Preparation method for carbon composite refractory and product prepared by preparation method

A refractory material and carbon composite technology, which is applied in the field of refractory materials, can solve the problems of low slag corrosion resistance and thermal shock resistance, thermal stability and specific surface area inferior to carbon nanotubes, and uneven dispersion of additional carbon nanotubes. Achieve the effects of promoting wettability, excellent slag corrosion resistance and thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

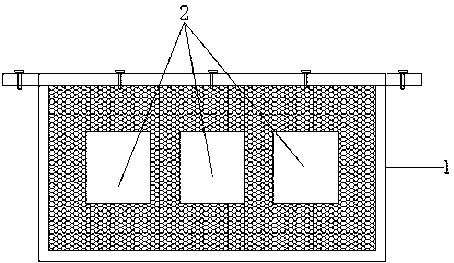

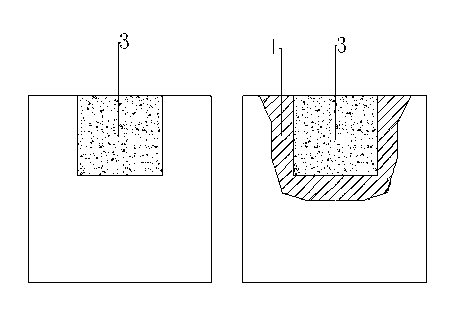

Method used

Image

Examples

Embodiment 1

[0040] (1) Add water to 10 mol of iron nitrate and 2 mol of nickel nitrate to prepare a 0.05 mol / L active material precursor solution, add 1000 g of 2 μm corundum powder to 1 L of the above solution and mix, and dry the mixture at 60 °C After 24 hours, use a ball mill to disperse into particles of 2 μm, and roast the above particles at 300°C for 2 hours to obtain the active material-alumina composite material; feed 99.99% argon into the active material-alumina composite material and raise the temperature to 500°C, and then Stop the flow of argon, and at the same time pass 200L / h, 99.99% hydrogen into the active material-alumina composite material for activation for 0.5h;

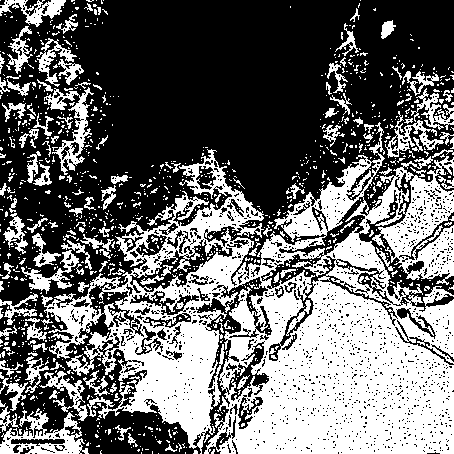

[0041] (2) Introduce 100L / h of natural gas with a purity of 98v% into the activated active matter-alumina composite material for cracking reaction, the cracking temperature is 900°C, and the cracking time is 1h to obtain alumina with a particle size of 43μm- Carbon nanotube composite material, wherein the di...

Embodiment 2

[0046] (1) Add water to 1 mol of iron nitrate and 5 mol of nickel nitrate to prepare a 0.5 mol / L active material precursor solution, add 10 kg, 500 μm magnesia to 1 L of the above solution and mix, and dry the mixture at 80 °C After 36 hours, use a ball mill to disperse the particles into 500 μm particles, and roast the above particles at 600°C for 30 minutes to obtain the active material-magnesia composite material; feed 99.99% argon gas into the active material-magnesia composite material and raise the temperature to 600°C, and then Stop the flow of argon, and at the same time pass 300L / h, 99.99% hydrogen into the active material-magnesia composite material for activation for 1h;

[0047] (2) Introduce 500L / h of natural gas with a purity of 95v% into the activated active material-magnesia composite material for cracking reaction. The cracking temperature is 600°C and the cracking time is 4h to obtain magnesium oxide- Carbon nanotube composite material, wherein the diameter o...

Embodiment 3

[0052] (1) Add water to 1 mol of iron nitrate and 3 mol of nickel nitrate to form a 0.3 mol / L active substance precursor solution, add 1500 g of 5 μm zirconia and 1500 g of 5 μm corundum powder to 1 L of the above solution and mix them. After the mixture was dried at 100°C for 12 hours, it was dispersed into 5 μm particles with a ball mill, and the above particles were fired at 400°C for 60 minutes to obtain the active material-zirconia-alumina composite; 99.99% argon and heat up to 400°C, then stop argon, and at the same time pass 400L / h 99.99% hydrogen into the active material-zirconia-alumina composite material for activation for 2h;

[0053] (2) Introduce 300L / h of ethane with a purity of 95v% and 1200L / h of high-purity hydrogen into the activated active material-zirconia-alumina composite material for cracking reaction. The cracking temperature is 800°C and the cracking time is For 2h, the zirconia-alumina-carbon nanotube composite material with a particle size of 43 μm w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com