Patents

Literature

35results about How to "Synthetic high purity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

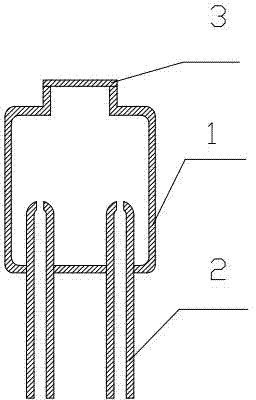

Rapid synthesis method of indium phosphide polycrystalline material and multi-tubular quartz phosphorus bubble thereof

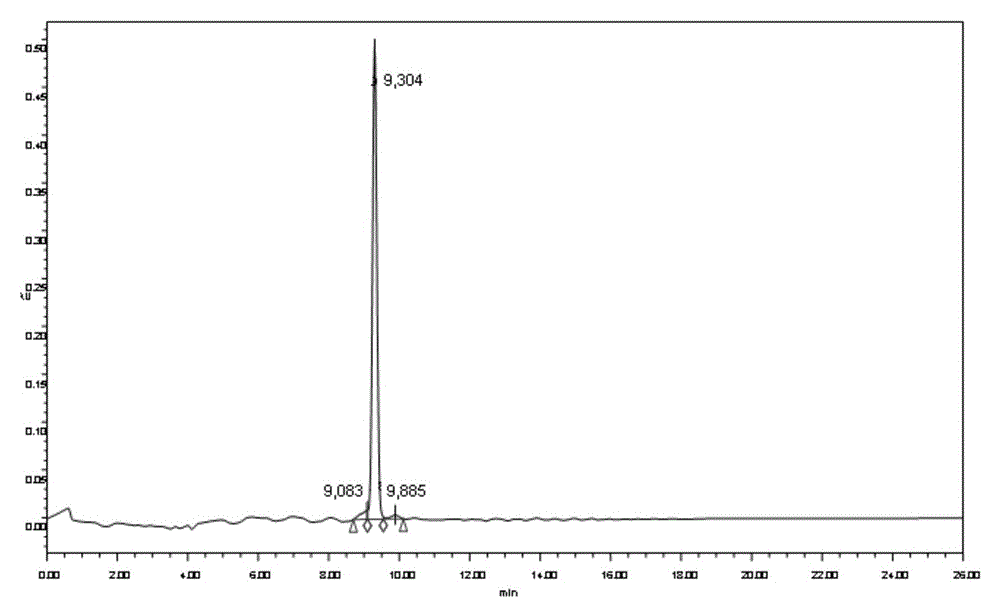

InactiveCN102965734ASynthetic high purityContinuous growthPolycrystalline material growthSingle crystal growth detailsIndiumSynthesis methods

The invention discloses a rapid synthesis method of an indium phosphide polycrystalline material, which comprises the following steps of: (I) performing surface cleaning treatment on indium; (II) placing a multi-tubular quartz phosphorus bubble with phosphorus into a phosphorus source furnace; (III) placing the pre-designed thermal insulation system, heater, crucible with indium, phosphorus source furnace and seed crystal and B2O3 into a high-pressure single-crystal furnace hearth; (IV) vacuumizing the inside of the furnace and filling high-purity argon; (V) heating to vaporize phosphorus in the phosphorus bubble and injecting into indium melt, and reacting to generate indium phosphide; and (VI) growing crystal. The multi-tubular quartz phosphorus bubble comprises a quartz phosphorus container, at least two quartz phosphorus bubble tubes and a quartz cover. By adopting a multi-tubular quartz phosphorus bubble, the method disclosed by the invention realizes a rapid multi-tubular phosphorus injection synthesis technology, solves the problems of long synthesis time, non-uniform melt proportioning, impurity pollution and the like in the original technology, realizes rapid, efficient and high-purity synthesis of the indium phosphide material, and performs InP single crystal growth more easily.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

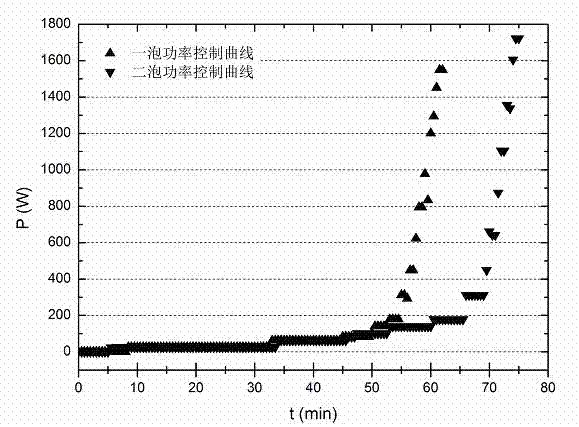

Eco-friendly general preparation method for pyridyl porphyrin metallization

ActiveCN108101918AImprove synthesis efficiency and post-application efficiencySimple processOrganic chemistryGramOrganic synthesis

The invention discloses an eco-friendly general preparation method for pyridyl porphyrin metallization and belongs to the technical field of organic synthesis chemistry. The method comprises mixing ahydrochloric acid solution of 5, 10, 15, 20-tetra(4-pyridyl)porphyrin or tetra(N-methyl-4-pyridinyl)porphine tetratosylate and different metal salts according to a molar ratio of 1: 1.1 to 2, carryingout a reaction process at the normal temperature or 25-180 DEG C for 5-48h, adding 0.5-1 M of a NaOH aqueous solution into the reaction solution, carrying out centrifugation, and washing the precipitates through water twice to obtain metal porphyrin. The preparation method does not utilize any organic solvent, realizes large-scale preparation of high purity metal porphyrin (in a gram level) through an eco-friendly synthesis route and is easy to operate. The preparation method has a certain versatility and is an efficient method for efficient preparation of metal porphyrin.

Owner:HENAN UNIVERSITY

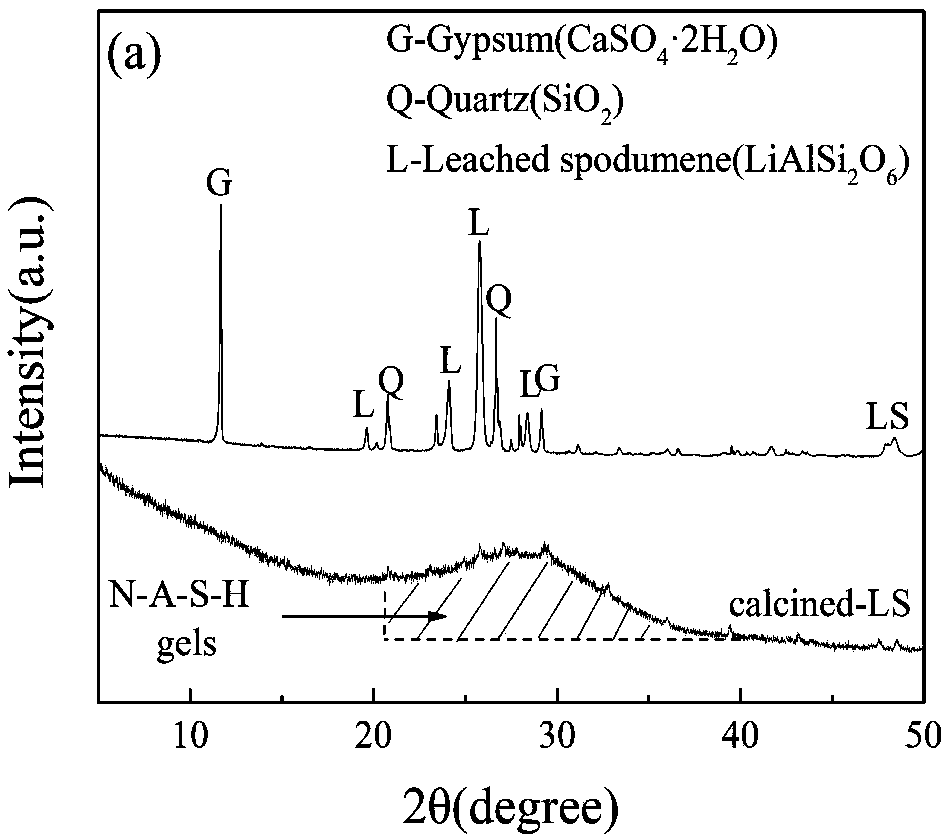

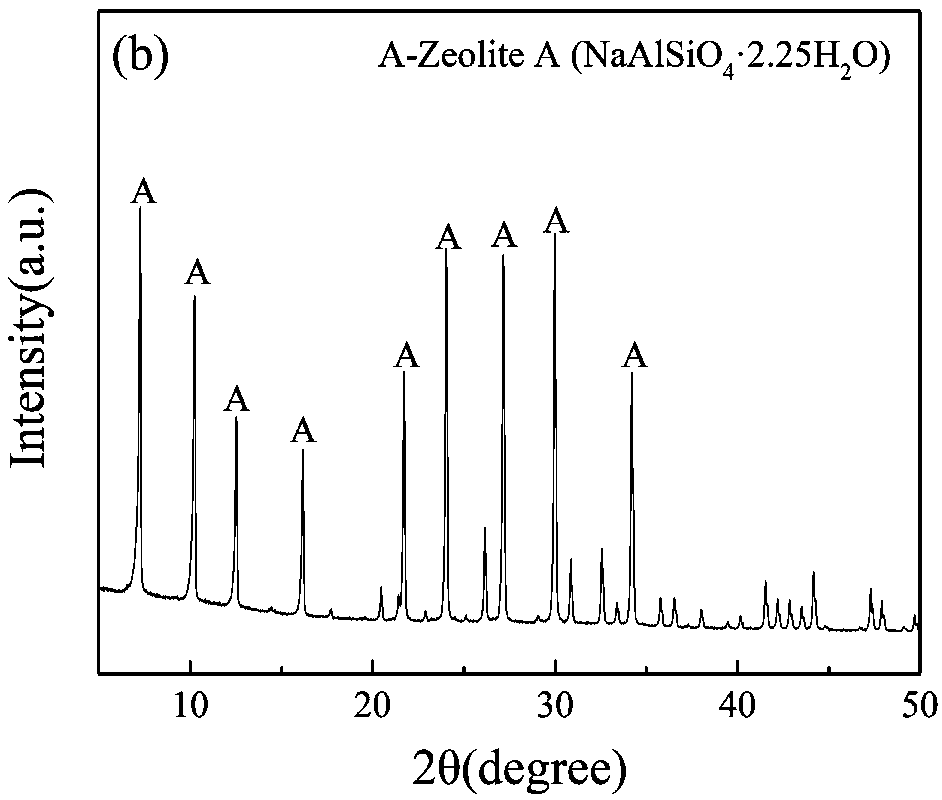

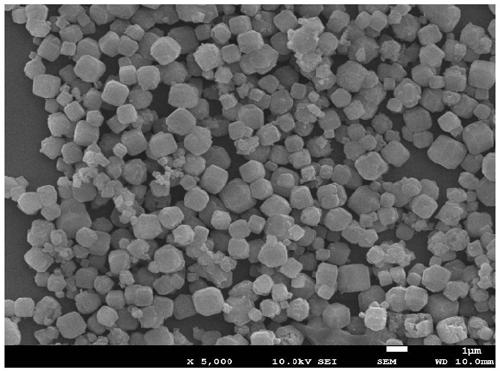

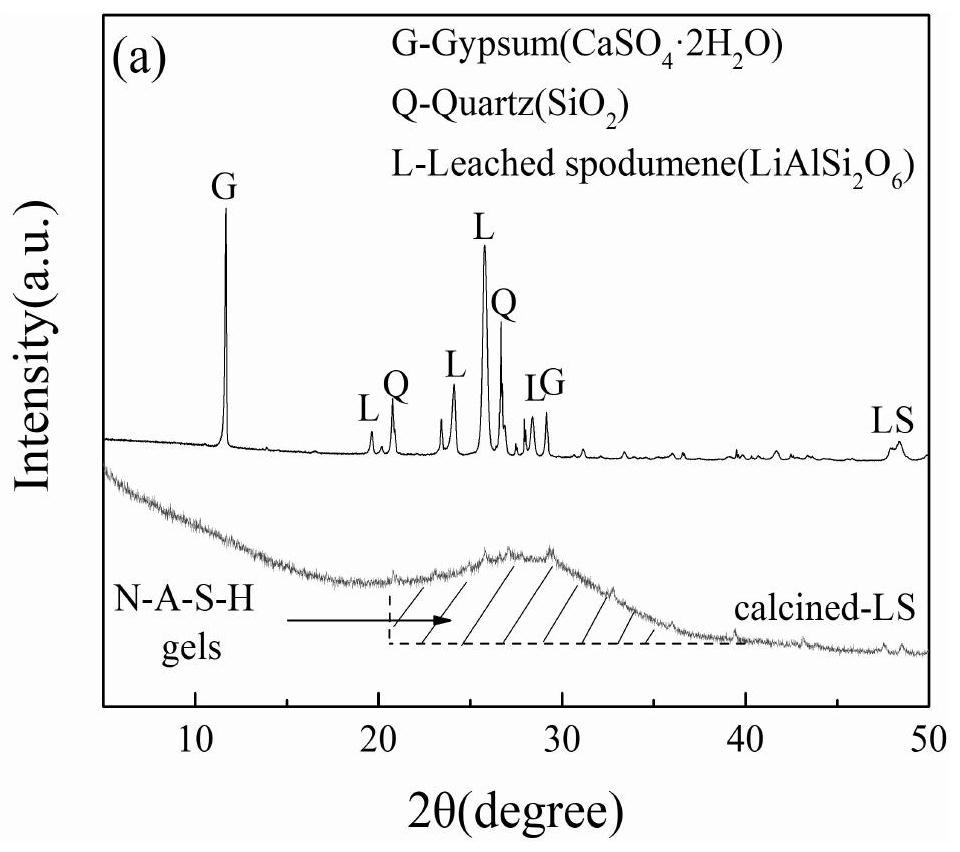

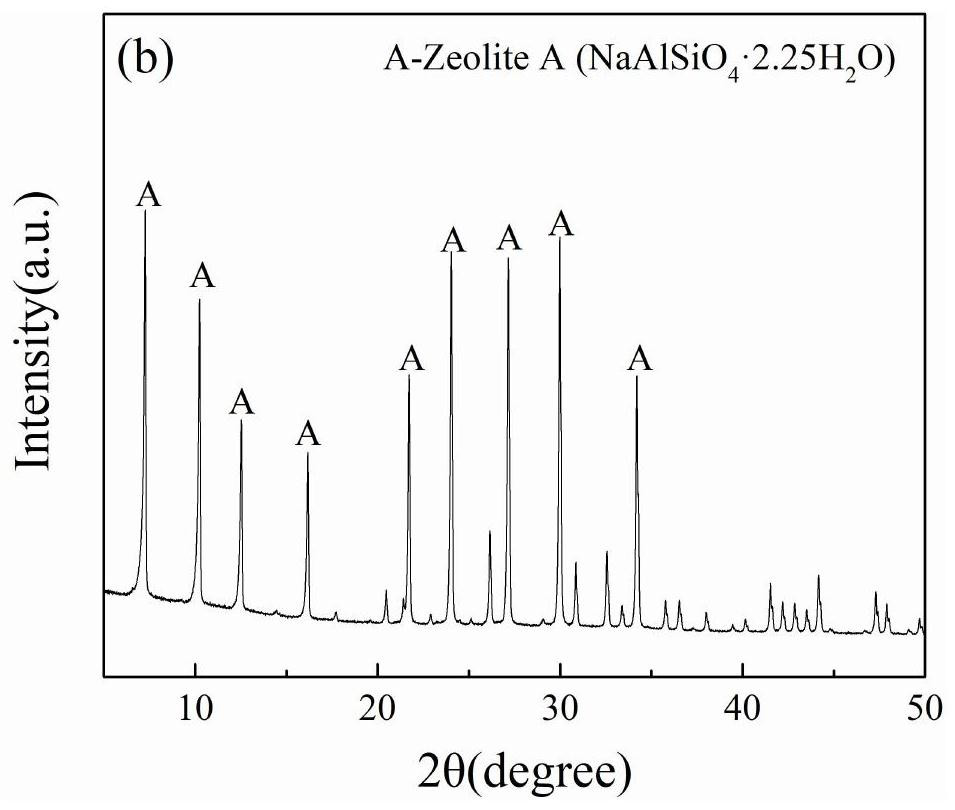

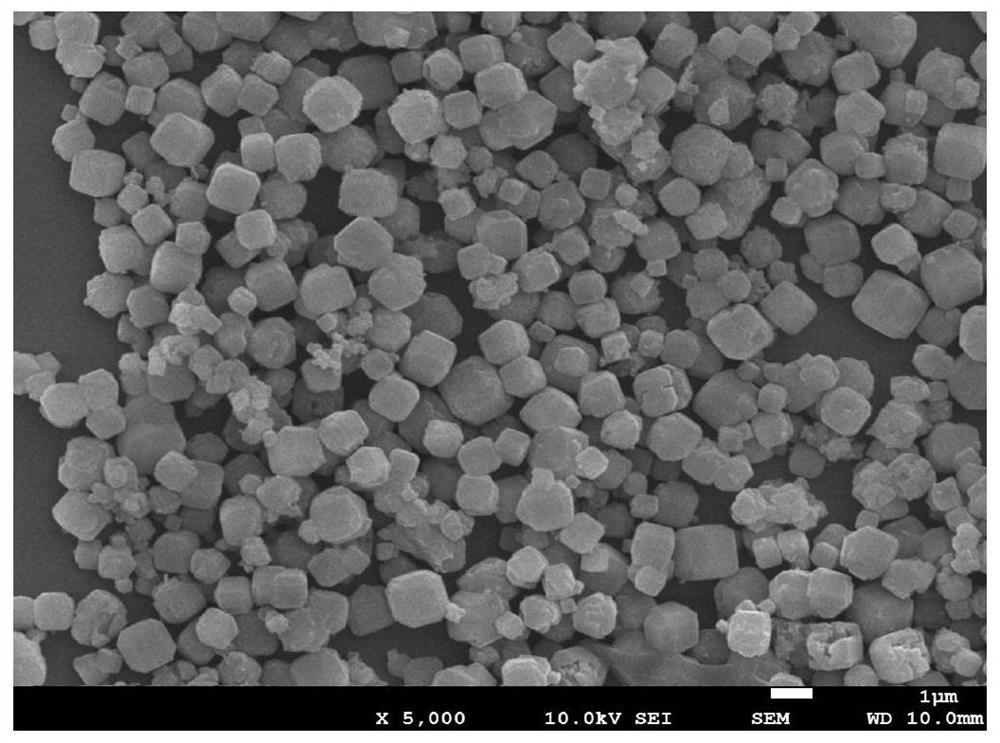

Low-temperature preparation method of lithium slag based NaA molecular sieve

ActiveCN109485062AHigh reactivityReduce hindranceAluminosilicate zeolite type-ALithiumMolecular sieve

The invention provides a low-temperature preparation method of a lithium slag based NaA molecular sieve and belongs to the technical fields of industrial solid waste recycling and molecular sieve preparation. The low-temperature preparation method comprises the following steps: (1) pre-treating raw lithium slag; (2) performing alkali fusion on the pretreated lithium slag by adopting an alkali fusion agent so as to obtain silicate clinker; (3) adding an aluminum source and a water source into the silicate clinker, regulating the silicon-aluminum molar ratio to be (1.0-2.4):1 and controlling a water-alkali molar ratio to be (40-80):1 so as to obtain a NaA molecular sieve precursor; and (4) carrying out a hydrothermal reaction on the NaA molecular sieve precursor at a temperature of 45-75 DEGC, thereby obtaining the lithium slag based NaA molecular sieve. According to the preparation method disclosed by the invention, the lithium slag serves as the raw material, the high-purity lithium slag based NaA molecular sieve can be prepared at a low hydrothermal temperature in short reaction time, and high value-added utilization of the lithium slag is realized.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

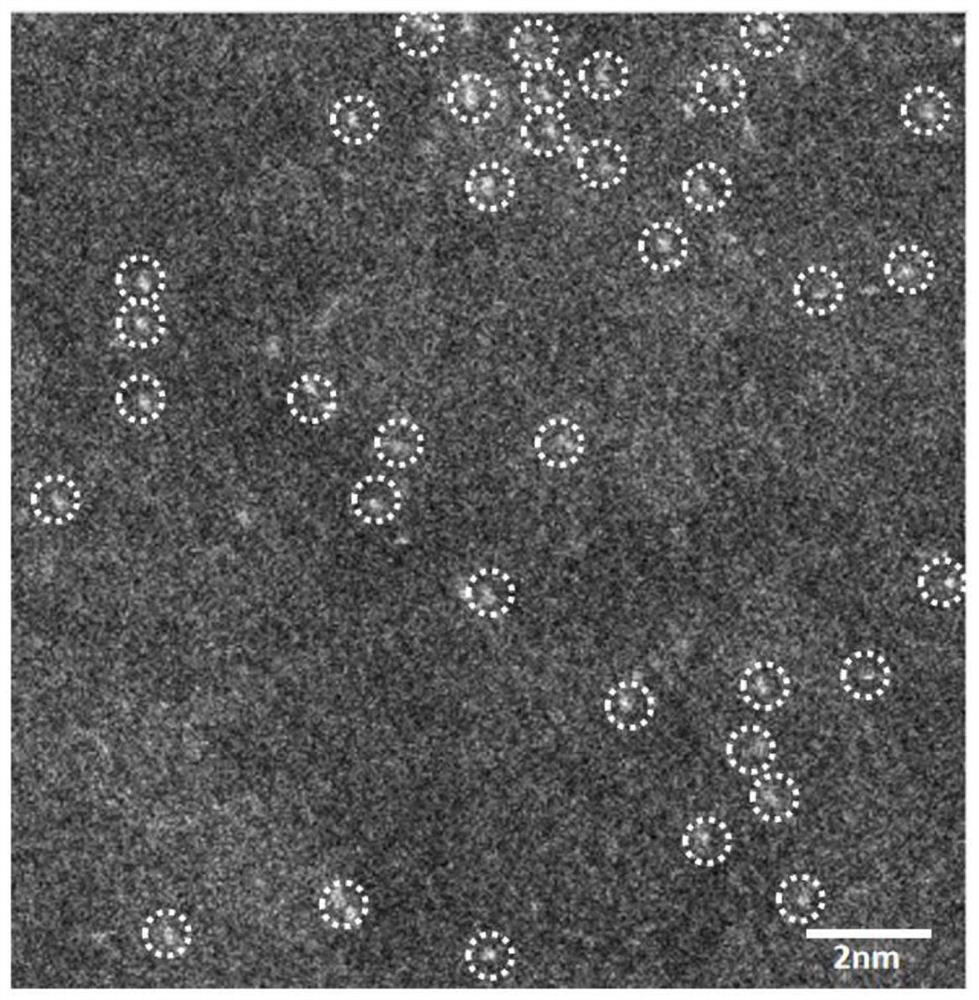

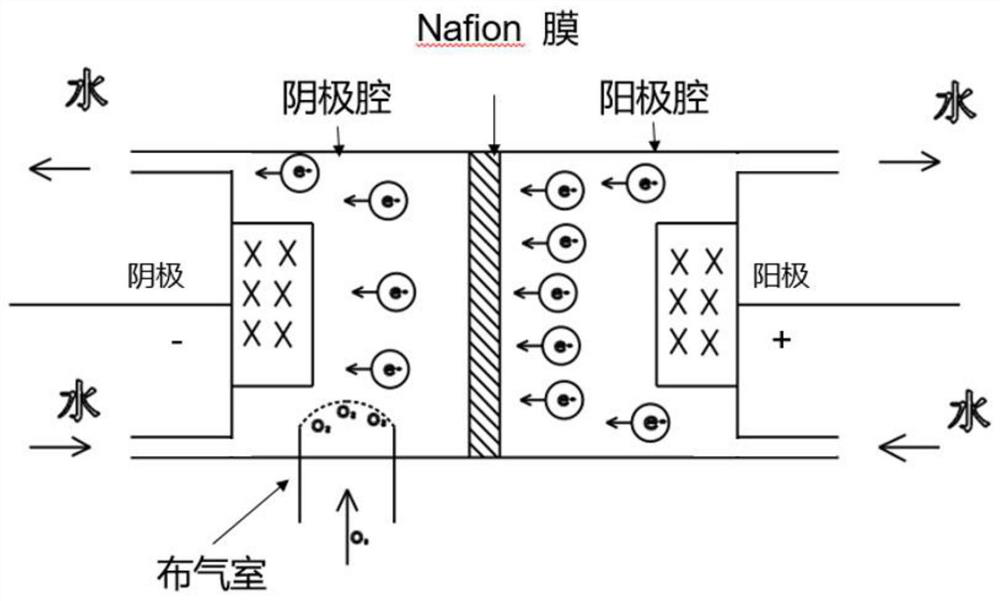

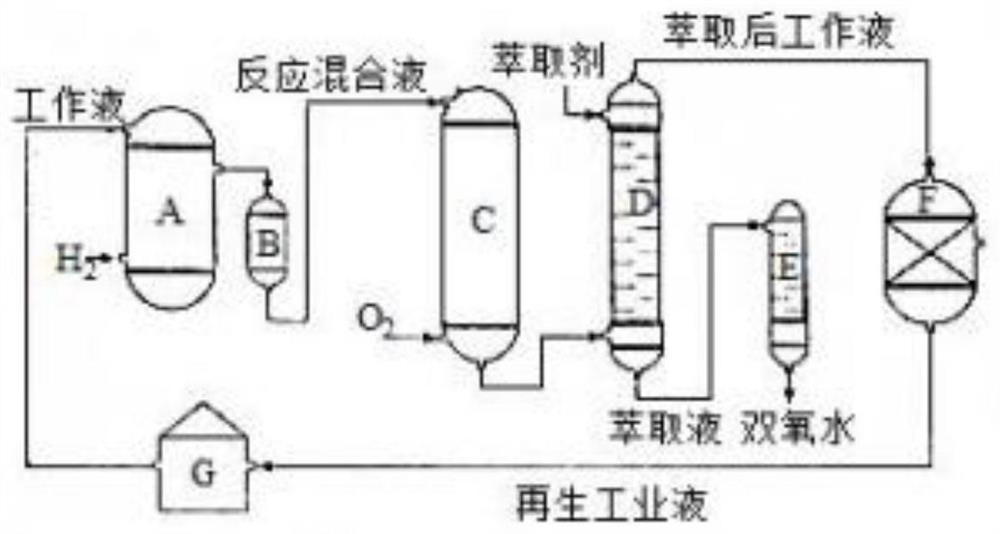

Monatomic catalyst for preparing hydrogen peroxide through electro-catalysis, preparation method and application thereof

The invention discloses a monatomic catalyst for preparing hydrogen peroxide through electro-catalysis and a preparation method and application thereof, and belongs to the technical field of electro-catalysis. The monatomic catalyst is composed of a carrier and transition metal, the carrier is nitrogen-doped porous carbon, the transition metal is one or more of Cu, Co, Fe and Mn, and the transition metal is fixed on the surface of the carrier in a monatomic form. The monatomic catalyst has high activity and high stability, and has optimal activity and selectivity in acidic ORR, the current and selectivity can be stabilized for more than 10 h, H2O2 of more than 3500 ppm can be accumulated, the selectivity exceeds 91% in a very wide voltage range, and the generation rate of the H2O2 corresponding to 550 mmol g <-1 > h <-1 > is achieved. The electro-catalysis device prepared from the monatomic catalyst can be widely applied to wastewater treatment, and has remarkable economic benefits and social benefits.

Owner:LINKWAY TECH CO LTD

Preparation method for film printing coating

InactiveCN108587367ALow priceSimple coating processPolyurea/polyurethane coatingsChemistryBonding strength

The invention relates to a preparation method for a film printing coating, belonging to the technical field of printing. According to the invention, fumed silica with high purity, good dispersity andstandard spherical particle shape is synthesized through gaseous detonation by using mixed gas of hydrogen and oxygen as a detonating source and silicon tetrachloride as a precursor, and the silicon hydroxyl group on the surface of the fumed silica is activated; a silane coupling agent is hydrolyzed to generate a dehydration reaction with the silicon hydroxyl group on the surface of the fumed silica, so an organism in the silane coupling agent is connected with the surface of the fumed silica; silane coupling agent modified fumed silica is dispersed into an adhesive cross-linked by waterborneacrylic resin and waterborne polyurethane in a cationic coating manner to prepare an ink-absorbing coating; the preparation method provided by the invention adopts the silane coupling agent modified fumed silica as a filling material, so ink-absorbing properties and glossiness of a coating are greatly reinforced; meanwhile, the adhesive cross-linked by the waterborne acrylic resin and the waterborne polyurethane facilitates improvement of bonding strength and wear resistance of the coating.

Owner:杨帮燕

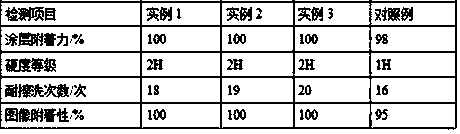

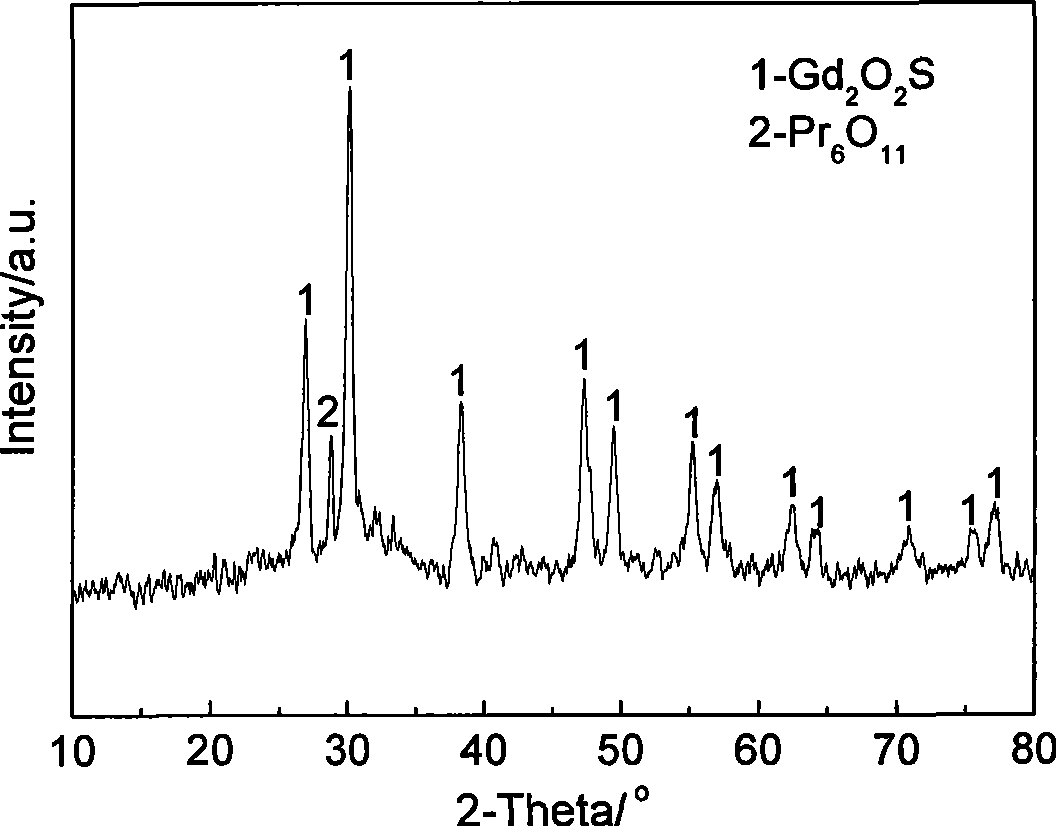

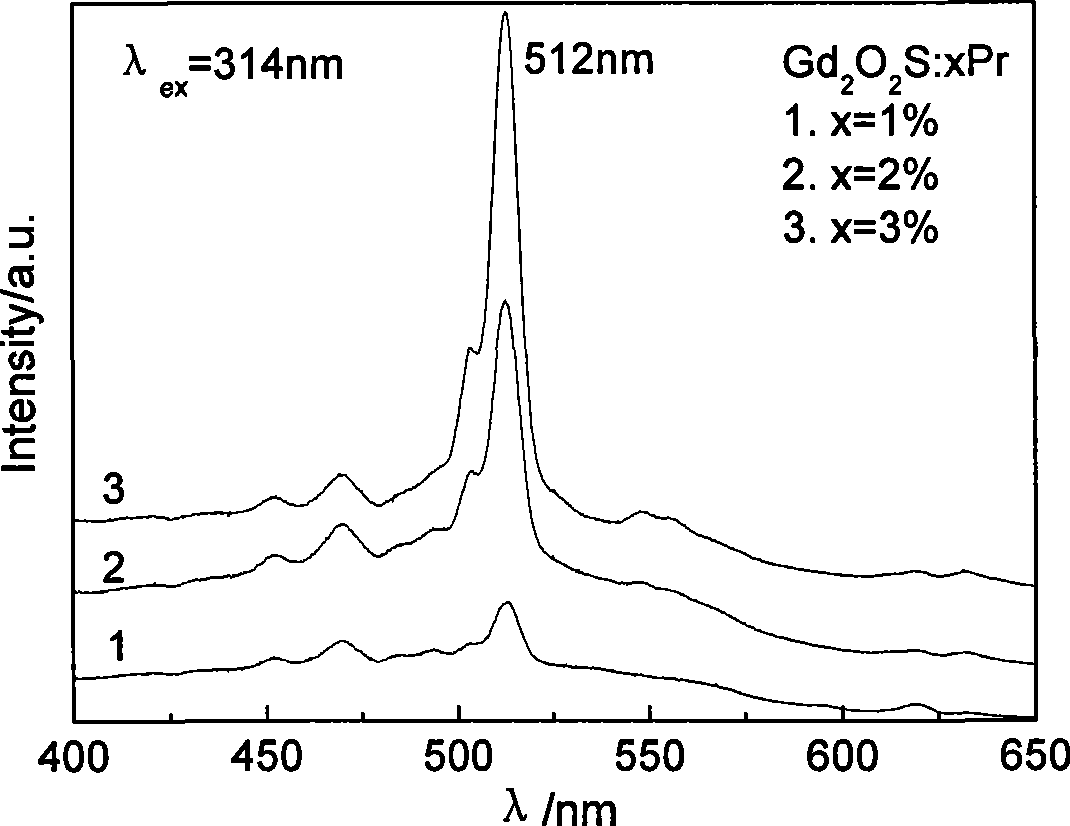

Method for synthesizing ceramic scintillator powder Gd2O2S:Pr

InactiveCN101376809AFast heatingShort heating timeLuminescent compositionsParticle-size distributionCorundum

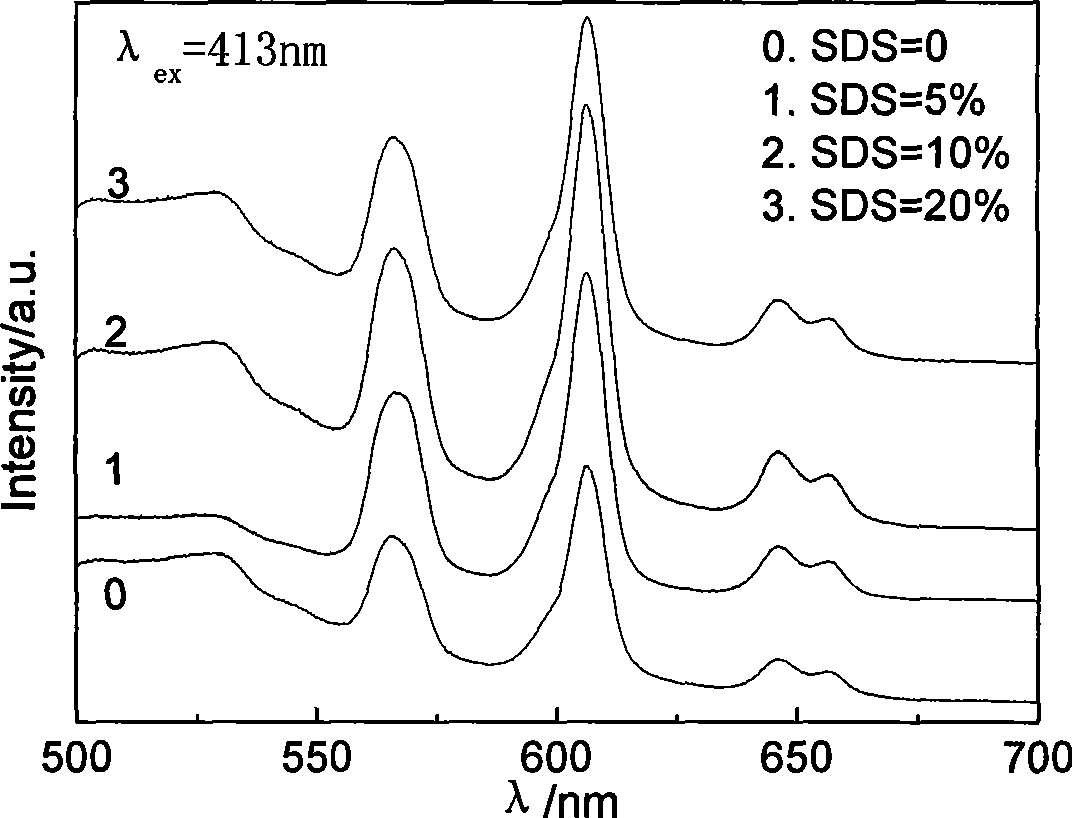

The invention discloses a synthesizing method of ceramics twinkling powder of Gd2O2S:Pr. Gd2O3, Na2CO3 and S are weighed according to a mol ratio of 1:1:1 to 3; Pr6O11 is added as an activator and the adding amount of the Pr6O11 is 1 to 3 percent of the mole number of the La2O3; besides, sodium dodecyl sulfate is added into a surface modifier and the adding amount of the sodium dodecyl sulfate is 5 to 20 percent of the mole number of the Gd2O3; then the mixture is fully grinded and mixed to be uniform in a mortar and then is arranged in a small corundum crucible; after the cover of the small corundum crucible is covered for compacting, the small corundum crucible is arranged in a large corundum crucible; carbon grains are filled in the clearance of the two corundum crucibles; the corundum crucible is arranged in a micro-wave oven for heating for 20 to 40 min and then a sample is obtained by taking the corundum crucible out after the corundum crucible is cooled. Being different from the traditional heating method, micro-wave heating refers to that the insides of the materials integrals heat, thus having a fast temperature rising time and a short heating time. Therefore, micro-wave synthesizing can effectively save energies; as the heating speed of the micro-wave is fast, the abnormal growing of crystal grains during the synthesizing process of the materials are avoided; the power material of Gd2O2S:Pr which has the advantages of high purity, small grain diameter and uniform granularity distribution can be synthesized in a shorter time; the product can be directly applied without grinding.

Owner:ZHEJIANG SCI-TECH UNIV

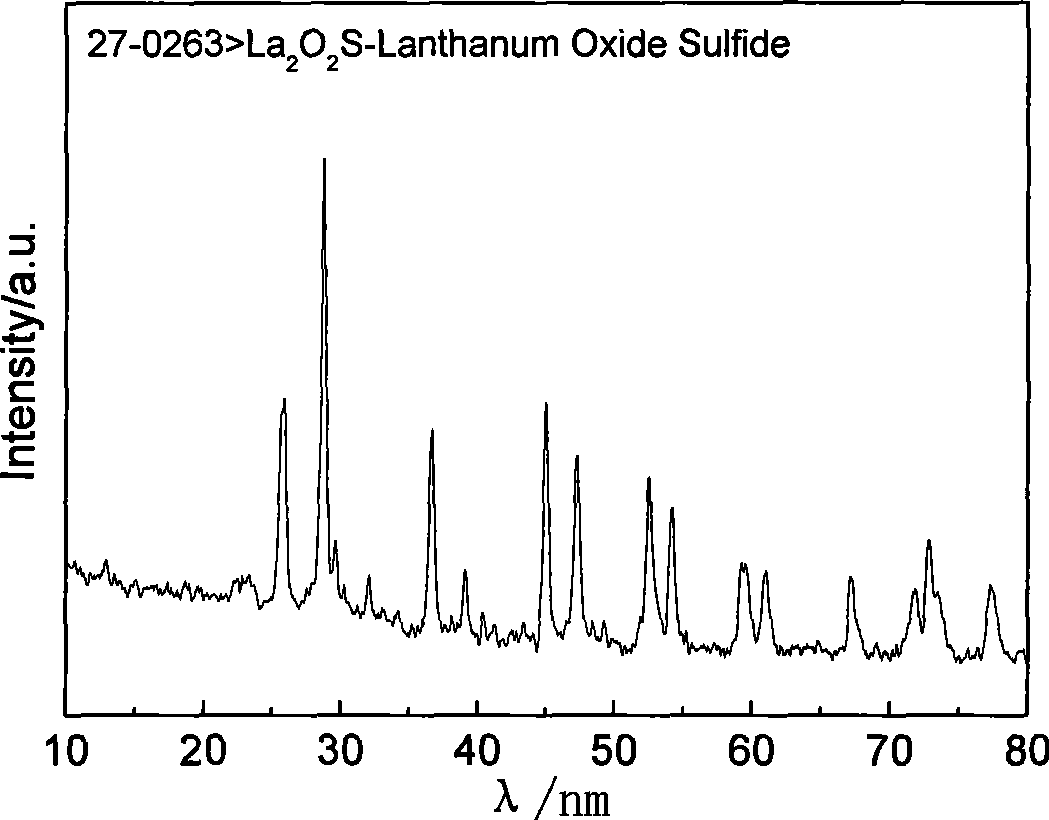

Method for synthesizing red long afterglow luminescent powder La2O2S: Sm

The invention discloses a synthesizing method of red long afterglow luminescent powder of La2O2S:Sm. La2O3, Na2CO3 and S are weighed according to a mol ratio of 1:1:2; Sm2O3 is added as an activator and the adding amount of the Sm2O3 is 2 to 8 percent of the mole number of the La2O3; besides, sodium dodecyl sulfate is added into a surface modifier and the adding amount of the sodium dodecyl sulfate is 5 to 20 percent of the mole number of the La2O3; then the mixture is fully grinded and mixed to be uniform in a mortar and then is arranged in a small corundum crucible; after the cover of the small corundum crucible is covered for compacting, the small corundum crucible is arranged in a large corundum crucible; carbon grains are filled in the clearance of the two corundum crucibles; the corundum crucible is arranged in a micro-wave oven for heating for 20 to 40 min and then a sample is obtained by taking the corundum crucible out after the corundum crucible is cooled. A micro-wave method can fast synthesize the luminescent powder of La2O2S:Sm which has the advantages of high purity, good crystallization and uniform granularity; besides, the adding of the sodium dodecyl sulfate can reduce the aggregation and growing of the grains, can obtain the luminescent powder with less grain diameters and effectively improves the luminescent intensity of the powder.

Owner:ZHEJIANG SCI-TECH UNIV

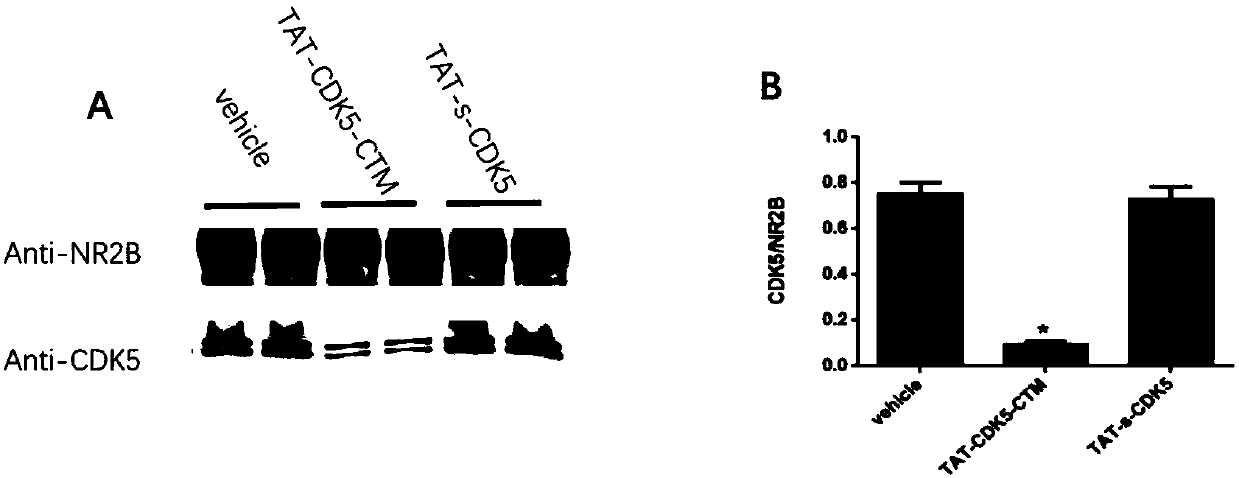

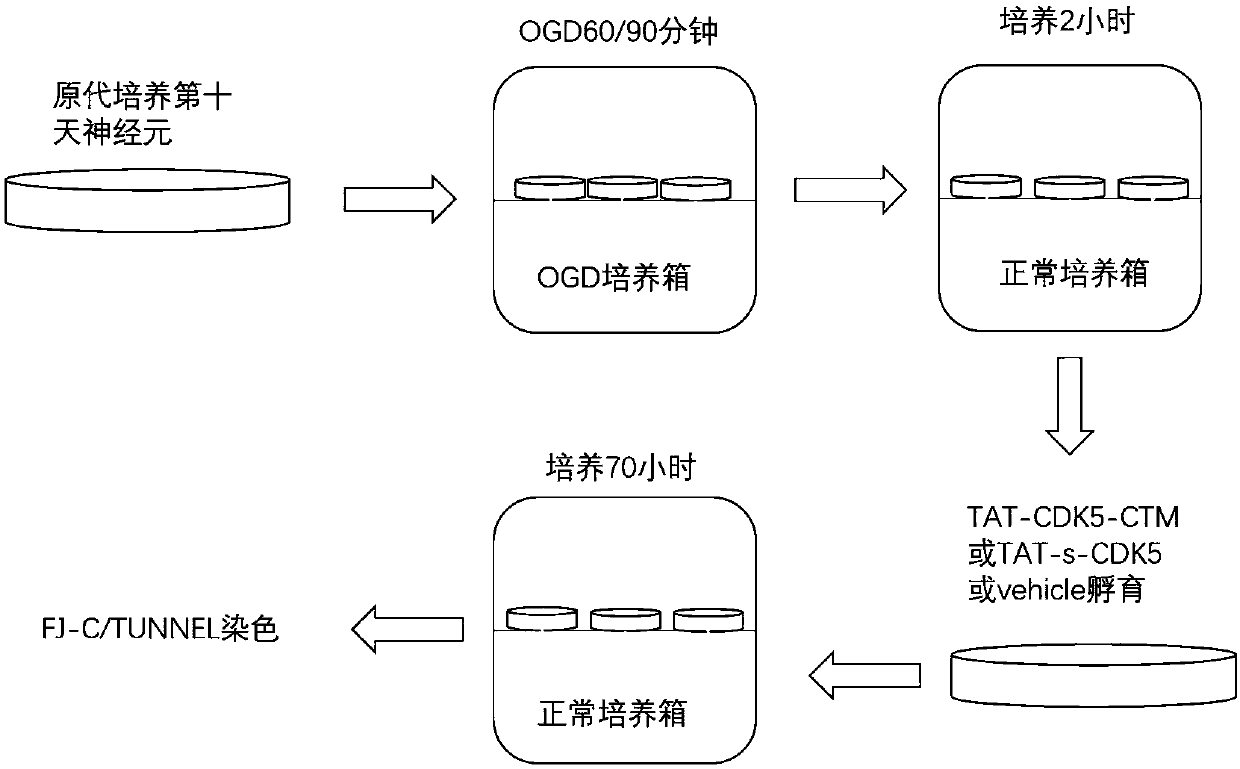

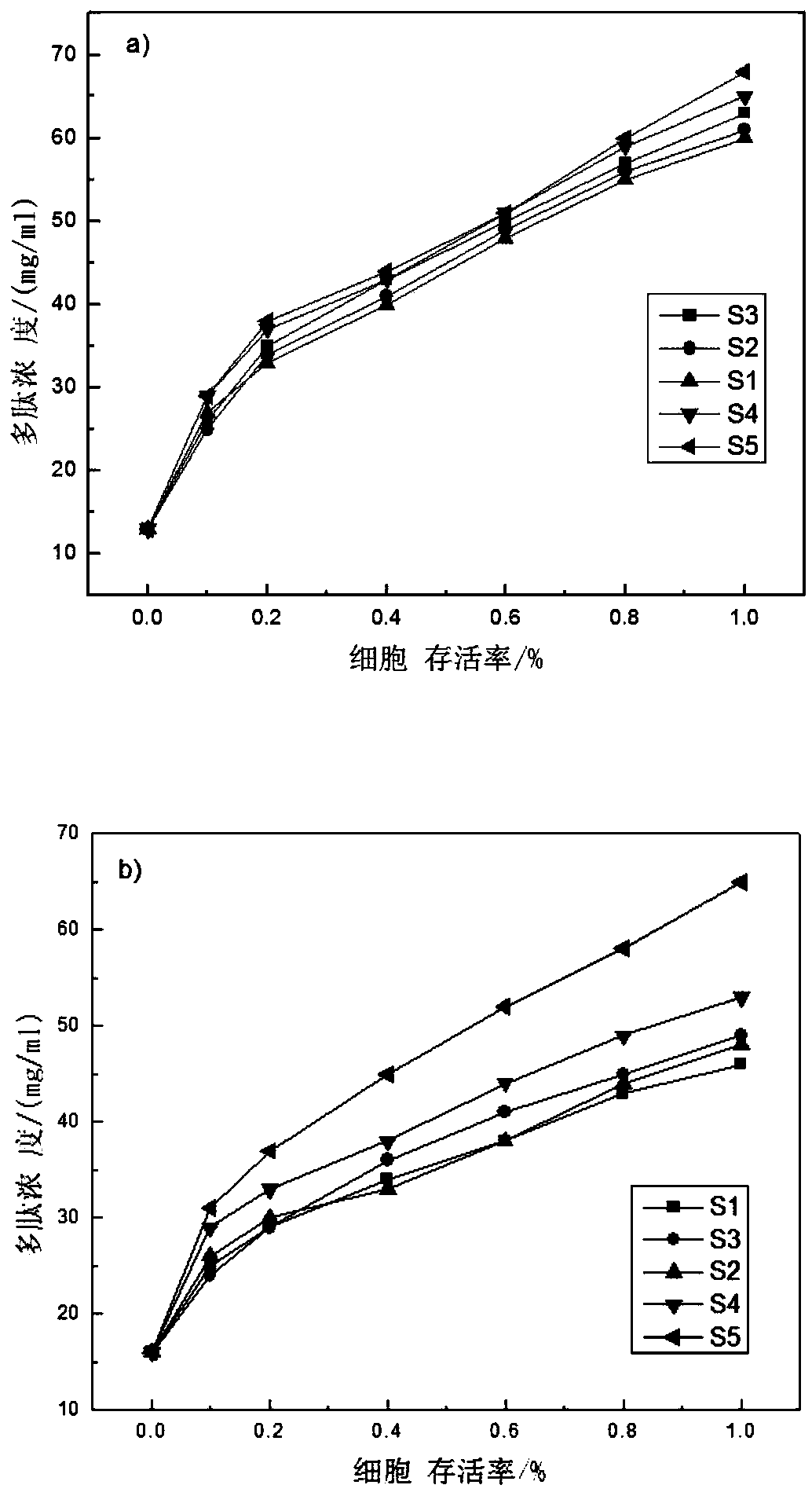

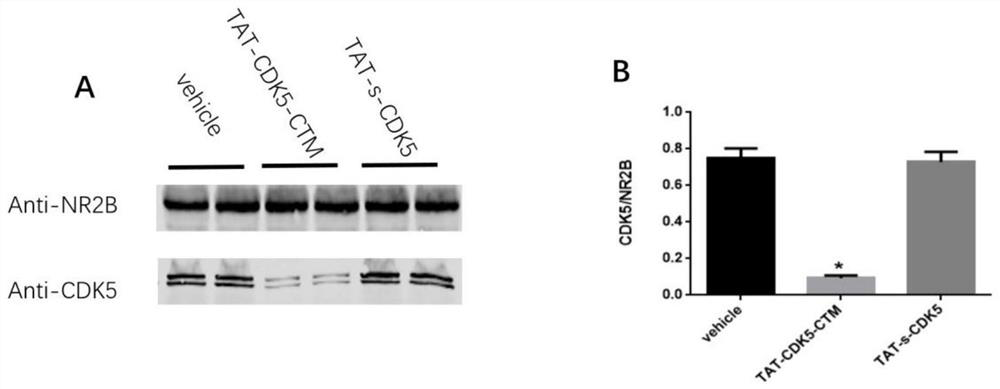

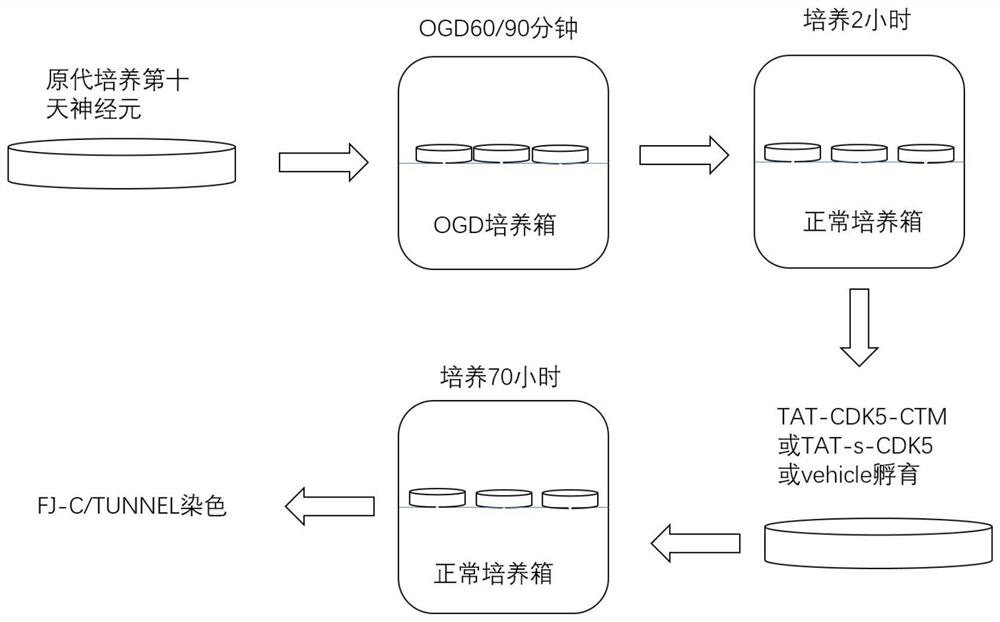

Small molecule polypeptide and application thereof in preparing medicine for preventing and treating ischemic stroke

ActiveCN109553685ASynthetic high purityImprove solubilityPolypeptide with localisation/targeting motifNervous disorderNeuronNecrosis

The invention discloses a small molecule polypeptide and an application thereof in preparing a medicine for preventing and treating ischemic stroke. By synthesizing a TAT protein transduction domain,the protein polypeptide of CDK5 and the fusion protein TAT-CDK5-CTM of the autophagy targeted motif CTM can be combined and inhibited, the TAT is used to carry the CDK5 protein polypeptide, which is transported by blood through a blood cerebral barrier, and is taken up by neurons. The peptide is applied to in-vitro and in-vivo ischemic stroke models to effectively block the bonding effect of the NR2B subunit of a N-methyl aspartate receptor (NMDAR) and the cyclin-dependent protein kinase 5 (CDK5), the CTM mediates the polypeptide molecules which are bonded with CDK5 protein to enter lysosomalfor degradation, neuronal apoptosis and necrosis induced by CDK5 downstream can be inhibited, brain damage after ischemic stroke can be reduced, and the application provides a molecular target for thedevelopment of drugs for the treatment of ischemic stroke.

Owner:HUAZHONG UNIV OF SCI & TECH

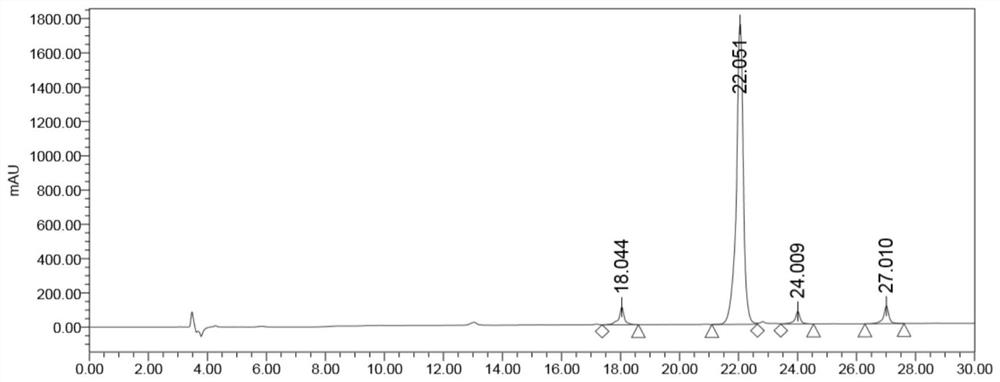

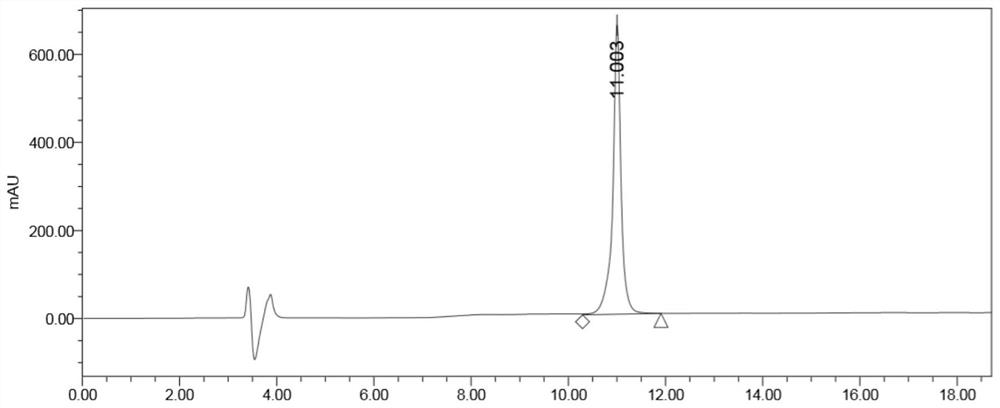

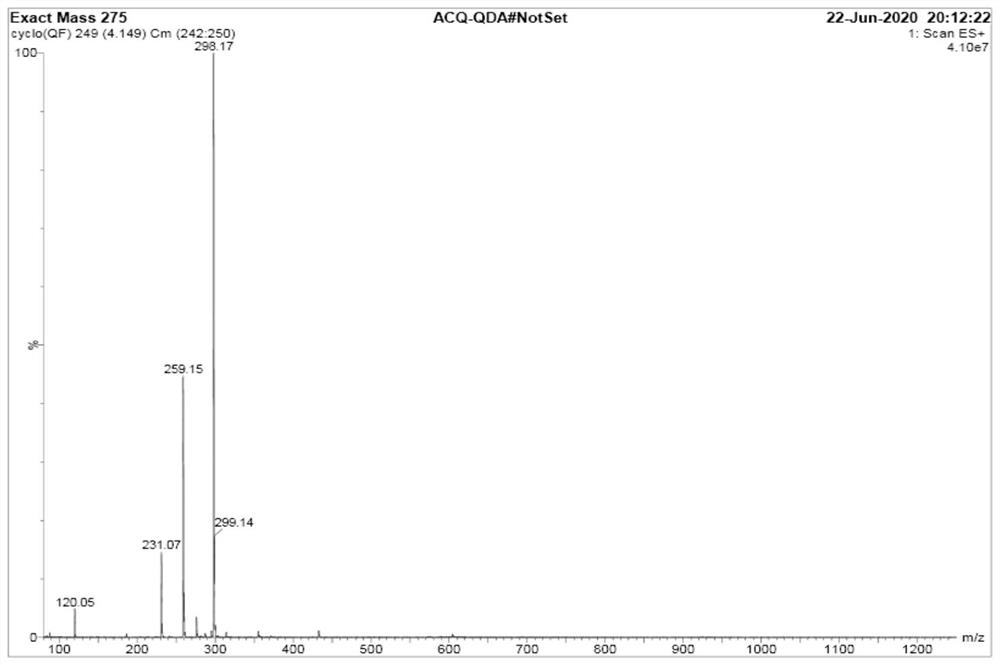

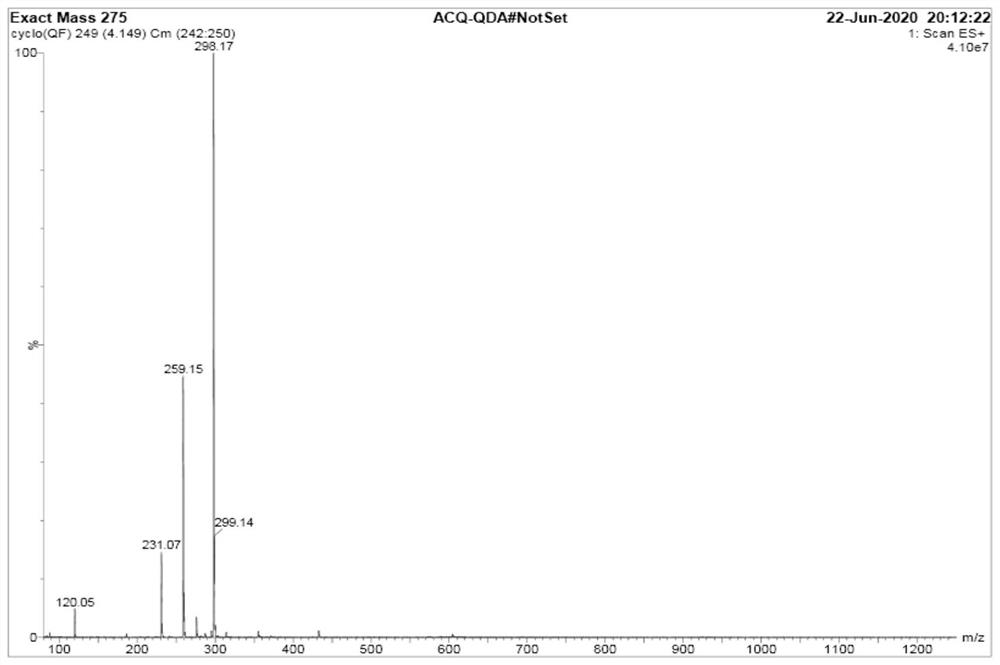

Synthesis method of cyclic dipeptide containing glutamine and asparagine

ActiveCN111875668AAvoid residueSynthetic operation is simplePeptide preparation methodsCyclic peptidesAmino acid side chainDipeptide

The invention discloses a synthesis method of a cyclic dipeptide. A cyclic dipeptide sequence contains L-asparagine or L-glutamine. The method comprises the following steps: by taking 2-Chlorotrityl Chloride Resin as a carrier, carrying out solid-phase synthesis to obtain a straight-chain dipeptide fragment H-Glu-AA-OH or H-Asp-AAOH, wherein AA is other alpha-amino acids except asparagine, glutamine, glutamic acid, aspartic acid and cysteine; then carrying out a methyl esterification reaction to obtain straight-chain dimethyl ester protected dipeptide H-Glu (OMe) -AA-OMe or H-Asp (OMe)- AA-OMe; then carrying out water-phase alkaline cyclization to obtain cyclic dipeptide Cyclo[ Glu (OMe)- AA] or Cyclo[ Asp (OMe)- AA] protected by side chain carboxyl methyl ester; and finally, carrying outammonolysis to obtain the cyclic dipeptide containing glutamine or asparagine. The method is simple in synthesis process and safe to operate, incomplete cyclization caused by steric hindrance of aminoacid side chain protecting groups in the cyclization process is effectively avoided, few byproducts are produced, purification is easy, and cyclic dipeptide containing Gln and Asn can be synthesizedin batches.

Owner:SHAANXI HUIKANG BIO TECH CO LTD

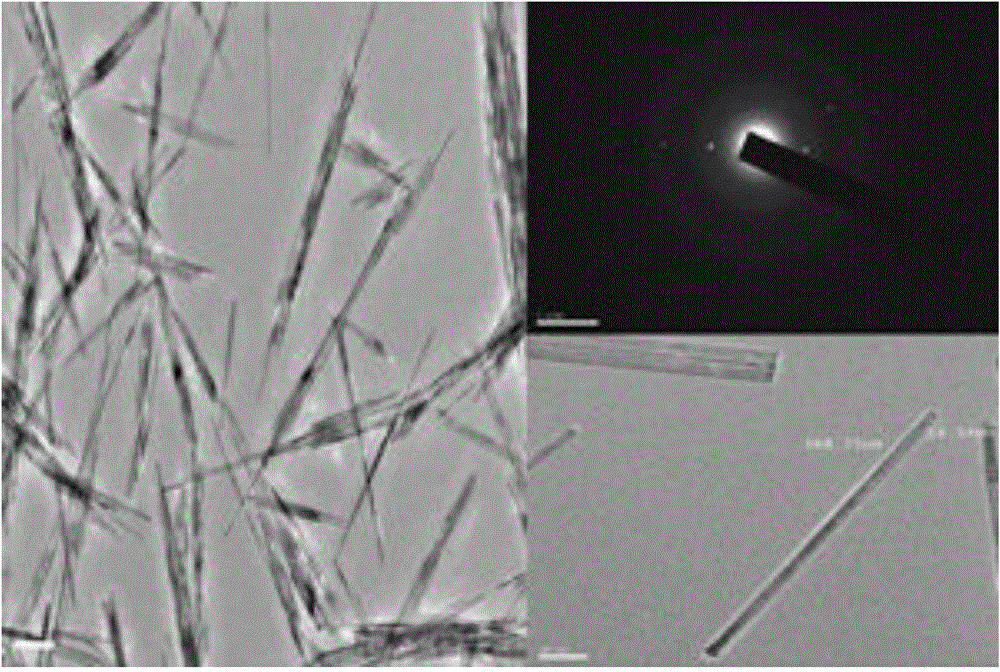

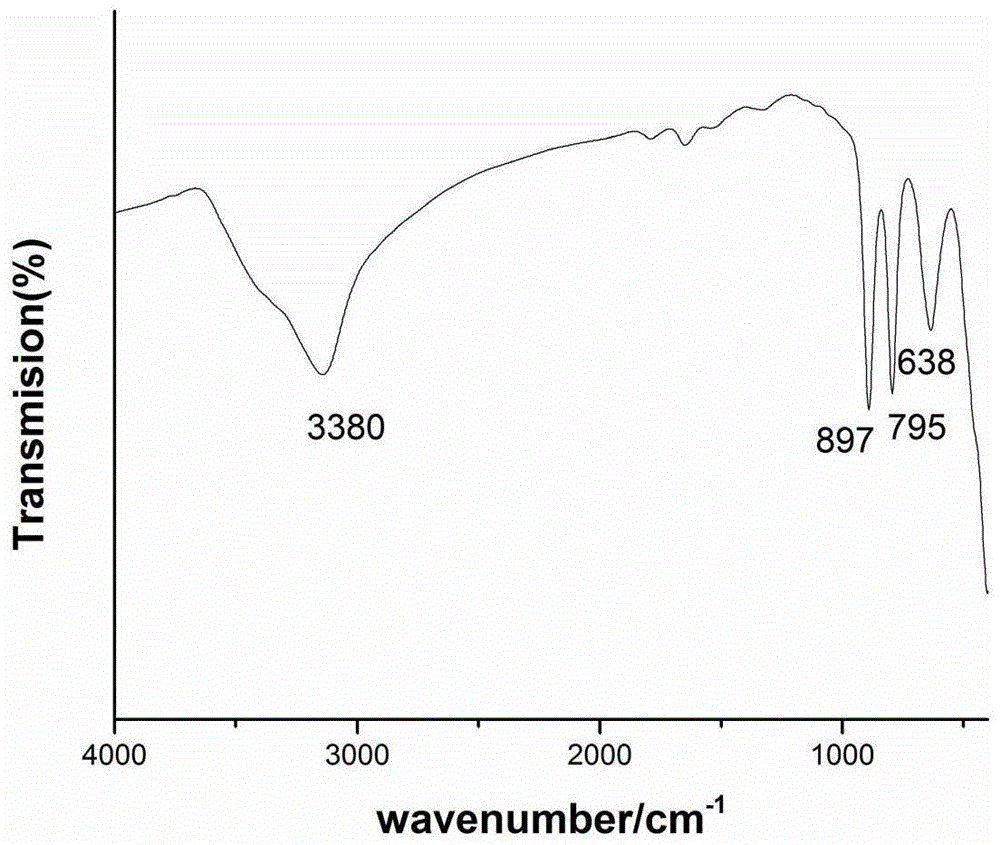

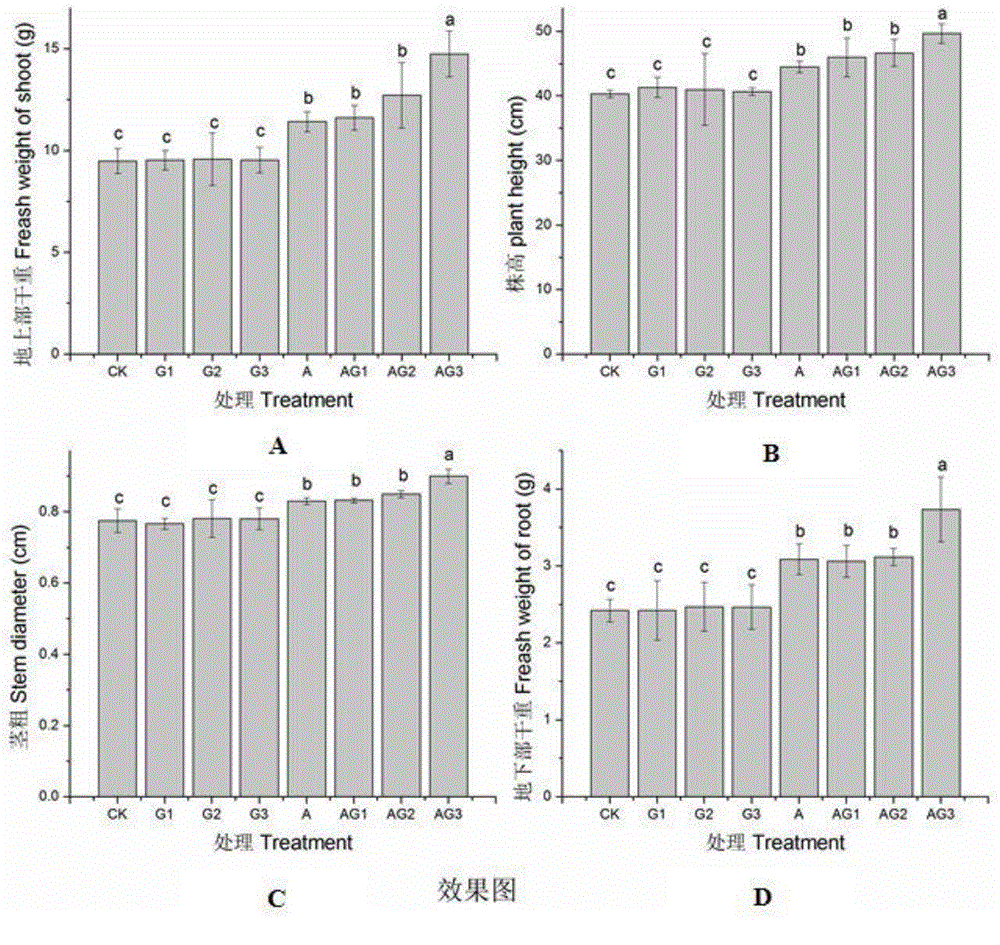

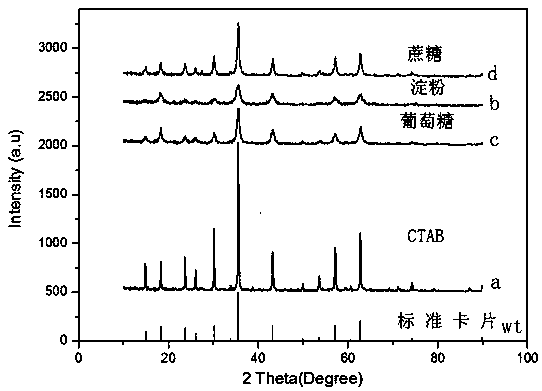

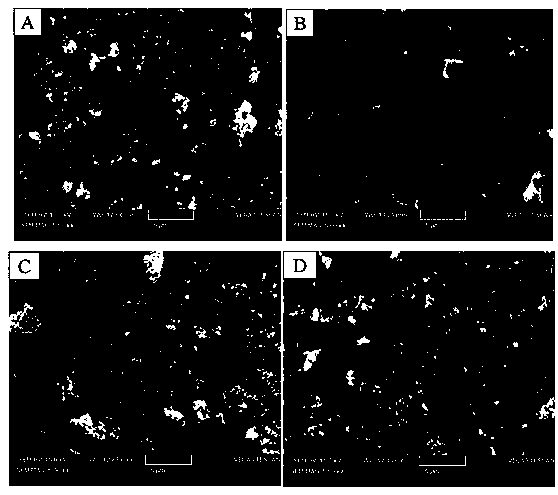

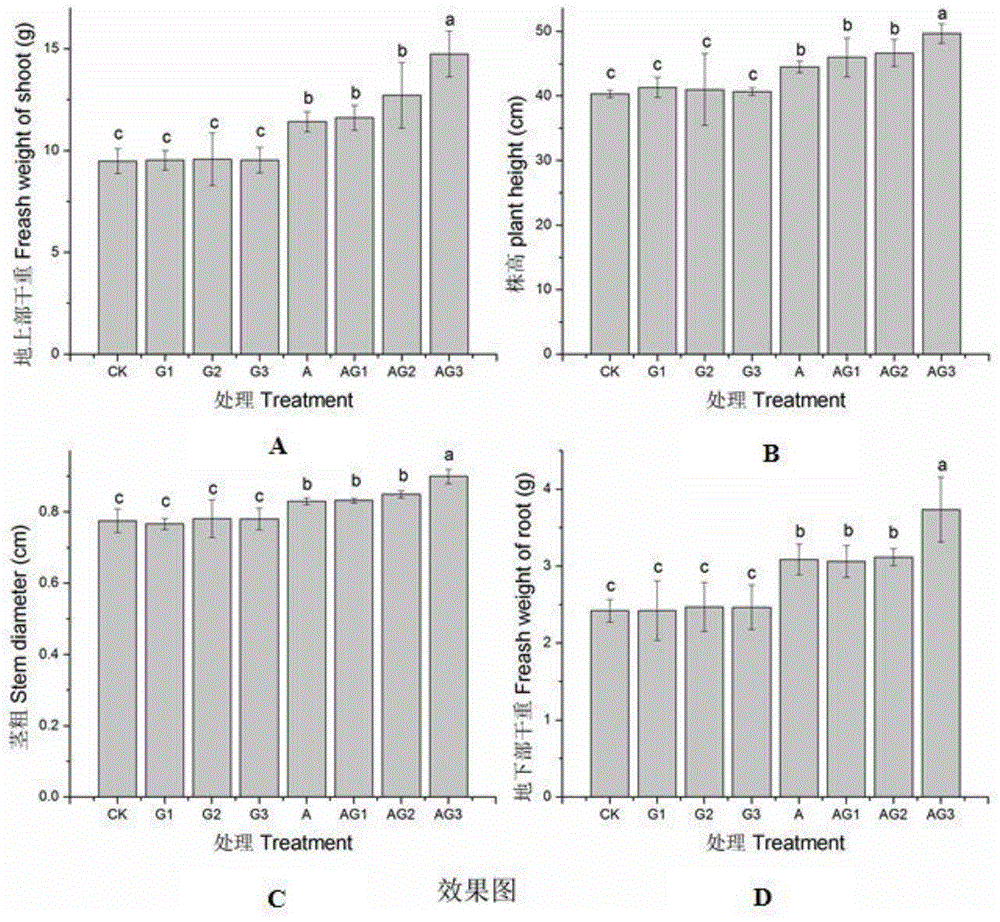

Nano goethite-amino acid compound leaf fertilizer as well as preparation method and application thereof

ActiveCN104446907ALarge specific surface areaHigh chemical activityNitrogenous fertilisersLiquid fertilisersHydrolysatePlantlet

The invention belongs to the field of fertilizer production and provides a preparation method and the application of a nano goethite-amino acid compound leaf fertilizer. The nano goethite-amino acid compound leaf fertilizer is prepared from nano goethite, amino acid hydrolysate and deionized water, wherein the concentration of the goethite is 1g / L. The preparation process of the nano goethite-amino acid compound leaf fertilizer comprises the following steps: (1) preparing the nano goethite; (2) preparing the amino acid hydrolysate; and (3) obtaining the nano goethite-amino acid compound leaf fertilizer. The nano goethite in the nano goethite-amino acid compound leaf fertilizer is capable of effectively adhering to the surfaces of plant leaves, and therefore, the problems of low utilization rate and non-obvious growth promoting effect due to short retention time period and poor stability of the leaf fertilizer on the plant leaves are solved, and furthermore, the acting time of the amino acid compound leaf fertilizer is effectively prolonged, the utilization rate and the application effect of the leaf fertilizer are increased and the growth of tomato plants is greatly promoted.

Owner:NANJING AGRICULTURAL UNIVERSITY

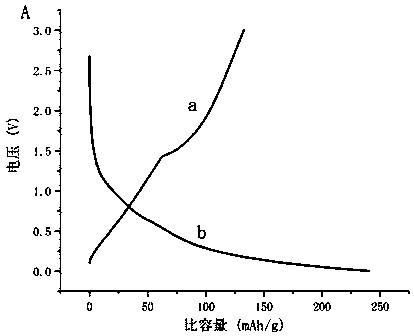

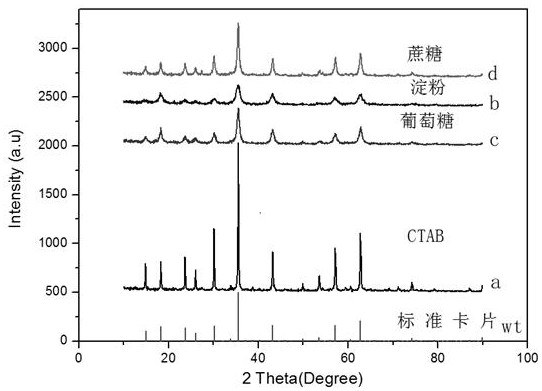

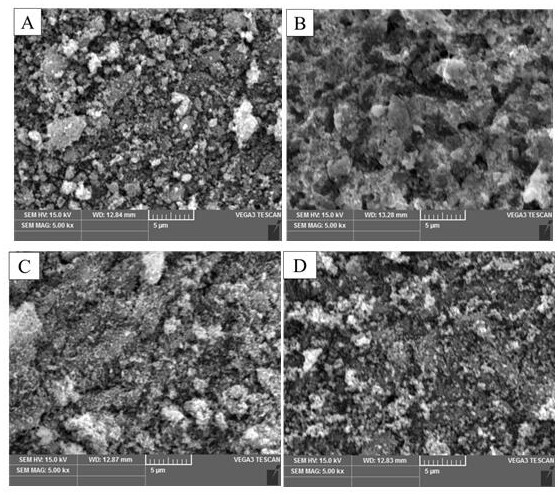

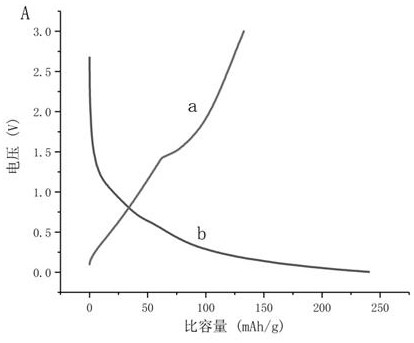

Preparation method of lithium zinc titanate/carbon nanometer composite negative electrode material for lithium ion battery

ActiveCN109888247AImprove conductivityImprove electrochemical performanceCell electrodesSecondary cellsZinc titanateSodium-ion battery

The invention discloses a preparation discloses a preparation method of a lithium zinc titanate / carbon nanometer composite negative electrode material for a lithium ion battery. The preparation methodcomprises the steps of firstly, performing liquid-phase reaction on a lithium source, a titanium source, a zinc source and a carbon source to form a metal complex, and performing oil bath heating toobtain precursor sol; and secondly, performing microwave processing to obtain the composite negative material for the lithium ion battery. Carbon-coated lithium zinc titanate prepared by the method islow in energy consumption, short in reaction time and uniform in particles; moreover, the electrochemical performance of the battery prepared by employing the carbon-coated lithium zinc titanate usedas a negative active material is excellent, and the capacity initial value of a lithium zinc titanate battery reaches 238.3mAh / g through cycle performance test under current density of 100mA / g; and after circulation for 10 times, the specific capacity is stilled maintained about 240mAh / g, the electrochemical performance is maintained very well, and the lithium zinc titanate battery has a favorable application prospect.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

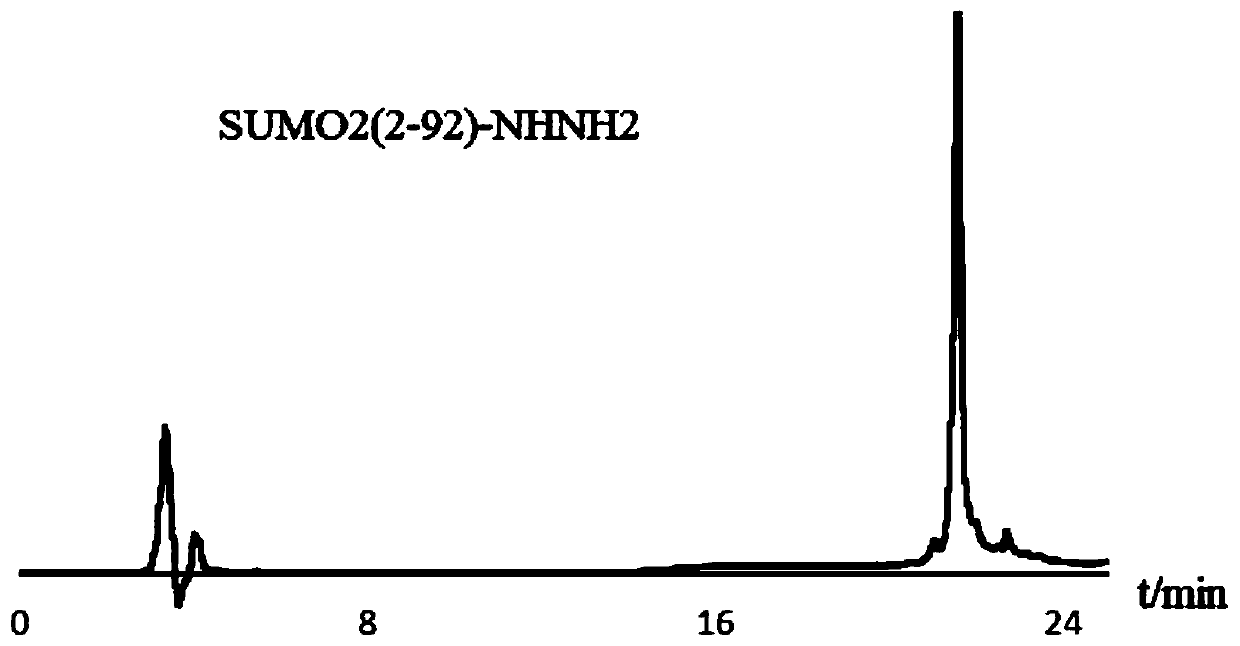

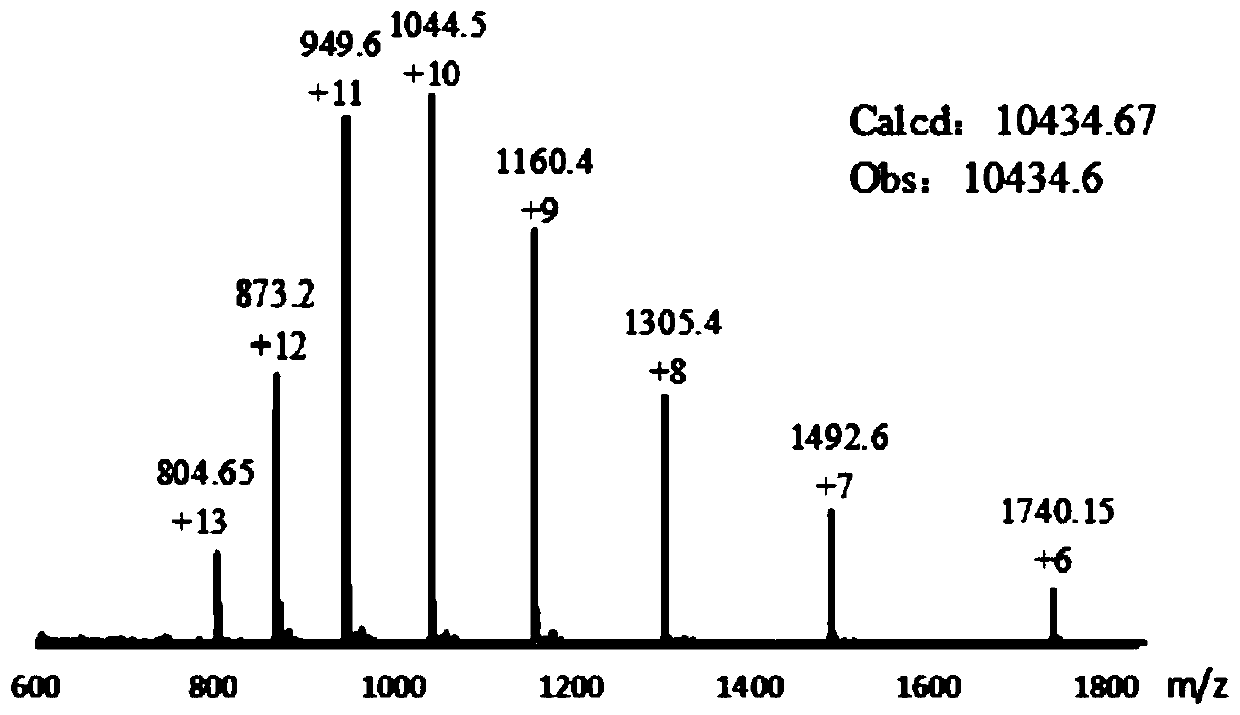

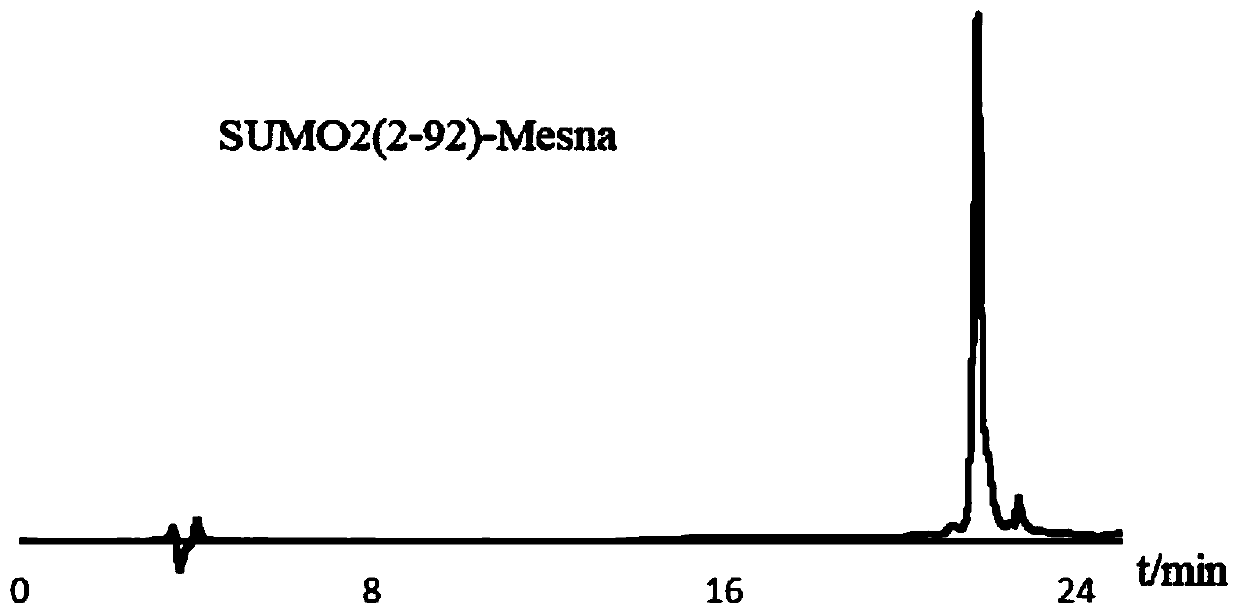

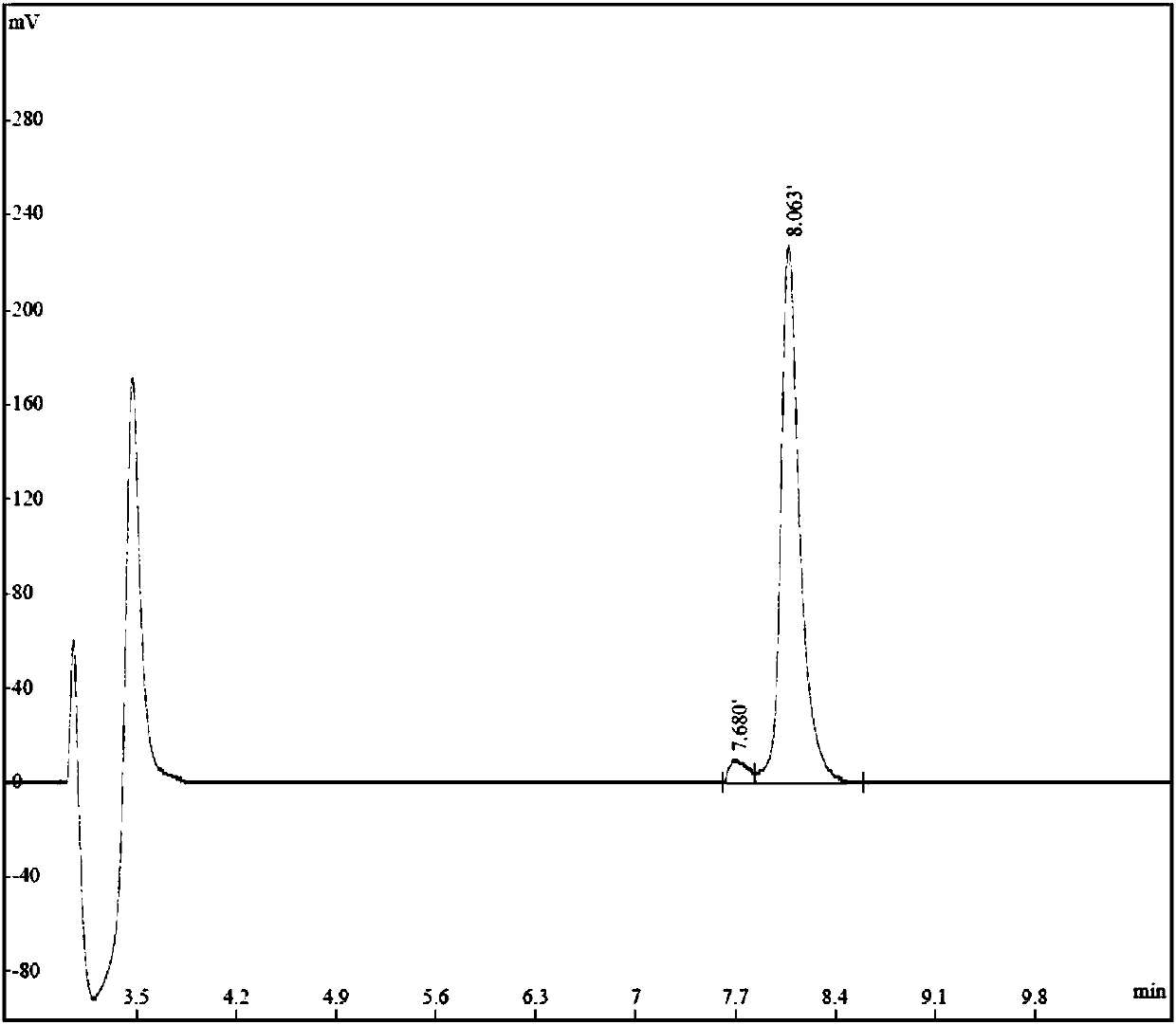

SUMO fluorescent probe and preparation method thereof

PendingCN110294793ALow costThe method steps are simpleBiological material analysisDepsipeptidesThioester synthesisFluorescein

The invention provides a SUMO fluorescent probe and a preparation method thereof. The method comprises the steps that 1, on the basis of Interin N-S migration method, SUMO hydrazide SUMO2(2-92)-NHNH2is prepared; 2, on the basis of the SUMO hydrazide SUMO2(2-92)-NHNH2, by means of the hydrazide method, SUMO thioester SUMO2(2-92)-Mesna is obtained; 3, on the basis of a reaction of the SUMO thioester SUMO2(2-92)-Mesna and the fluorescein micromolecule rhodamine, the SUMO fluorescent probe with rhodamine can be obtained conveniently. The preparation method has the advantages of being high in preparation yield, high in synthesis purity, easy to implement and capable of achieving large-scale preparation, and suitable for application of industrial production of the UMO fluorescent probe.

Owner:合肥科生景肽生物科技有限公司

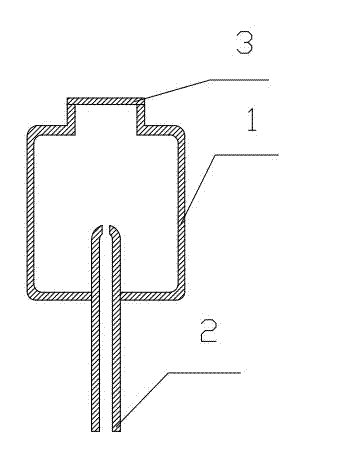

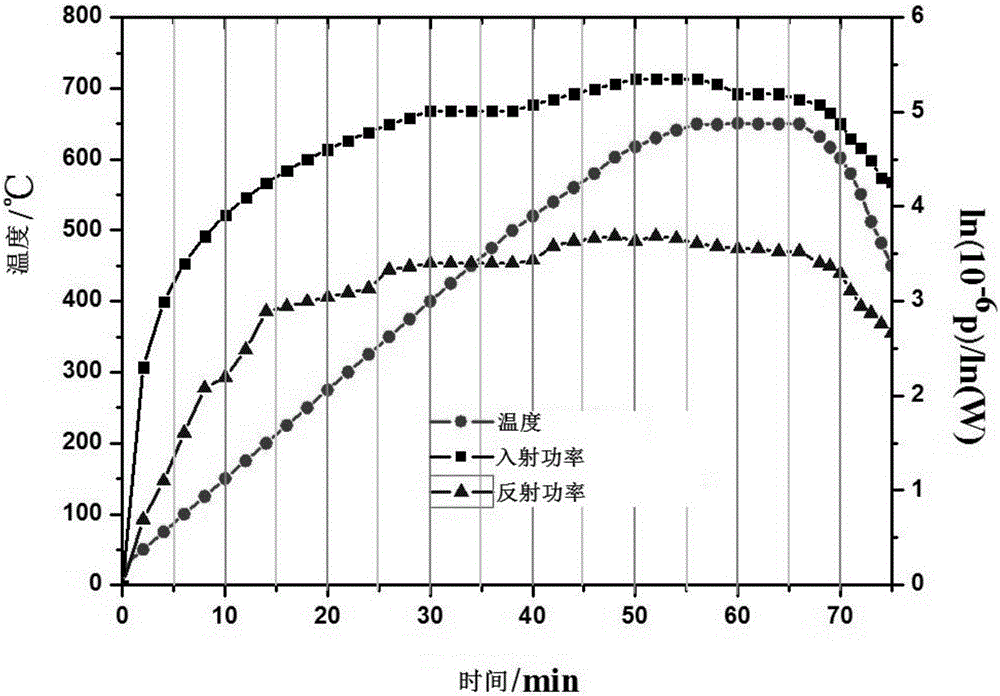

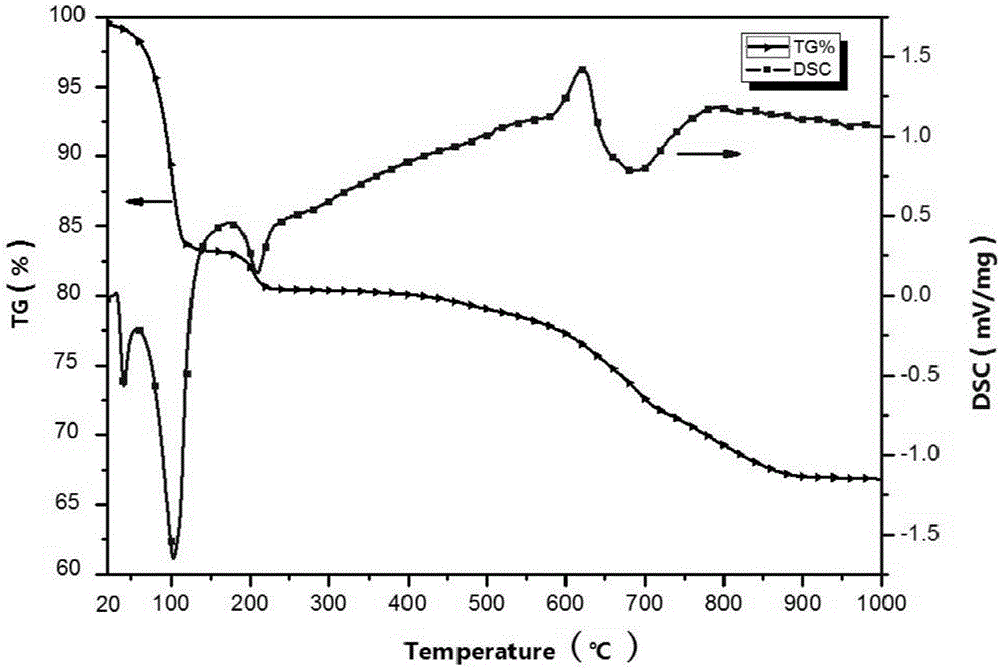

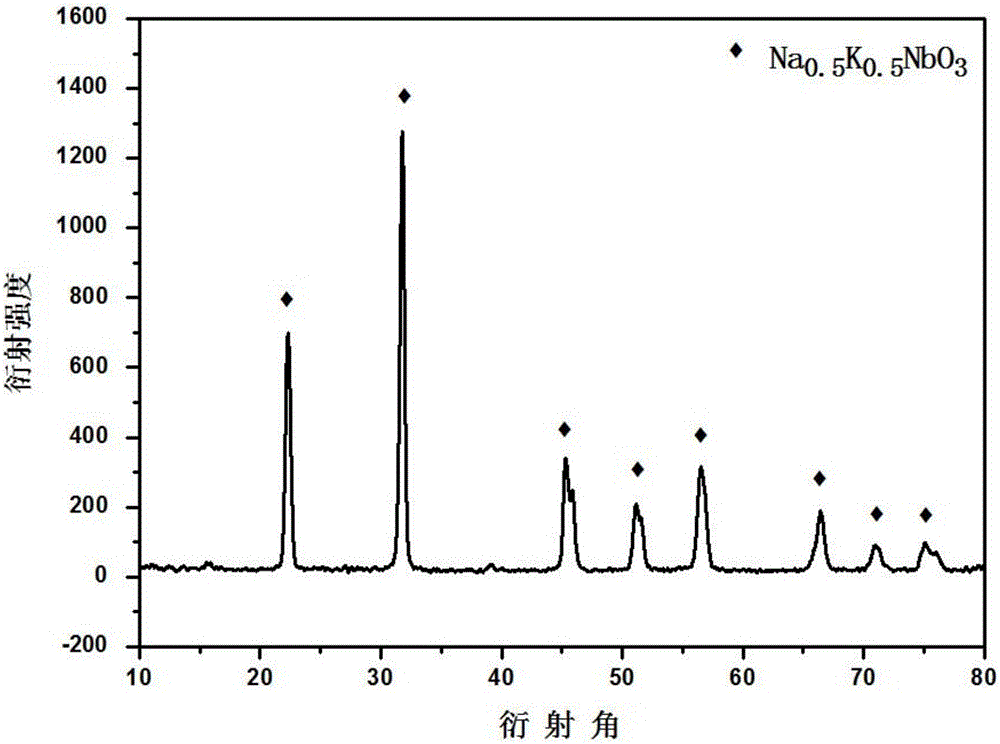

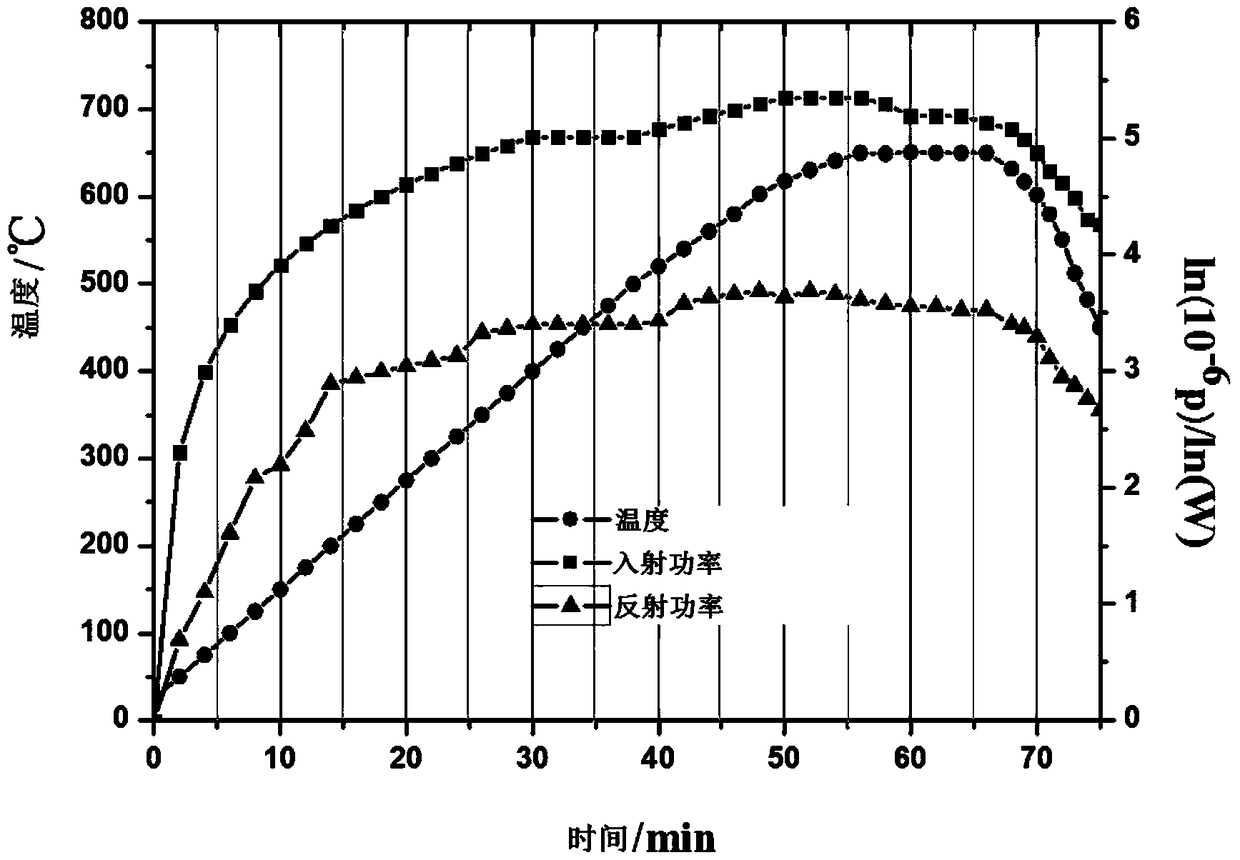

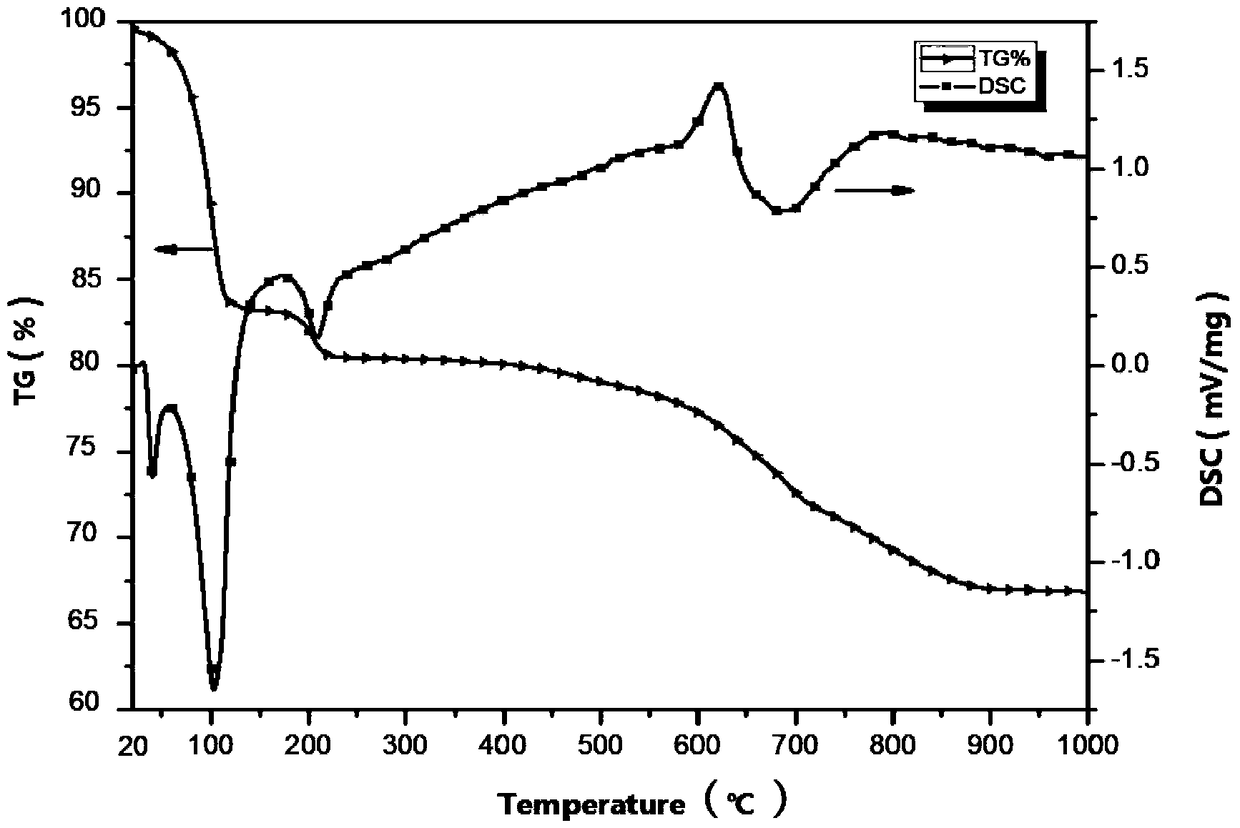

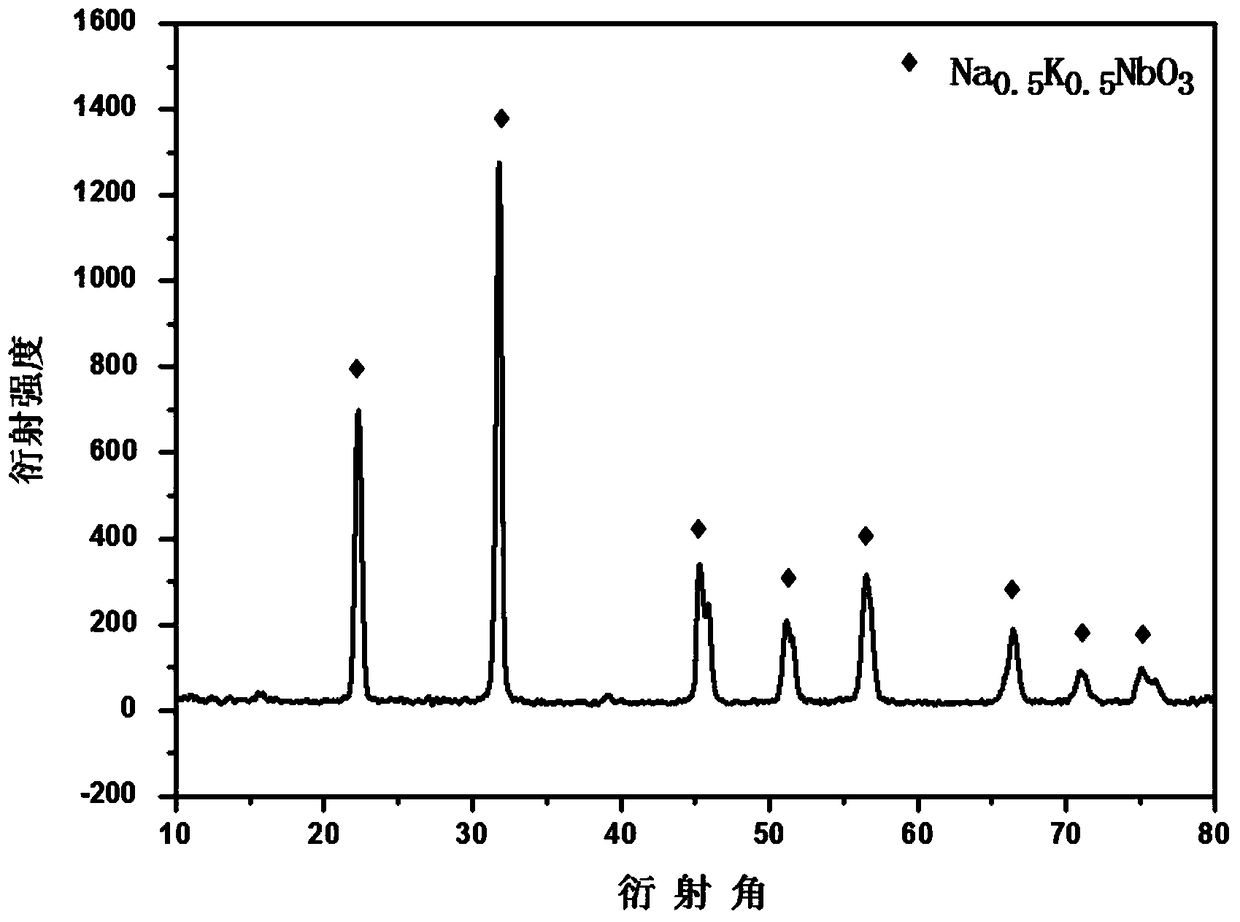

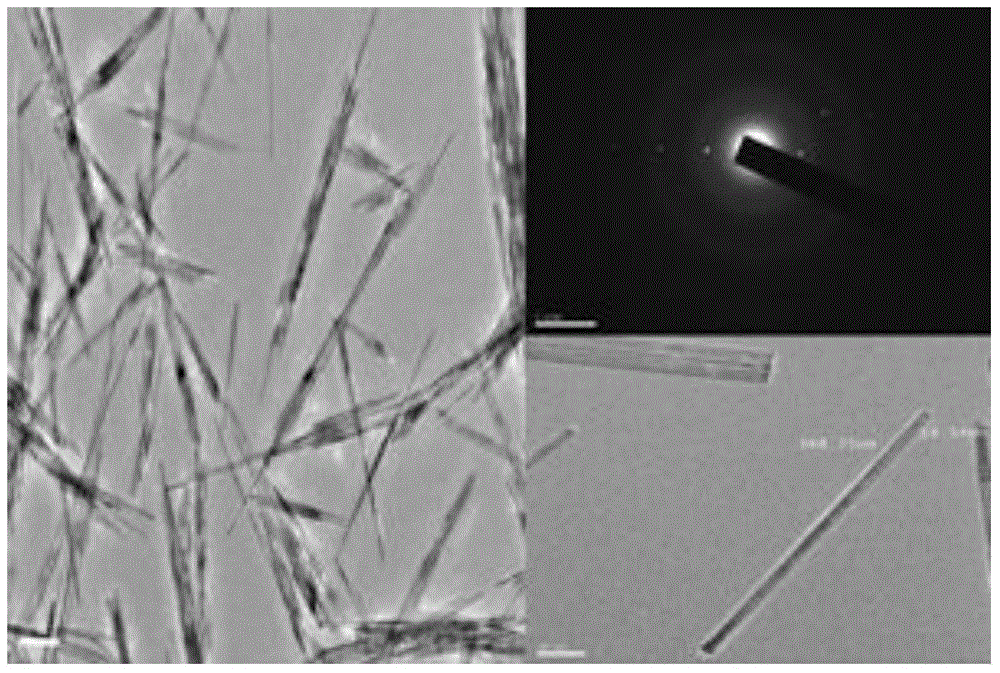

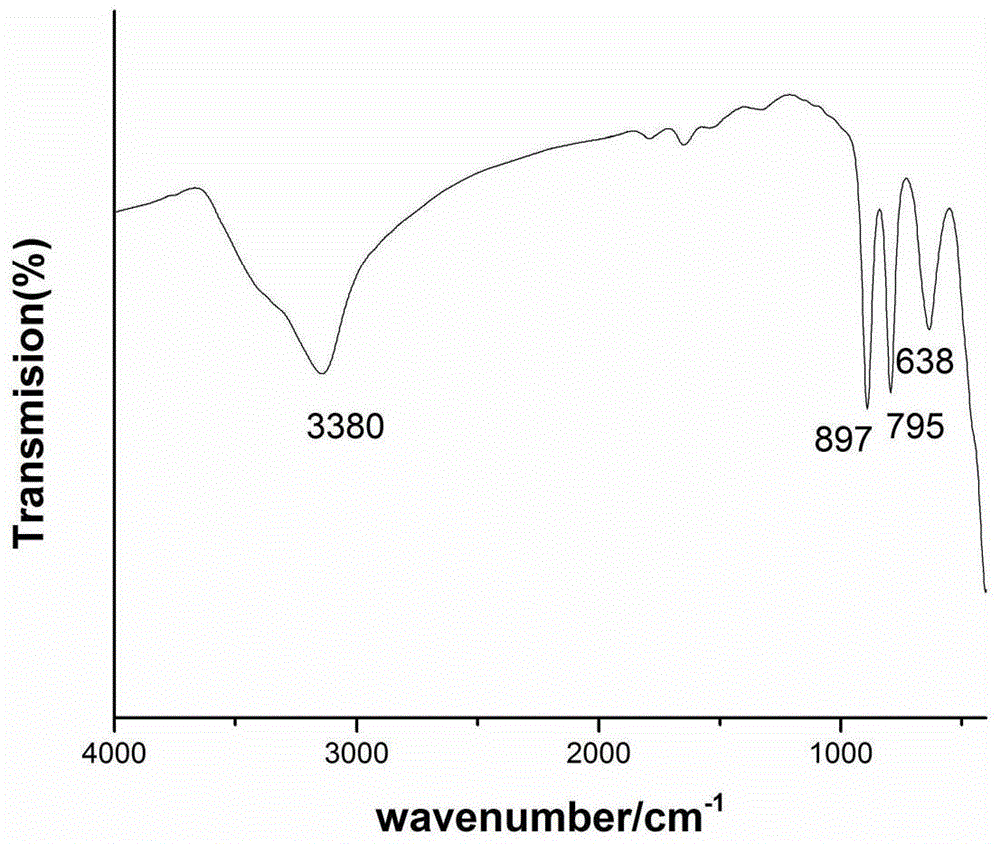

Microwave synthesis method of potassium-sodium niobate leadless piezoelectric ceramic powder

ActiveCN106242568ANo deviation from stoichiometric ratio phenomenonNot volatileTemperature controlMicrowave

The invention discloses a microwave synthesis method of potassium-sodium niobate leadless piezoelectric ceramic powder. The microwave synthesis method of the potassium-sodium niobate leadless piezoelectric ceramic powder comprises the following steps of (1) mixing raw materials of K2CO3, Na2CO3 and Nb2O5 to obtain a mixed material; (2) performing microwave synthesis: starting a microwave source; regulating the input power so that the mixed materials realize temperature rise at the speed of 10 to 15DEG C / min until the reflecting power is stable; then, raising the temperature to 600 to 800 DEG C at the speed of 5 to 10 DEG C / min; performing heat insulation for 5 to 20min; cooling the materials to the room temperature; obtaining the potassium-sodium niobate leadless piezoelectric ceramic powder. The microwave synthesis method of potassium-sodium niobate leadless piezoelectric ceramic powder provided by the invention has the advantages that through raw material optimization and microwave heating temperature control, the self wave adsorption effect of the raw material powder is utilized; the low-temperature fast synthesis of the potassium-sodium niobate leadless piezoelectric ceramic powder is realized; in the process, alkali metal elements cannot be easily volatilized; the obtained powder does not have a phenomenon of deviating from the stoichiometric proportion.

Owner:ZHENGZHOU UNIV

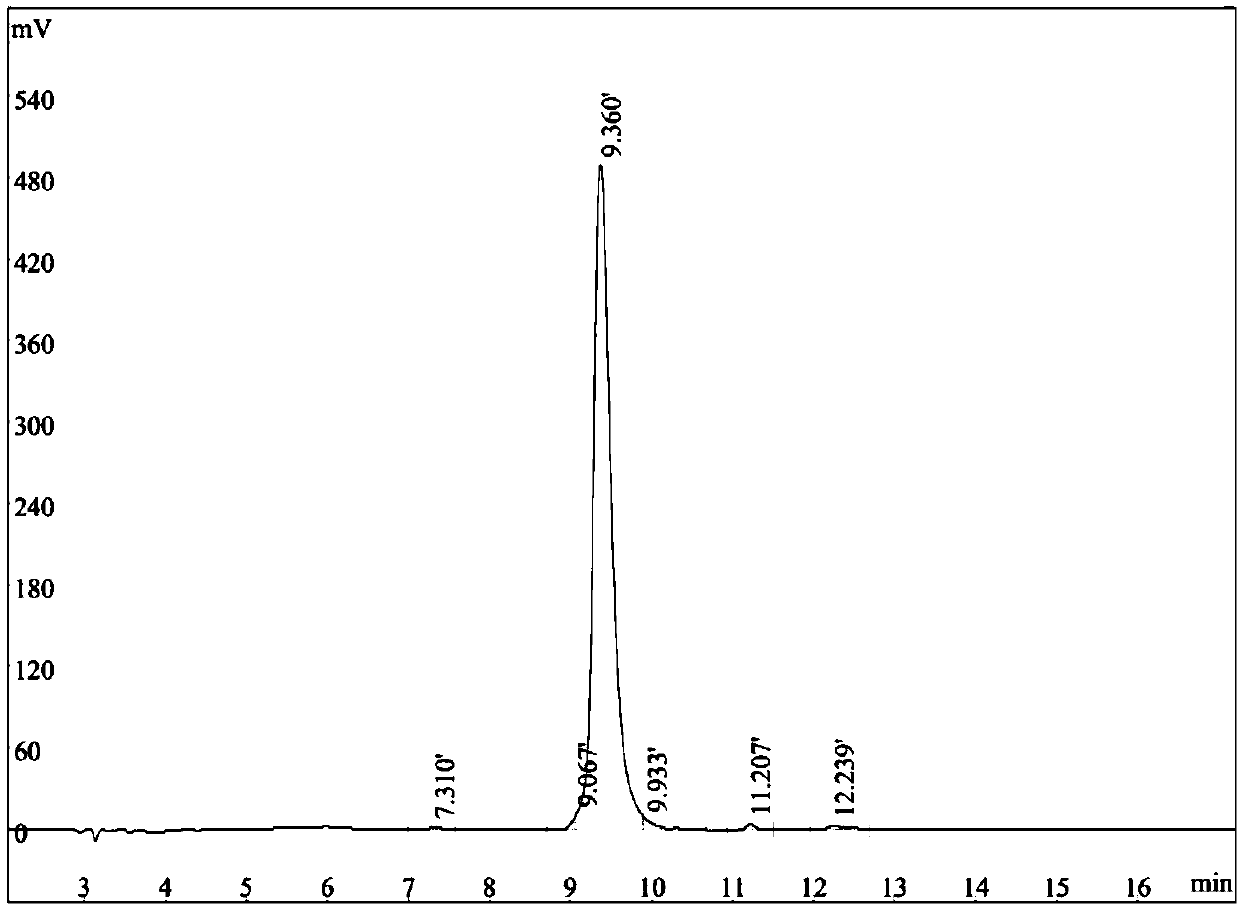

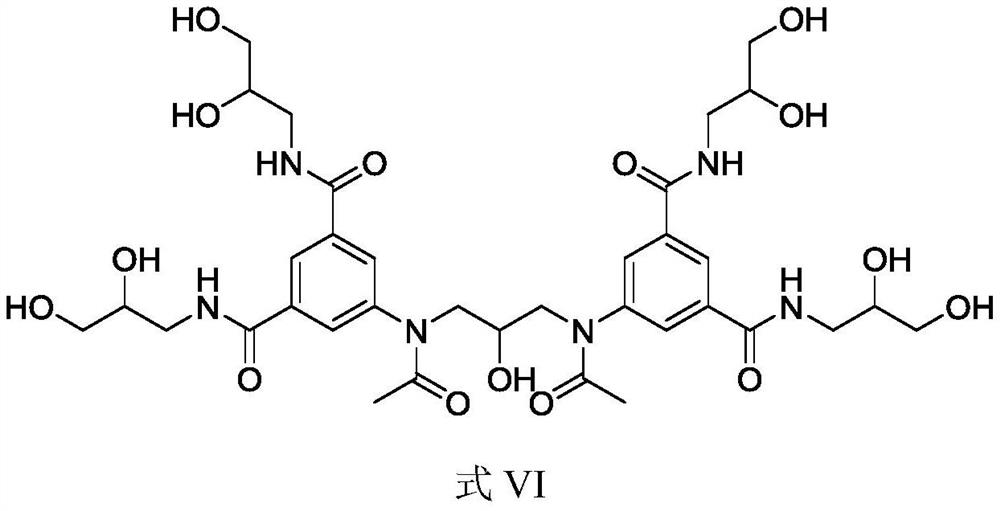

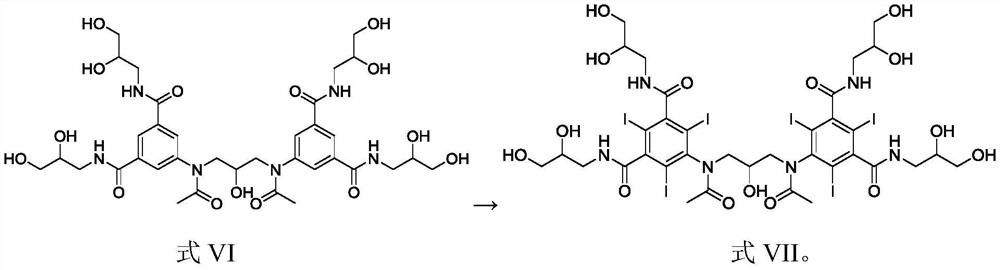

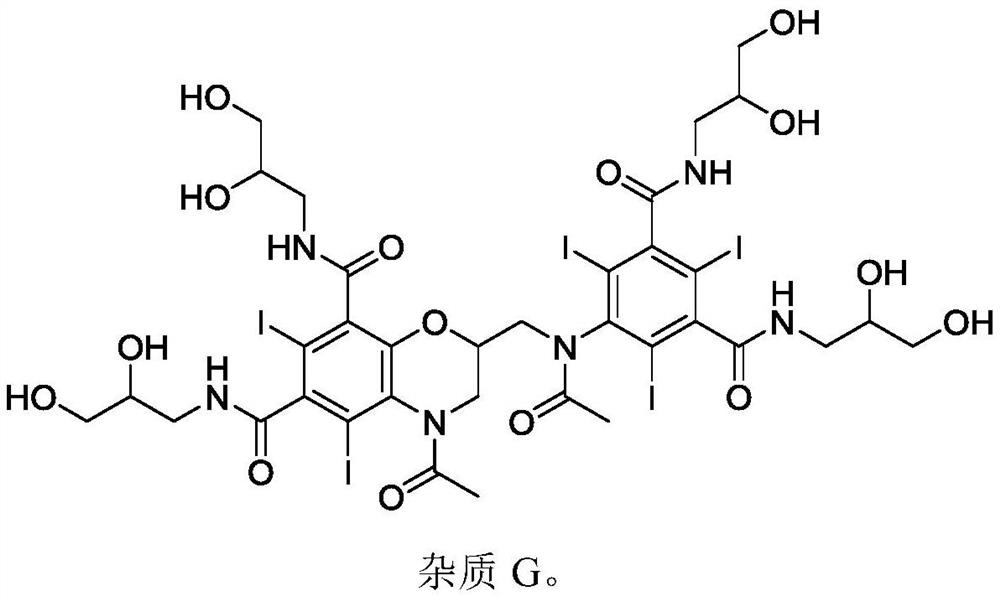

Intermediate of iodixanol and method for preparing iodixanol by using intermediate

PendingCN113831256ASynthetic high purityHigh synthesis efficiencyOrganic compound preparationCarboxylic acid amides preparationDimerCombinatorial chemistry

The invention provides a method for preparing iodixanol from an intermediate of iodixanol. The intermediate of iodixanol is shown as a formula VI: 5,5'-[(2-hydroxy-1,3-propanediyl)bis(acetylimino)]bis[N,N'-bis(2,3-dihydroxypropyl)-1,3-benzenedicarboxamide], and iodination is performed through the formula VI to obtain a finished product of iodixanol. The invention provides a brand new synthesis thought of forming a dimer first and then conducting iodinating, and in the prepared iodixanol finished product, the total impurity content is less than or equal to 1.0%, and the impurity G content is less than or equal to 0.5%. The method disclosed by the invention is mild in reaction condition, low in equipment damage, simple in process, green, environment-friendly, low in cost, capable of ensuring continuous production of high-quality products, relatively high in application value and suitable for industrial production.

Owner:江苏宇田医药有限公司

Preparation method of novel non-natural antioxidation peptide

ActiveCN109438555ASynthetic high purityImproves antioxidant activityAntinoxious agentsPeptide preparation methodsAgent CombinationPotassium tert-butoxide

The invention provides a preparation method of a novel non-natural antioxidation peptide and belongs to the field of biological medicine. The synthesis method of the novel polypeptide comprises the steps of performing resin grafting reaction on Fmoc-Pro(Boc)-OH, and then performing coupled reaction with Pro or Trp amino acid and taurine to form the novel polypeptide such as Tau-Trp-Pro, Trp-Tau-Pro, Tau-Trp-Pro-Pro, Trp-Pro-Tau-Pro and Trp-Tau-Pro-Pro, wherein a Fmoc removal group adopts a deprotection agent combination: piperidine, potassium tert-butoxide and HOBT in a reaction process. Taurine reacts with a tegillarca granosa tripeptide Trp-Pro-Pro to form the novel polypeptide with improved antioxidation activity or anticancer activity; in a synthesis process of the polypeptide, amino deprotection is complete; and the synthesis purity of the polypeptide is high.

Owner:ZHEJIANG OCEAN UNIV

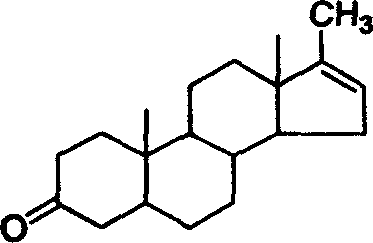

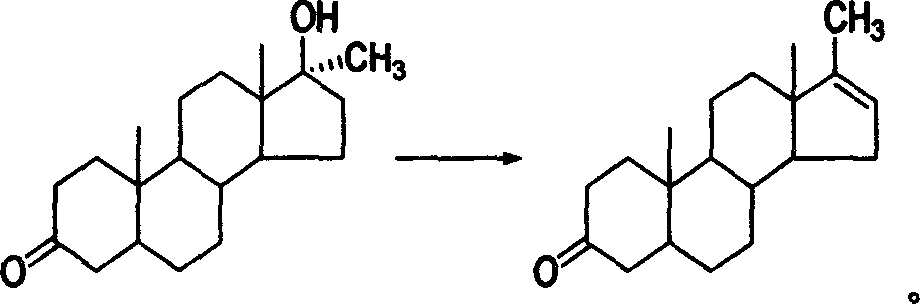

17-methyl-5 alpha-androstane-16-olefin-3-ketone and preparation method

The invention belongs to the field of organic chemical synthesis technology, and relates to a compound methylene androsterone (17-methyl-5 alpha-androst-16-ene-3-ketone) and its preparation method. Said invention uses mestanolone (17 beta-hydroxy-17-alpha-methyl-5-alpha-androstane-3-keton) as raw material, and makes it undergo the process of dehydraton reaction to obtain the invented methylene androsterone. The raw material of said invention is cheap and easily available, the acetic anhydride can be used as anhydrating agent, and the new compound methylene androsterone with high purity can be synthesized, and its synthetic method is simple and convenient.

Owner:FUDAN UNIV

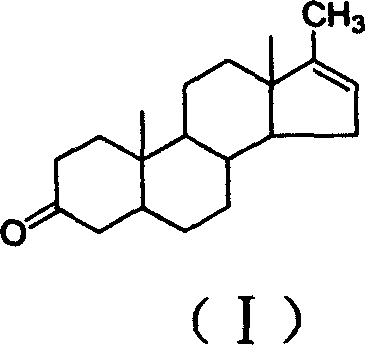

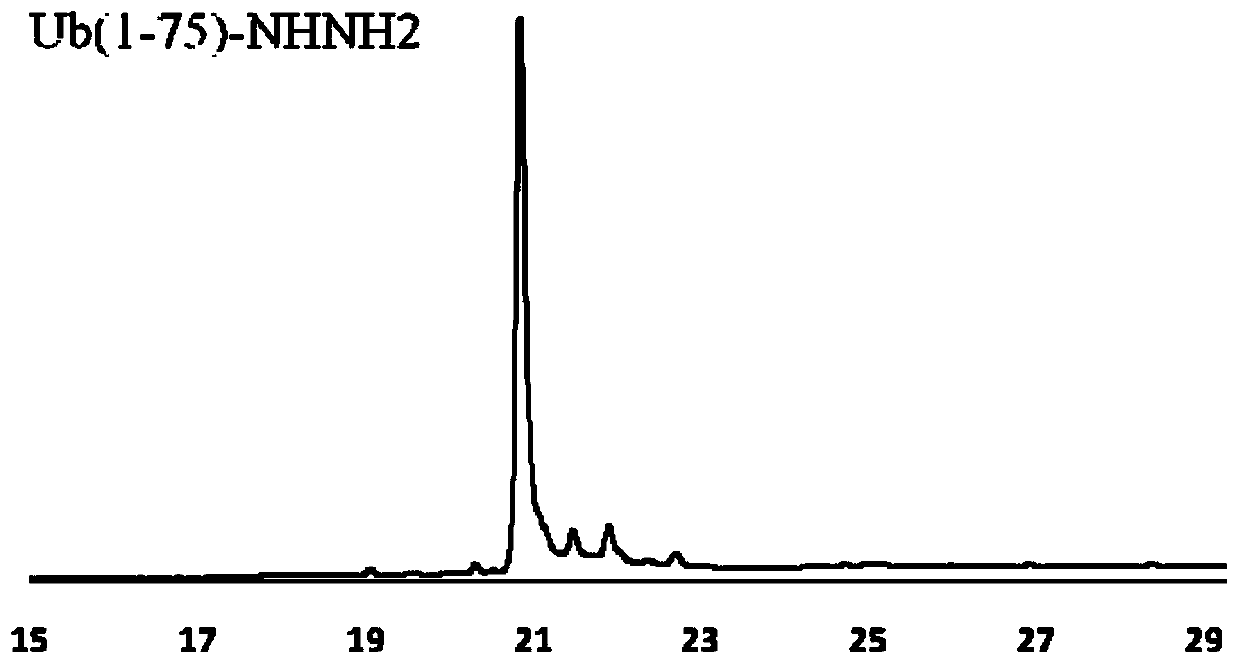

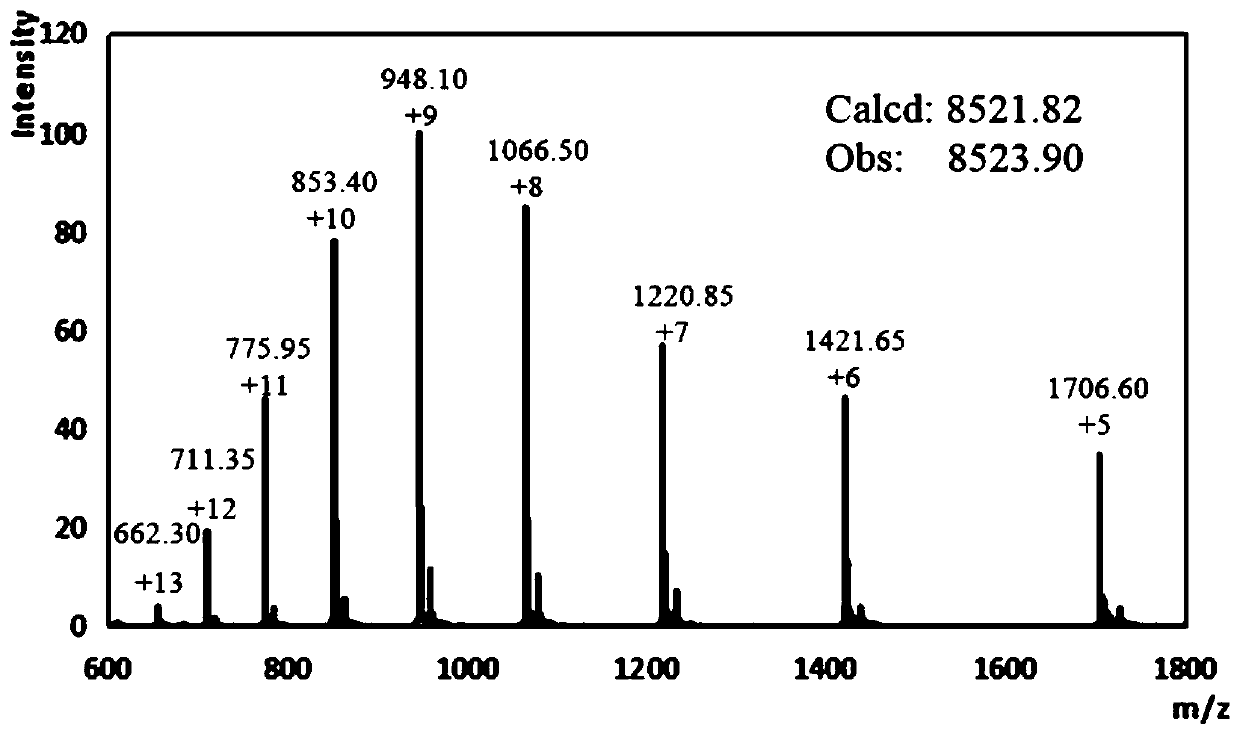

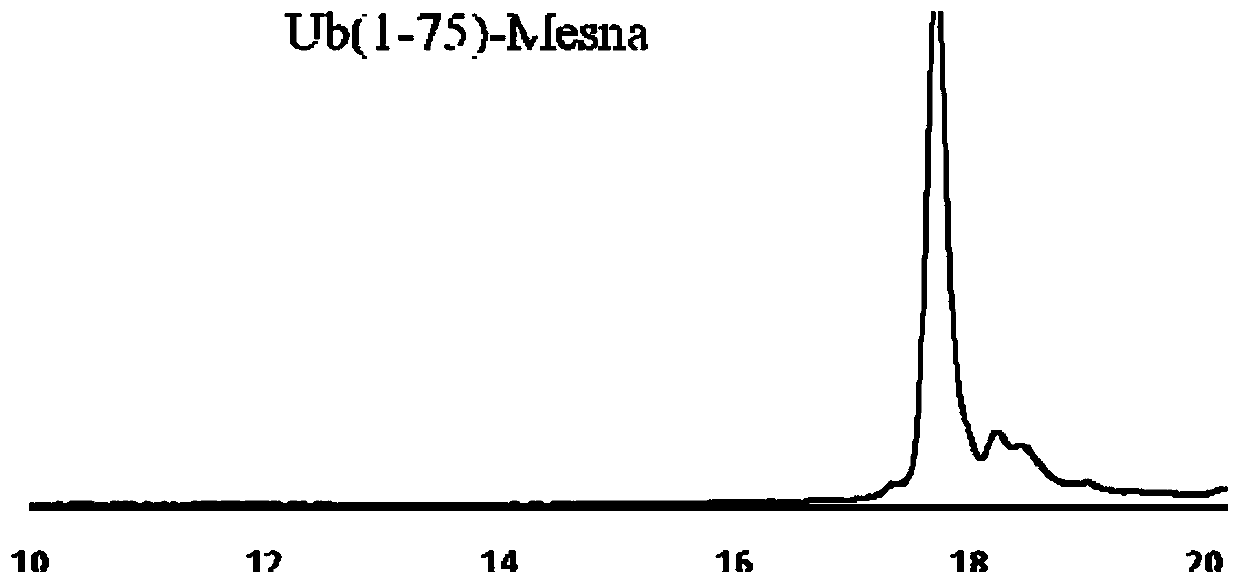

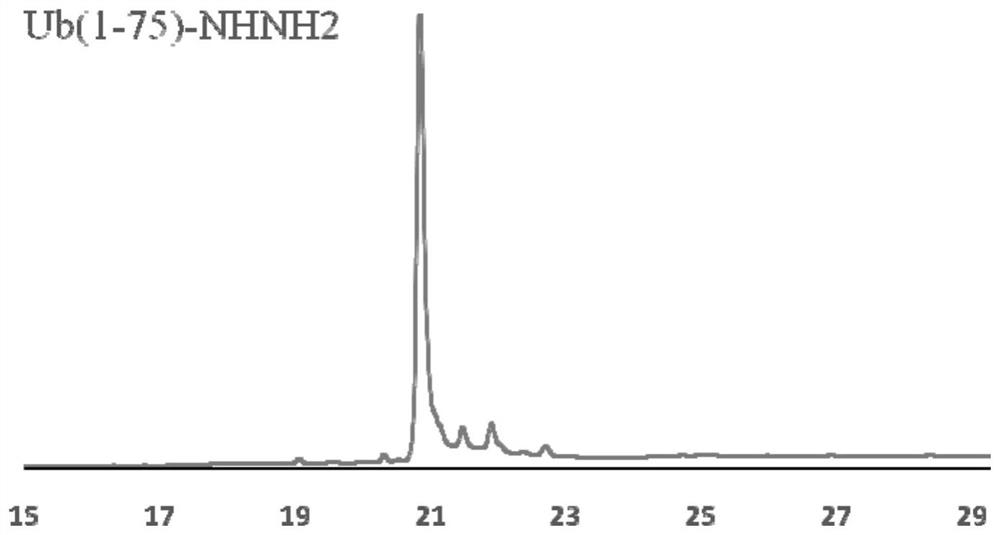

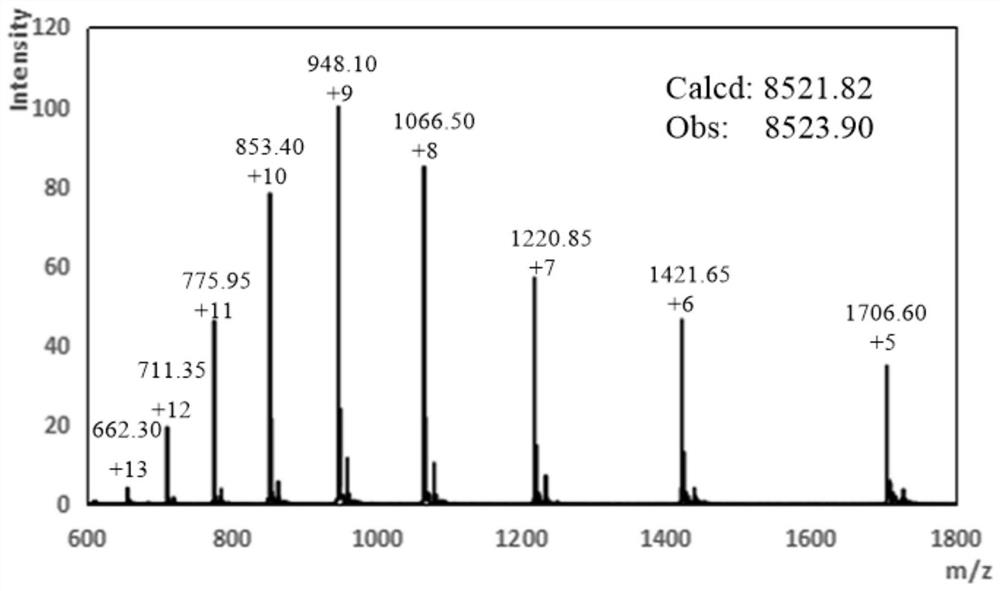

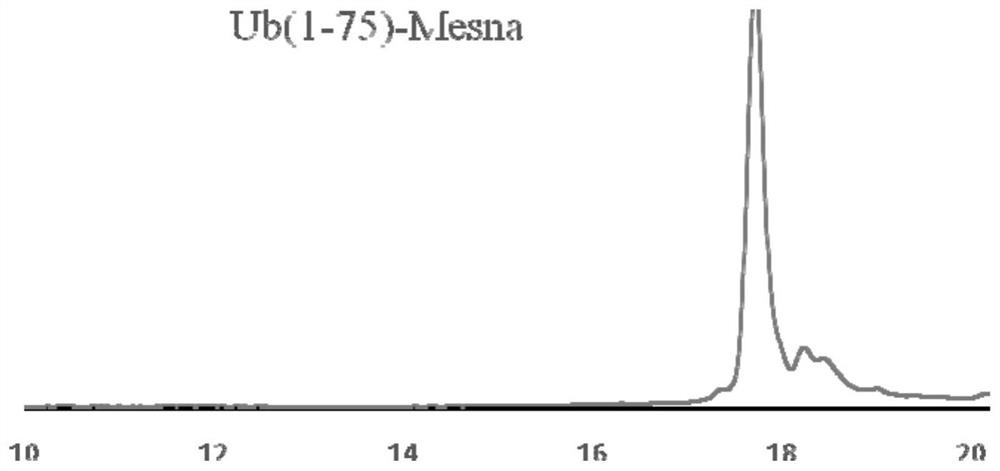

Method for simply synthesizing ubiquitin probe Ub-Rho110-Gly

ActiveCN109824764AHigh production yieldSynthetic high purityPeptide preparation methodsDepsipeptidesUbiquitinChemistry

The invention discloses a method for simply synthesizing ubiquitin probe Ub-Rho110-Gly.The method comprises the following steps: firstly, preparing ubiquitin hydrazideUb (1-75)-NHNH2 by using an N-S acyl group migration semi-synthesis strategy, further converting into ubiquitin thioesterUb (1-75)-Mesna based on a hydrazide method, and then obtaining the ubiquitin probe Ub-Rho110-Gly by direct ammonolysis.The method has the characteristics of high preparation yield, high synthetic purity (about Ub (1-75)-NHNH230-40mg can be obtained per 1L culture medium after freeze-drying), simple operation and mass preparation.

Owner:HEFEI UNIV OF TECH

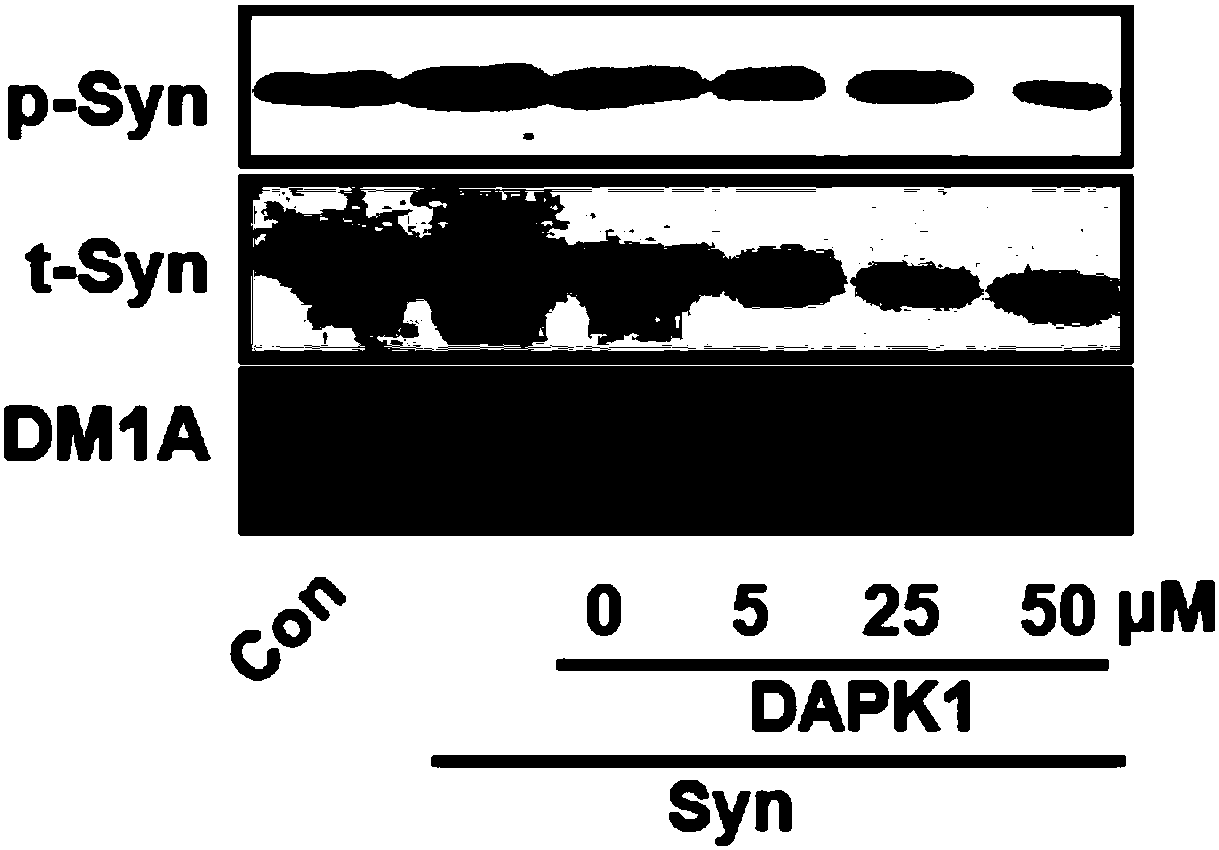

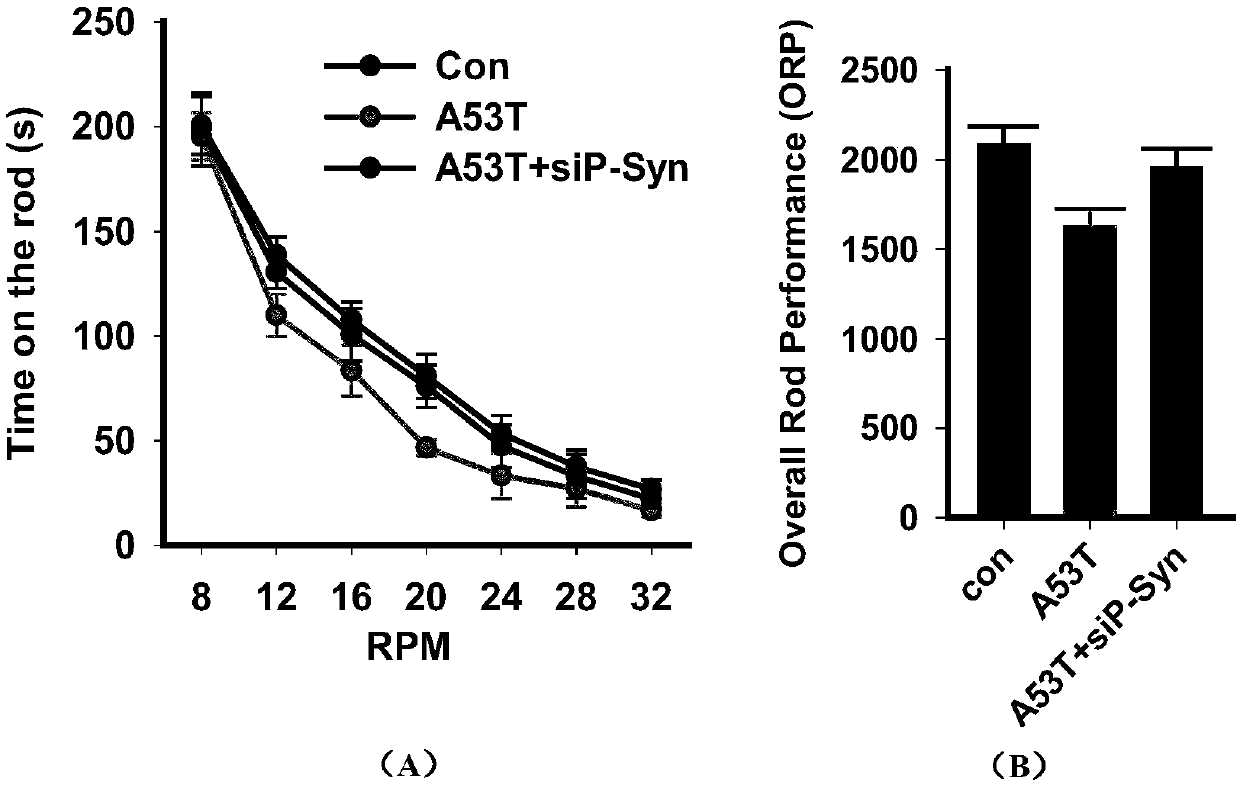

Micromolecule polypeptide and application thereof to preparation of medicines for preventing and treating Parkinson's disease

ActiveCN110041408ASynthetic high purityImprove solubilityNervous disorderPeptide/protein ingredientsNerve cellsAlpha-synuclein

The invention discloses micromolecule polypeptide TAT-PSYN and an application thereof to preparation of medicines for preventing or treating Parkinson's disease. Through synthesizing a TAT protein transduction domain and combining and restraining fusion protein TAT-pSyn of protein polypeptide of alpha-synuclein (alpha-synuclein), pSyn protein polypeptide carried through TAT passes through blood-brain barriers through blood transportation and is taken in by nerve cells. The polypeptide is applied to an Alpha-synuclein(A53T) transgenic Parkinson mouse model, so that the effect of the polypeptidefor blocking combination of alpha-synuclein (alpha-synuclein) and death associated protein kinase 1 (DAPK1) can be effectively exerted, loss of dopaminergic neurons and nerve projection, caused by alpha-synuclein phosphorylation and abnormal gathering can be restrained, the dyskinesia of the Parkinson model is reduced, and a molecular target is provided for medicines for clinical treatment of theParkinson's disease.

Owner:HUAZHONG UNIV OF SCI & TECH

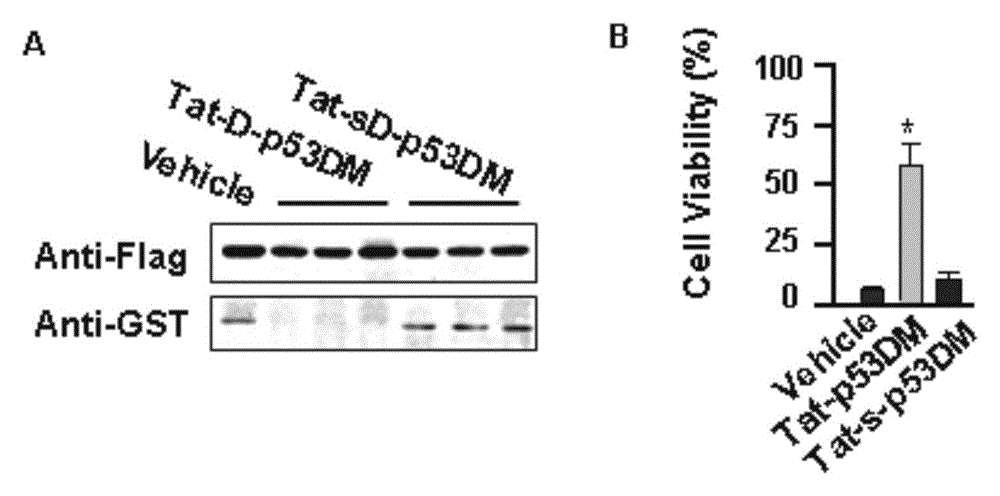

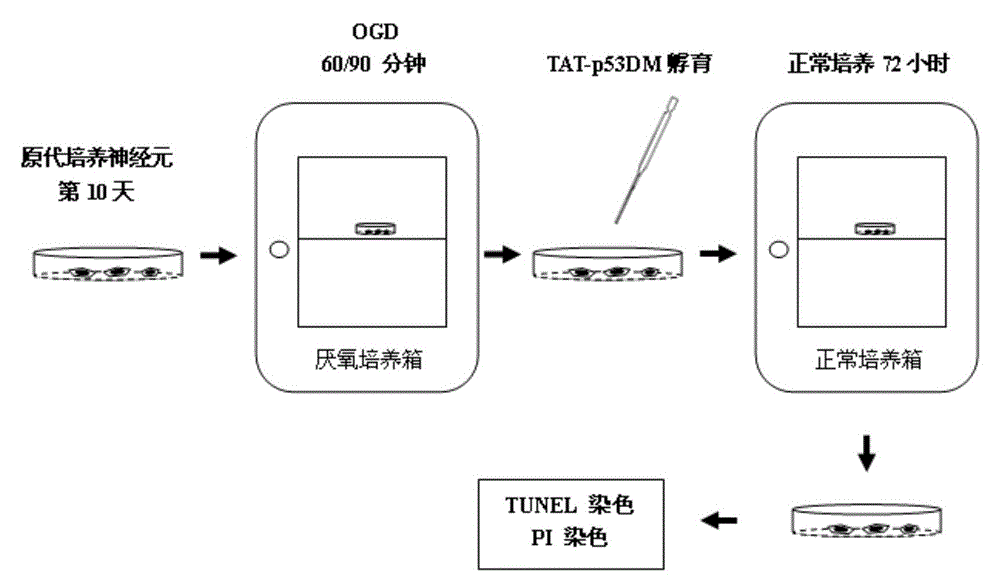

Small molecule polypeptide tat-p53dm and its application in the preparation of medicines for treating or preventing ischemic stroke

ActiveCN103936838BSynthetic high purityNo side effectsPolypeptide with localisation/targeting motifNervous disorderInjury brainBiologic DMARD

The invention discloses a micro-molecule polypeptide TAT-p53DM and an application thereof to preparing a medicine for treating or preventing ischemic stroke. A fusion protein polypeptide TAT-p53DM of a TAT protein transduction domain and p53DM is artificially synthesized; TAT carries p53DM protein polypeptide to pass through a blood brain barrier through blood so as to be taken by nerve cells; used in an in-vitro and in-vivo ischemic stroke model, the micro-molecule polypeptide TAT-p53DM is capable of effectively playing a biological role in blocking binding between death domain of death associated protein kinase 1 (DAPK1DD) and tumor suppression protein p53DNA binding motifs (p53DM), inhibiting signals capable of causing neuronal apoptosis and necrosis at DAPK1 downstream, and reducing ischemic stroke brain injury; moreover, molecular targets are provided for further developing medicines for clinically treating ischemic stroke.

Owner:WUHAN QR SCI & TECH DEV +1

A kind of low-temperature preparation method of lithium slag-based naa molecular sieve

ActiveCN109485062BHigh reactivityReduce hindranceAluminosilicate zeolite type-AMolecular sieveLithium

The invention provides a low-temperature preparation method of a lithium slag based NaA molecular sieve and belongs to the technical fields of industrial solid waste recycling and molecular sieve preparation. The low-temperature preparation method comprises the following steps: (1) pre-treating raw lithium slag; (2) performing alkali fusion on the pretreated lithium slag by adopting an alkali fusion agent so as to obtain silicate clinker; (3) adding an aluminum source and a water source into the silicate clinker, regulating the silicon-aluminum molar ratio to be (1.0-2.4):1 and controlling a water-alkali molar ratio to be (40-80):1 so as to obtain a NaA molecular sieve precursor; and (4) carrying out a hydrothermal reaction on the NaA molecular sieve precursor at a temperature of 45-75 DEGC, thereby obtaining the lithium slag based NaA molecular sieve. According to the preparation method disclosed by the invention, the lithium slag serves as the raw material, the high-purity lithium slag based NaA molecular sieve can be prepared at a low hydrothermal temperature in short reaction time, and high value-added utilization of the lithium slag is realized.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

A preparation method of zinc lithium titanate/carbon nanocomposite negative electrode material for lithium ion battery

ActiveCN109888247BImprove conductivityImprove electrochemical performanceCell electrodesSecondary cellsElectrical batteryPhysical chemistry

The invention discloses a method for preparing a lithium zinc titanate / carbon nanocomposite negative electrode material for a lithium ion battery. Firstly, a lithium source, a titanium source, a zinc source and a carbon source are subjected to a liquid phase reaction to form a metal complex, and then heated in an oil bath. The precursor gel is obtained, and then the composite negative electrode material of the lithium ion battery is obtained by microwave treatment. Adopting the method of the present invention to prepare carbon-coated lithium zinc titanate not only has low energy consumption, short reaction time, and uniform particle size, but also has excellent electrochemical properties of batteries made of it as negative electrode active materials, at 100mA / g The cycle performance test was carried out under the current density. The initial value of the capacity of the lithium zinc titanate battery reached 238.3mAh / g. After 10 cycles, the specific capacity was still around 240mAh / g, and the electrochemical performance was maintained very well. Application prospect.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

A simple method for the synthesis of ubiquitin probe ub-rho110-gly

ActiveCN109824764BProduct yield is highSynthetic high purityPeptide preparation methodsDepsipeptidesAcyl groupAminolysis

Owner:HEFEI UNIV OF TECH

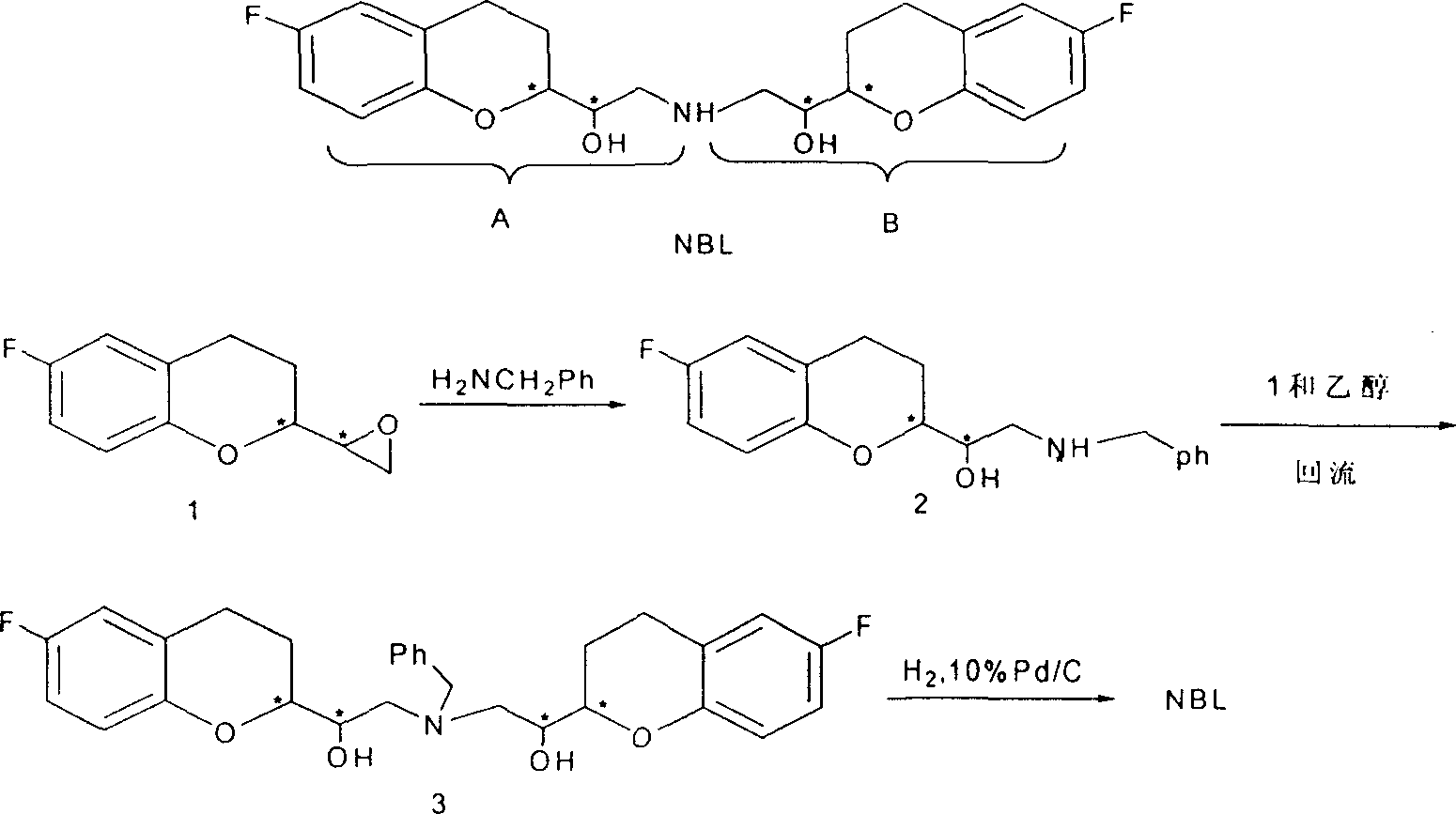

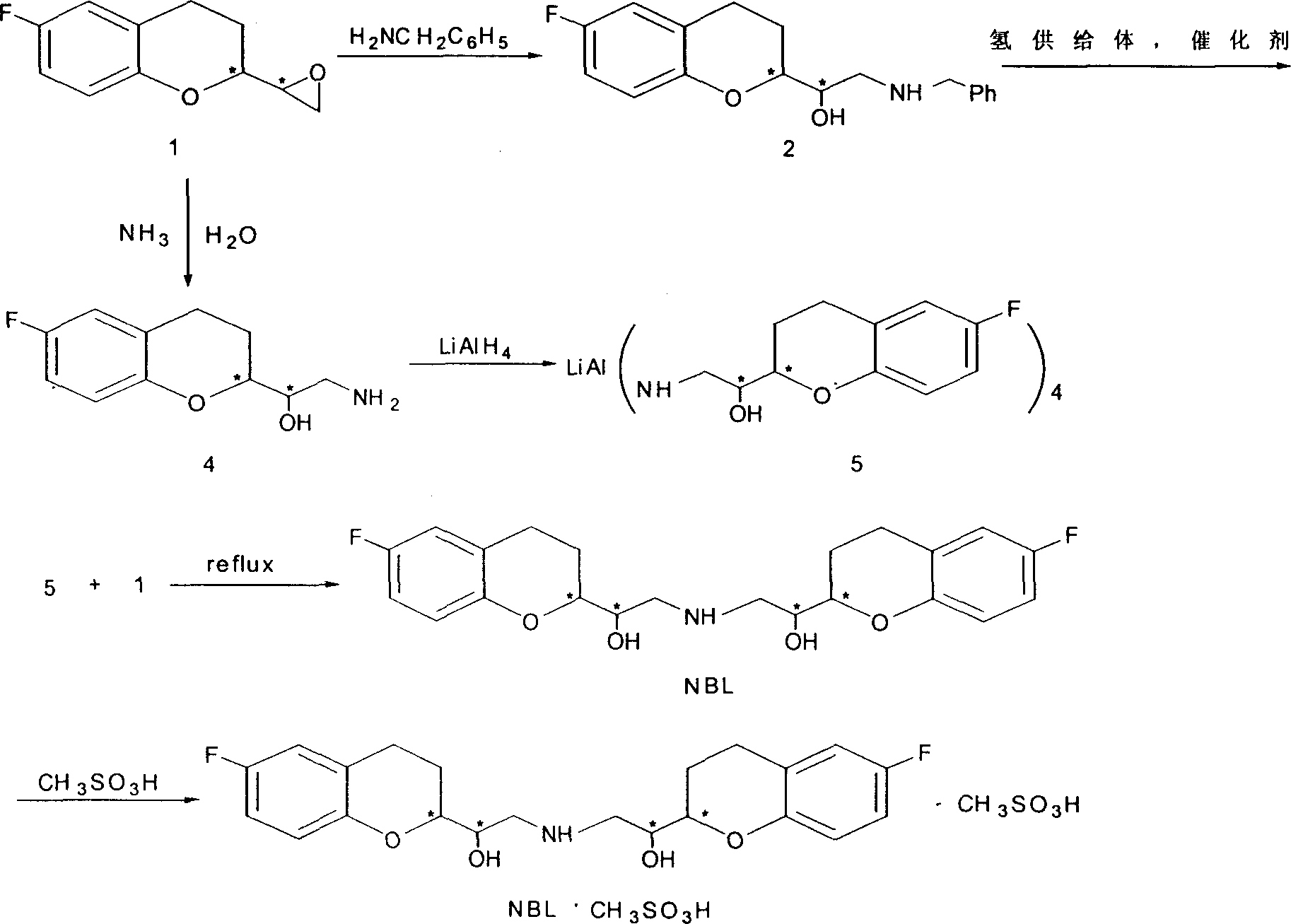

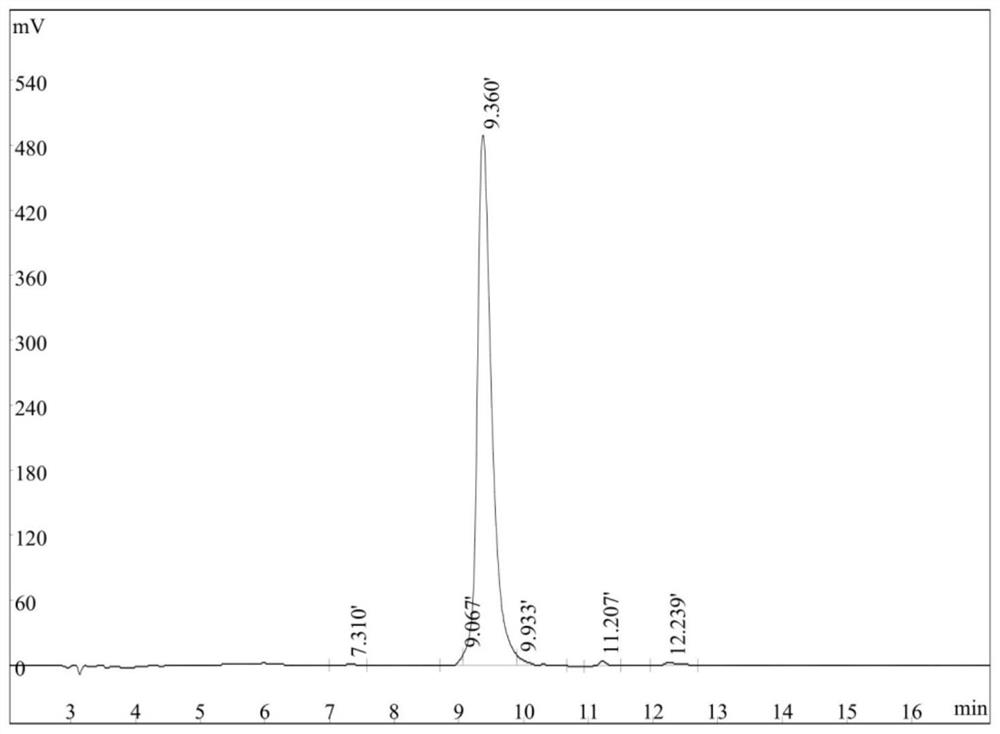

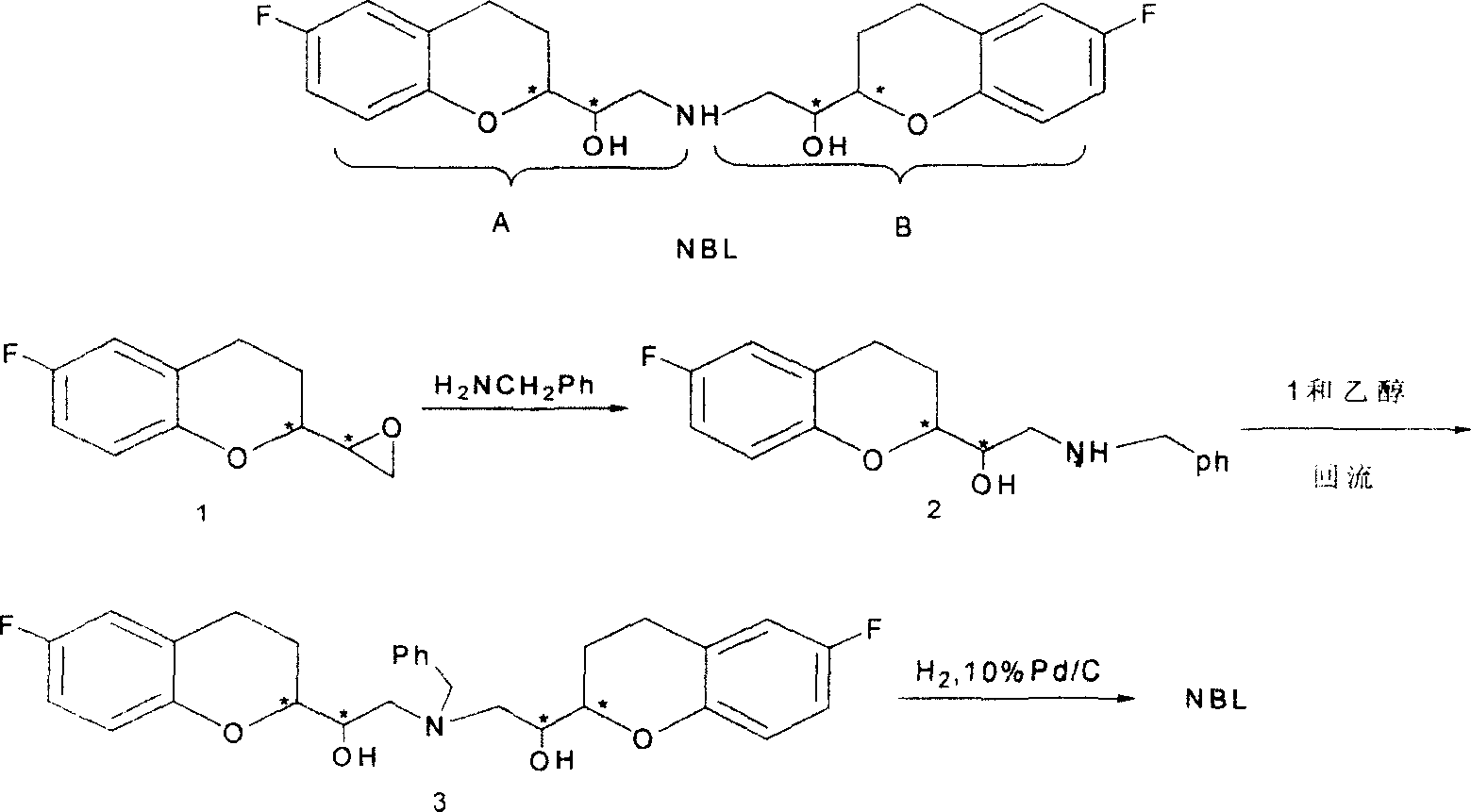

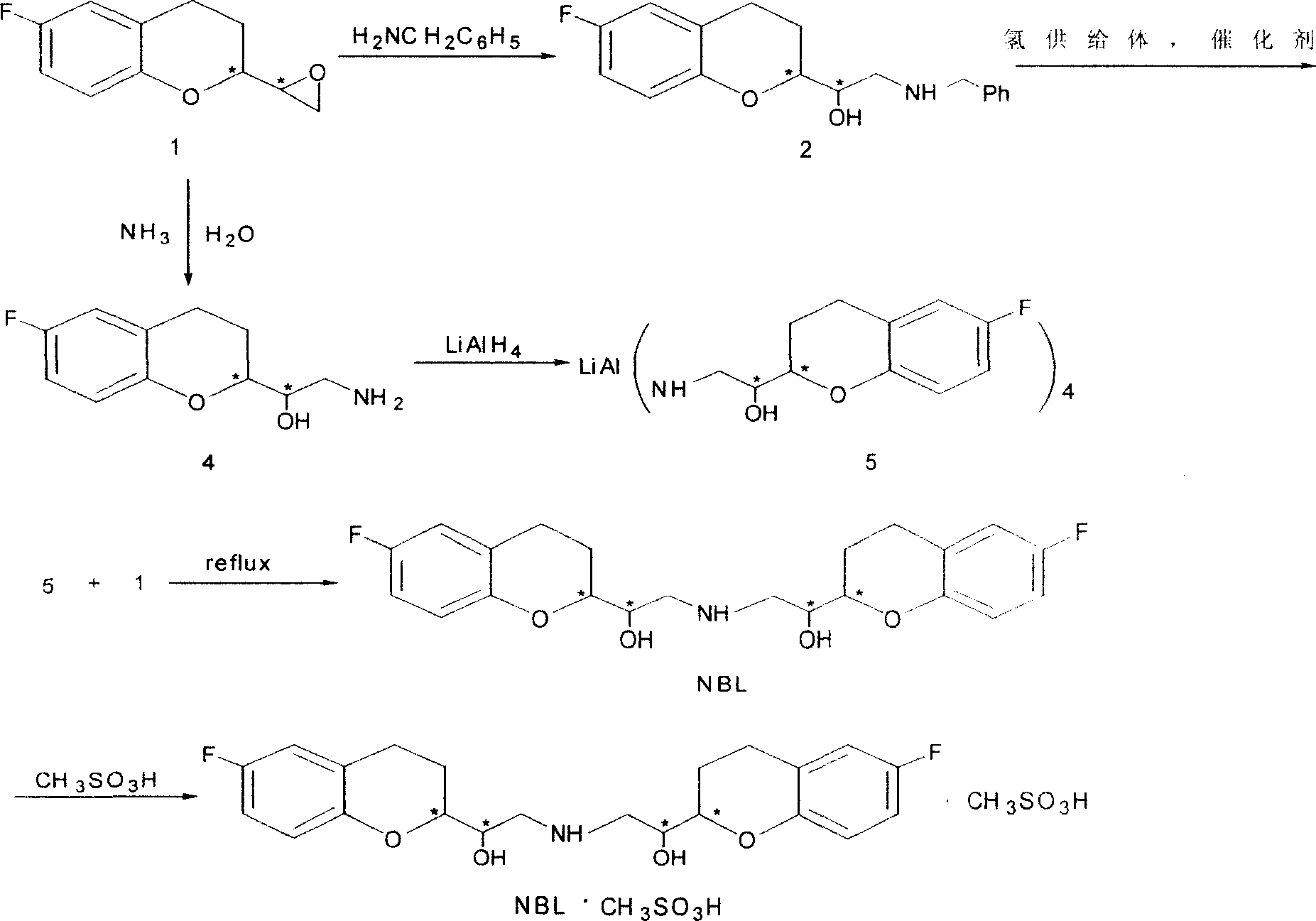

2,2'-[iminodi(methylene)di-(6-fluoro-3,4-dihydro-2h-1-benzenepyran-2- methanol) methane sulfosalt

This invention relates to a synthetic method for beta1-receptor blocking agent and 2, 2'-[imino di(methylene)]-di-(6-fluorine-3, 4-dihydro-2H-1-benzopyrane-2-methanol) methanesulfonate. First, prepare 6-fluorine-3, 4-dihydro-1-[amino (methylene)]-2H-1-benzopyrane-2-methanol using 6-fluorine-3, 4-dihydro-2- oxirane group -2H-1- benzopyrane as raw material; then, use LiAlH4 to dispose and get the compound Li-Al amidate; finally, enable Li-Al amide to react with 6-fluorine-3, 4-dihydro-2-oxirane group-2H-1- benzopyrane to get NBL. Advantages:low cost, simple operation and high purity of NBL methanesulfonate.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

A kind of small molecule polypeptide and its application in preparing medicine for preventing and treating ischemic stroke

ActiveCN109553685BSynthetic high purityImprove solubilityPolypeptide with localisation/targeting motifNervous disorderLysosomeReceptor

The invention discloses a small molecule polypeptide TAT‑CDK5‑CTM and its application in the preparation of drugs for preventing or treating ischemic stroke. By synthesizing the fusion protein TAT-CDK5-CTM of the TAT protein transduction domain, the protein polypeptide that can bind and inhibit CDK5, and the autophagy element CTM, TAT is used to carry the CDK5 protein polypeptide through the blood to transport through the blood-brain barrier, and taken up by neurons. Applying the peptide to ischemic stroke models in vitro and in vivo, it can effectively block the NR2B subunit of N-methylaspartate receptor (NMDAR) and cyclin-dependent protein kinase 5 (CDK5) binding, and the polypeptide molecule bound to CDK5 protein is mediated by CTM, enters the lysosome for degradation, inhibits neuronal apoptosis and necrosis caused by the downstream of CDK5, and reduces brain damage after ischemic stroke. Drug development for the treatment of ischemic stroke provides molecular targets.

Owner:HUAZHONG UNIV OF SCI & TECH

2,2'-[iminodi(methylene)di-(6-fluoro-3,4-dihydro-2H-1-benzenepyran-2- methanol) methane sulfosalt

InactiveCN100341866CSynthetic high purityHigh purityOrganic chemistryMethyl palmoxirateReceptor blockade

This invention relates to a synthetic method for beta1-receptor blocking agent and 2, 2'-[imino di(methylene)]-di-(6-fluorine-3, 4-dihydro-2H-1-benzopyrane-2-methanol) methanesulfonate. First, prepare 6-fluorine-3, 4-dihydro-1-[amino (methylene)]-2H-1-benzopyrane-2-methanol using 6-fluorine-3, 4-dihydro-2- oxirane group -2H-1- benzopyrane as raw material; then, use LiAlH4 to dispose and get the compound Li-Al amidate; finally, enable Li-Al amide to react with 6-fluorine-3, 4-dihydro-2-oxirane group-2H-1- benzopyrane to get NBL. Advantages:low cost, simple operation and high purity of NBL methanesulfonate.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

A microwave synthesis method of potassium sodium niobate lead-free piezoelectric ceramic powder

ActiveCN106242568BNo deviation from stoichiometric ratio phenomenonNot volatileElectricityTemperature control

The invention discloses a microwave synthesis method of potassium-sodium niobate leadless piezoelectric ceramic powder. The microwave synthesis method of the potassium-sodium niobate leadless piezoelectric ceramic powder comprises the following steps of (1) mixing raw materials of K2CO3, Na2CO3 and Nb2O5 to obtain a mixed material; (2) performing microwave synthesis: starting a microwave source; regulating the input power so that the mixed materials realize temperature rise at the speed of 10 to 15DEG C / min until the reflecting power is stable; then, raising the temperature to 600 to 800 DEG C at the speed of 5 to 10 DEG C / min; performing heat insulation for 5 to 20min; cooling the materials to the room temperature; obtaining the potassium-sodium niobate leadless piezoelectric ceramic powder. The microwave synthesis method of potassium-sodium niobate leadless piezoelectric ceramic powder provided by the invention has the advantages that through raw material optimization and microwave heating temperature control, the self wave adsorption effect of the raw material powder is utilized; the low-temperature fast synthesis of the potassium-sodium niobate leadless piezoelectric ceramic powder is realized; in the process, alkali metal elements cannot be easily volatilized; the obtained powder does not have a phenomenon of deviating from the stoichiometric proportion.

Owner:ZHENGZHOU UNIV

A kind of nano goethite-amino acid compound foliar fertilizer, preparation method and application

ActiveCN104446907BLarge specific surface areaHigh chemical activityNitrogenous fertilisersLiquid fertilisersRetention timeHydrolysate

The invention belongs to the field of fertilizer production and provides a preparation method and the application of a nano goethite-amino acid compound leaf fertilizer. The nano goethite-amino acid compound leaf fertilizer is prepared from nano goethite, amino acid hydrolysate and deionized water, wherein the concentration of the goethite is 1g / L. The preparation process of the nano goethite-amino acid compound leaf fertilizer comprises the following steps: (1) preparing the nano goethite; (2) preparing the amino acid hydrolysate; and (3) obtaining the nano goethite-amino acid compound leaf fertilizer. The nano goethite in the nano goethite-amino acid compound leaf fertilizer is capable of effectively adhering to the surfaces of plant leaves, and therefore, the problems of low utilization rate and non-obvious growth promoting effect due to short retention time period and poor stability of the leaf fertilizer on the plant leaves are solved, and furthermore, the acting time of the amino acid compound leaf fertilizer is effectively prolonged, the utilization rate and the application effect of the leaf fertilizer are increased and the growth of tomato plants is greatly promoted.

Owner:NANJING AGRICULTURAL UNIVERSITY

Synthetic method of a class of cyclic dipeptides containing glutamine or asparagine

ActiveCN111875668BAvoid residueSynthetic operation is simplePeptide preparation methodsCyclic peptidesAmino acid side chainDipeptide

Owner:SHAANXI HUIKANG BIO TECH CO LTD

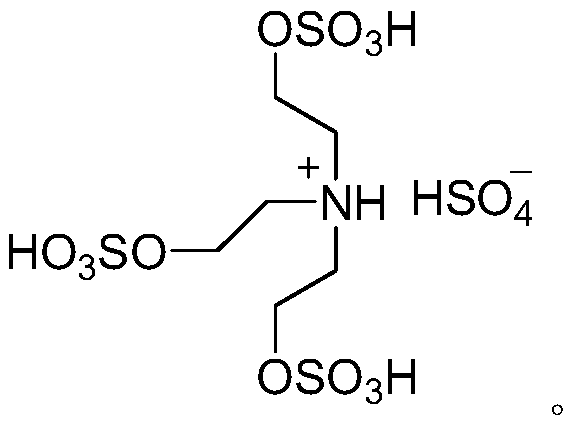

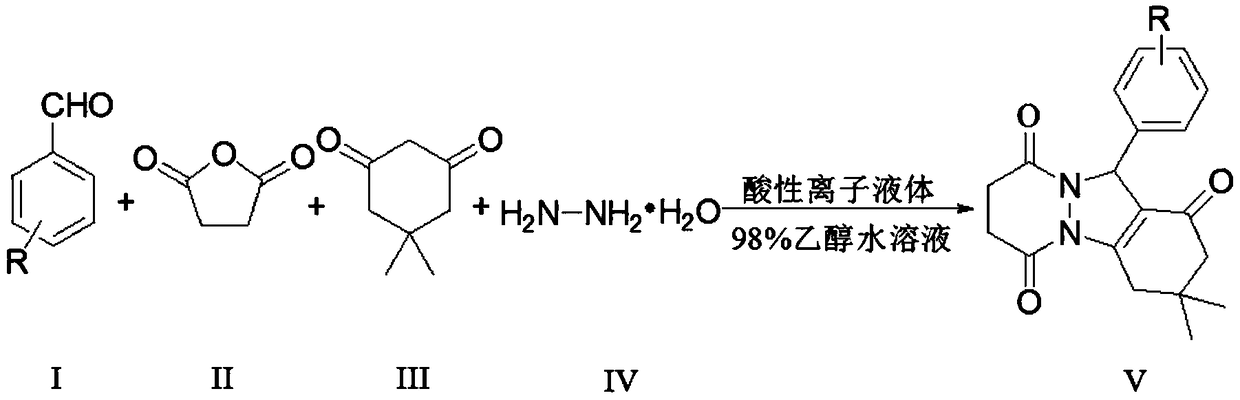

A kind of phthalazinone derivative, preparation method of the derivative and catalyst for preparation thereof

ActiveCN106243112BHigh yieldGood atom economyOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsFiltrationSolvent

Owner:东港智科产业园有限公司

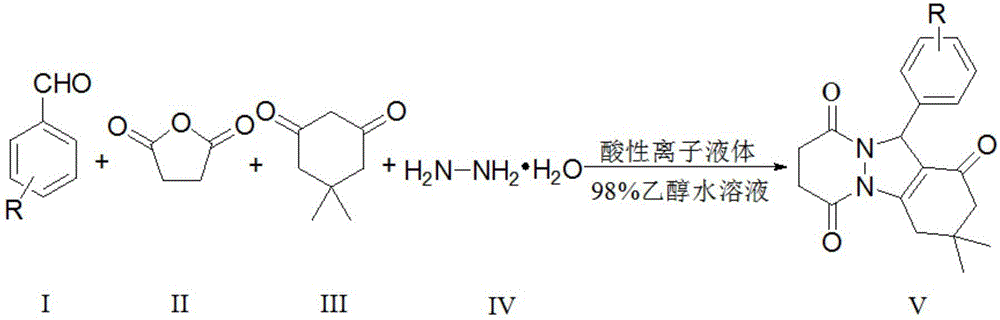

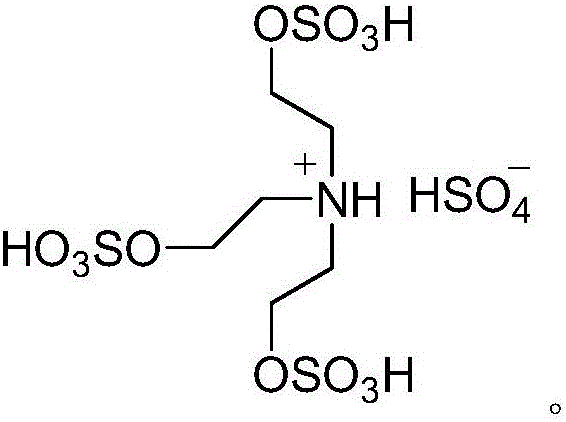

Phthalazinone derivative and preparation method thereof, and catalyst used for preparation of phthalazinone derivative

ActiveCN106243112AHigh yieldGood atom economyOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsHydrazine compoundFiltration

The invention discloses a phthalazinone derivative and a preparation method thereof, and a catalyst used for preparation of the phthalazinone derivative, belonging to the technical field of ionic liquid catalysis. According to the invention, a mol ratio of aromatic aldehyde to succinic anhydride to 5,5-dimethyl-1,3-cyclohexanedione to hydrazine hydrate is 1: 1: 1: (1.0-1.2); the molar weight of an ionic liquid catalyst is 8 to 15% of the molar weight of aromatic aldehyde; the volume dose of a reaction solvent aqueous ethanol solution in terms of milliliter is 5 to 8 times of the molar weight of aromatic aldehyde in terms of millimole; reflux time is 21 to 53 min; after completion of the reaction, cooling to room temperature and pumping filtration are successively carried out; and a filter residue is subjected to washing and vacuum drying so as to obtain 3,4,7,8-tetrahydro-3,3-dimethyl-11-aryl-2H-phthalizine[1,2-alpha]-indolo-1,6,9(11H)-trione. The invention has the characteristics that the catalyst is high in activity; reaction time is short; the prepared derivative is simple to purify; the raw materials are high in utilization rate; the whole preparation process is simple and convenient in operation; etc.; so the preparation method is suitable for industrial large-scale application.

Owner:东港智科产业园有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com