Method for growing large-size and low-defect silicon carbide monocrystal and wafer

A silicon carbide single crystal, low-defect technology, applied in chemical instruments and methods, single crystal growth, crystal growth, etc., can solve problems such as dislocation defects in large-diameter SiC crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in detail below in conjunction with the accompanying drawings:

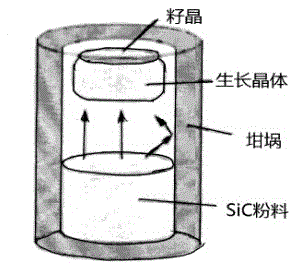

[0022] A method for growing large-scale low-defect silicon carbide single crystals and wafers, comprising the steps of:

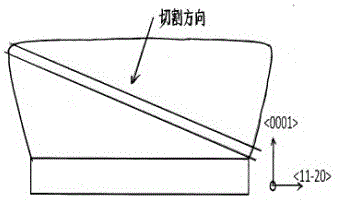

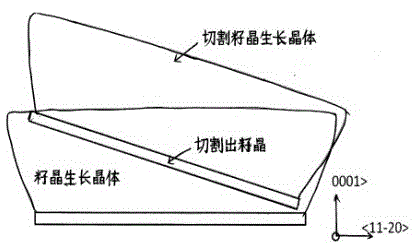

[0023] 1. Use the mainstream {0001} plane or {0001} plane off-angle direction 0, 4 degree SiC wafer as the seed crystal for growth, especially, there is no special requirement for its defects, and there are many defects and Less defects are available, (the level of SiC wafers purchased on the market is determined by the number of defects, the higher the level, the higher the price). In addition, the seed crystal diameter must be the desired wafer diameter plus 0.5 to 1 inch (due to the large radial temperature gradient at the crystal edge during growth and the interference of the lining edge, the quality of the crystal edge is poor, and high-quality crystals must be obtained And wafers need to remove the part with poor edge quality during processing,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com