Low-temperature preparation method of lithium slag based NaA molecular sieve

A molecular sieve and low-temperature technology, which is applied in the direction of A-type crystalline aluminosilicate zeolite and crystalline aluminosilicate zeolite, etc., can solve problems such as poor controllability, long reaction time, unfavorable economic benefit improvement and environmental protection, etc., to avoid Effect of nucleation and improvement of synthesis purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a low-temperature preparation method of lithium slag-based NaA molecular sieve, comprising the following steps:

[0027] (1) Carry out pretreatment to raw material lithium slag;

[0028] (2) Alkali melting is carried out to the pretreated lithium slag by using an alkali melting agent to obtain silicate clinker;

[0029] (3) adding an aluminum source and a water source to the silicate clinker, adjusting the molar ratio of silicon to aluminum to 1.0 to 2.4:1 and the molar ratio of water to alkali to 40 to 80:1 to obtain a NaA molecular sieve precursor; the silicon Al molar ratio to SiO 2 and Al 2 o 3 In terms of the amount of substance, the molar ratio of water to alkali is expressed in H 2 O and Na 2 A measure of the substance of O;

[0030] (4) The NaA molecular sieve precursor is subjected to a hydrothermal reaction at 45-75° C. to obtain a lithium slag-based NaA molecular sieve.

[0031] The invention pretreats the raw material lithium sl...

Embodiment 1

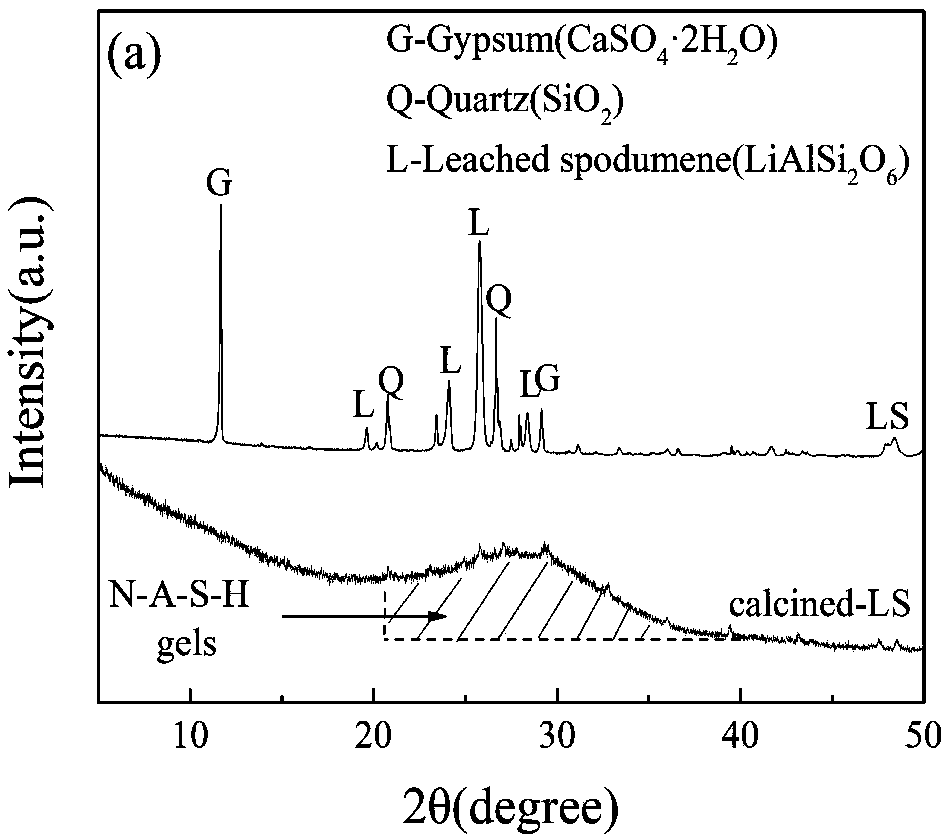

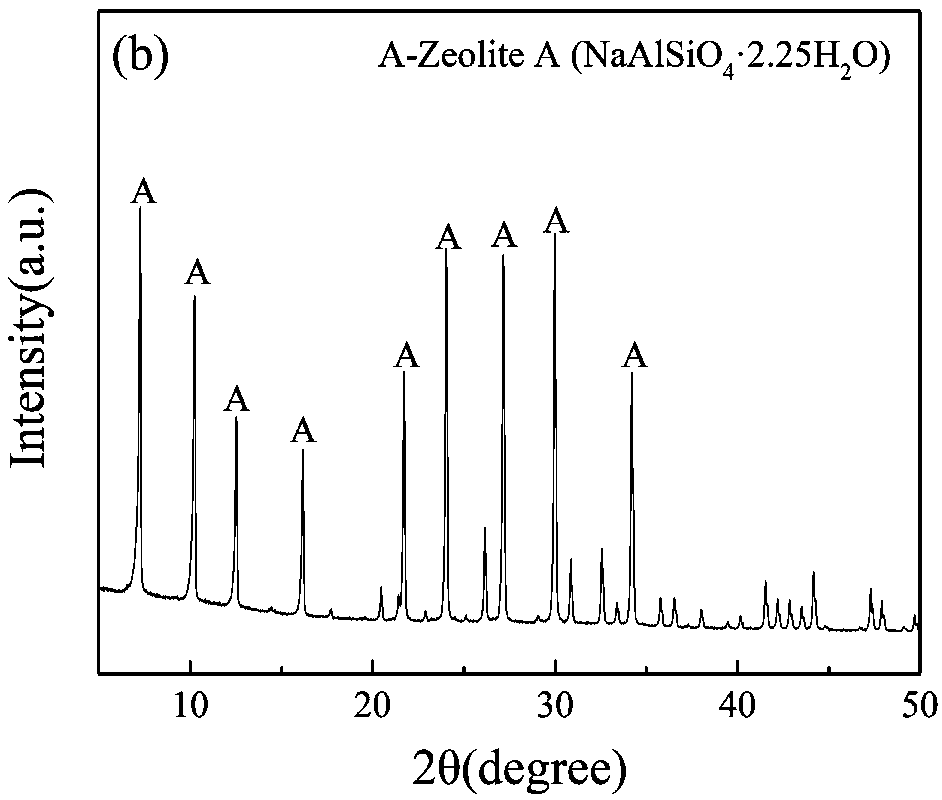

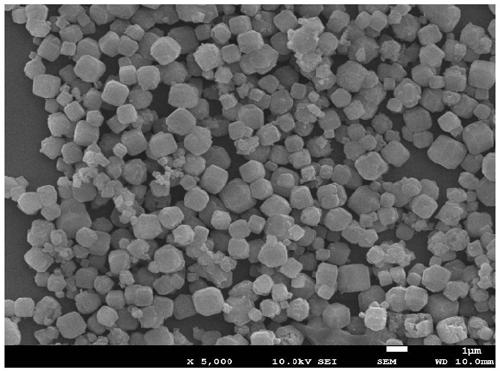

[0043] According to the reaction condition of table 1, take lithium slag 5g (containing SiO 2 :58.27wt%, Al 2 o 3 : 23.75wt%, SO 3 :9.06wt%, CaO: 5.81wt%, Fe 2 o 3 : 1.36wt%, other 1.75wt%, main crystalline phase is gypsum, quartz and spodumene), be pulverized to 200 orders, water eluting acid; Add solid sodium hydroxide 7.5g, make alkali-silicon mol ratio (Na 2 O / SiO 2 ) is 1.9, mix well and grind quickly. Alkali-melt the uniformly mixed raw materials at 600°C for 4 hours to obtain silicate clinker; grind the clinker until there is no graininess, add 6.05g NaAlO 2 , the SiO in the clinker 2 / Al 2 o 3 Molar ratio is adjusted to 1.0, then adds 130.66g deionized water, makes water / alkali mol ratio (H 2 O / Na 2 O) reached 56 to obtain the NaA molecular sieve precursor; stirred and aged at room temperature for 12 hours to obtain the reaction material; transferred the reaction material to the reaction kettle, crystallized at 60°C for 8 hours, and washed the product repeat...

Embodiment 2~12

[0047] The reaction steps are the same as in Example 1, and the reaction conditions are shown in Table 1.

[0048] XRD test and SEM observation were carried out on the products finally obtained in Examples 2-12, and the results are shown in Table 1.

[0049] The reaction condition and product of table 1 embodiment 1~12

[0050]

[0051] As can be seen from the results in Table 1, the present invention can obtain NaA molecular sieve at a low temperature of 45-75°C by controlling the reaction conditions, which significantly reduces the temperature of the hydrothermal reaction; in addition, the hydrothermal reaction time of the present invention is only 2-2 24h, which is much shorter than the reaction time at room temperature (2-7 days), and the obtained NaA molecular sieve crystallizes well, and no sodalite appears.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com