A kind of chemical polishing solution and polishing method of titanium cathode roll for electrolytic copper foil

A technology for chemical polishing and electrolysis of copper foil, applied in the field of polishing liquid, can solve the problems of coarse crystals, affecting the growth of electrodeposited crystal form of copper foil, poor conductivity of cathode rollers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

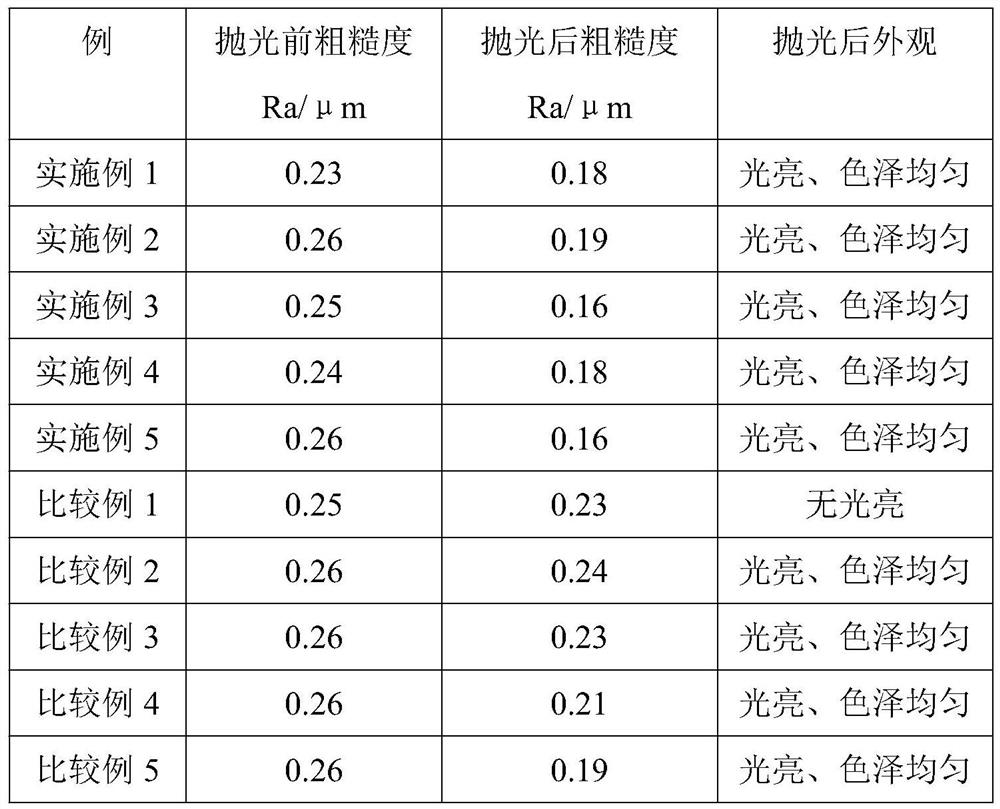

Embodiment 1

[0012] Slowly dissolve monochloroacetic acid in deionized water, slowly add an aqueous solution of disodium edetate under stirring conditions, then add an aqueous solution of nonylphenol polyoxyethylene ether (NP-10), mix to obtain a polishing solution, and polish The concentration of monochloroacetic acid in the liquid is 10g / L, the concentration of disodium edetate is 10g / L, and the concentration of nonylphenol polyoxyethylene ether (NP-10) is 0.01g / L. After the titanium plate is cleaned and degreased, it is placed in a chemical polishing solution, soaked for 20 minutes under the condition of stirring the chemical polishing solution at 20°C, and the purpose of polishing the titanium plate can be achieved. The appearance and roughness results of the titanium plates are listed in Table 1.

Embodiment 2

[0014] Slowly dissolve dichloroacetic acid in deionized water, slowly add an aqueous solution of disodium edetate under stirring conditions, then add an aqueous solution of nonylphenol polyoxyethylene ether (NP-10), mix to obtain a polishing solution, and polish The concentration of dichloroacetic acid in the liquid is 50g / L, the concentration of disodium edetate is 20g / L, and the concentration of nonylphenol polyoxyethylene ether (NP-10) is 0.05g / L. After the titanium plate is cleaned and degreased, it is placed in a chemical polishing solution, soaked for 15 minutes under the condition of stirring the chemical polishing solution at 30°C, and the purpose of polishing the titanium plate can be achieved. The appearance and roughness results of the titanium plates are listed in Table 1.

Embodiment 3

[0016] Slowly dissolve trichloroacetic acid in deionized water, slowly add an aqueous solution of disodium edetate under stirring conditions, then add an aqueous solution of nonylphenol polyoxyethylene ether (NP-10), mix to obtain a polishing solution, and polish The concentration of trichloroacetic acid in the liquid is 75g / L, the concentration of disodium edetate is 30g / L, and the concentration of nonylphenol polyoxyethylene ether (NP-10) is 0.1g / L. After the titanium plate is cleaned and degreased, it is placed in a chemical polishing solution, soaked for 10 minutes under the condition of stirring the chemical polishing solution at 40°C, and the purpose of polishing the titanium plate can be achieved. The appearance and roughness results of the titanium plates are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com