A microwave synthesis method of potassium sodium niobate lead-free piezoelectric ceramic powder

A lead-free piezoelectric and microwave synthesis technology, applied in the field of lead-free piezoelectric ceramics, can solve the problems of easy deviation from stoichiometric ratio in high-temperature synthesis, and achieve the effects of improving chemical reaction rate, uniform distribution, sintering and performance optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A microwave synthesis method of potassium sodium niobate lead-free piezoelectric ceramic powder, the following steps are adopted:

[0030] 1) Press (K 0.5 Na 0.5 )NbO 3 The stoichiometric ratio of raw material K 2 CO 3 、Na 2 CO 3 and Nb 2 o 5 ; The raw material, ZrO 2 Balls and absolute ethanol were added to a nylon ball mill tank at a mass ratio of 1:4:1.5 and mixed with a planetary ball mill for 6 hours; after mixed grinding, dried at 120°C for 6 hours to obtain a mixture;

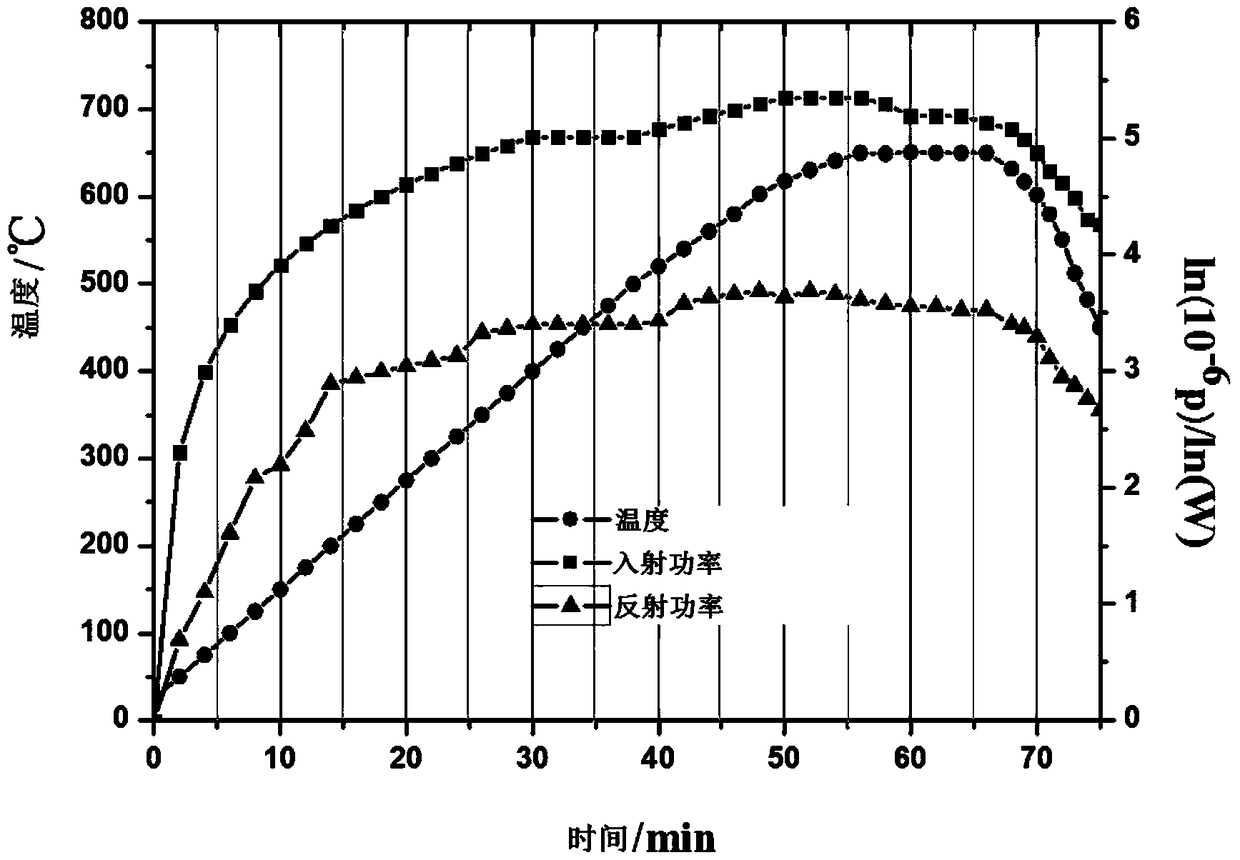

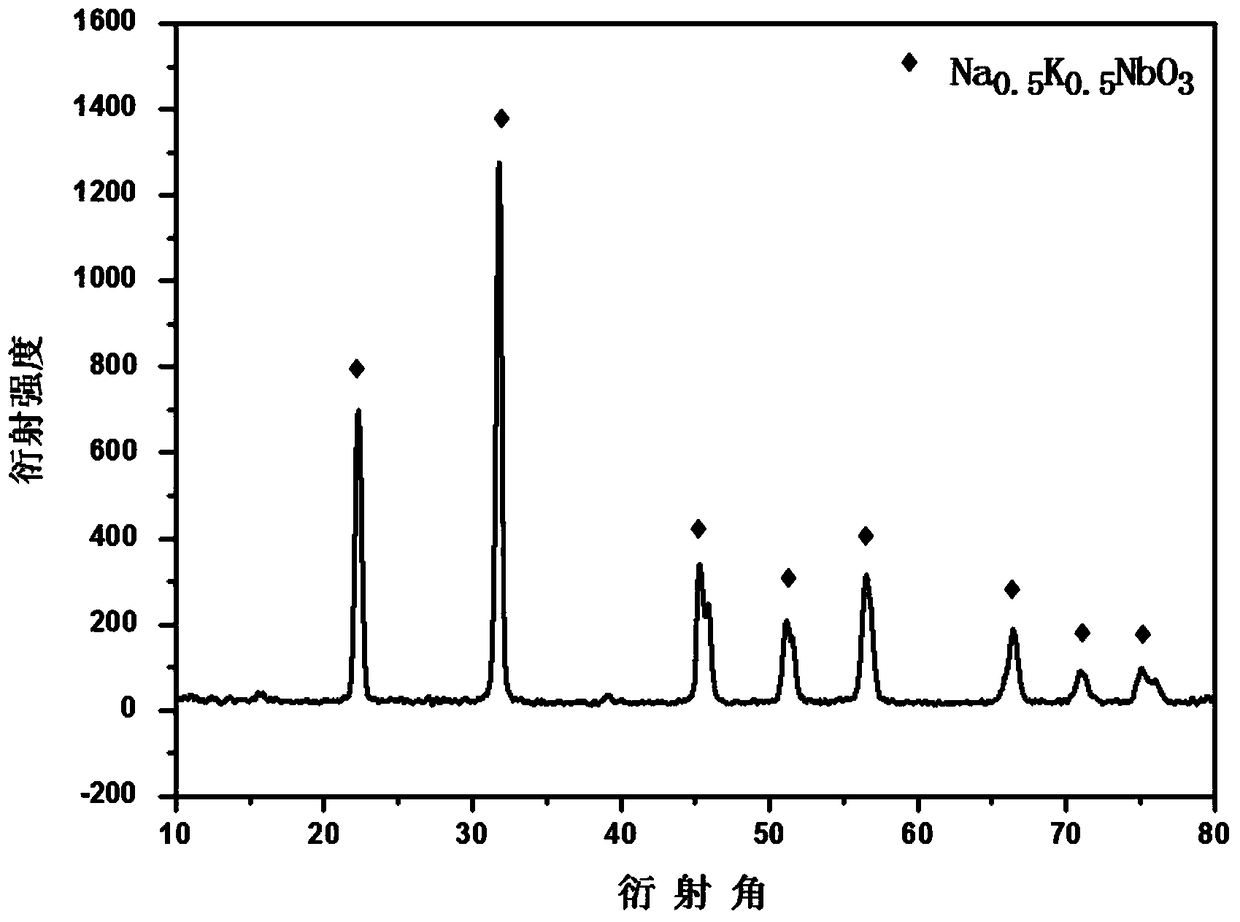

[0031] 2) Microwave synthesis: Put the heat preservation device containing the mixture into the microwave resonator cavity, turn on the microwave source, adjust the input power of the microwave, so that the mixture is heated at a rate of 10°C / min until the reflected power is stable; Raise the temperature to 650°C at a rate of 1 min, monitor the reflected power at the same time, adjust the input power, keep it warm for 10 minutes, and cool it down to room temperature naturally to obtain th...

Embodiment 2

[0033] A microwave synthesis method of potassium sodium niobate lead-free piezoelectric ceramic powder, the following steps are adopted:

[0034] 1) Press (K 0.5 Na 0.5 )NbO 3 The stoichiometric ratio of raw material K 2 CO 3 、Na 2 CO 3 and Nb 2 o 5 ; The raw material, ZrO 2 Balls and absolute ethanol were added to a nylon ball mill tank at a mass ratio of 1:4:1.5 and mixed with a planetary ball mill for 6 hours; after mixed grinding, dried at 120°C for 6 hours to obtain a mixture;

[0035]2) Microwave synthesis: Put the heat preservation device containing the mixture into the microwave resonator cavity, turn on the microwave source, adjust the input power of the microwave, so that the mixture is first heated at a rate of 15°C / min until the reflected power is stable; then at 5°C / min Raise the temperature to 700°C at a rate of 1 min, monitor the reflected power at the same time, adjust the input power, keep it warm for 20 min, and cool it down to room temperature natur...

Embodiment 3

[0037] A microwave synthesis method of potassium sodium niobate lead-free piezoelectric ceramic powder, the following steps are adopted:

[0038] 1) Press (K 0.5 Na 0.5 )NbO 3 The stoichiometric ratio of raw material K 2 CO 3 、Na 2 CO 3 and Nb 2 o 5 ; The raw material, ZrO 2 Balls and absolute ethanol were added to a nylon ball mill tank at a mass ratio of 1:4:1.5 and mixed with a planetary ball mill for 6 hours; after mixed grinding, dried at 120°C for 6 hours to obtain a mixture;

[0039] 2) Microwave synthesis: Put the heat preservation device containing the mixture into the microwave resonator cavity, turn on the microwave source, adjust the input power of the microwave, so that the mixture is first heated at a rate of 12°C / min until the reflected power is stable; then at 8°C / min Raise the temperature to 800°C at a rate of 1 minute, monitor the reflected power at the same time, adjust the input power, keep it warm for 15 minutes, and cool it down to room temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| piezoelectric charge coefficient | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com