Electro-deposition method for preparing bulk nano ferro-nickel alloy crystalline

A ferroalloy and electrodeposition technology, which is applied in the field of preparing bulk nano-metal crystals, can solve the problems of small size of nano-crystalline alloy materials, inability to perform mechanical properties, containing pores, etc., and achieves the effects of low price, fine crystallization and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] 1. Embodiment 1

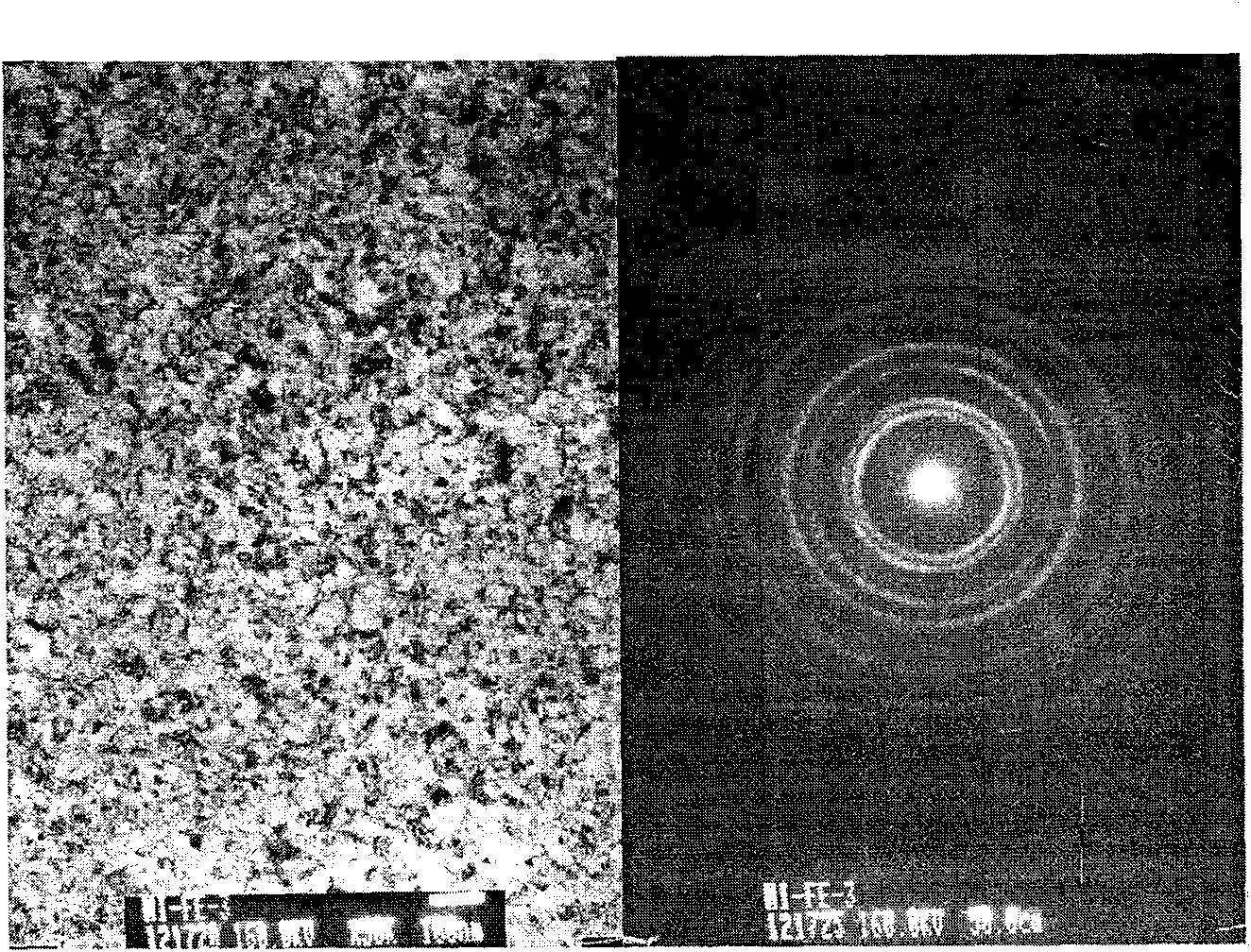

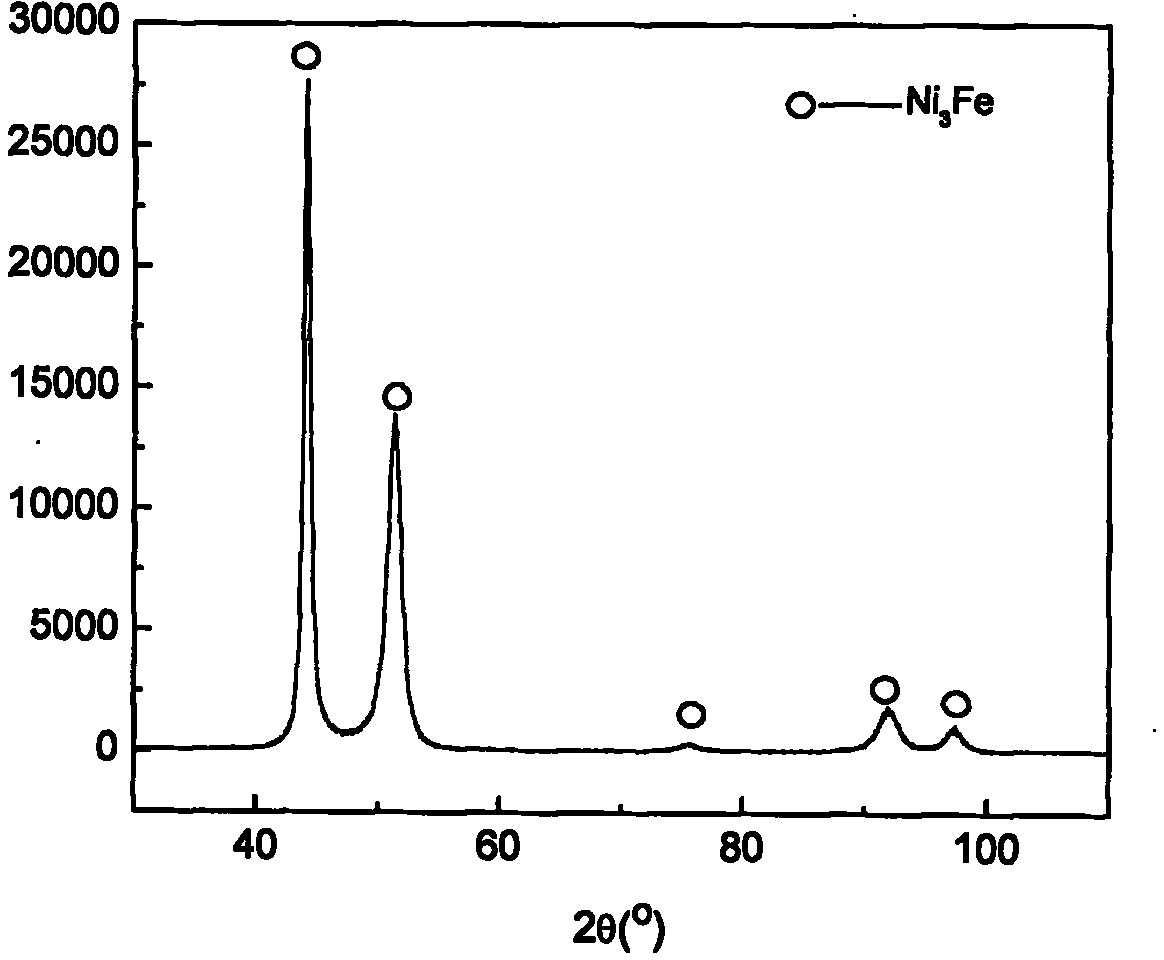

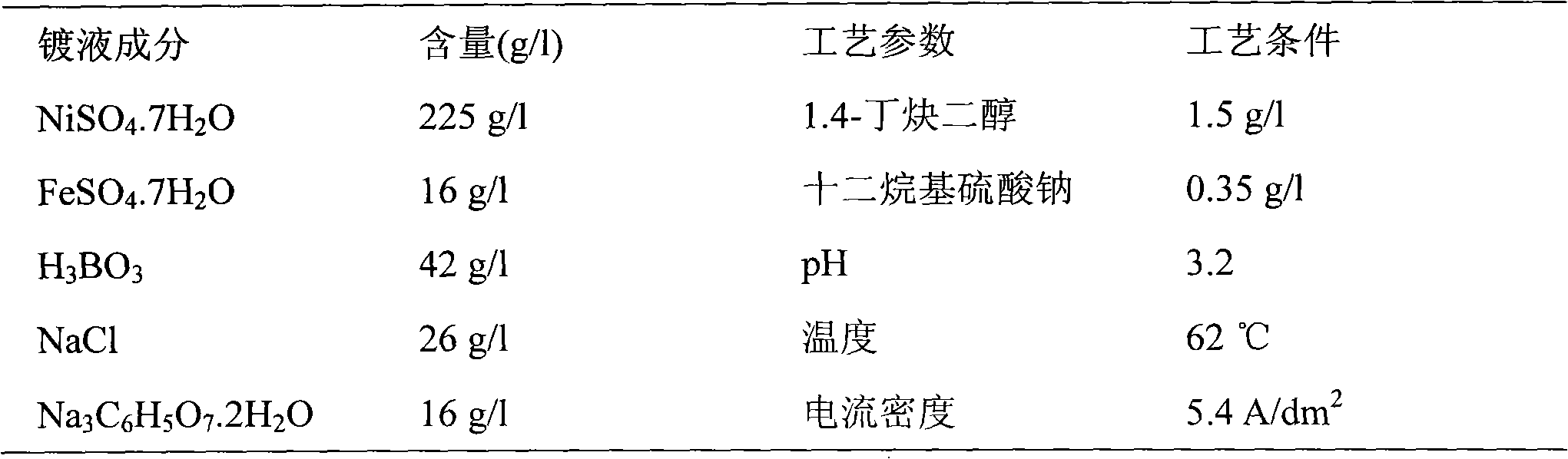

[0022] The low-carbon steel sample was used as the cathode material in the test, and the electrolytic nickel plate and the pure iron plate were used as the anode materials. The area of the electrolytic nickel plate was 100mm×100mm; the area of the pure iron plate was 100mm×20mm. Electroplating power supply adopts silicon controlled rectifier power supply. The cathode moving device and circulation filter device are used in the electroplating process. The low-carbon steel samples were electroplated with nickel-iron alloy under the conditions of circulating stirring and cathode movement after derusting, degreasing and surface activation treatment. The composition of the plating solution and the plating conditions are shown in Table 1. The microstructure and phase structure of the obtained nanocrystalline nickel-iron alloy materials are as follows: figure 1 , figure 2 shown.

[0023] 2. Embodiment 2

[0024] After the above-mentioned low carbon s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com