Growth device for sapphire crystal hemisphere cover and growth method for sapphire crystal hemisphere cover

A sapphire crystal and growth device technology, applied in crystal growth, single crystal growth, single crystal growth and other directions, can solve the problems of easy deformation of the growth interface, uneven shape and instability of the growth interface, and achieve good cooling effect and optimized temperature. Distributed and uniform cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

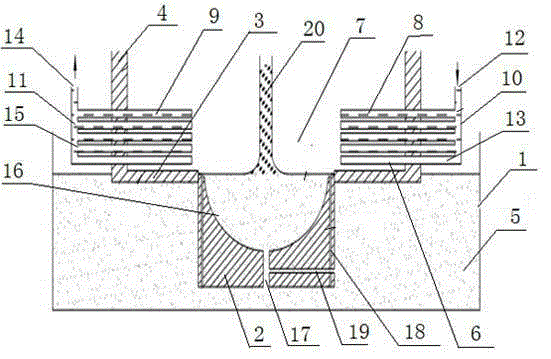

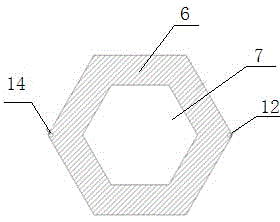

[0036] Such as figure 1 As shown, the present invention discloses a sapphire crystal hemispherical cover guided mode growth device, including a crystal growth furnace, a crucible 1 installed in the furnace, a mold 2, a suspension plate 3 and a suspension rod 4 installed on the upper end surface of the suspension plate 3 , the lower end of the mold 2 is immersed in the alumina melt 5 in the crucible 1, and its upper end is installed in the center of the suspension plate 3 and driven by the suspension rod 4 to move up and down; a gas cooling plate 6 is also installed on the suspension rod 4, The gas cooling plate 6 is a hollow cylinder with a rotary structure, and the gas cooling plate 6 is horizontally arranged above the hanging plate 3; the center of the gas cooling plate 6 is a seeding channel for the seed crystal 20 to descend and grow 7. Its inner wall has several layers of cooling fins 8 uniformly distributed in the axial direction; each layer of cooling fins 8 is annular,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com