Method for preparing nanocrystalline nickel-ferro-cobalt ternary alloy through pulse electrodeposition

A ternary alloy, electrodeposition technology, applied to the improvement of process efficiency, photographic technology, instruments, etc., can solve the problems of low deposition rate, low current density, coarse grains, etc., to achieve uniform composition, small linear expansion coefficient, The effect of small internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

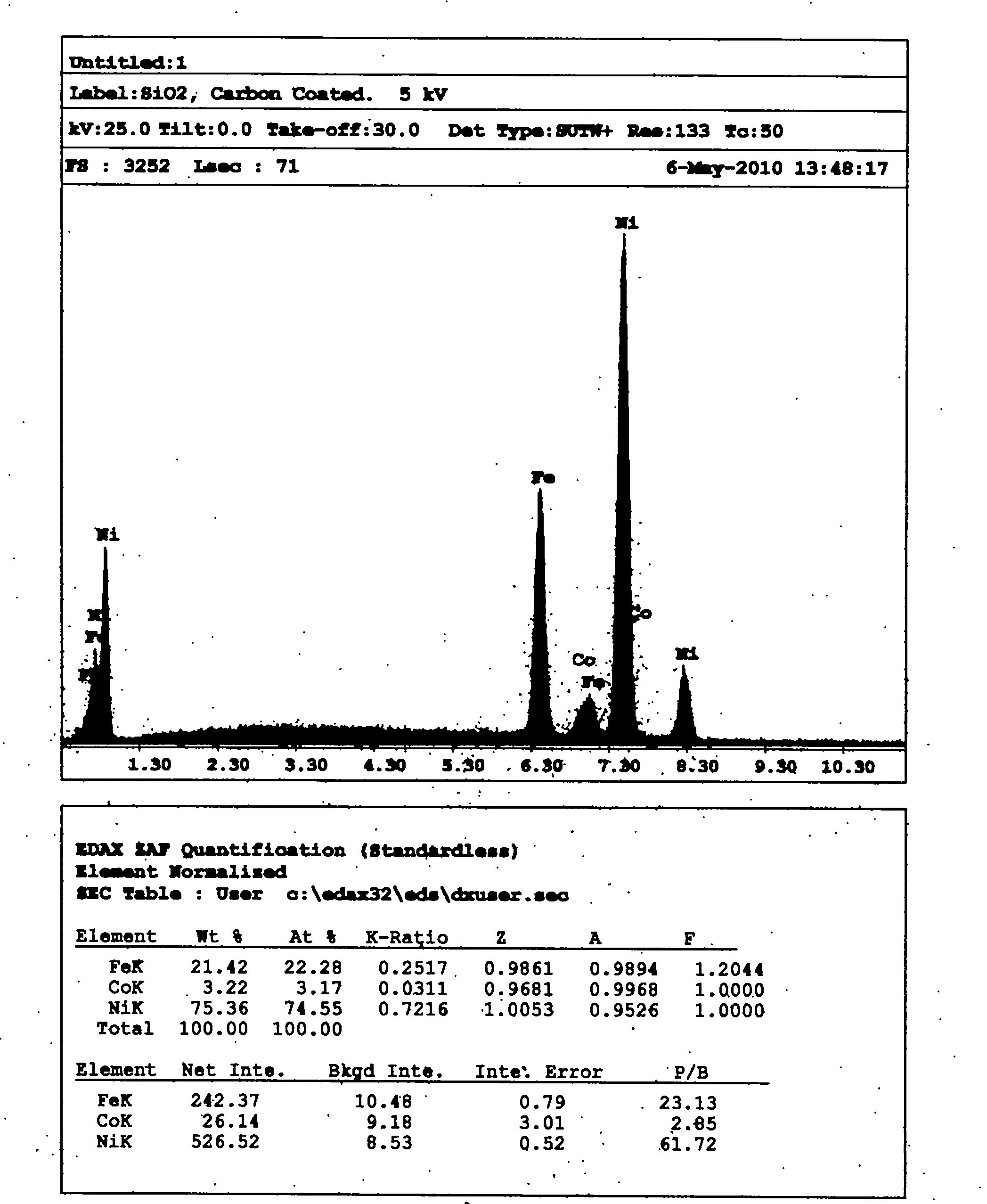

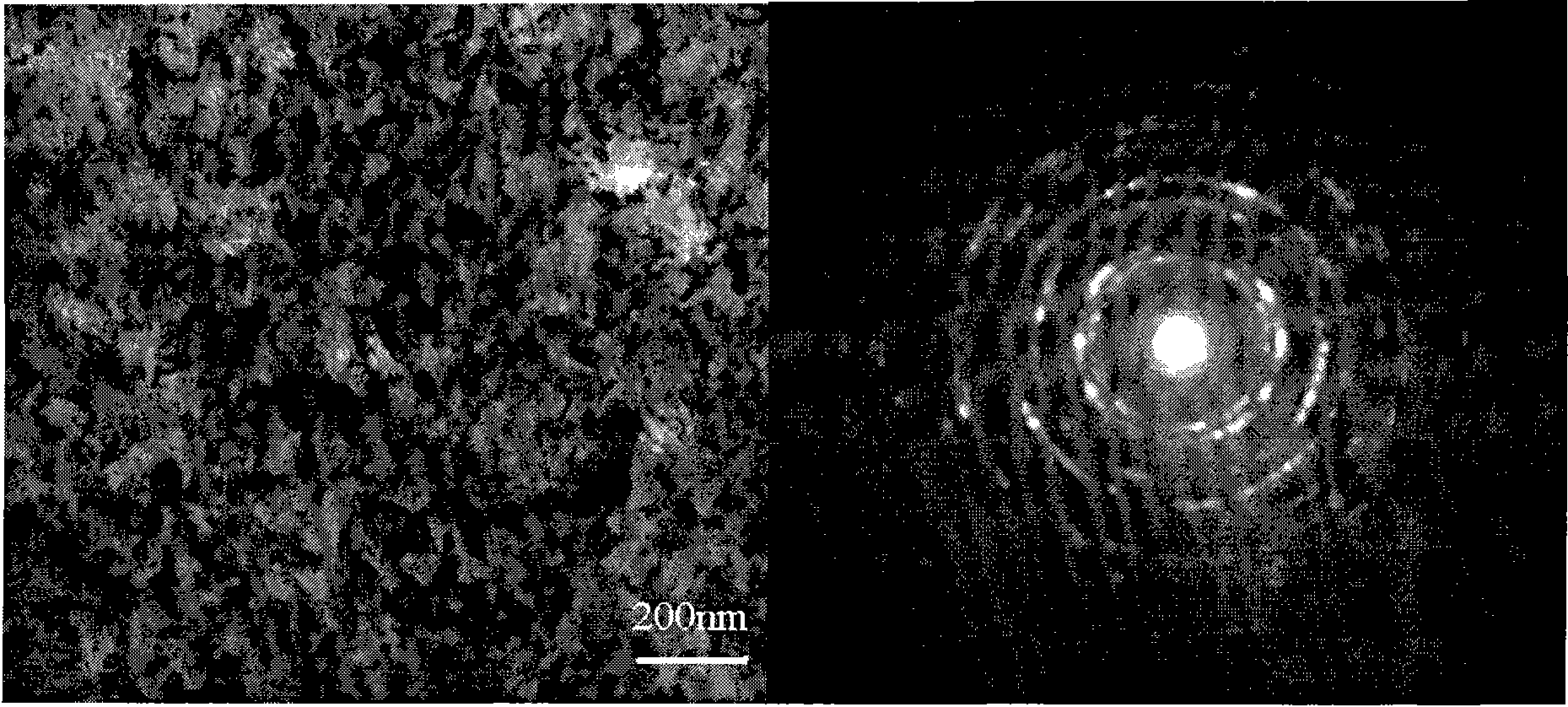

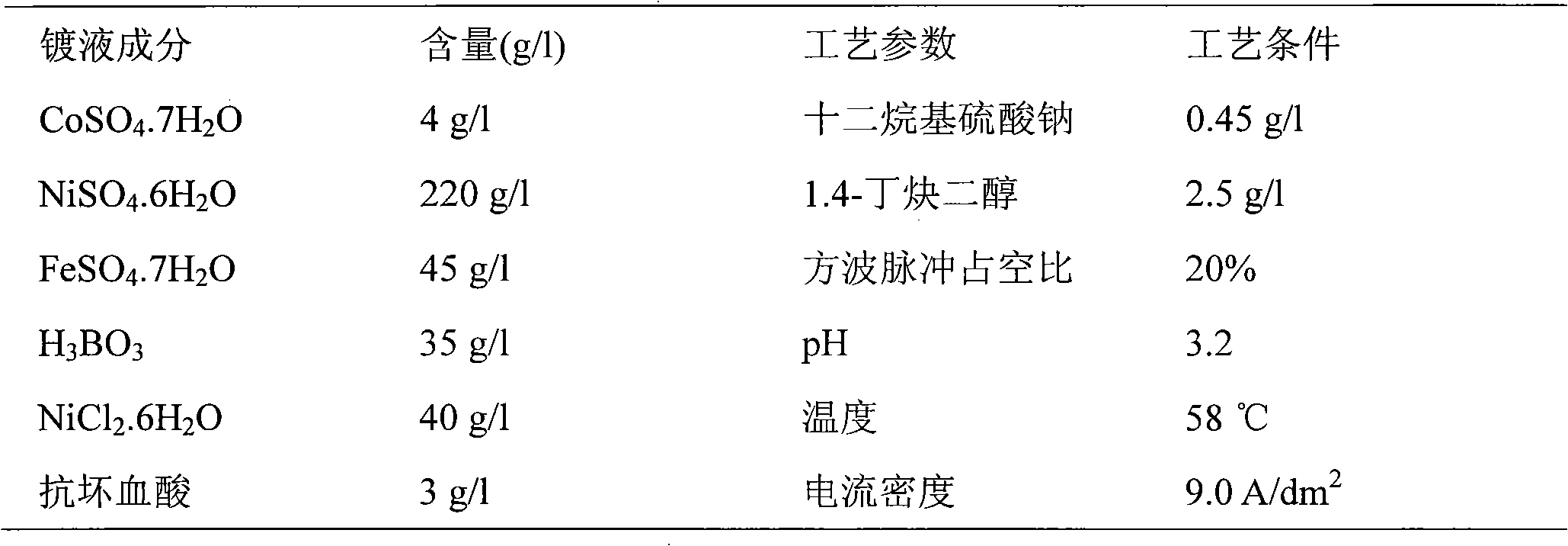

[0021] 1. Embodiment 1

[0022] The pure copper plate sample is used as the cathode material in the test, and the electrolytic nickel plate and pure iron plate are used as the anode material. The area of the electrolytic nickel plate is 120mm×120mm; the area of the pure iron plate is 120mm×20mm. The electroplating power supply adopts double-pulse numerical control controllable power supply. The cathode moving device and circulation filter device are used in the pulse electroplating process. After derusting, degreasing, and surface activation treatment, the pure copper plate sample was subjected to pulse electroplating of nickel-iron-cobalt ternary alloy under the conditions of circulating stirring and cathode movement. The composition of the plating solution and the plating conditions are shown in Table 1. The microstructure and composition energy spectrum of the obtained nanocrystalline nickel-iron-cobalt ternary alloy material are as follows: figure 1 , figure 2 show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com