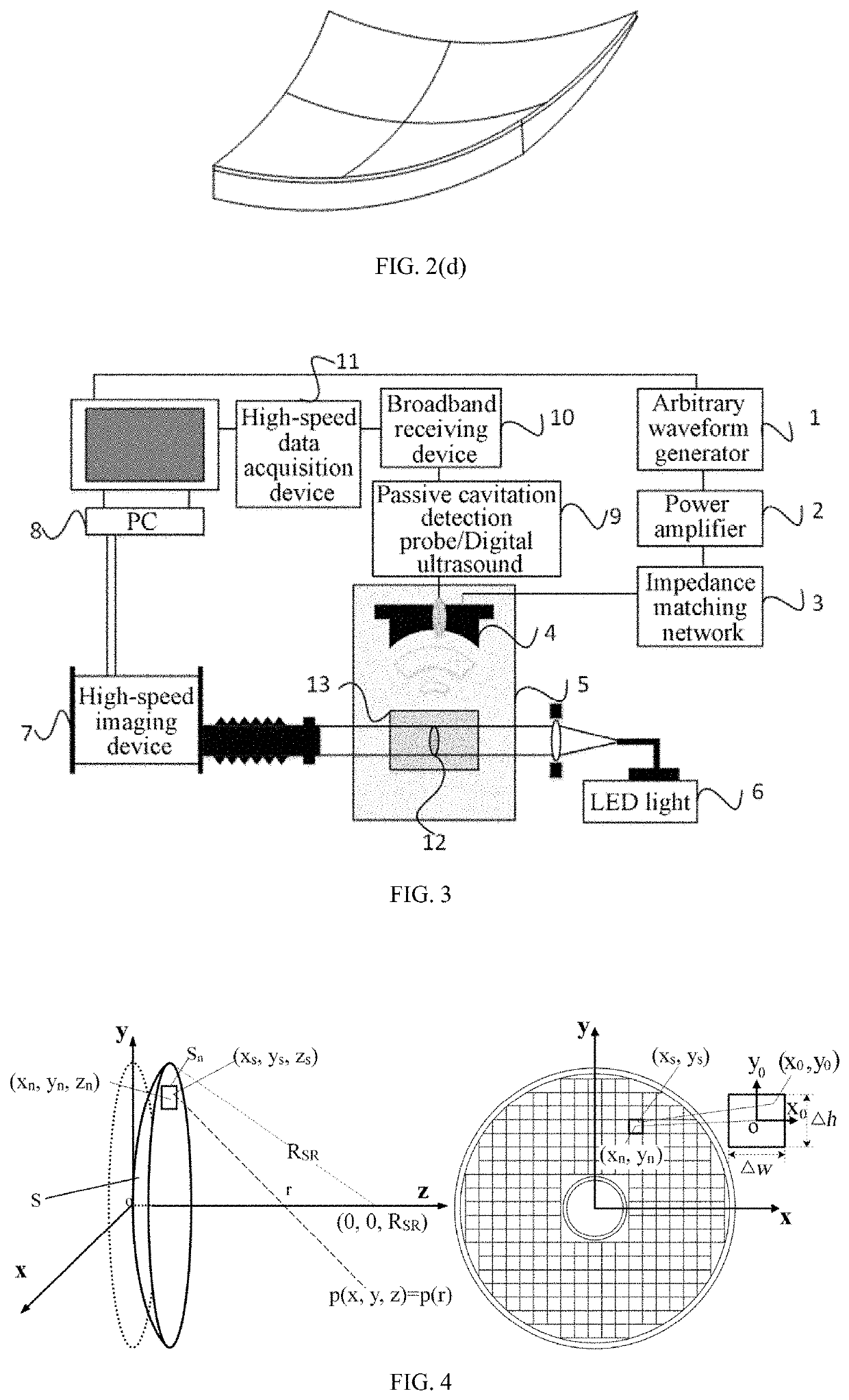

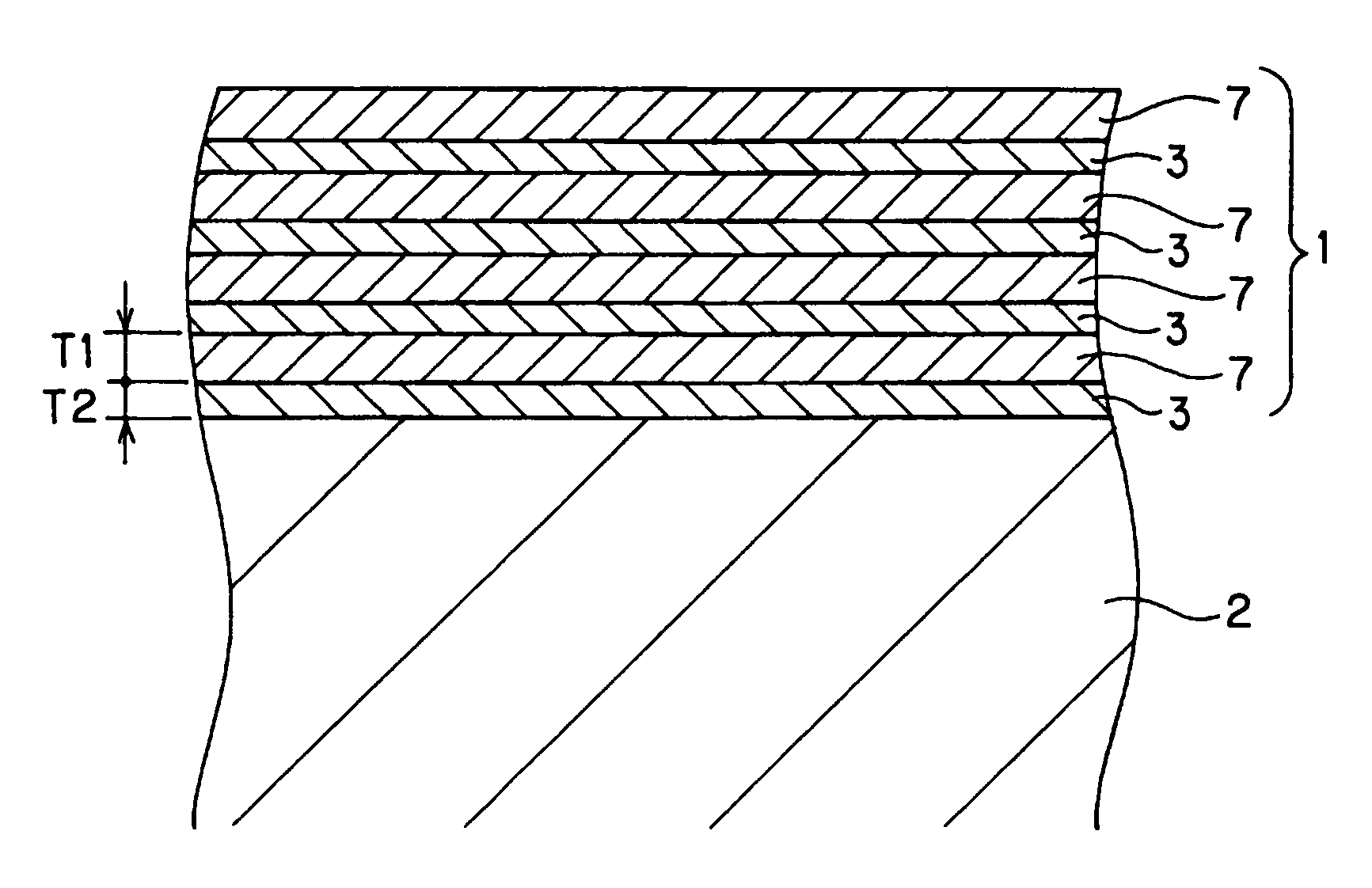

A method for controlling a histotripsy using a confocal fundamental and harmonic superposition combined with hundred-microsecond ultrasound pulses, including: 1) positioning a target tissue by a monitoring and guiding system and adjusting a position of the target tissue to a focal point of a transducer; 2) first stage: controlling the confocal fundamental and harmonic superposition combined with hundred-microsecond ultrasound pulses to form a shock wave in a focal zone; wherein a negative acoustic pressure exceeds a cavitation threshold; an inertial cavitation occurs to generate boiling bubbles; the boiling bubbles collapse and achieve partial homogenization of the target tissue; 3) second stage: controlling the confocal fundamental and harmonic superposition combined with hundred-microsecond pulsed-ultrasound sequences to simultaneously irradiate a target zone and further mechanically disintegrate and homogenize the target tissue.

Owner:XI AN JIAOTONG UNIV

High-frequency magnetic thin film, composite magnetic thin film, and magnetic device using same

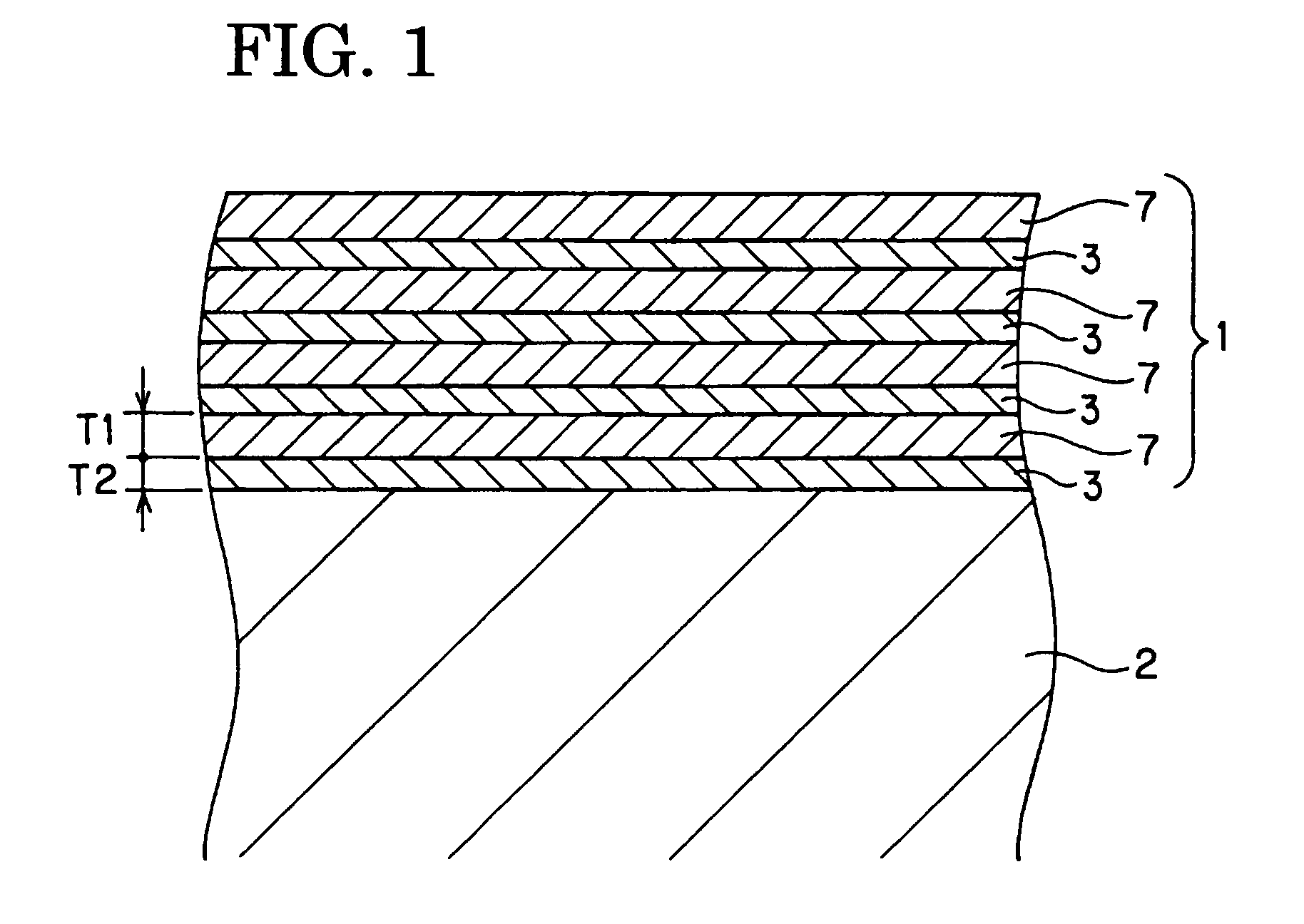

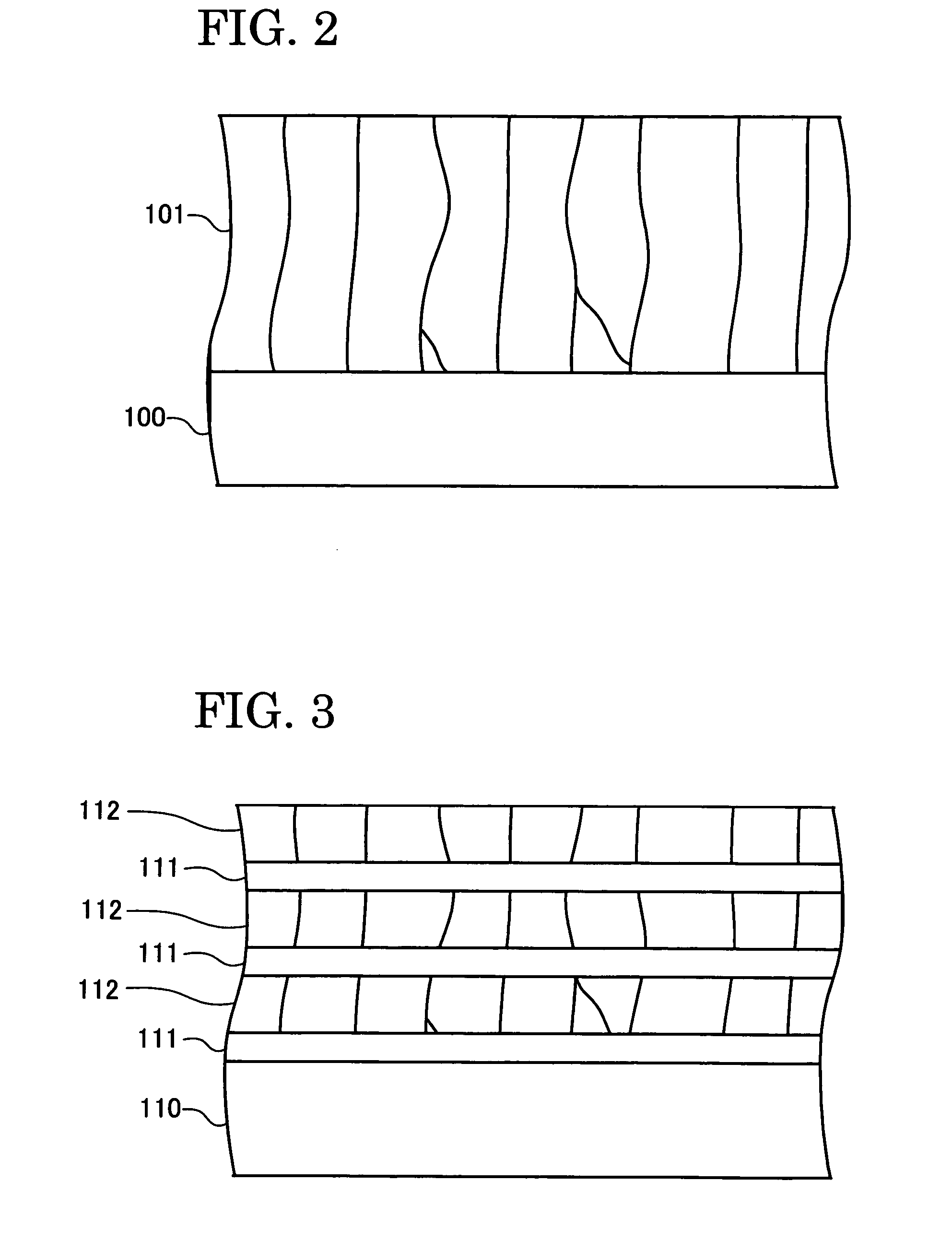

InactiveUS7224254B2Raise the resonance frequencyIncrease frequencyNanomagnetismTransformers/inductances coils/windings/connectionsMagnetizationAlloy

A high frequency magnetic thin film characterized by comprising a first layer made of a T-L composition (here, T is Fe or FeCo, and L is one or more of C, B, and N) and a second layer comprising a Co-based amorphous alloy arranged on either of the surfaces of the first layer. The high frequency magnetic thin film is a multilayer film of a plurality of the first layers and a plurality of the second layers or desirably is a multilayer film of alternately laminated first and second layers. The high frequency magnetic thin film of the present invention exhibits the properties such that the real part (μ′) of the complex permeability is 400 or more at 1 GHz, a quality factor Q (Q=μ′ / μ″) is 4 or more, and a saturation magnetization is 14 kG (1.4T) or more.

Owner:TDK CORPARATION

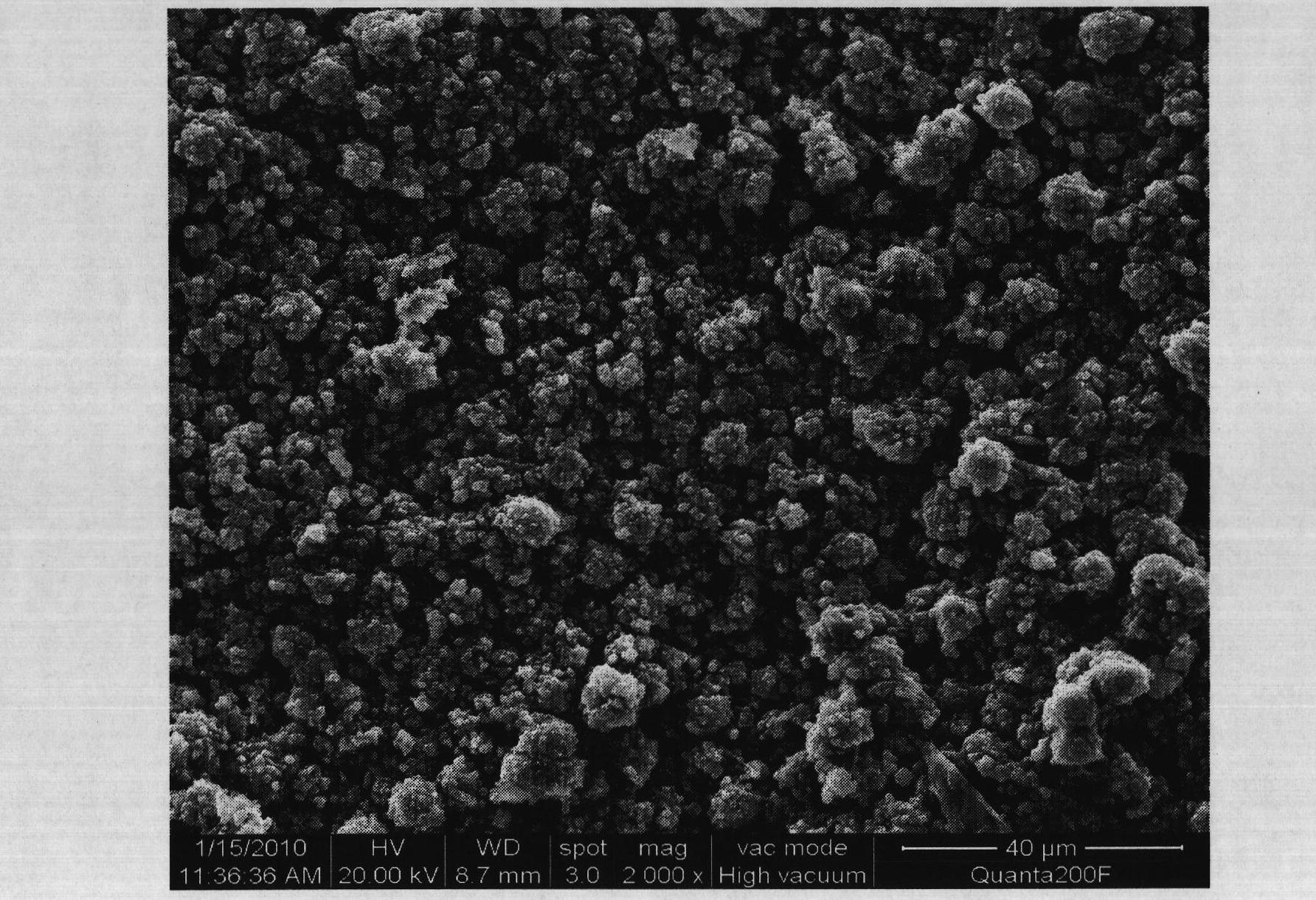

Preparation method for carbon composite refractory and product prepared by preparation method

The invention discloses a preparation method for carbon composite refractory. The preparation method comprises the following steps of: firstly, preparing an active matter precursor into solution, adding oxide in the solution and mixing, and drying, dispersing and roasting the mixture to obtain an active matter-oxide composite material; secondly, catalyzing carbon source gas or mixed gas of the carbon source gas and hydrogen gas by using the activated active matter-oxide composite material, and performing cracking reaction to obtain an oxide-carbon nanotube composite material; thirdly, impregnating the oxide-carbon nanotube composite material in ethanol solution to form a preimpregnation body; fourthly, mixing at least one of oxide micro powder, carbon black and graphite with an antioxidant to form a premixing body; and fifthly, sequentially adding a binding agent, the preimpregnation body and the premixing body in base stock and aging, forming and drying to obtain the carbon composite refractory. Carbon nanotubes in the prepared refractory are uniform in distribution and are strongly combined with a refractory raw material; and the prepared refractory is suitable for high-temperature environment in the metallurgical steelmaking industry.

Owner:PUYANG REFRACTORIES GRP CO LTD

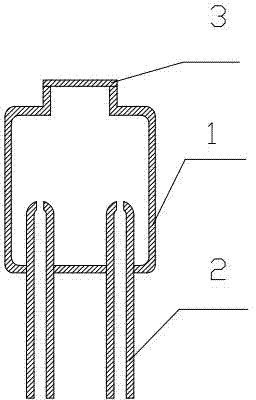

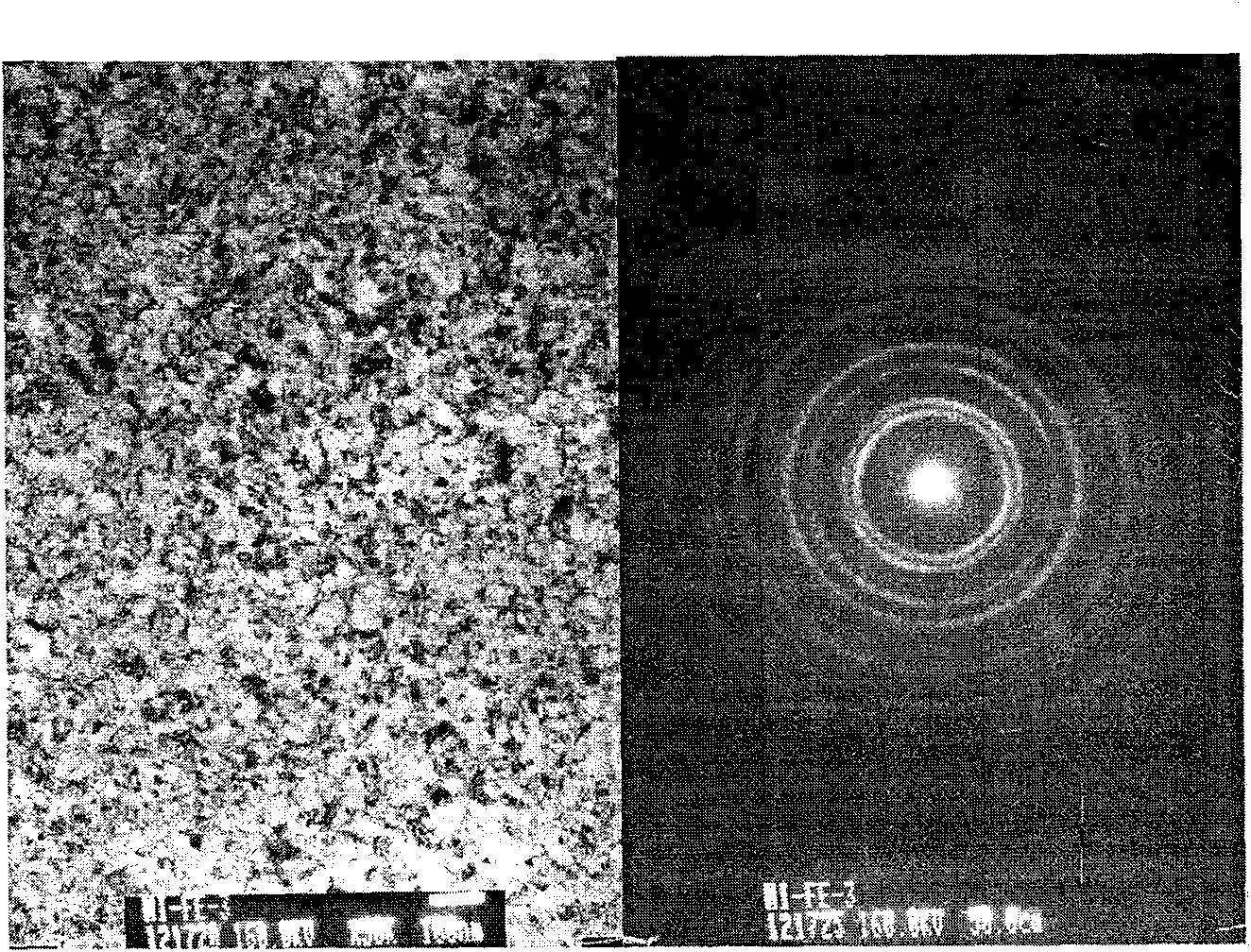

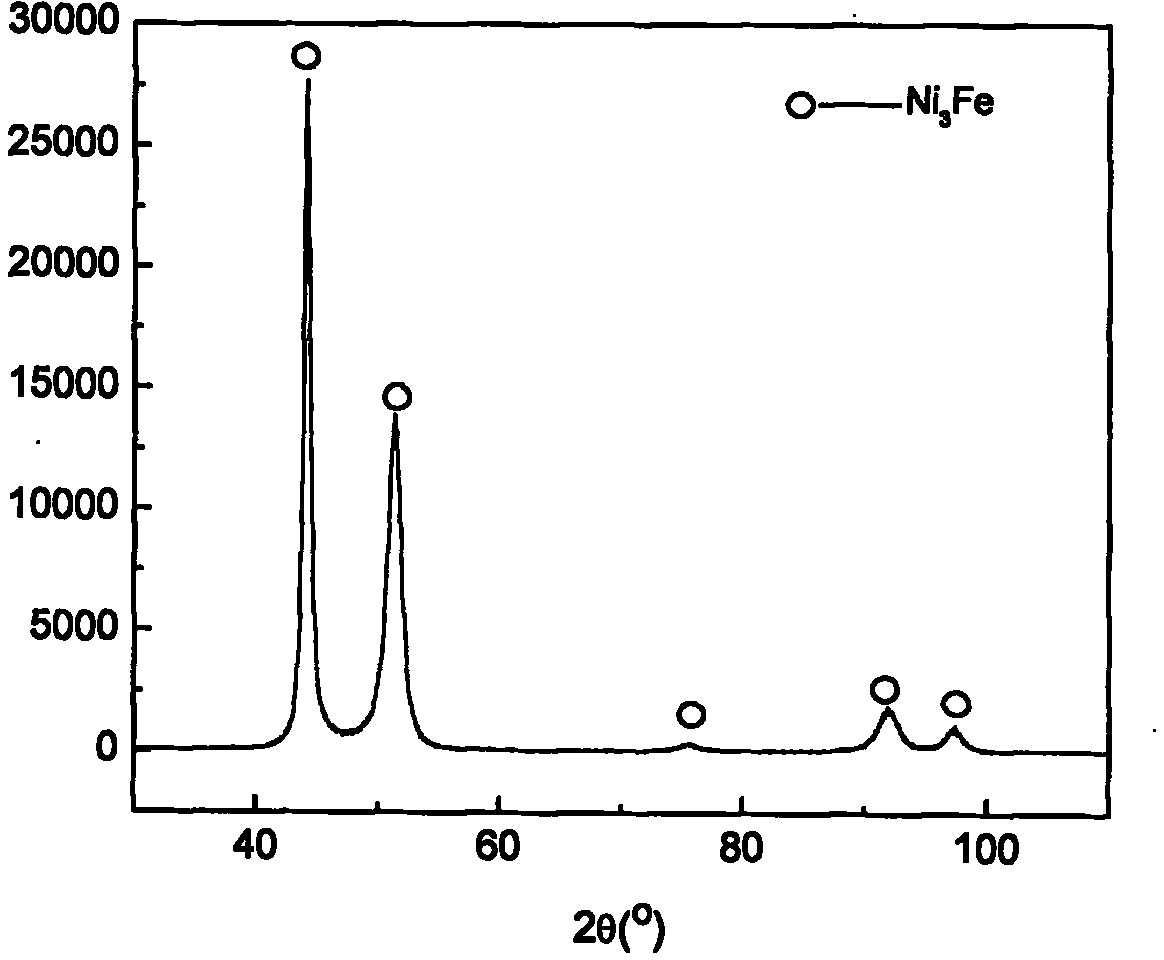

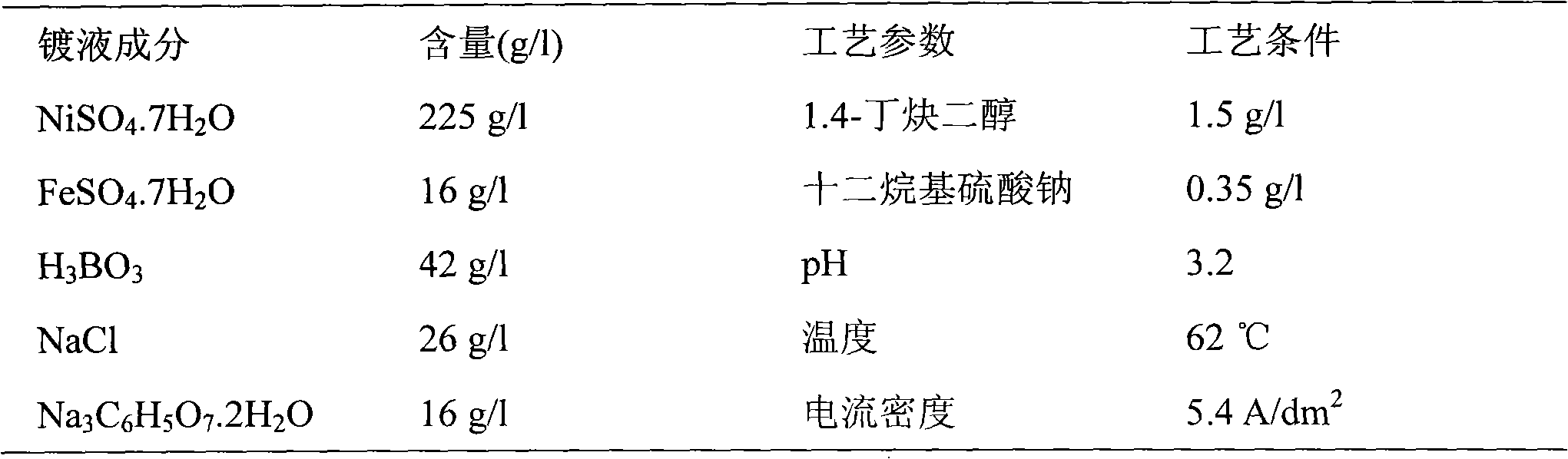

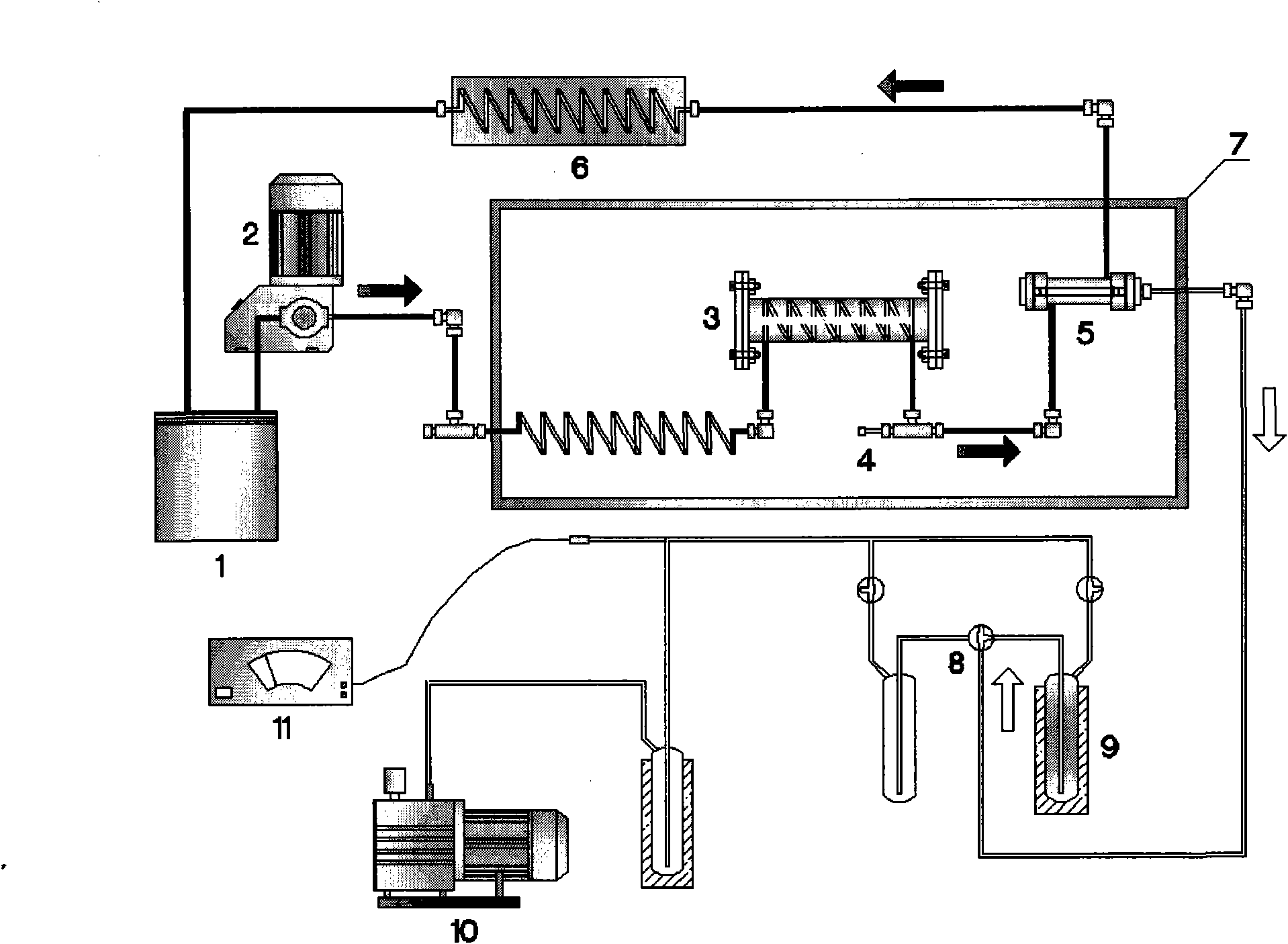

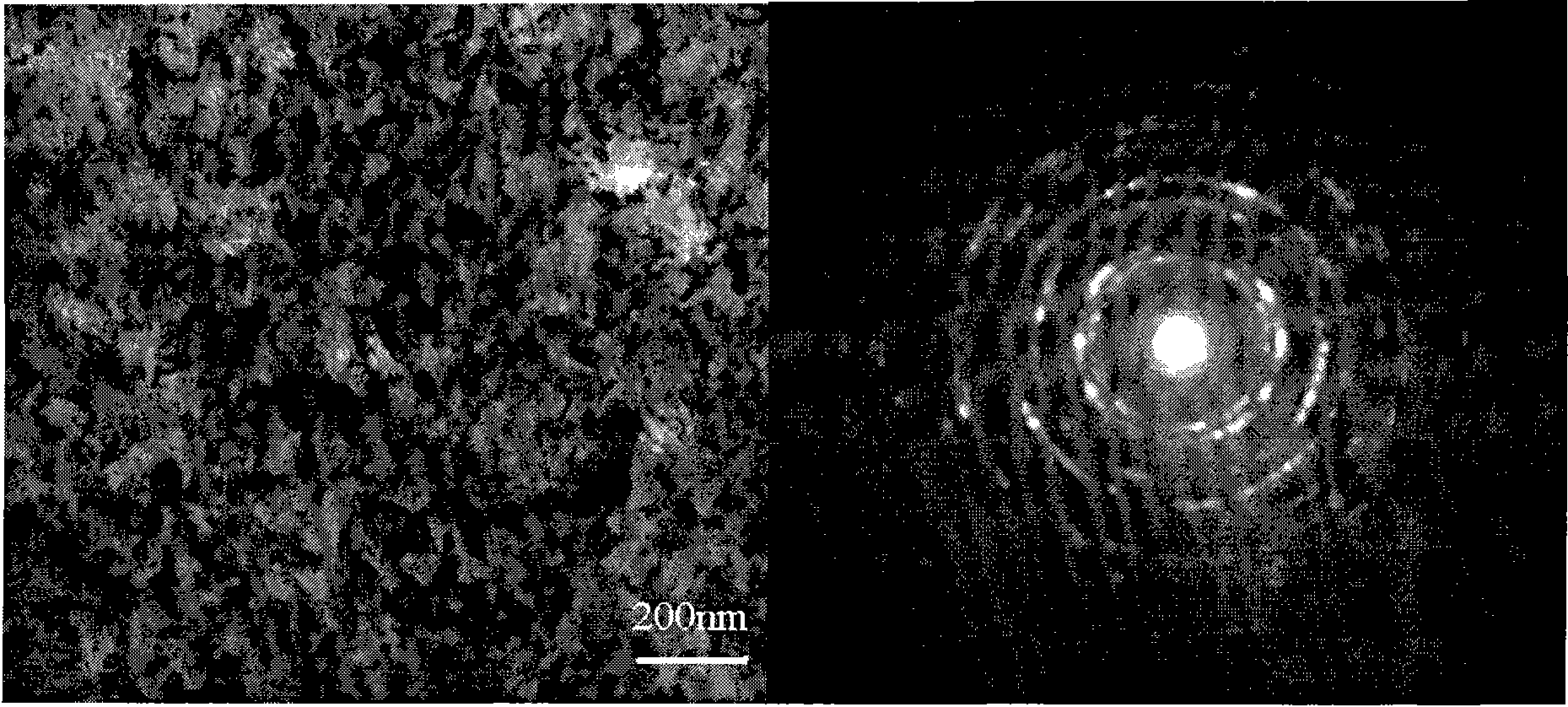

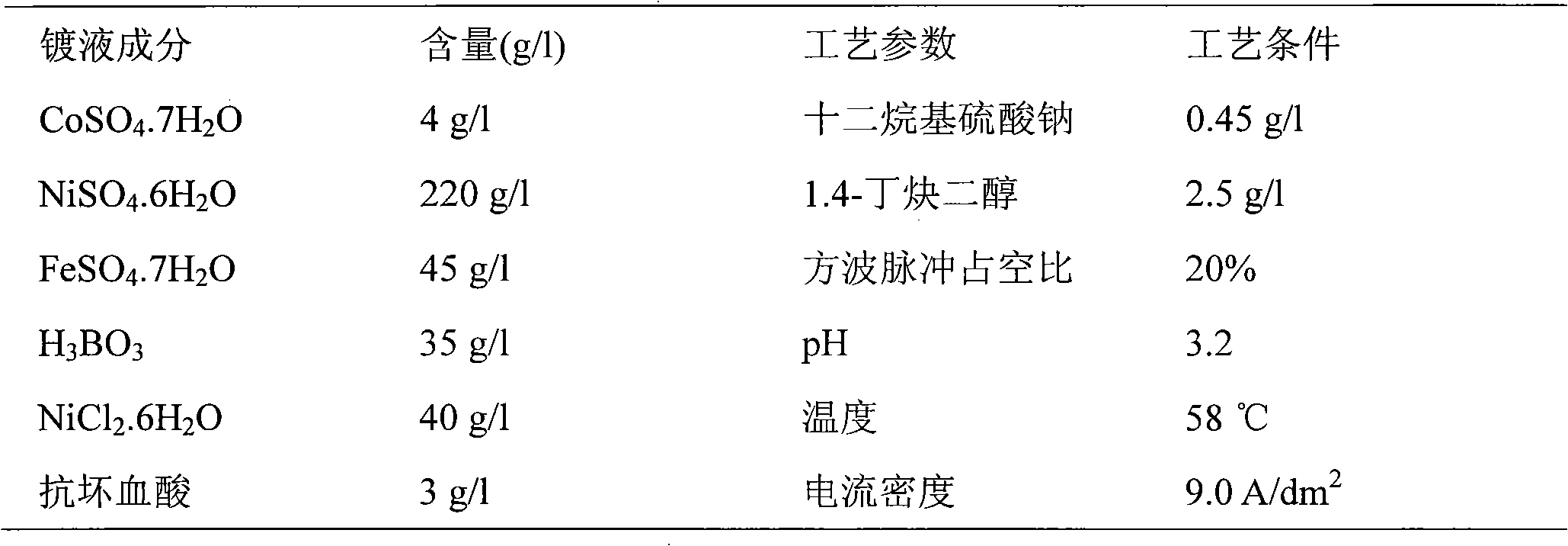

Electro-deposition method for preparing bulk nano ferro-nickel alloy crystalline

InactiveCN102115898ACrystal fine and denseReduce pollutionTemperature controlHydrogen-Ion Concentrations

The invention provides an electro-deposition method for preparing bulk nano-crystalline ferro-nickel alloy. Electro-deposition equipment capable of circularly filtering, stirring, temperature control and cathode movement is adopted; 1g / l to 3g / l of additive A and 0.25g / l to 0.75g / l of additive B are adopted; and the bulk nano ferro nickel alloy is acquired under the technological parameters that the electroplating solution temperature is 55 DEG C to 65 DEG C, the pH (hydrogen ion concentration) value is 3.2 to 3.8, and the cathode current density is 2A / dm2 to 8A / dm2. The invention has the characteristics of simple and easy-to-control technological process, steady product quality, small crystallite dimension, even structure, high purity, little environmental pollution, low production cost, and the like.

Owner:CHANGCHUN UNIV OF TECH

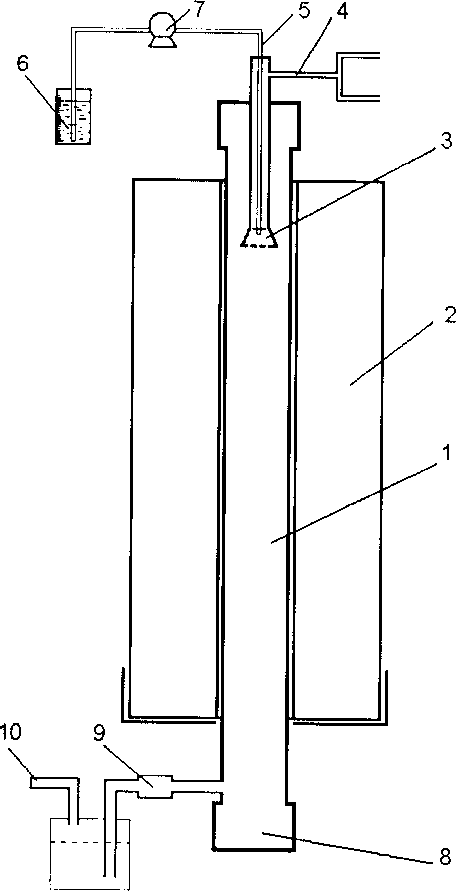

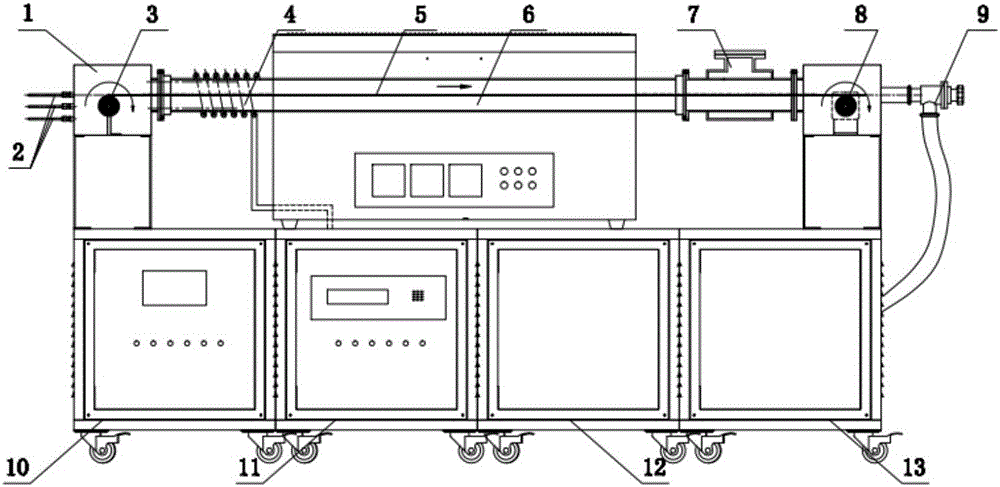

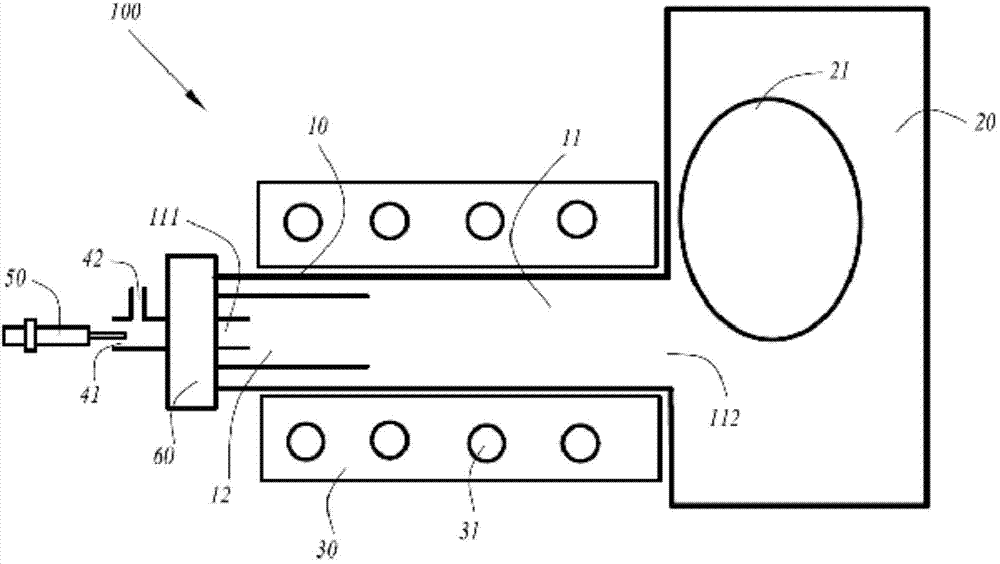

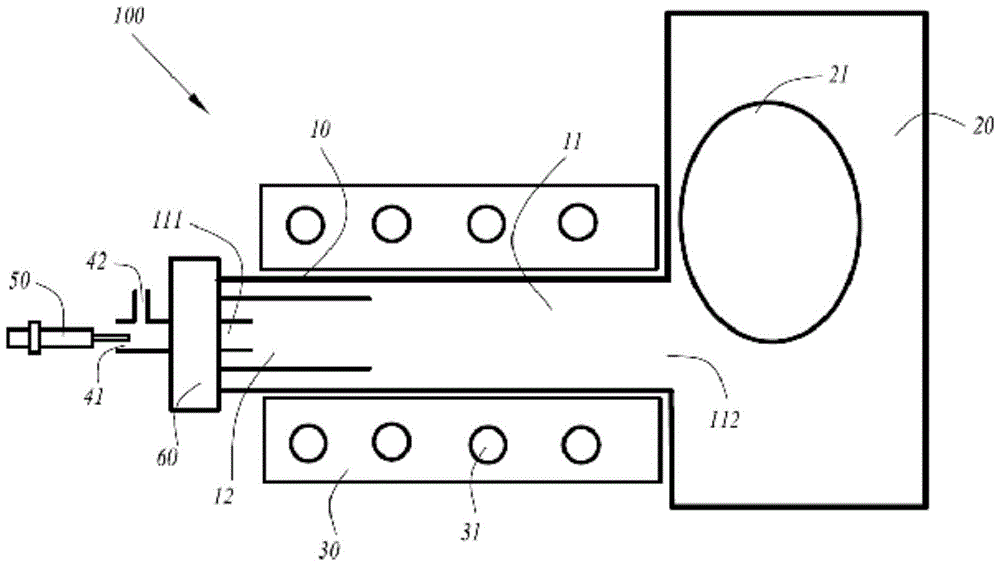

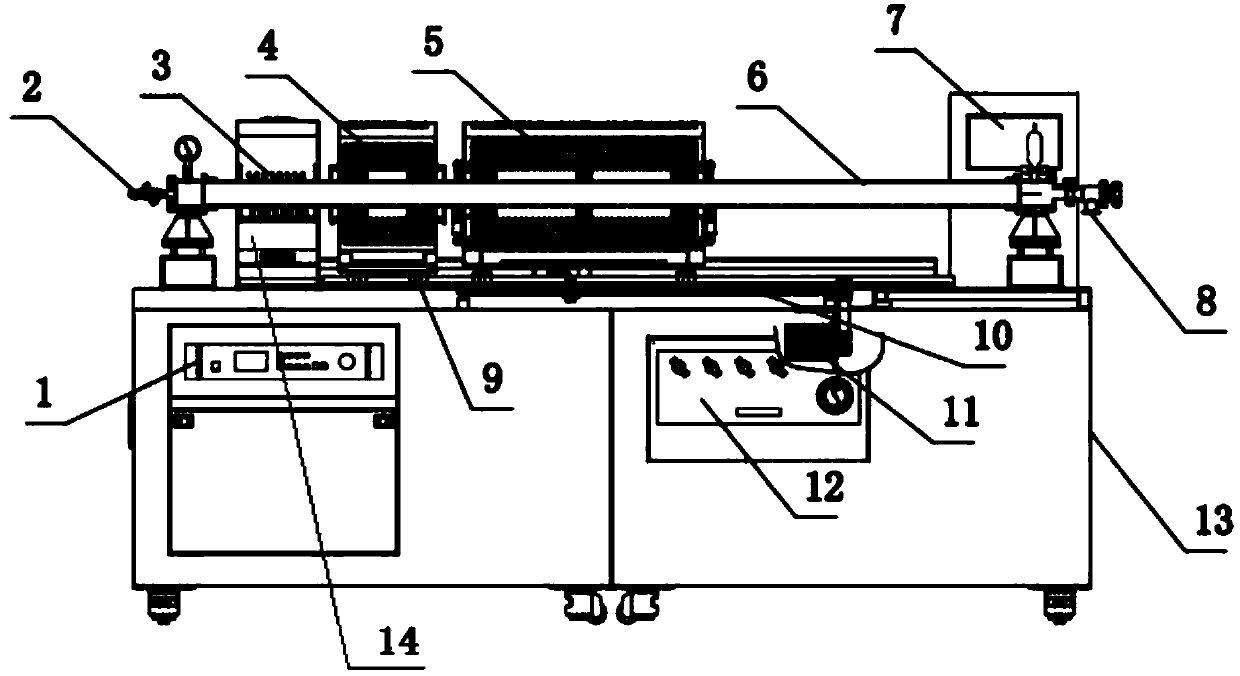

Fast cooling reel-to-reel plasma enhanced CVD (chemical vapor deposition) continuous growth furnace

InactiveCN104988471AContinuous growthQuality improvementChemical vapor deposition coatingCvd grapheneRadio frequency plasma

The invention discloses a fast cooling reel-to-reel plasma enhanced CVD (chemical vapor deposition) continuous growth furnace, and relates to the technical field of graphene growth CVD equipment. The fast cooling reel-to-reel plasma enhanced CVD continuous growth furnace comprises a CVD tubular furnace, wherein the two ends of a furnace pipe of the CVD tubular furnace are respectively provided with a feeding air inlet vacuum cavity and a discharging exhaust vacuum cavity; an unreeling roller and a reeling roller are respectively and correspondingly arranged in the vacuum cavities; a radio frequency plasma generator is arranged between the feeding air inlet cavity and the furnace body; a liquid nitrogen cold trap is arranged between the discharging exhaust cavity and the furnace body. The fast cooling reel-to-reel plasma enhanced CVD continuous growth furnace is used for preparing graphene. Compared with the prior art, the fast cooling reel-to-reel plasma enhanced CVD continuous growth furnace has the advantages of fast cooling and continuous growth. The large-area high-quality graphene scale growth can be realized.

Owner:ANHUI BEQ EQUIP TECH

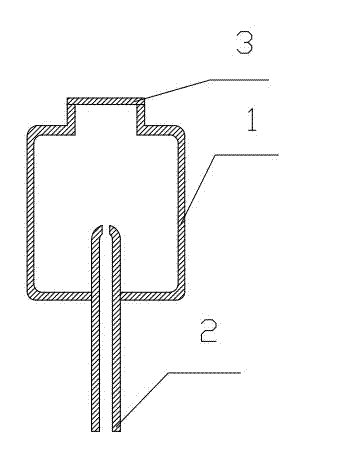

Device for growth of carbon nano-tube aerogel

ActiveCN104843666ASolving the disadvantages of growing carbon nanotubesContinuous growthMaterial nanotechnologyCarbon nanotubeReaction chamber

The present invention discloses a device for growth of a carbon nano-tube aerogel. The device comprises a main reaction cavity and a collection box, wherein the main reaction cavity is provided with an air inlet and an air outlet formed opposite to the air inlet; the collection box is communicated with the main reaction cavity; at least one secondary reaction cavity communicated with the main reaction cavity is sleeved in the main reaction cavity, the secondary reaction cavities are formed close to the air inlet of the main reaction cavity, and the length of each of the secondary reaction cavities in the axial direction of the main reaction cavity is less than that of the main reaction cavity. Compared with the prior art, the defect that a single reaction cavity is taken as a reaction chamber for the growth of the carbon nano-tube is overcome by virtue of sleeving the secondary reaction cavities in the main reaction cavity, so that not only is continuous and uniform carbon nano-tube aerogel generated, but also the yield of the carbon nano-tube aerogel is greatly improved by enlarging the tube diameter of the reaction chamber. The production cost is saved, the production period is shortened, and the industrial production of the carbon nano-tube aerogel becomes probable.

Owner:SUZHOU CREATIVE CARBON NANOTECH

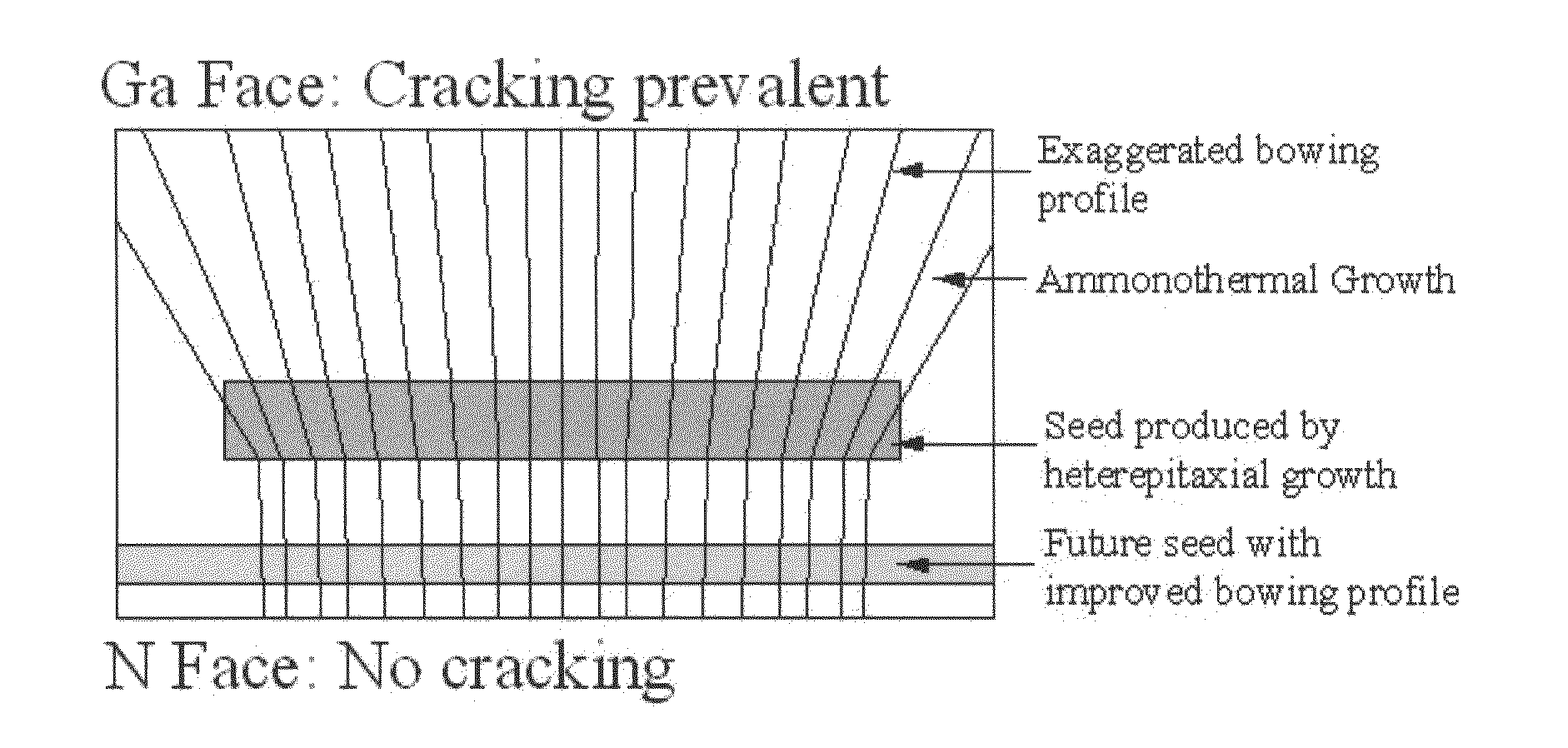

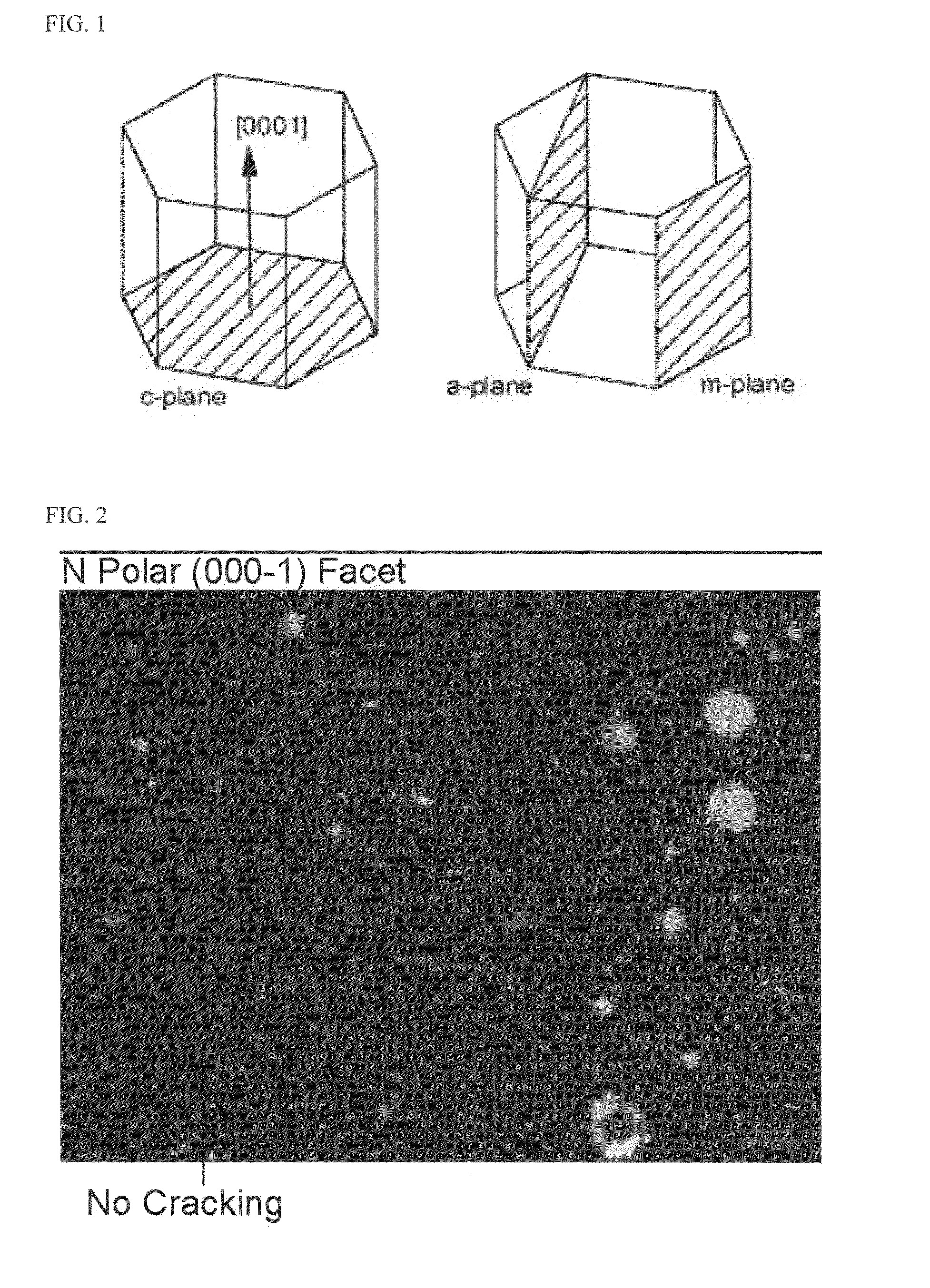

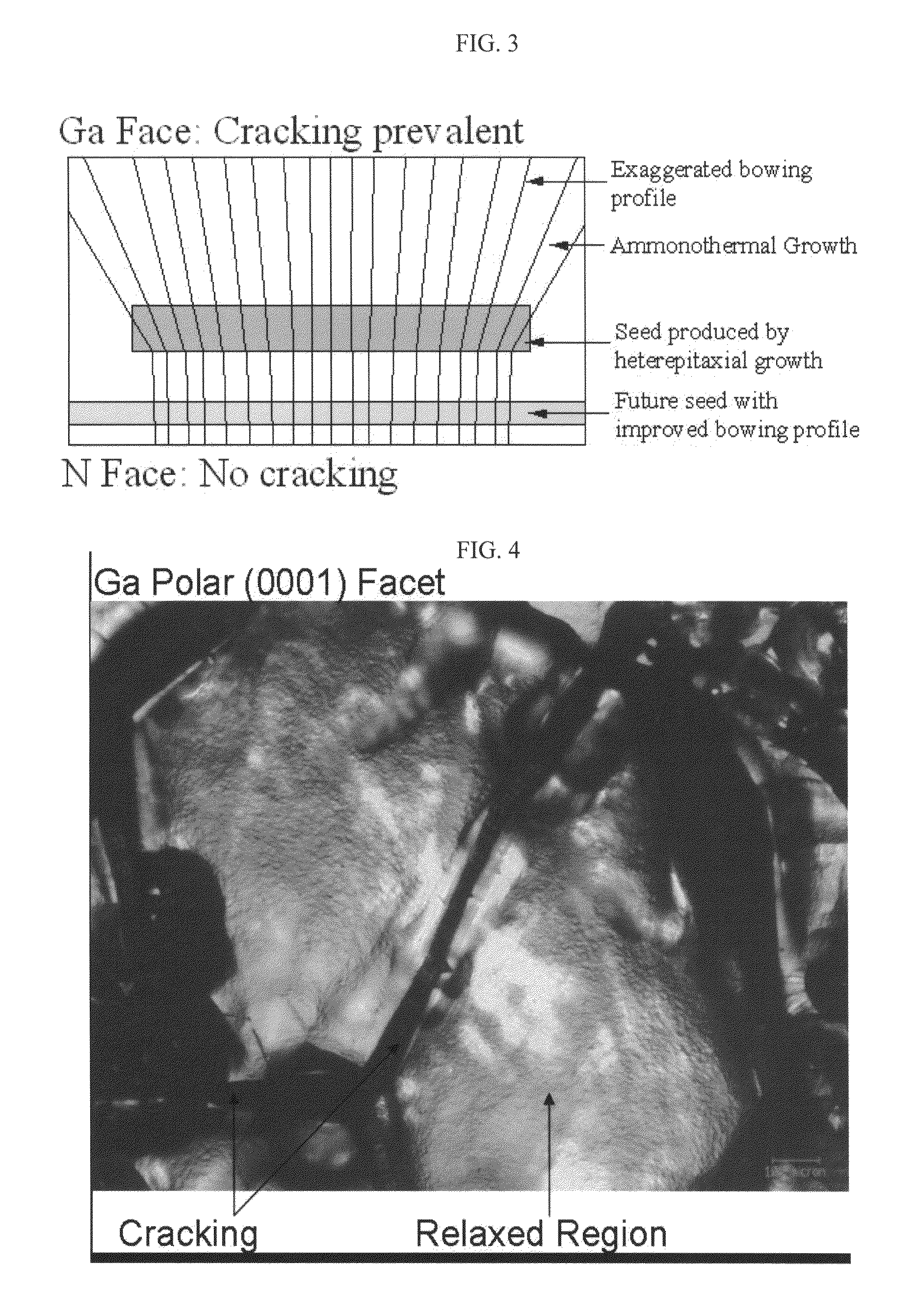

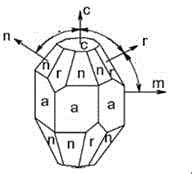

Methods for producing improved crystallinity group III-nitride crystals from initial group III-nitride seed by ammonothermal growth

ActiveUS8728234B2Improve crystal qualityAvoid crackingPolycrystalline material growthAfter-treatment detailsIngotCrystallinity

The present invention discloses methods to create higher quality group III-nitride wafers that then generate improvements in the crystalline properties of ingots produced by ammonothermal growth from an initial defective seed. By obtaining future seeds from carefully chosen regions of an ingot produced on a bowed seed crystal, future ingot crystalline properties can be improved. Specifically, the future seeds are optimized if chosen from an area of relieved stress on a cracked ingot or from a carefully chosen N-polar compressed area. When the seeds are sliced out, miscut of 3-10° helps to improve structural quality of successive growth. Additionally a method is proposed to improve crystal quality by using the ammonothermal method to produce a series of ingots, each using a specifically oriented seed from the previous ingot. When employed, these methods enhance the quality of Group III nitride wafers and thus improve the efficiency of any subsequent device.

Owner:SIXPOINT MATERIALS

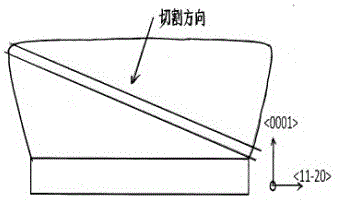

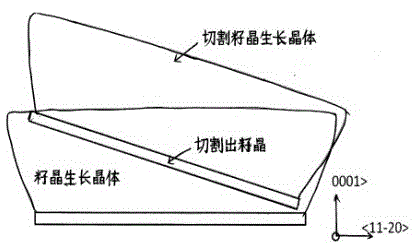

Method for growing large-size and low-defect silicon carbide monocrystal and wafer

InactiveCN105525350AContinuous growthPolycrystalline material growthFrom condensed vaporsWaferingIngot

The invention discloses a method for growing large-size and low-defect silicon carbide monocrystal and wafer, and is used for solving the problem of dislocation defects in a large-diameter SiC crystal. The method comprises the steps: adopting large-diameter SiC wafer having more or less defects and basically parallel to a (0001) plane as a seed crystal, and growing to obtain an SiC crystal ingot; processing the crystal ingot to obtain a wafer with largest deflection angle, and taking the wafer as a seed crystal; repeating the steps until a growing plane of the crystal ingot is substantially parallel to a (11-20) plane or a (1-100) plane; and after repeating the steps at the plane for multiple times, making the growing plane of the crystal ingot substantially parallel to the (0001) plane according to reverse steps, and processing to obtain an SiC wafer with a required deflection angle in the meanwhile. The continuity of growth of the SiC wafer with large diameter and low defect density is guaranteed.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 2 RES INST

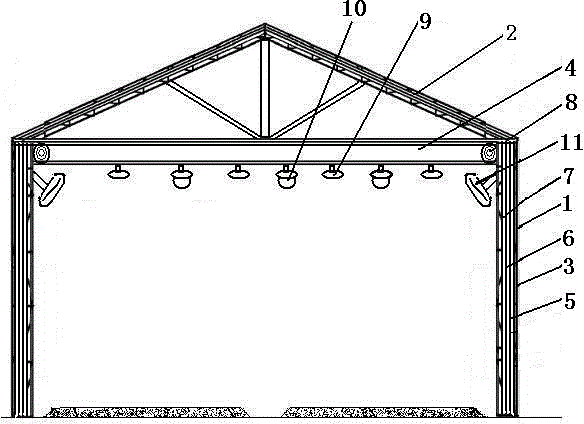

Dwarf culture method of cedrela sinensis

ActiveCN104521525AIncrease productionImprove qualityPlant cultivationCultivating equipmentsGreenhouseSprayer

A dwarf culture method of cedrela sinensis comprises the seven steps of greenhouse construction, lifting of seedlings and heeling in temporary planting, soil preparation, cultivation, growth management, dwarf treatment and harvesting, and has the advantages that a greenhouse special for cedrela sinensis is adopted, sun shading in summer and heat collection and preservation in winter are facilitated by rolling or opening one or more of heat collection films, heat preservation films and sunshade nets according to needs, or the heat collection films, the heat preservation films and the sunshade nets are all opened in seasons with proper temperature; meanwhile, sprayers, light supplementing lamps or air fans are opened according to needs to conveniently adjust the humidity, illumination time or air flow in the greenhouse; plants can well absorb nutrient through deep planting, the yield of cedrela sinensis is improved through dwarf treatment, it can be ensured that plants continuously grow and germinate by carrying out topdressing in advance before pinching and harvesting and leaving compound leaves at base portions when harvesting, and through the comprehensive method, the yield and quality of cedrela sinensis are greatly improved.

Owner:PENGSHUI BAIYEXING FOREST FOOD DEV LIMITED

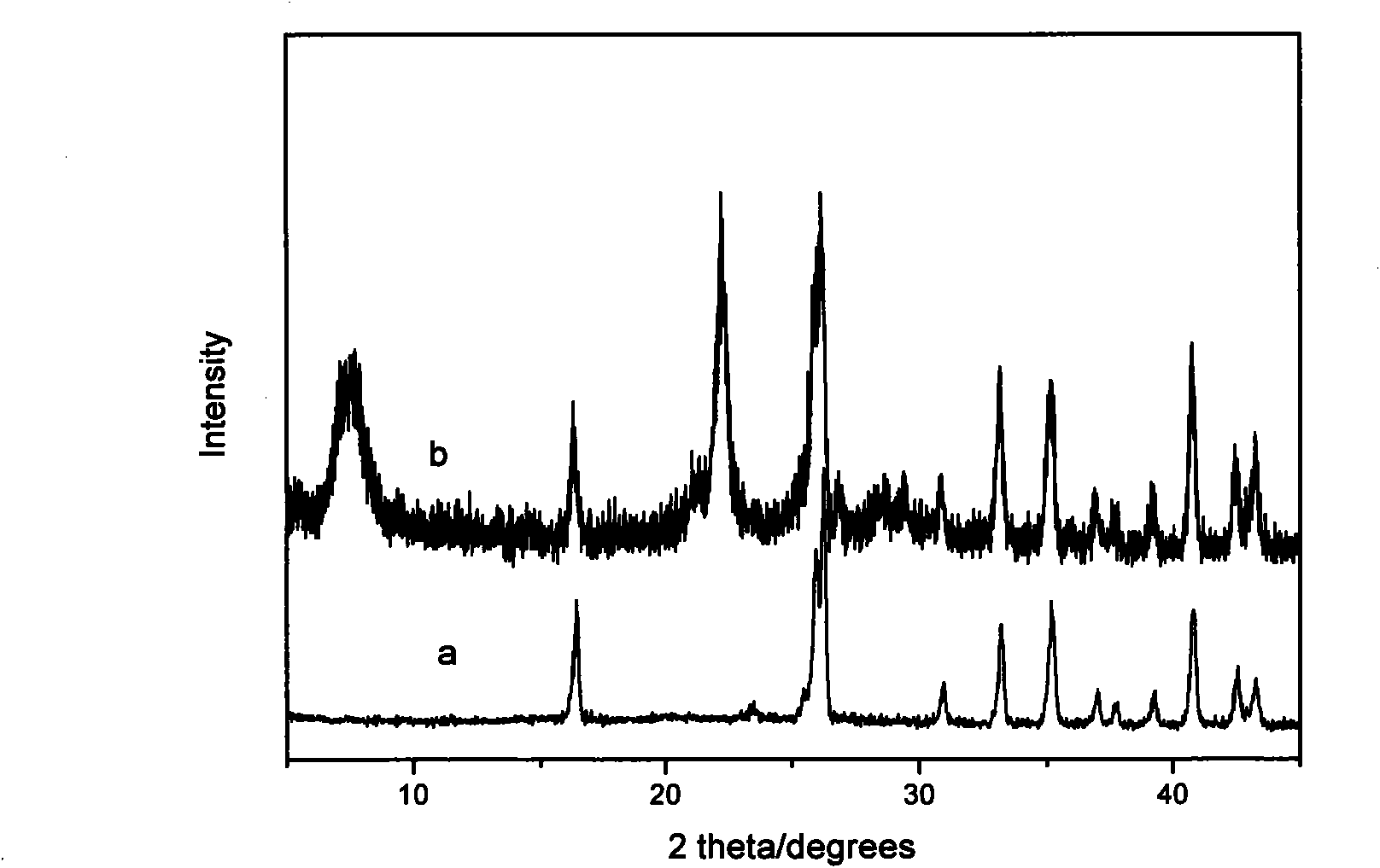

Method for separating methanol/methyl methacrylate mixed system

ActiveCN101857522ALower requirementLower synthesis costSemi-permeable membranesHydroxy compound separation/purificationPervaporationMethyl methacrylate

The invention relates to a method for separating a methanol / methyl methacrylate mixed system, which is implemented by adopting a pervaporation process of a Beta molecular sieve membrane. In the method for preparing the Beta molecular sieve membrane for separating the methanol / methyl methacrylate mixed system, the dense and continuous Beta molecular sieve membrane is prepared by adopting a secondary growth method under the condition of high water-silicon ratio and the use of a cheap template agent. The Beta molecular sieve membrane prepared on tubular supporting bodies of various materials hasa good shape-selective separation effect and meets the requirement of separating the methanol from the methanol / methyl methacrylate mixed system. When the Beta molecular sieve membrane prepared underan optimized condition is used for performing pervaporation on the 60-DEG C methanol / methyl methacrylate (with mol percentage of 50:50) system, and the flux and the separation factors are more than 0.50 kg / m<2>*h and 650 respectively. The continuous Beta molecular sieve membrane with dense crystal is prepared through a series of test on synthesis steps of a seed crystal coating method, a formula of raw materials, a reaction condition and the like, so the method for separating the methanol / methyl methacrylate system is determined.

Owner:JIANGXI NORMAL UNIVERSITY

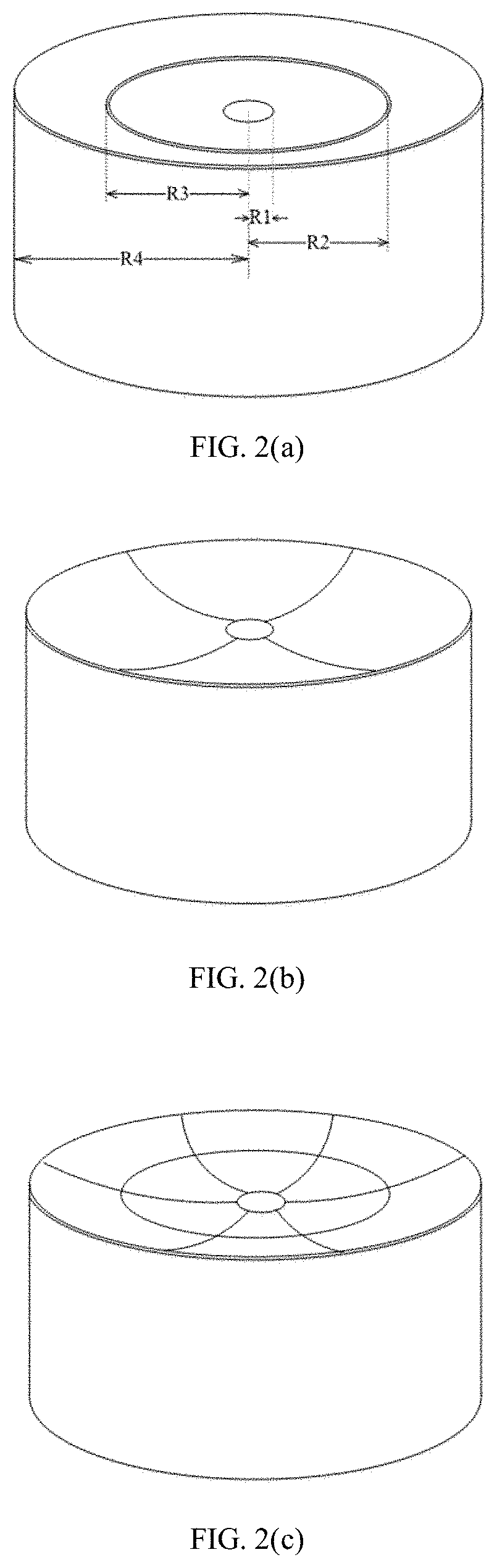

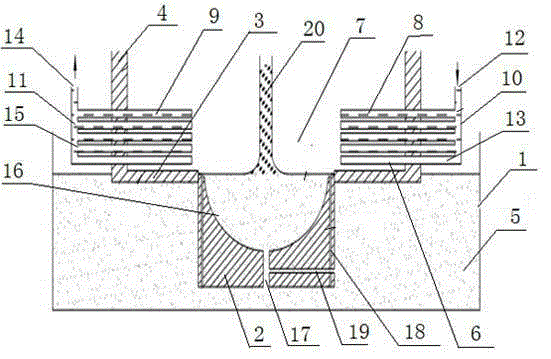

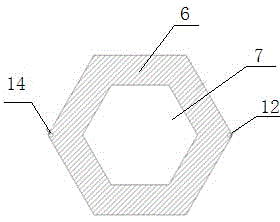

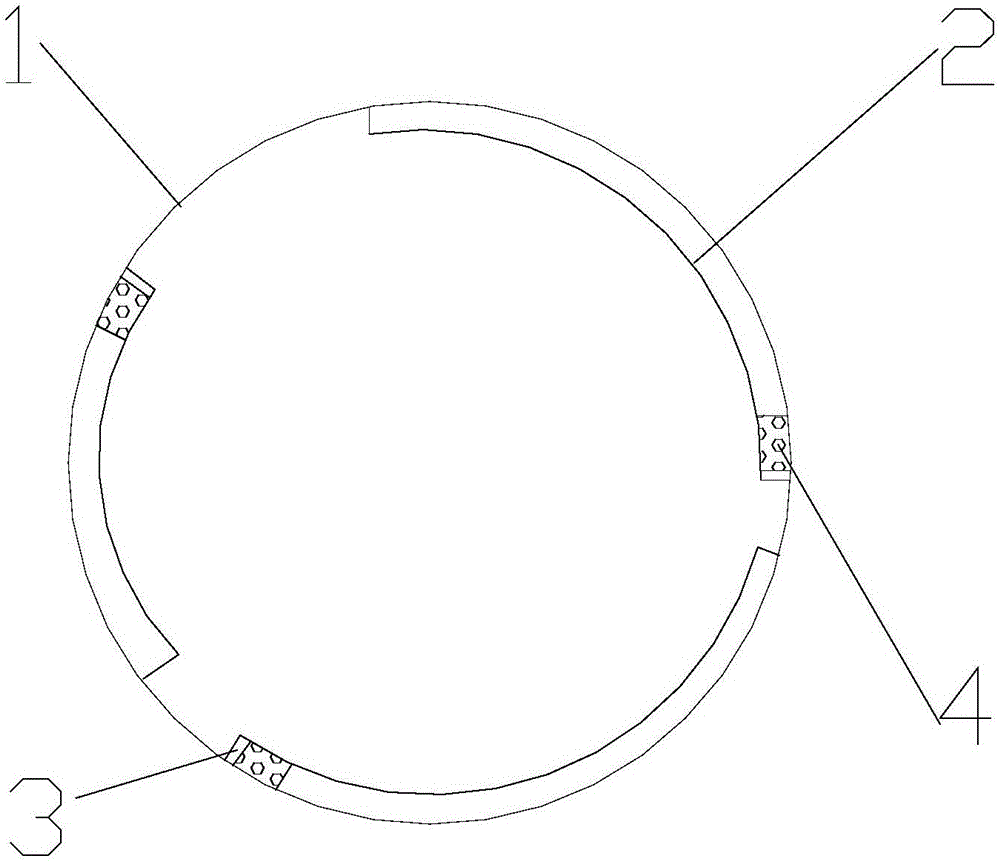

Growth device for sapphire crystal hemisphere cover and growth method for sapphire crystal hemisphere cover

InactiveCN104862775AAvoid situations where the interior of the growth interface cannot be cooled uniformlyImprove qualityPolycrystalline material growthBy pulling from meltCrucibleGas cooler

The invention relates to a growth device and a growth method for a sapphire crystal hemisphere cover by employing an edge-defined film-fed crystal growth method. The method specifically comprises the following main steps: respectively introducing a protective gas and a cooling gas into a crystal growth furnace and a cooler pan; heating the crystal growth furnace until a high-purity aluminum oxide material is fused; adjusting a hoist pan, so that aluminum oxide melt ascends to the top end of a mold along a center through hole and an annular capillary fissure in the symmetric axis of the mold; descending seed crystal to fuse with the aluminum oxide melt; under the action of affinity and surface tension, enhancing radiation heat exchange between a growth interface and the gas cooler pan by adjusting the flow of the cooling gas in the cooler pan, so as to quicken the expansion of the crystal; and finally limiting the expansion of the crystal by the top edge of the mold. The growth device has the advantages that supply of the melt in the mold is adjusted by controlling the relative positions of the mold and the crucible; continuous providing of the melt in the capillary fissure is ensured, so as to realize continuous growth; and a hexagonal annular cooler pan is prevented from being carbonized to deform by employing the cooling gas.

Owner:JIANGSU CEC ZHENHUA CRYSTAL TECH

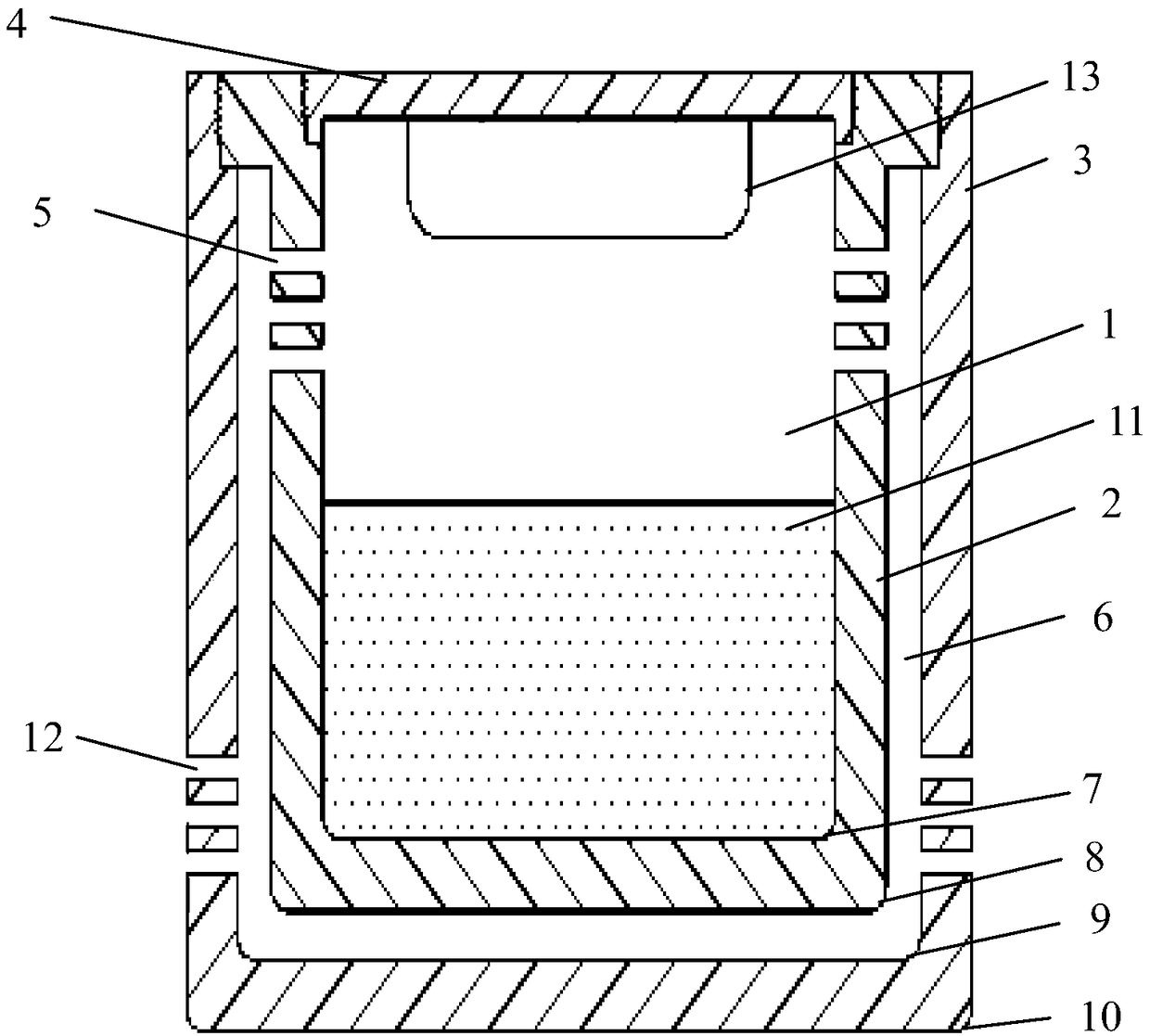

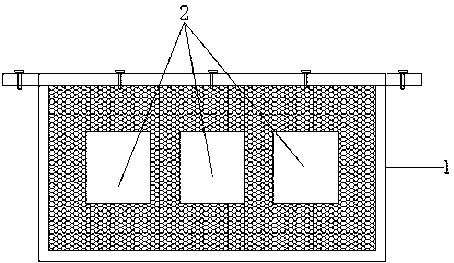

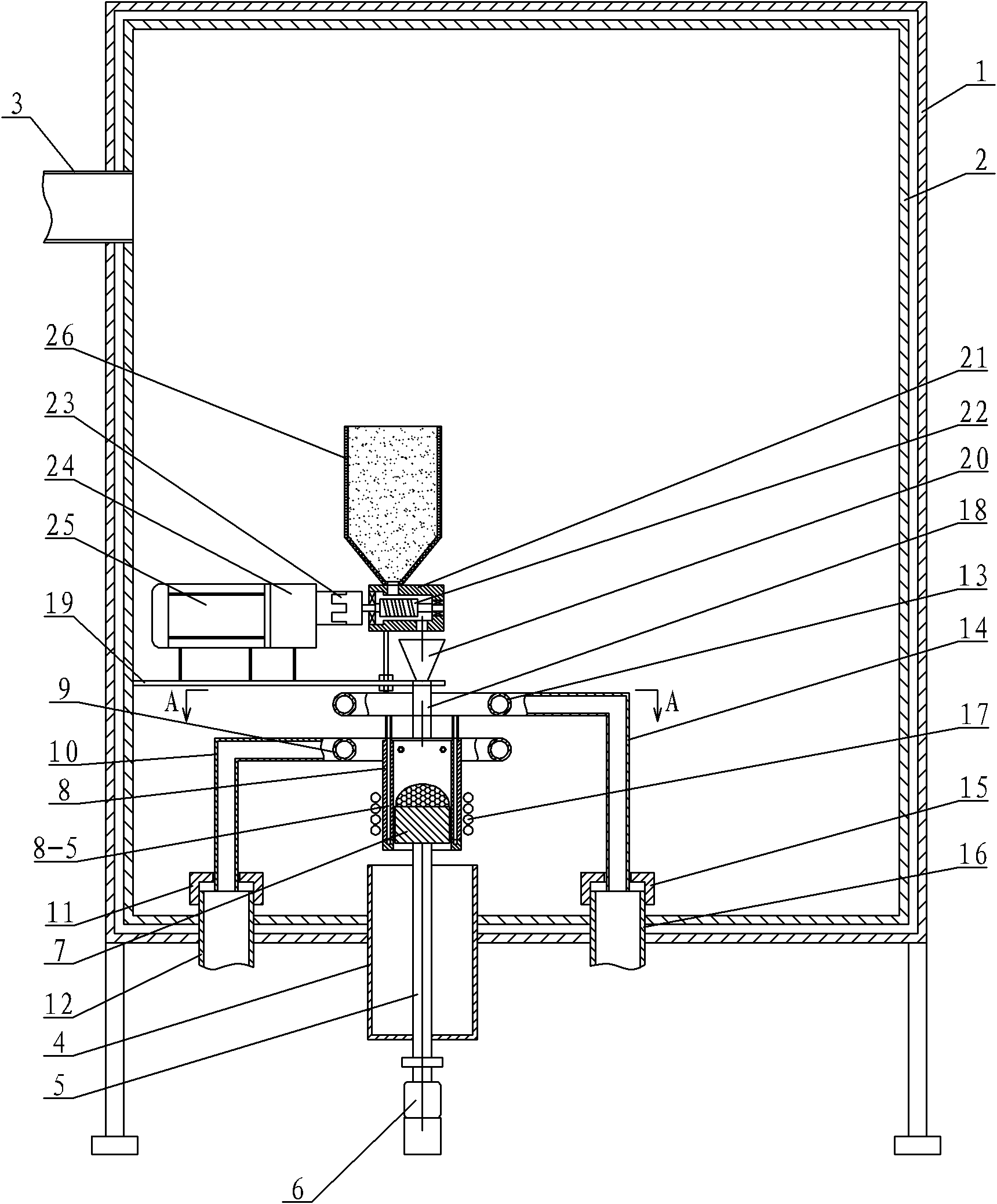

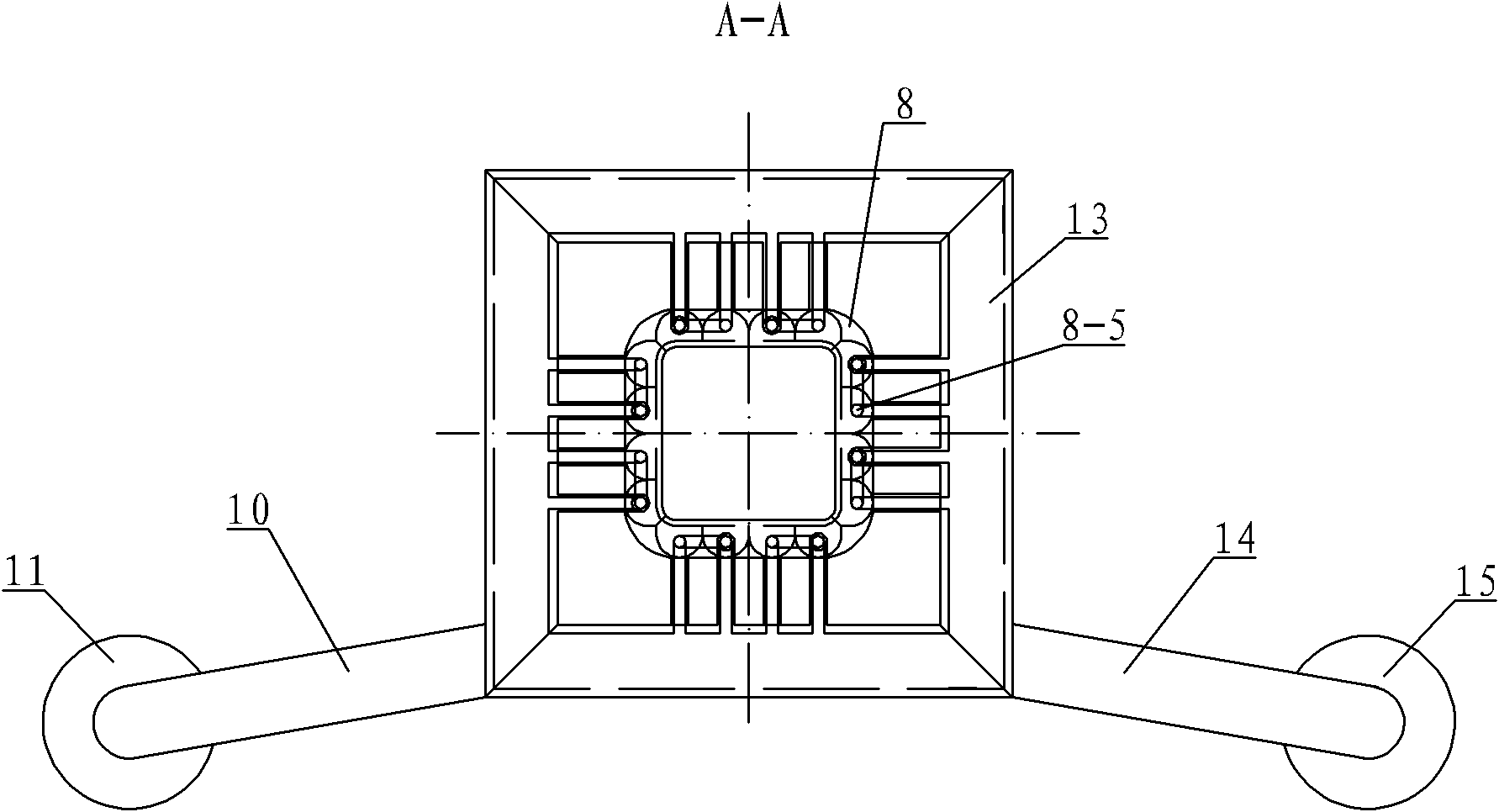

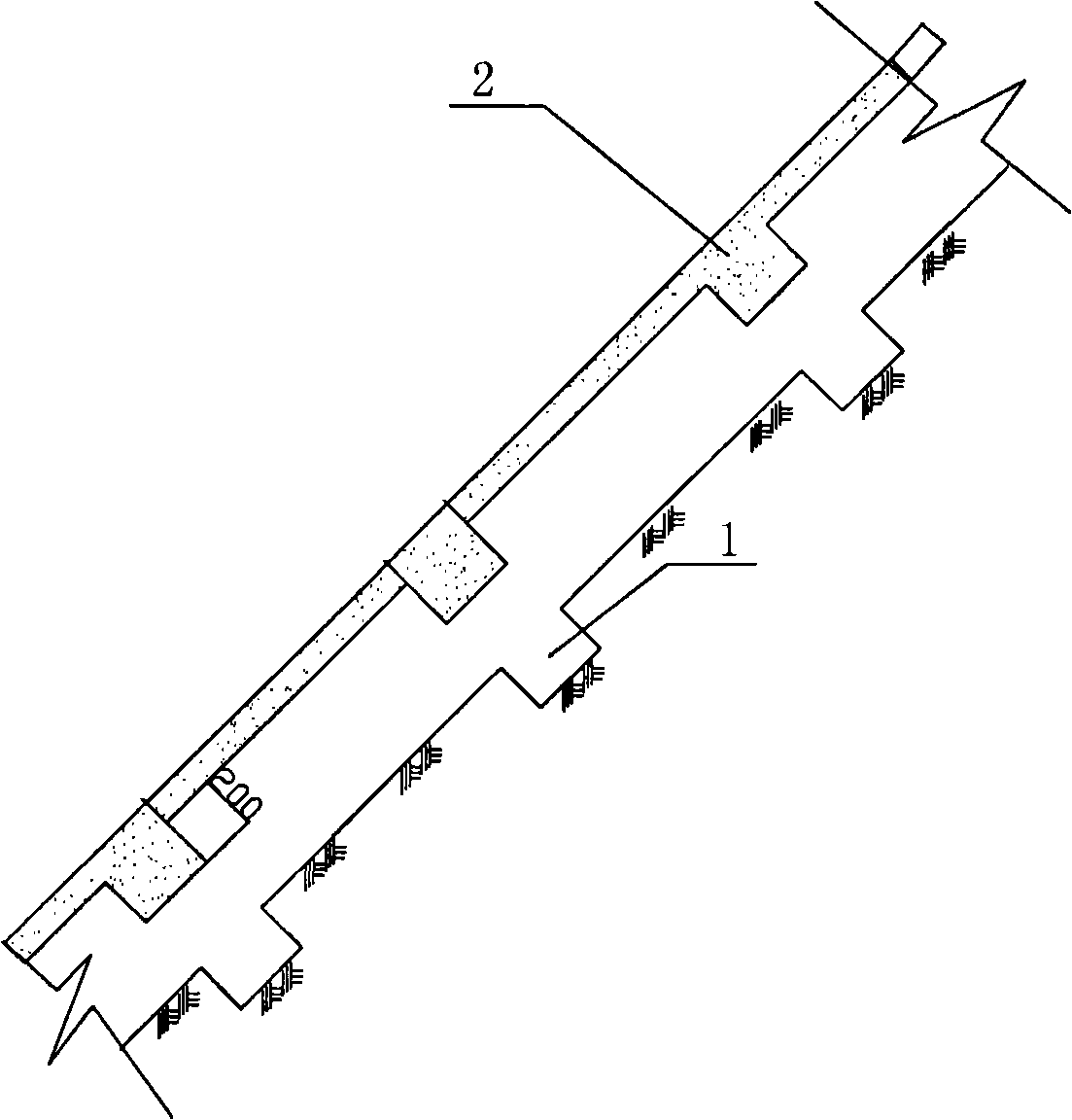

Device for preparing polycrystalline silicon ingots with directional solidification microstructures

InactiveCN102094233AHigh purityPurity and pollution-freePolycrystalline material growthFrom frozen solutionsDirectional solidificationPolycrystalline silicon

The invention discloses a device for preparing polycrystalline silicon ingots with directional solidification microstructures, and relates to a device for preparing polycrystalline silicon ingots to solve the problem that the polycrystalline silicon ingots have low purity because polycrystalline silicon is polluted by the inner wall of a sleeve when the polycrystalline silicon ingots are prepared in the ceramic or graphite sleeve in the prior art. A cooler is arranged on a baseplate of a vacuum chamber; a pull rod is arranged in the cooler, is connected with a servomotor and is connected with a graphite base; the graphite base is arranged in a cold crucible; each water through hole on the cold crucible is communicated with a square ring-shaped water outlet pipe through a thin connecting pipe, and is communicated with a square ring-shaped water inlet pipe through a thin connecting pipe; one end of a water inlet connecting pipe is connected with the square ring-shaped water inlet pipe; an induction coil is wound on the outer wall of the cold crucible; the outlet of a graphite pipe is opposite to the inner cavity of the cold crucible; a gathering hopper is arranged on the graphite pipe; the outlet of a shell is opposite to the gathering hopper; a screw rod is arranged on the shell; and a hopper is arranged at the feeding hole of the shell. The device is used for preparing the polycrystalline silicon ingots.

Owner:HARBIN INST OF TECH

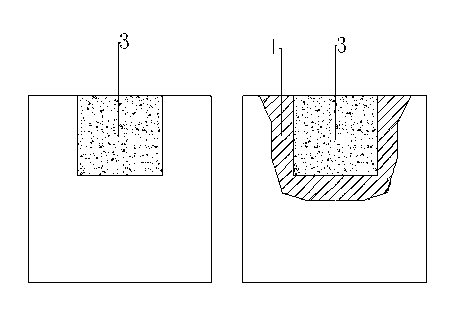

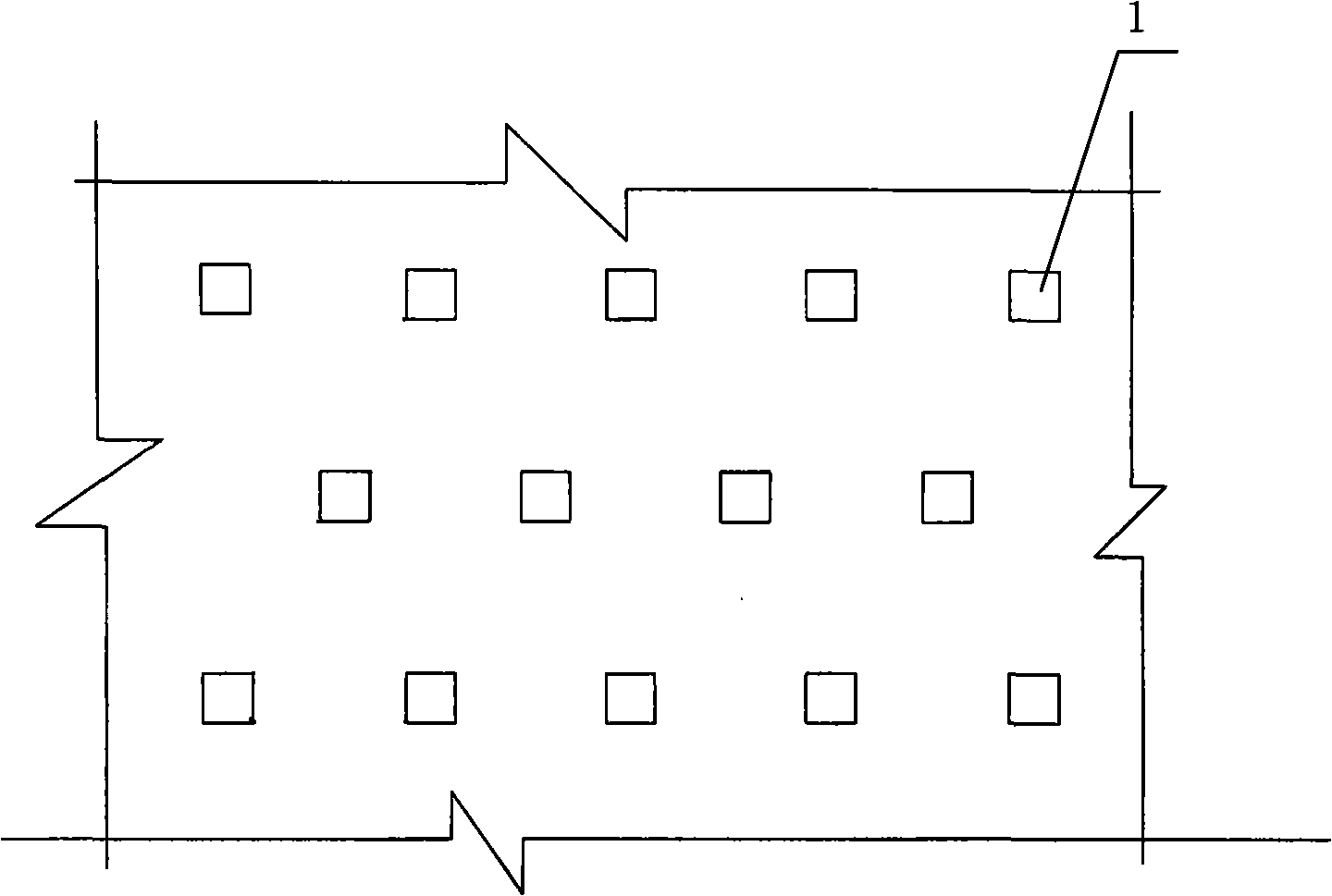

Novel ecological slope protection substrate building method

ActiveCN101280567AImprove stabilityImprove adhesionSoil lifting machinesExcavationsVegetationEngineering

Disclosed is a novel method for constructing an ecological slope protection substrate, which pertains to the field of slope protection engineering, ecological restoration engineering and greening engineering. The construction process of the method of the invention is: first, leveling the slope surface needing restoring, excavating mouth-shaped pits on the slope surface, filling the mouth-shaped pits with multi-functional soil and finishing the construction of the slope protection substrate. The method for constructing the ecological slope protection substrate provided by the invention, by arranging the mouth-shaped pits on the slope surface, not only can change the status of soil impoverishment and the growth environment of vegetations, and provide essential fertilizers and nutrient substances for the sustainable growth of plants, but also can greatly increase the cohesive force between the guest soil layer and the fraction excavated, and increase the integral stability of the guest soil layer so as to effectively prevent the slope surface from integral damage by the continuous effect of rain. The method of the invention changes the mechanical characteristics and construction modes of the substrate and improves the present statuses of the poor stability and soil impoverishment of the substrate in the ecological slope protection.

Owner:湖北润智生态科技有限公司

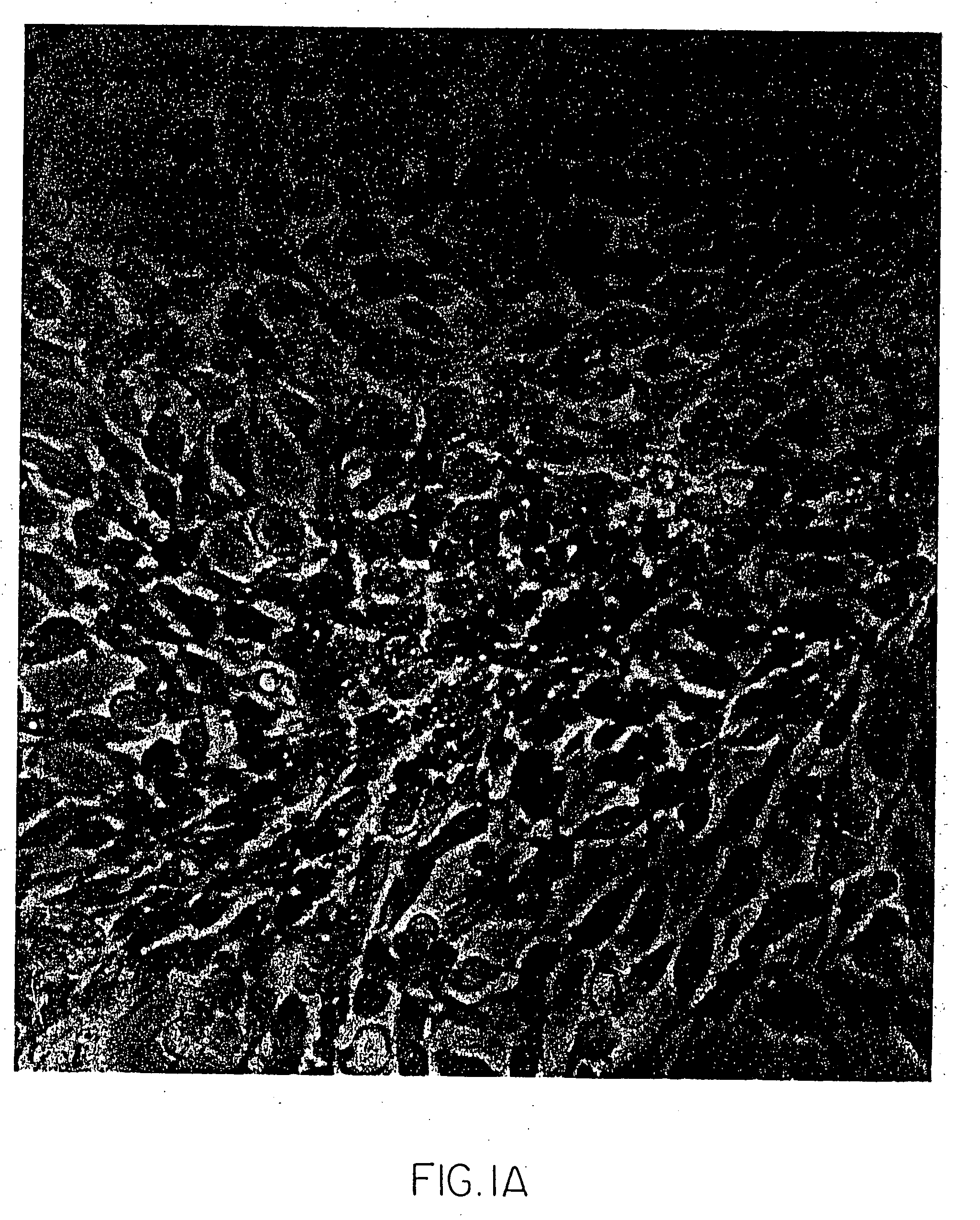

Long-term cell culture compositions and genetically modified animals derived therefrom

InactiveUS20050132426A1FocusImprove isolationNervous disorderGenetically modified cellsTelomeraseStem cell line

The present invention generally relates to neural stem cells, preferably fetal neural stem cells and their progeny thereof. The present invention provides methods of isolating culturing and propagating neural stem cells and the development of neural stem cell lines and lineages. The present invention also relates to the use of neural stem cells and somatic cells and cells expressing the telomerase catalytic component (TERT) for gene targeting and gene knockout experiments and for producing genetically modified animals.

Owner:MORRISON JOHN RODERICK +4

Method for mulching film seedling culture and planting of purple potatoes

InactiveCN105359776AIncrease heightFast germinationSeed and root treatmentVegetative propogationPlastic mulchSolanum tuberosum

The invention discloses a method for mulching film seedling culture and planting of purple potatoes. The method belongs to the technical field of seedling culture and planting of potatoes. The method comprises the steps including (1) the mulching film seedling culture of the purple potatoes, (2) management of purple potato sprouts, (3) growth of young seedlings of the purple potato, (4) growth of the purple potatoes and (5) harvesting of the purple potatoes. By using the method disclosed by the invention, a germination period of the planted purple potatoes is short, and a germination rate during the same period increases by about 16.8%; the sprouts are healthy, strong and tall and have high quality and excellent performance, and a survival rate and survival quality of young seedlings of the purple potatoes are effectively guaranteed; the maturing purple potatoes have a high yield, planting benefits and income increase obviously, and income of farmer households is increased obviously. Pesticides of a small amount are applied continuously at intervals to the purple potatoes planted by the method disclosed by the invention, so that the purple potatoes can absorb sufficient nutrients during the growth, and the maturing potatoes have the advantages ofa big size, fresh and tender flesh, abundant nutrients and high edible values.

Owner:魏晓露 +2

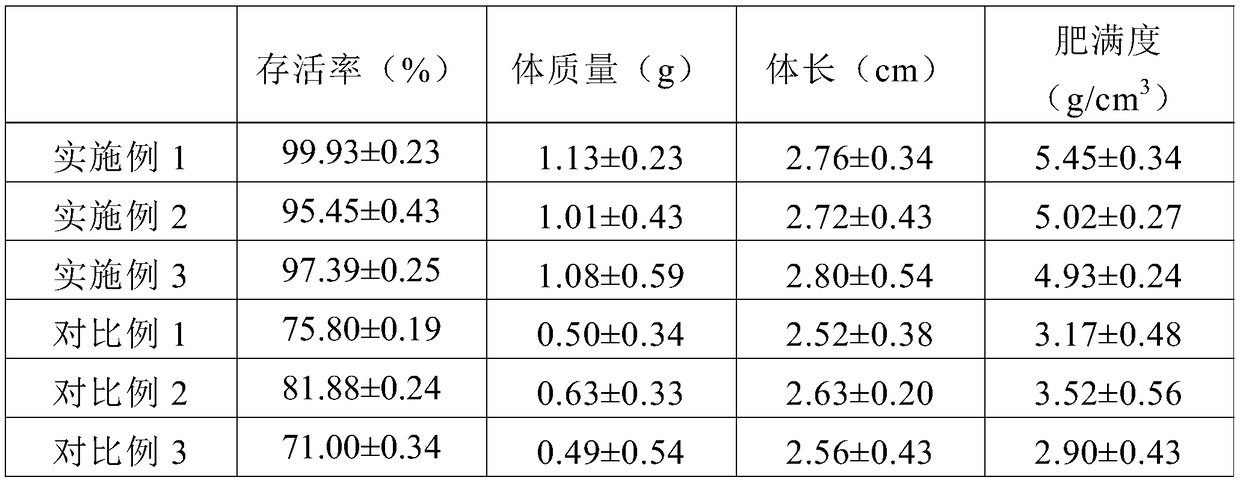

Method for feeding high-survival-rate and high-growth-rate Hulong hybridized groupers in pond

ActiveCN108770737AShorten the timeAvoid it happening againClimate change adaptationAnimal feeding stuffWater qualityHigh survival rate

The invention provides a method for feeding high-survival-rate and high-growth-rate Hulong hybridized groupers in a pond. The method includes fry breeding pond selection, water quality control, fry distribution, light adjustment, bait feeding and other steps. The unique comprehensive water quality control technology is adopted, and by adopting suitable biological bait, suitable ratios and precisefeeding time sequences, high survival rate and high growth rate of bred fry are achieved. By adopting the method, 30 days after fry breeding, the survival rate of the Hulong hybridized groupers is upto 99.93%, the fatness is up to 5.45 g / cm3, the crude protein content is up to 50.13%, and the crude fat content is up to 50.13%; the survival rate of normal groupers is 75.82-81.88%, the fatness is2.90-3.52g / cm3, the crude protein content is 42.49%-45.90% and the crude fat content is 6.52%-7.63%. Compared with the normal groupers, the survival rate, fatness, crude protein content and crude fatcontent of the Hulong hybridized groupers are obviously improved.

Owner:HAINAN CHENHAI AQUATIC CO LTD

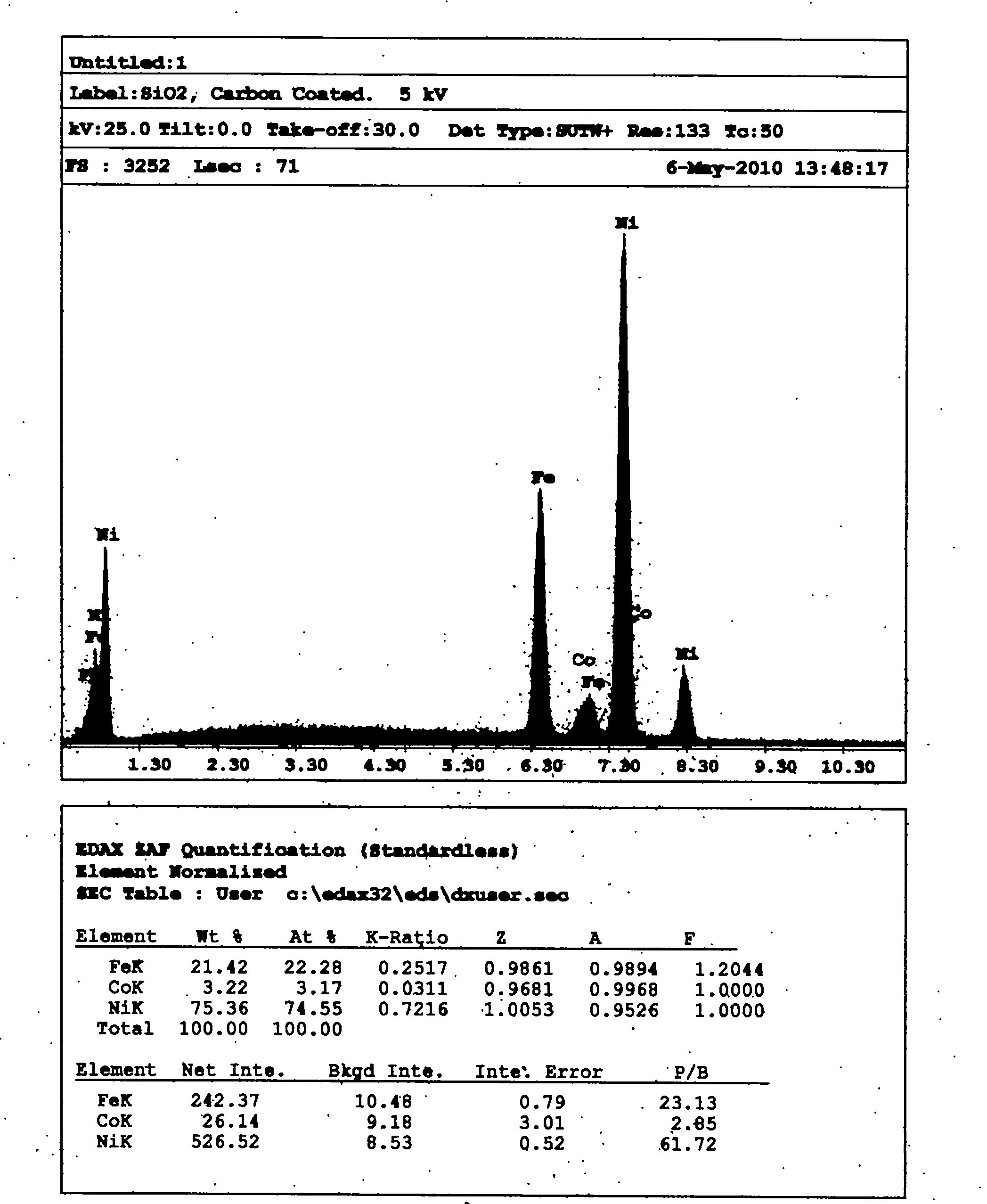

Method for preparing nanocrystalline nickel-ferro-cobalt ternary alloy through pulse electrodeposition

InactiveCN102312257ACrystal fine and denseReduce pollutionPhotography auxillary processesProcess efficiency improvementTemperature controlPower flow

The invention provides a method for preparing a nanocrystalline nickel-ferro-cobalt ternary alloy through pulse electrodeposition. By adopting electrodeposition equipment which comprises a cycling filtration device, a stirring device, a temperature control device and a cathode moving device and an additive agent a 2-5g / l and an additive agent b 0.25-1g / l, the nanocrystalline nickel-ferro-cobalt ternary alloy is obtained under the technological parameters of electroplating solution temperature of 20-60 DEG C, pH of 3.2-3.6, and cathode current density of 2-12A / dm2. The method provided by the invention has the characteristics of simpleness and easiness in control of the technological process, stable product quality, fine grain size, uniform structure, high purity, small environment pollution, low production cost and the like.

Owner:CHANGCHUN UNIV OF TECH

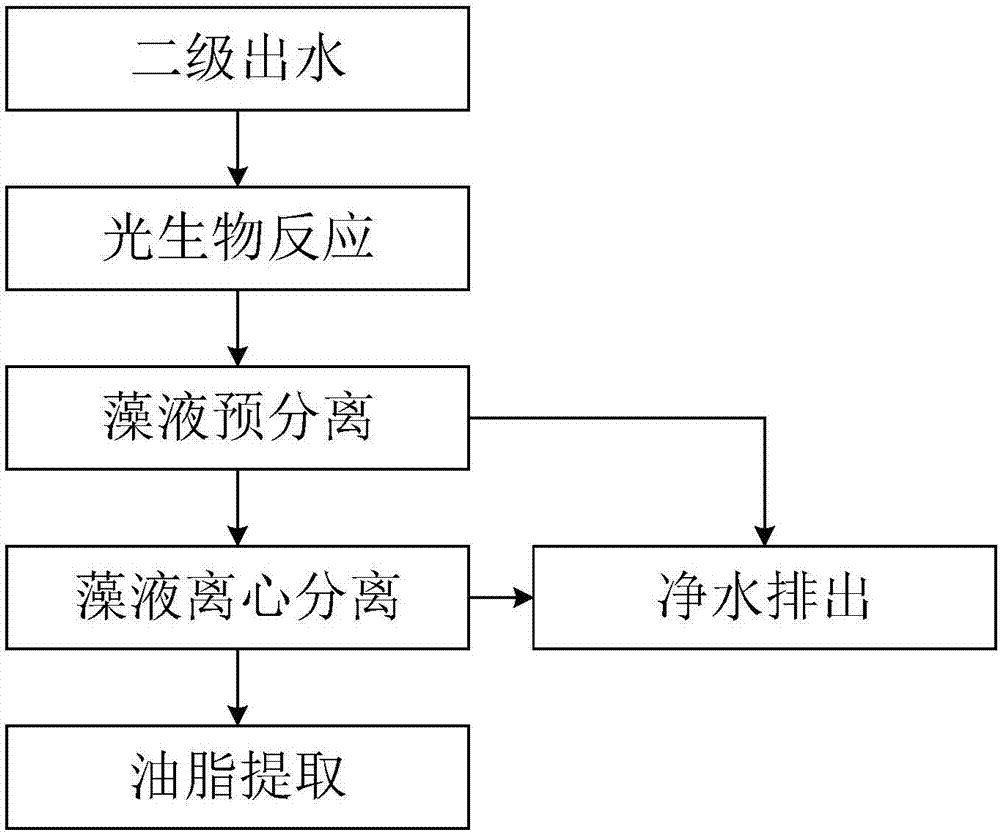

Advanced purification process for secondary effluent from municipal wastewater treatment plant

InactiveCN107140781AContinuous growthRealize continuous productionWater/sewage treatment by centrifugal separationWater/sewage treatment by irradiationActivated sludgeEconomic benefits

The invention discloses an advanced purification process for secondary effluent from a municipal wastewater treatment plant and aims at solving the problems of complex treatment process, high cost and the like in a conventional secondary effluent purification treatment process. The invention adopts the technical scheme that the advanced purification process comprises the following steps: a. carrying out biological reaction and algae liquid separation, wherein the biological reaction means that wastewater of the secondary effluent is fed into a photobioreactor for carrying out a photobiological reaction; algae-bacteria symbionts are inoculated into water in the photobioreactor, and the algae-bacteria symbionts consist of chlorella and activated sludge bacteria. The algae liquid separation means that reaction liquid finishing reaction in the photobioreactor is fed into an algae-bacteria separating chamber and preseparated by a gravity sedimentation method to obtain upper supernatant and lower algae liquid; the lower algae liquid undergoes centrifugal separation to obtain centrifugal supernatant and a centrifugal algae body, the upper supernatant and the centrifugal supernatant are naturally discharged. The advanced purification process disclosed by the invention has the advantages of simple process, short hydraulic retention time, good wastewater treatment effect, environment friendliness and additional economic benefits.

Owner:HUBEI UNIV OF TECH

A device for growing carbon nanotube aerogels

ActiveCN104843666BSolving the disadvantages of growing carbon nanotubesContinuous growthMaterial nanotechnologyCarbon nanotubeEngineering

Owner:SUZHOU CREATIVE CARBON NANOTECH

Plasma-reinforced carbon nanotube growth device

PendingCN109553088AGuaranteed continuous evaporationContinuous growthCarbon compoundsRadio frequencyCarbon nanotube

The invention discloses a plasma-reinforced carbon nanotube growth device. The plasma-reinforced carbon nanotube growth device comprises a radio-frequency controller, an air inlet, a coil, a preheating furnace, a heating furnace, a quartz tube, a touch control screen, an air suction opening, a slide rail, a device frame and a radio-frequency power source, wherein the platform surface of the top part of the device frame is fixedly provided with the quartz tube through two supporting seats; one end of the quartz tube is connected with a vacuum flange which is provided with the air inlet; the quartz tube successively penetrates through the radio-frequency power source, the preheating furnace and the heating furnace which are arranged at the top part of the device frame; the other end of the quartz tube is connected with a vacuum flange which is provided with the air suction opening; the platform surface of the top part of the device frame is horizontally provided with the slide rail; thepreheating furnace is placed on the slide rail to slide; and the platform surface of the top part of the device frame is fixedly provided with the touch control screen. The plasma-reinforced carbon nanotube growth device provided by the invention enables a Fe component to be constant, has controllable diameter and can well control the growth quality of carbon nanotubes.

Owner:ANHUI BEQ EQUIP TECH

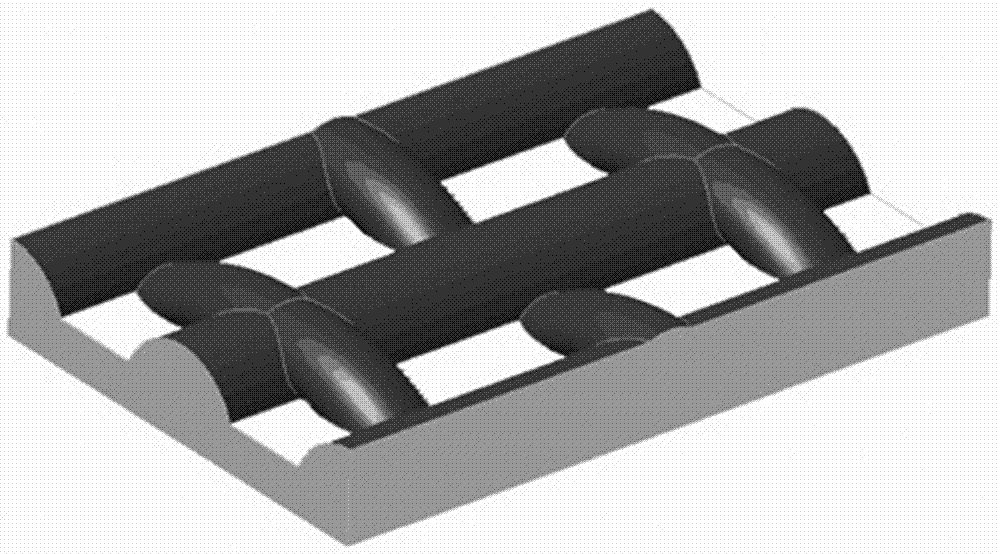

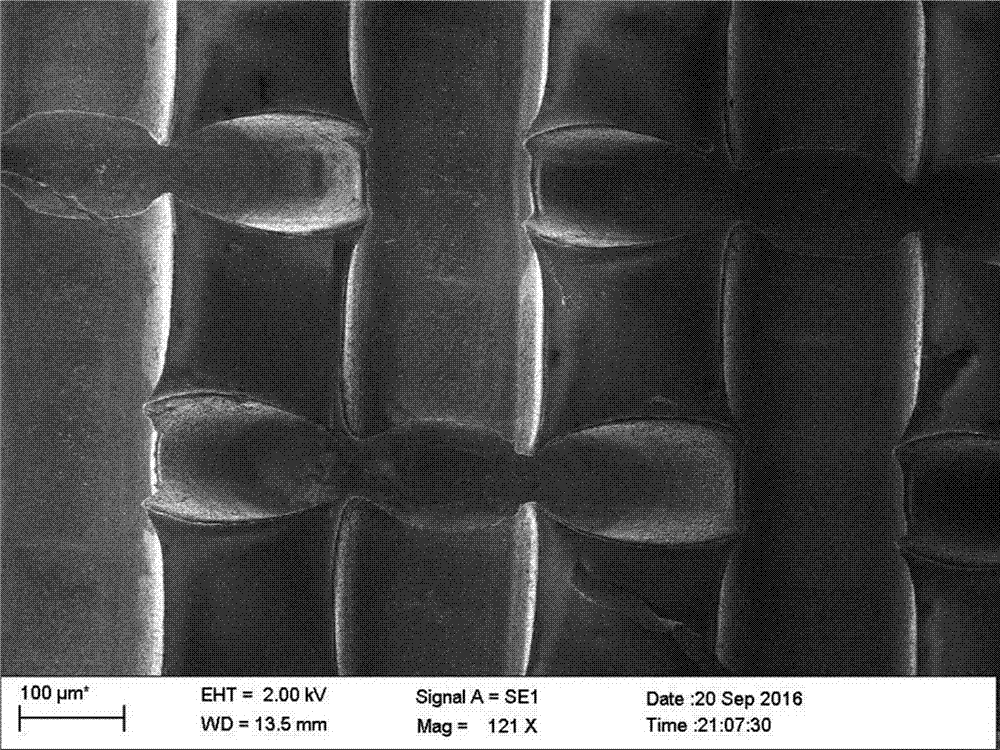

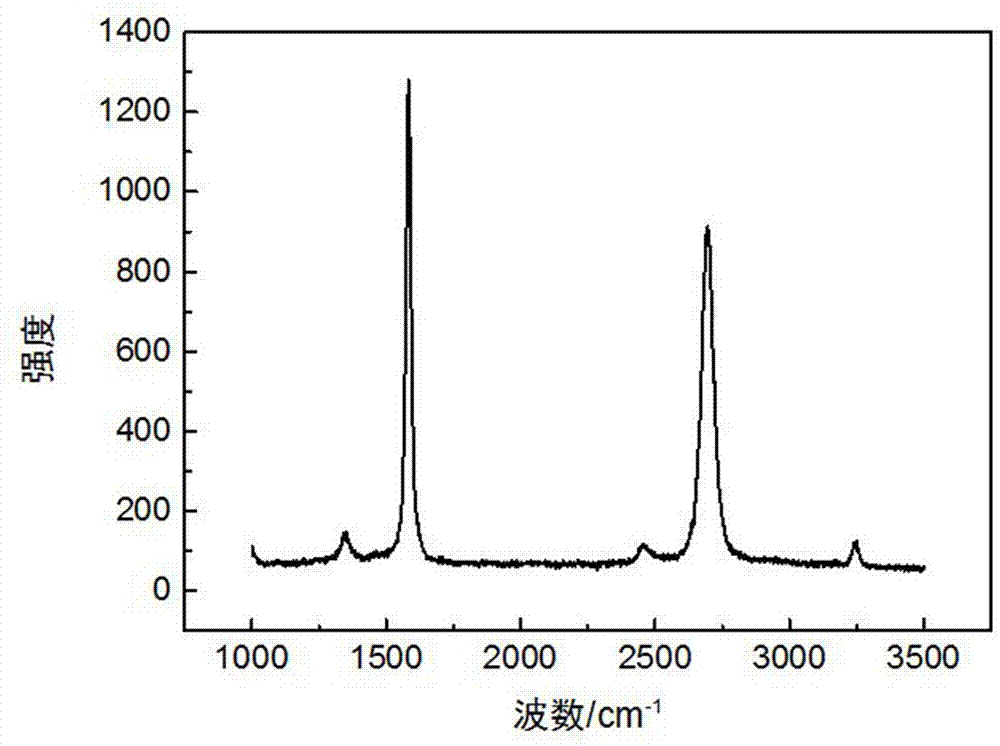

Preparation method of arched graphene three-dimensional network

The invention discloses a preparation method of an arched graphene three-dimensional network. On the basis that graphene grows on a conventional copper substrate through chemical vapor deposition, the number of layers and the continuity of graphene are controlled by introducing trace metallic nickel steam, so that the graphene three-dimensional network growing on a three-dimensional copper-catalyzed template has the best self-supporting property and the best electrical transport performance suitable for stress sensing detection during transferring, and is transferred to a flexible target substrate with a soft gel half-coating method during separation transferring of the graphene three-dimensional network, and the graphene three-dimensional network with the special arched structure is prepared.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

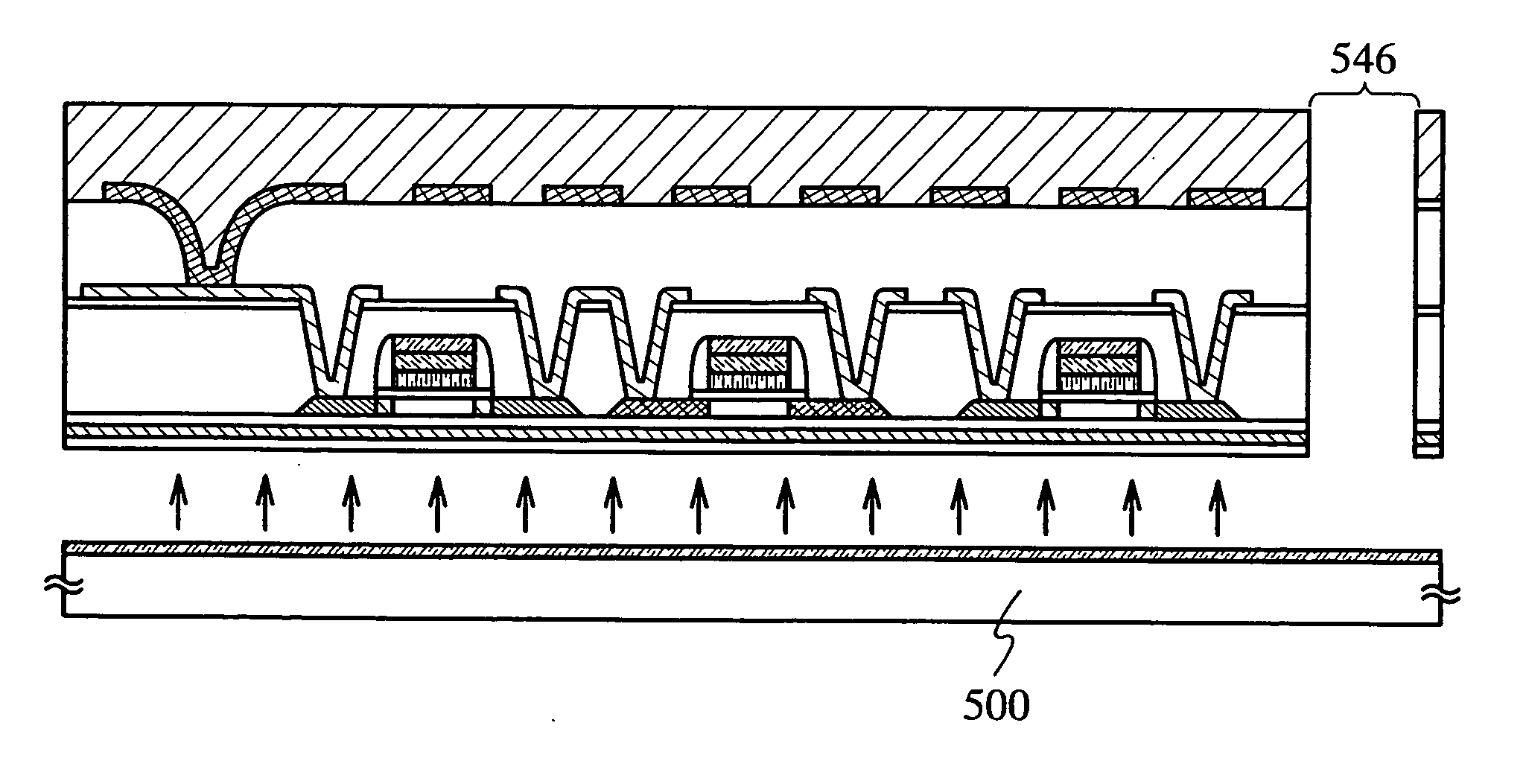

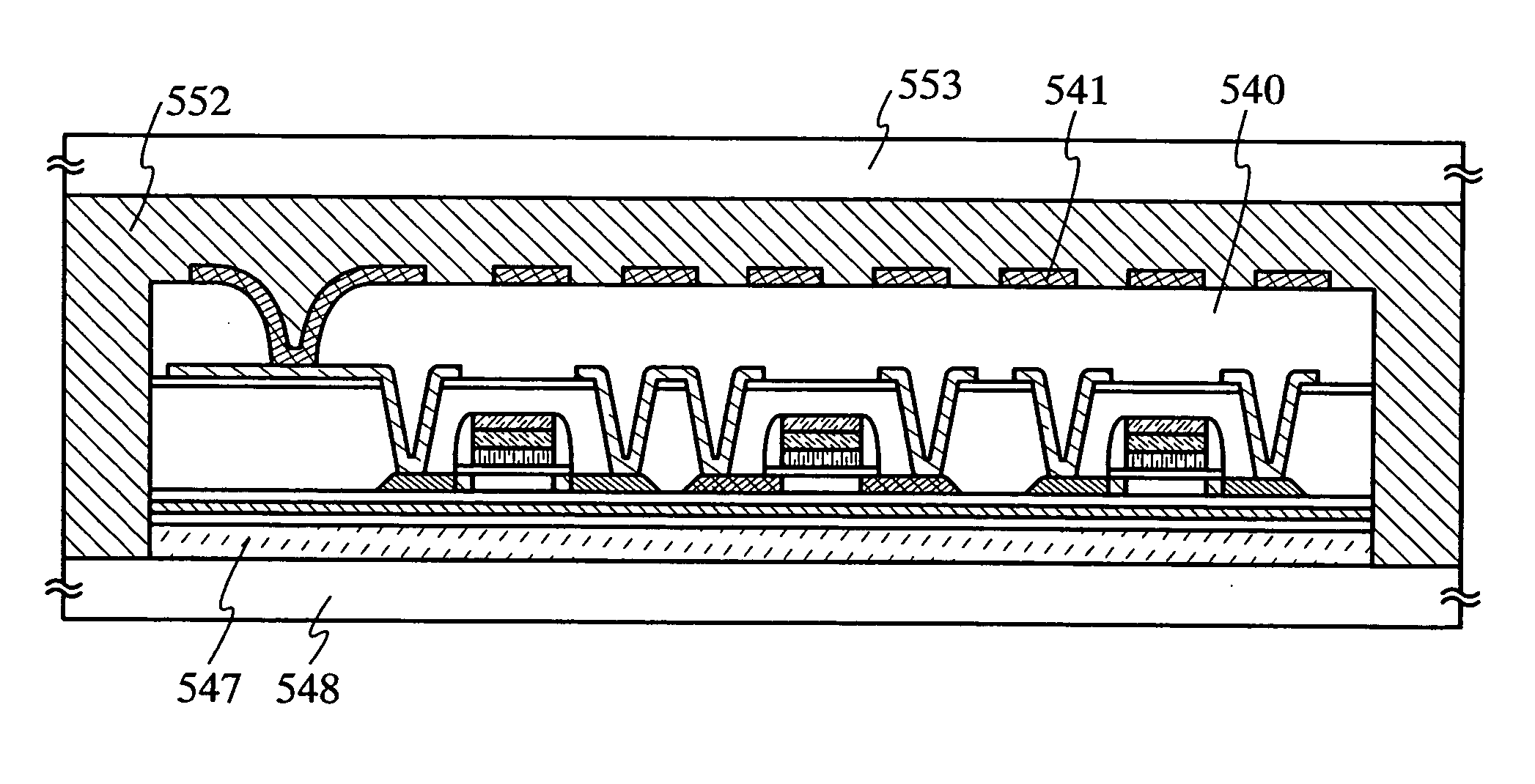

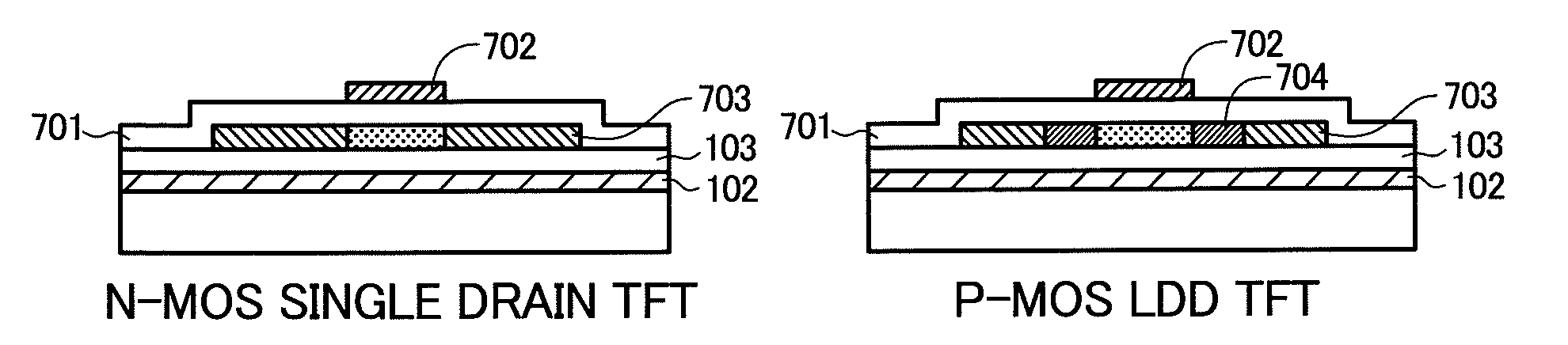

Display Device and Fabrication Method Thereof

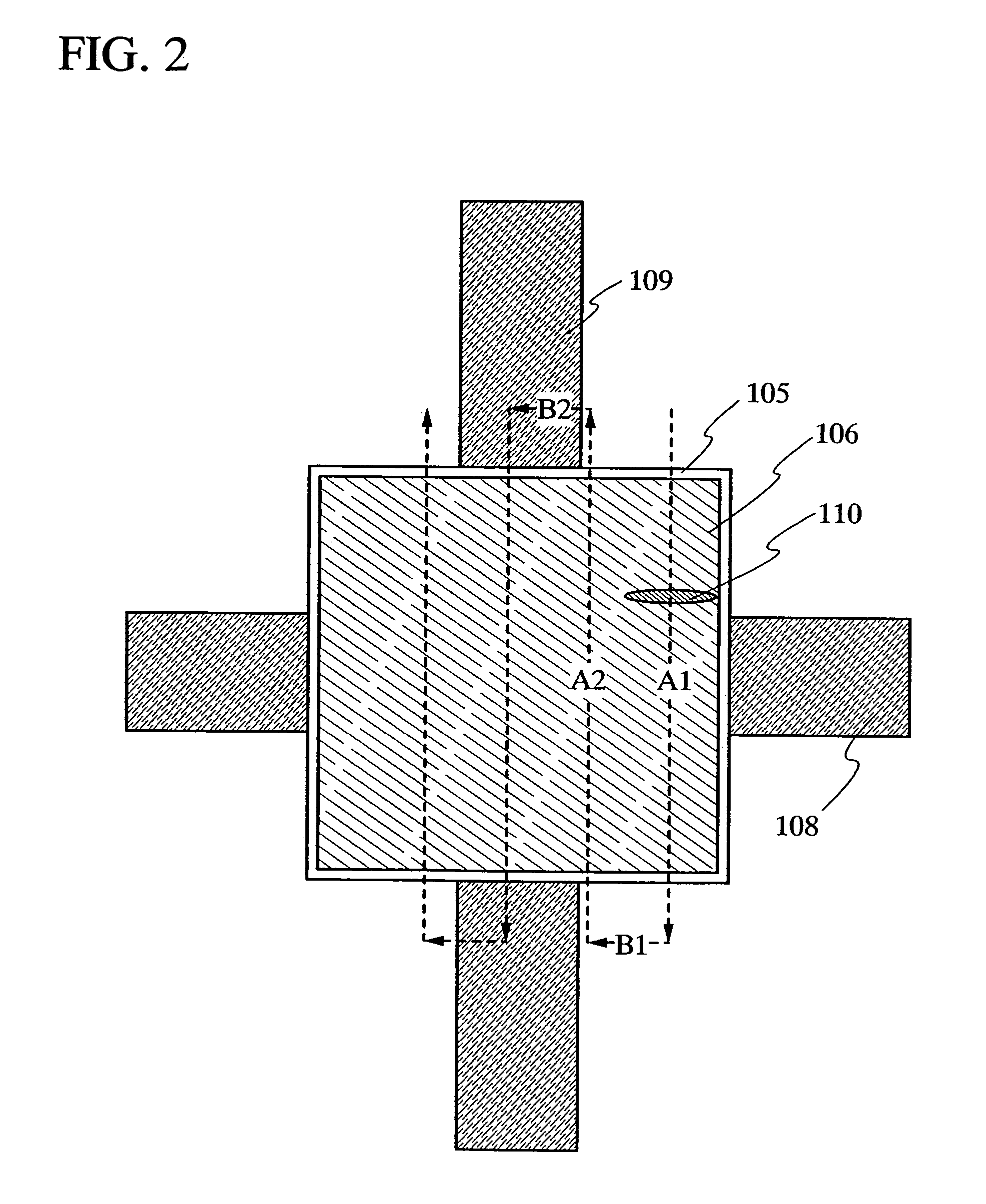

InactiveUS20080023704A1Enhancement of transistor characteristicSuppress aggregationSolid-state devicesSemiconductor/solid-state device manufacturingSilicon nitrideSurface plate

The present invention obtains a system-in-panel display device using a high-performance thin film transistor by suppressing aggregation of a molten semiconductor at the time of allowing strip-like pseudo-single crystal to grow continuously with a direction control by radiating beams of continuous oscillation laser to a semiconductor film made of silicon while scanning. A display device includes a silicon nitride film formed on the insulation substrate, a silicon oxide film formed on the silicon nitride film, a semiconductor film formed on the silicon oxide film, and a thin film transistor which uses the semiconductor film. Here, the silicon oxide film is constituted of a first silicon oxide film formed using SiH4 and N2O as raw material gases and a second silicon oxide film formed using a TEOS gas as a raw material gas, and the semiconductor film is made of pseudo-single crystal having strip-like grains.

Owner:HITACHI DISPLAYS

Method for obtaining liquid silicon, and crucible for achieving method

ActiveCN106521629AImprove solubilityImprove growth efficiencyPolycrystalline material growthFrom melt solutionsSolubilityHigh carbon

The present invention relates to a method for obtaining liquid silicon, and a crucible for achieving the method. According to the method, the liquid silicon solution having the high carbon solubility is obtained by using a synchronous cosolvent melting method. The crucible for achieving the method comprises a crucible body, wherein the inner wall of the crucible body is provided with a concave groove, one end of the concave groove is provided with a baffle, and the bottom portion on the terminal end of the concave groove are uniformly provided with small fine pores. With the method and the crucible having the corresponding structure of the present invention, the problem that different melting points of the cosolvents cause the asynchronous melting during the silicon carbide preparation process can be solved, the melting interval can be shortened, the liquid silicon solution having the fixed chemical ratio can be formed, the solubility of the carbon can be improved, and the rapid growth of the crystal can be ensured.

Owner:SICC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com