Method for obtaining liquid silicon, and crucible for achieving method

A liquid silicon and crucible technology, applied in chemical instruments and methods, crystal growth, and self-melting solvent melts, etc., can solve problems such as erosion, crucible leakage, consumption of Al, etc., and achieve increased solubility, facilitated growth, and reduced costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

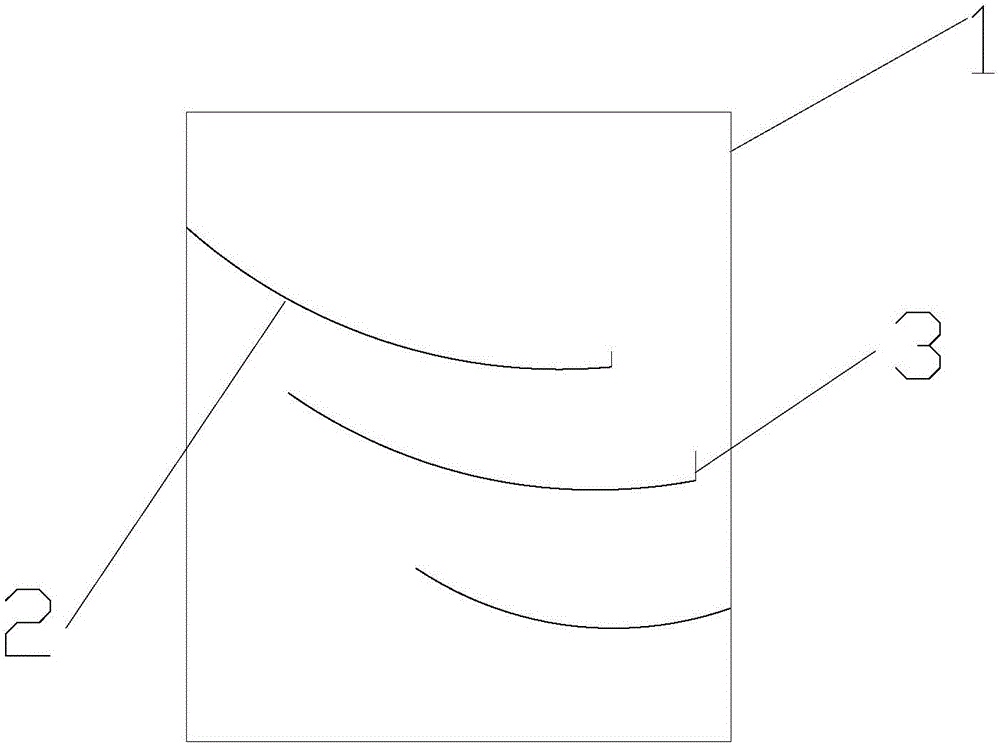

[0021] A method for obtaining liquid silicon. The specific steps are: synchronously melting a cosolvent in a crucible and automatically adding it into the liquid silicon, thereby increasing the solubility of carbon in the liquid silicon; using the temperature gradient in the crucible to promote the cosolvent and The silicon element melts simultaneously.

[0022] The co-solvent is selected from one or more of Fe, Mn, Ti, Cr, Al.

Embodiment 2

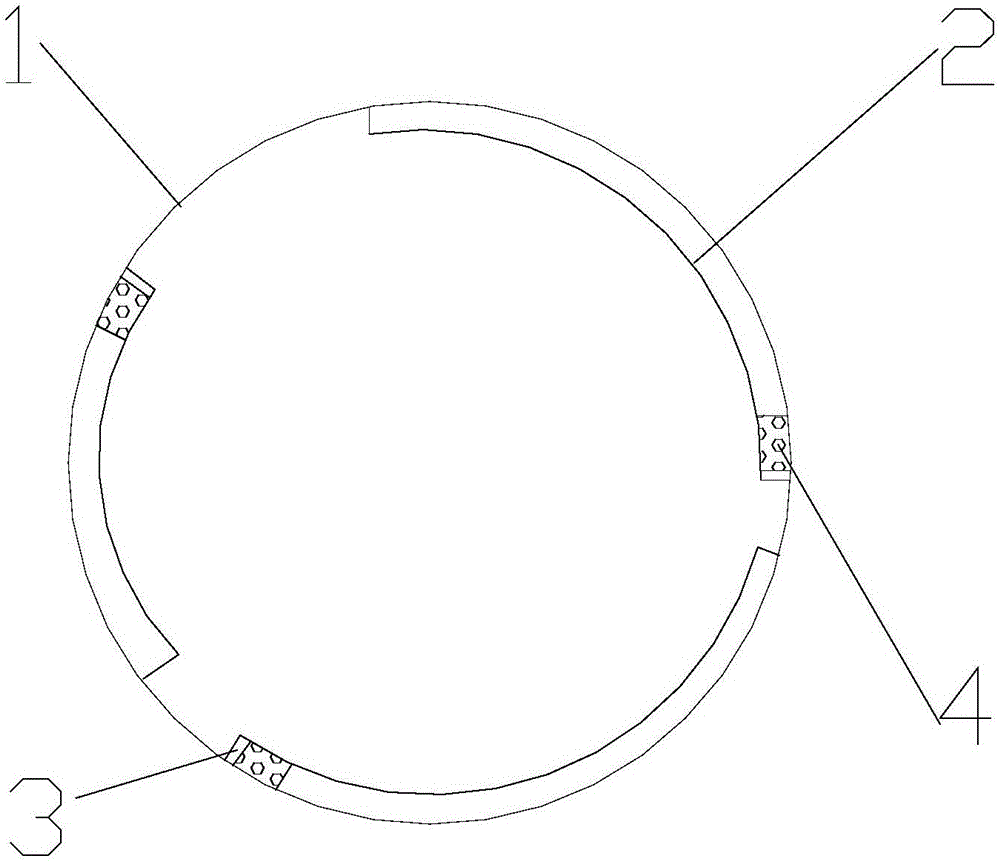

[0024] A kind of crucible, described crucible comprises crucible body 1, and described crucible body 1 is provided with three grooves 2, and described groove one end is provided with baffle plate 3; Described groove is provided with small pores 4;

[0025] The groove 2 is arranged on the inner wall of the crucible body 1; the groove 2 is spiral;

[0026] The small pores 4 are evenly placed at the bottom of the tail end of the groove 2; the three grooves are arranged in a staggered manner, and the vertical heights from the starting end to the bottom of the crucible are different.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com