Method for separating methanol/methyl methacrylate mixed system

A methyl methacrylate, methanol technology, applied in the separation/purification of hydroxyl compounds, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of high energy consumption, complex process, etc. Continuous, less demanding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: the separation of methanol and methyl methacrylate mixed system methanol

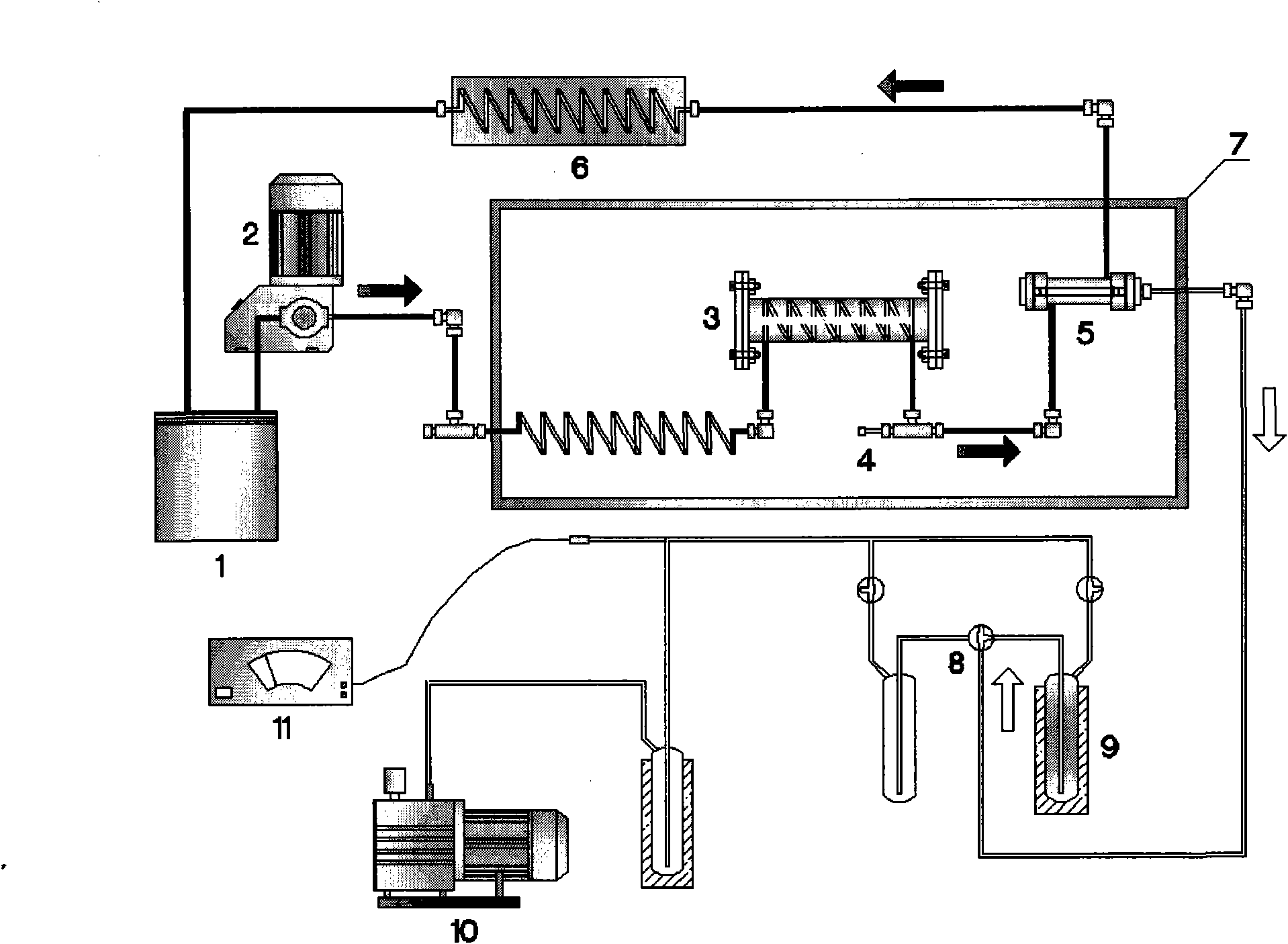

[0036] The prepared Beta molecular sieve membrane was figure 1 The pervaporation device shown. The Beta molecular sieve membrane assembly is placed in a programmable oven 7, the inner cavity of the membrane tube is connected to a vacuum pump 10, and the inner side is evacuated. The mixed raw material solution 1 of methanol and methyl methacrylate is injected into the circulation pipeline through the electric metering pump 2, and after flowing through the preheater 3, the feed solution enters the membrane module 5 for osmotic separation. The permeated vapor (methanol vapor) enters the cold trap 9 driven by negative pressure, and is rapidly condensed and collected by liquid nitrogen. The liquid separated by the membrane module is cooled by the condenser 6 and then returned to the feed liquid tank.

Embodiment 2

[0038] Embodiment 2: Beta molecular sieve membrane preparation

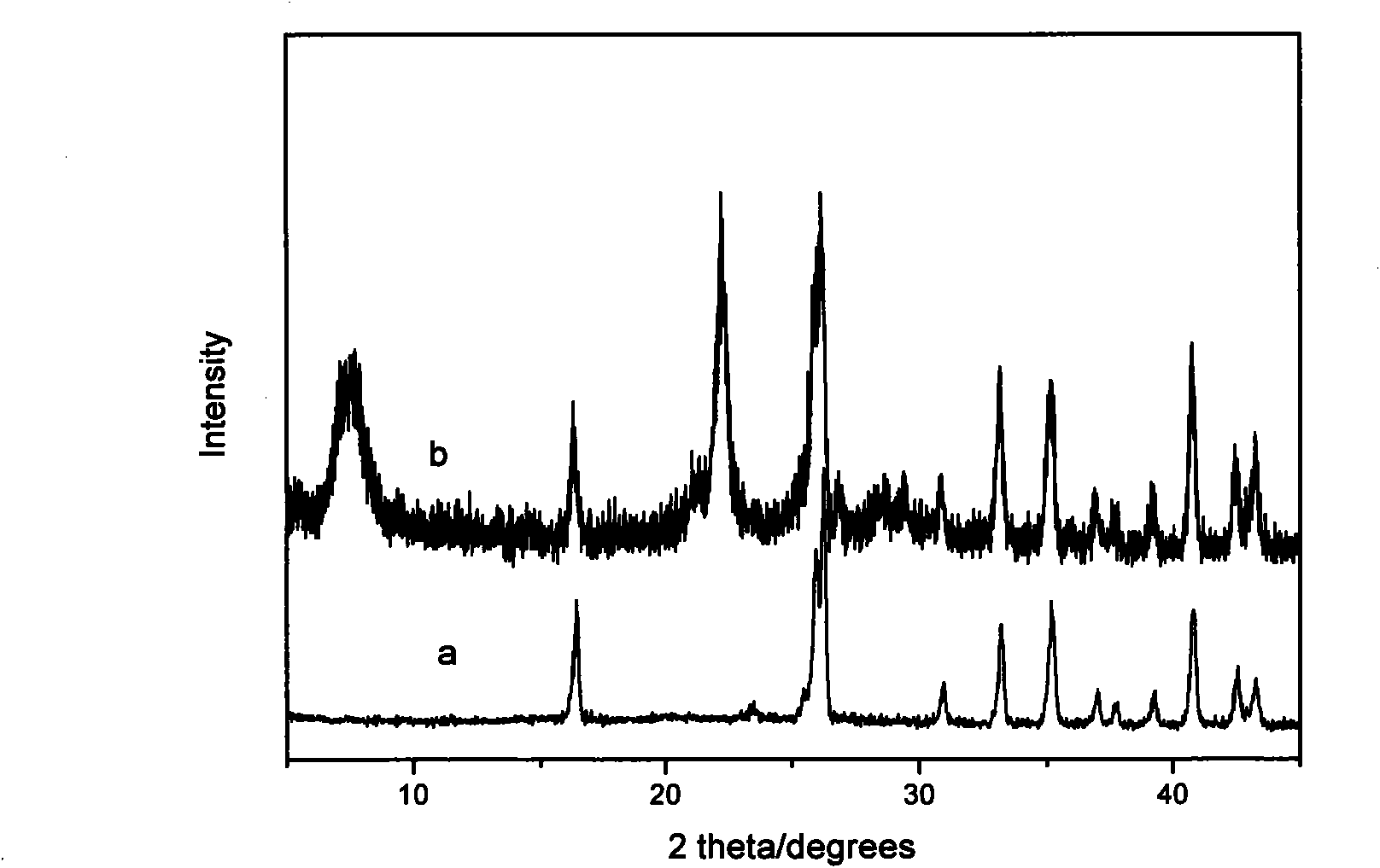

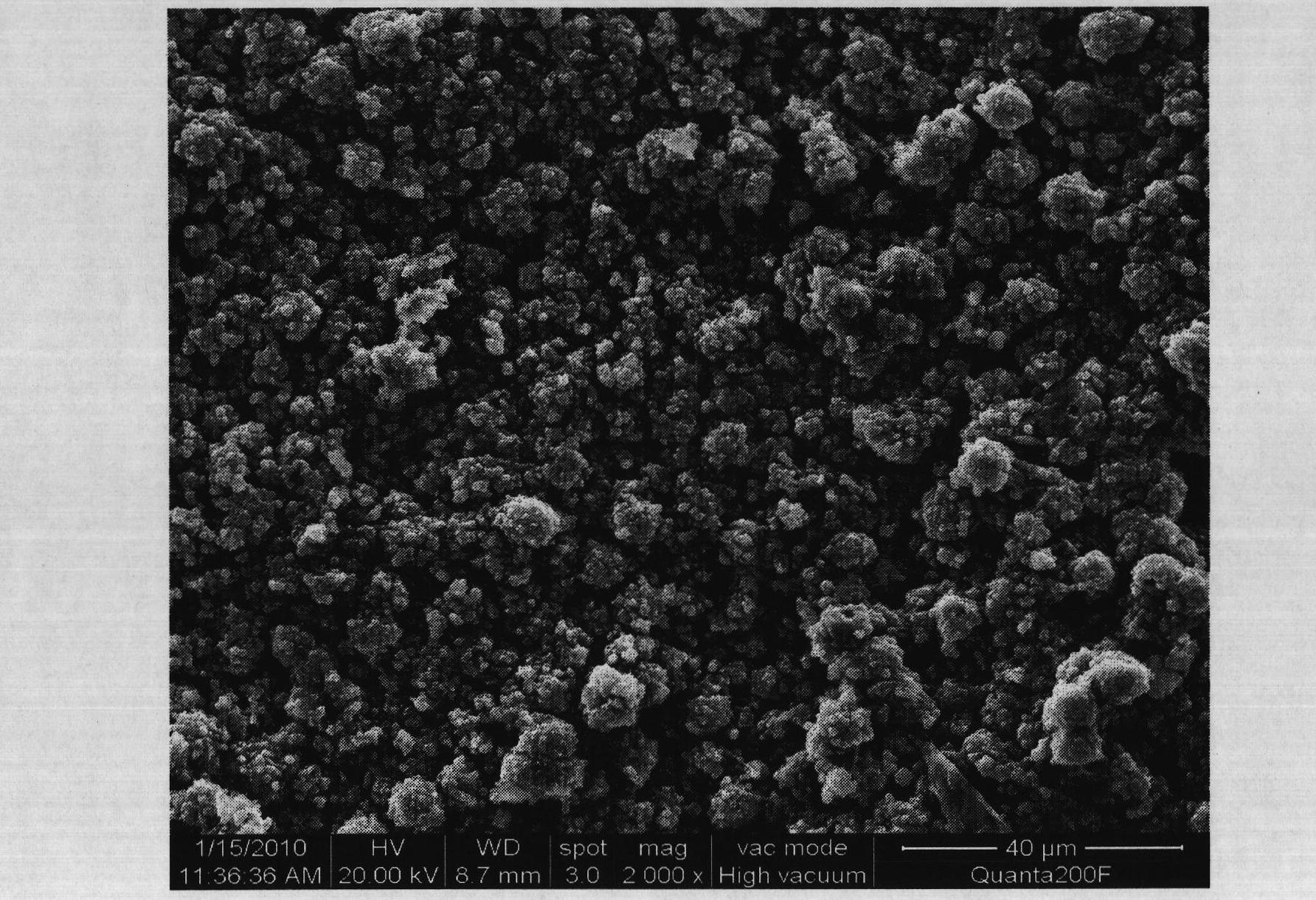

[0039] The support body adopts the porous mullite tube made by Japan Nikkato Co., Ltd. as the substrate for membrane synthesis, and the composition of mullite is 67wt%Al 2 o 3 and 33wt% SiO 2 . The support was polished with 800-grit sandpaper, ultrasonically cleaned, and dried. On the one hand, soak the dried support in methanol solution containing 50% dimethyldiethoxysilane for 30 minutes to make the surface of the support positively charged; on the other hand, in 10% Beta molecular sieve seed crystal solution NaOH solution was added dropwise to adjust the pH value to 10, so that the surface of the seed crystal was negatively charged, and the positively charged support was placed in the negatively charged seed solution, and the seed crystal was evenly coated on the support by the action of charge On the outer surface of the beta, put it for 10 minutes, slowly lift it out of the solution, dry it, soak it repe...

Embodiment 3

[0045] Embodiment 3 (Beta molecular sieve membrane preparation)

[0046] The supporting body is made of tubular stainless steel produced by Mott Company of the United States. The support was polished with 800-grit sandpaper, ultrasonically cleaned, and dried. On the one hand, soak the dried support in methanol solution containing 30% dimethyldiethoxysilane for 30 minutes to make the surface of the support positively charged; on the other hand, in 10% Beta molecular sieve seed crystal solution NaOH solution was added dropwise to adjust the pH value to 10, so that the surface of the seed crystal was negatively charged, and the positively charged support was placed in the negatively charged seed solution, and the seed crystal was evenly coated on the support by the action of charge On the outer surface of the beta, put it for 20 minutes, slowly lift it out of the solution, dry it, soak it repeatedly 4 times, the thickness of the Beta seed layer is 0.5-3 μm, and dry it for later ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com