Method for electroplating nickel on surface of magnesium alloy

A technology of electroplating nickel and magnesium alloys, which is applied in the direction of superimposed layer plating, metal material coating process, coating, etc., can solve the problems of sensitive plating quality stability, poor stability of electroplating solution, ecological environment pollution, etc. Low cost, light environmental pollution, uniform surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The sample for implementation uses AZ91D magnesium alloy with a specification of 30mm×20mm×2mm as the electroplating cathode, which is polished with 240#~600# sandpaper, and is subjected to conventional alkali degreasing and acid derusting treatment.

[0021] 1. Embodiment 1

[0022] The above samples were treated in 40% HF at room temperature for 10 minutes. After the magnesium alloy surface with certain chemical activity is obtained, galvanizing treatment is carried out. The formula and process of the treatment solution are shown in Table 1.

[0023] Formulation and technological conditions of table 1 galvanizing solution

[0024]

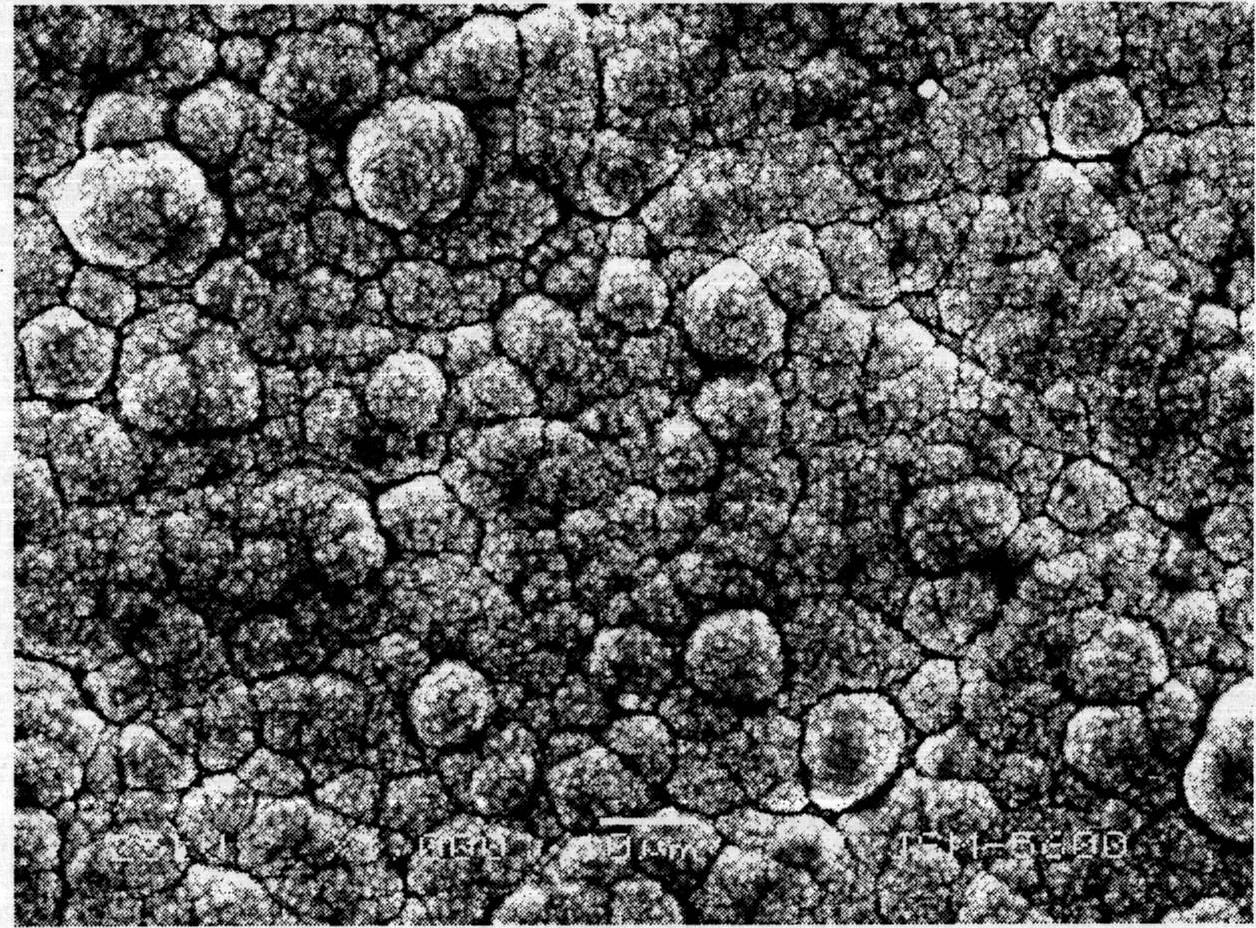

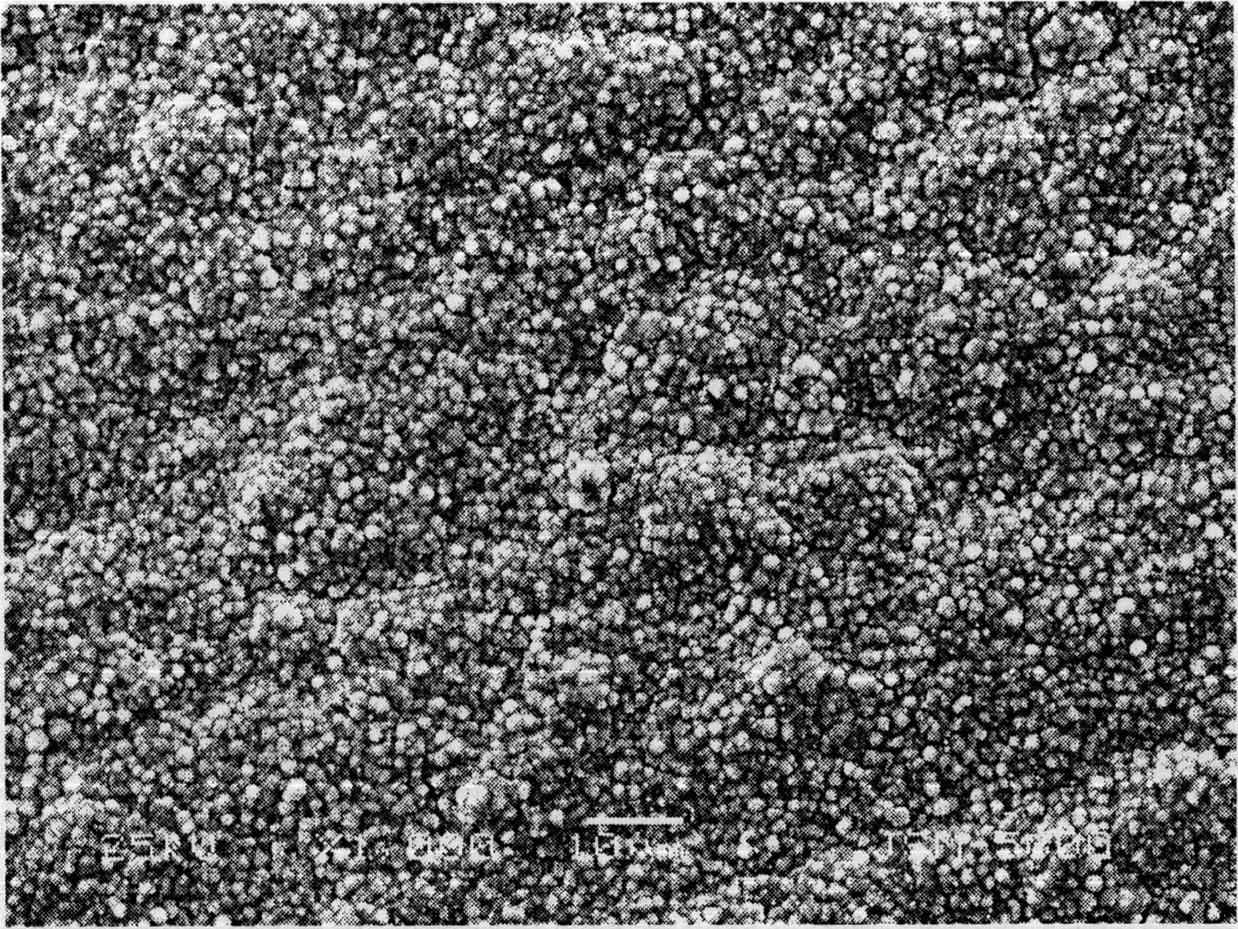

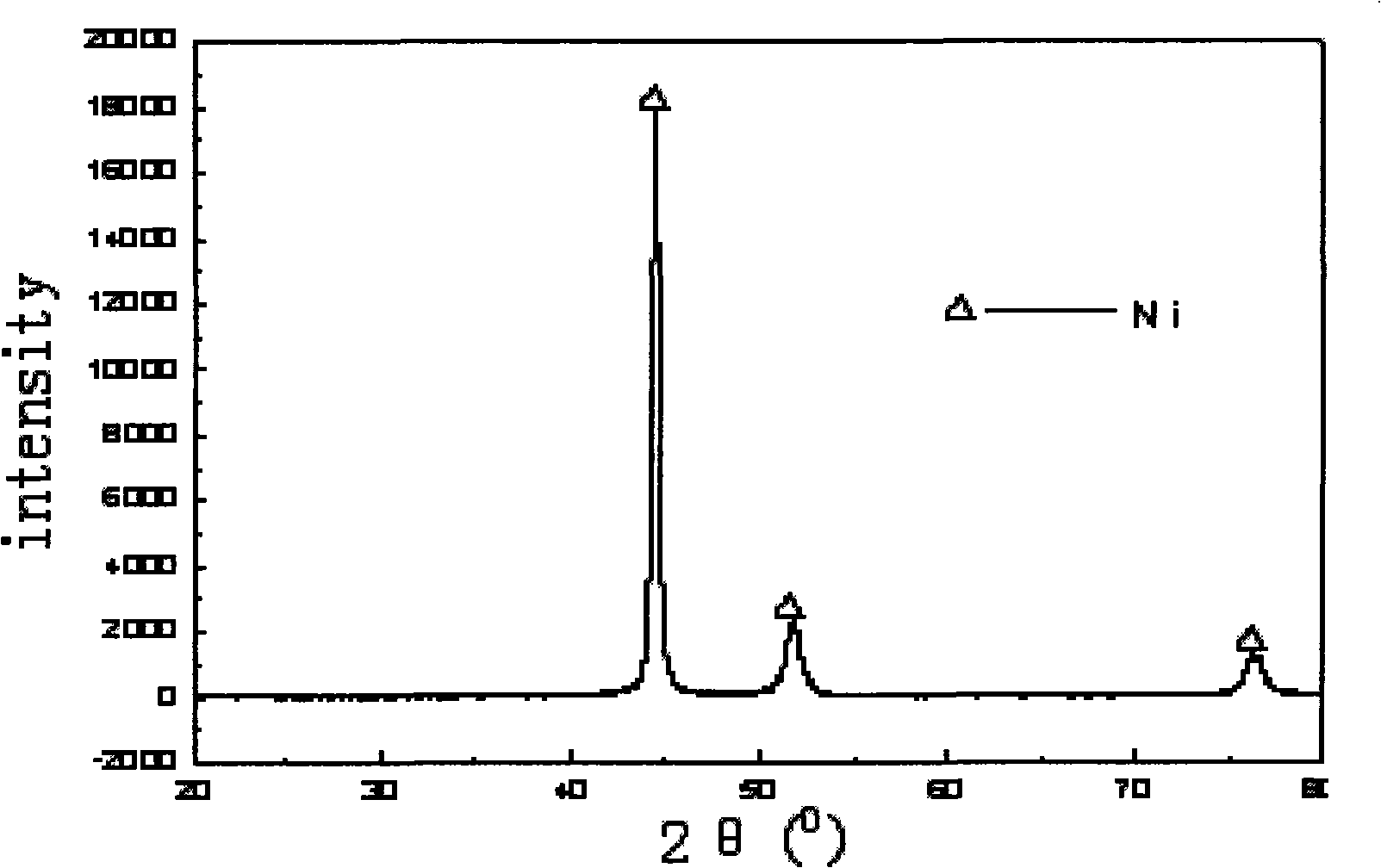

[0025] The samples after galvanizing were pre-plated with copper-tin alloy, and the plating solution formula and process conditions are shown in Table 2. After pre-plating copper-tin alloy, the surface morphology can be obtained as follows: figure 1 Copper-tin alloy plating shown. The samples after the pre-plating of copper-tin all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com