Fast cooling reel-to-reel plasma enhanced CVD (chemical vapor deposition) continuous growth furnace

A plasma and rapid cooling technology, used in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problem of not being able to quickly cool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

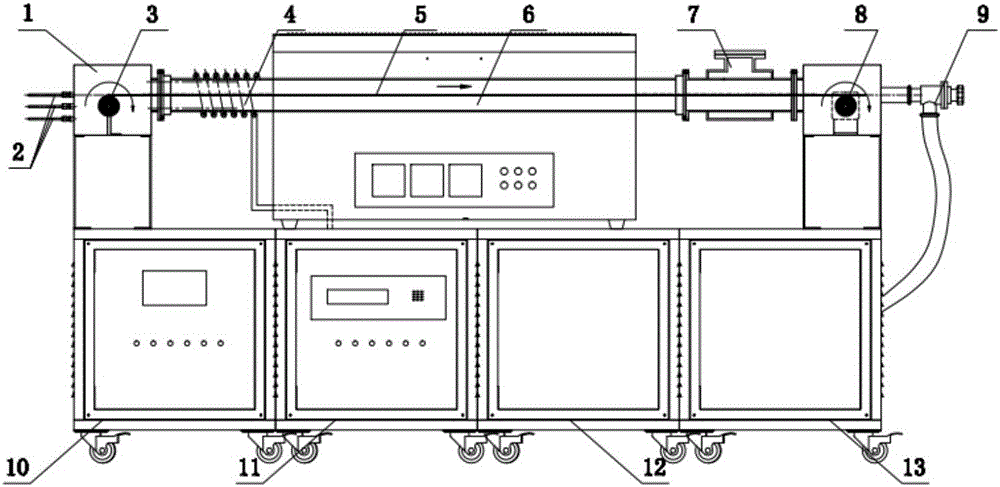

[0018] see figure 1 The specific embodiment of the present invention adopts the following technical solutions: it includes a CVD tube furnace 6, and the two ends of the furnace tube of the CVD tube furnace 6 are respectively equipped with a feed intake vacuum chamber 1 and a discharge exhaust vacuum chamber In the vacuum chamber, unwinding rollers 3 and winding rollers 8 are correspondingly installed, and a radio frequency plasma generator 4 is installed between the feeding inlet chamber 1 and the furnace body, and the discharging and exhausting A liquid nitrogen cold trap 7 is installed between the cavity and the body of furnace; the feed and intake vacuum chamber 1 is connected to the gas supply system 10; a vacuum rotating motor is also installed in the discharge and exhaust vacuum chamber; The material exhaust vacuum chamber is connected with a vacuum unit 13 with a vacuum valve 9; the vacuum chamber can be opened, and it is made of metal material; the radio frequency plas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com