Method for synthesizing ceramic scintillator powder Gd2O2S:Pr

A synthesis method and scintillator technology, applied in chemical instruments and methods, luminescent materials, etc., can solve problems such as uneven particle size distribution, decreased luminescent performance, particle crystal shape damage, etc., to achieve improved structure and performance, fast heating speed, The effect of short heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Weigh 1.813g (0.005mol) Gd 2 o 3 , 0.530g (0.005mol) Na 2 CO 3 and 0.480g (0.015mol) S, the molar ratio of the three is 1:1:3, and the number of moles added is Gd 2 o 3 1% (0.051g) of Pr 6 o 11 As an activator; fully grind and mix the above raw materials in a mortar, put them into a small corundum crucible, compact and cover them, put them into a large crucible, and fill the gap between the two crucibles with carbon particles as a microwave absorber; put the crucible In a microwave oven, the frequency is 2.45 GHz, the power is adjusted to a low level, and the time is 20 minutes. After cooling, the synthesized product is taken out.

Embodiment 2

[0018] Weigh 3.626g (0.010mol) Gd 2 o 3 , 1.060g (0.010mol) Na 2 CO 3 and 0.640g (0.020mol) S, the molar ratio of the three is 1:1:2, and the number of moles added is Gd 2 o 3 The amount of 2% (0.204g) of Pr 6 o 11 As an activator; fully grind and mix the above raw materials in a mortar, put them into a small corundum crucible, compact and cover them, put them into a large crucible, and fill the gap between the two crucibles with carbon particles as a microwave absorber; put the crucible In a microwave oven, the frequency is 2.45 GHz, the power is adjusted to mid-range, and the time is 30 minutes. After cooling, the synthesized product is taken out.

Embodiment 3

[0020] Weigh 5.439g (0.015mol) Gd 2 o 3 , 1.590g (0.015mol) Na 2 CO 3 and 0.480g (0.015mol) S, the molar ratio of the three is 1:1:1, and the number of moles added is Gd 2 o 3 The amount of 3% (0.460g) of Pr 6 o 11 As an activator; fully grind and mix the above raw materials in a mortar, put them into a small corundum crucible, compact and cover them, put them into a large crucible, and fill the gap between the two crucibles with carbon particles as a microwave absorber; put the crucible In a microwave oven, the frequency is 2.45 GHz, the power is adjusted to a medium-to-high range, and the time is 40 minutes. After cooling, the synthesized product is taken out.

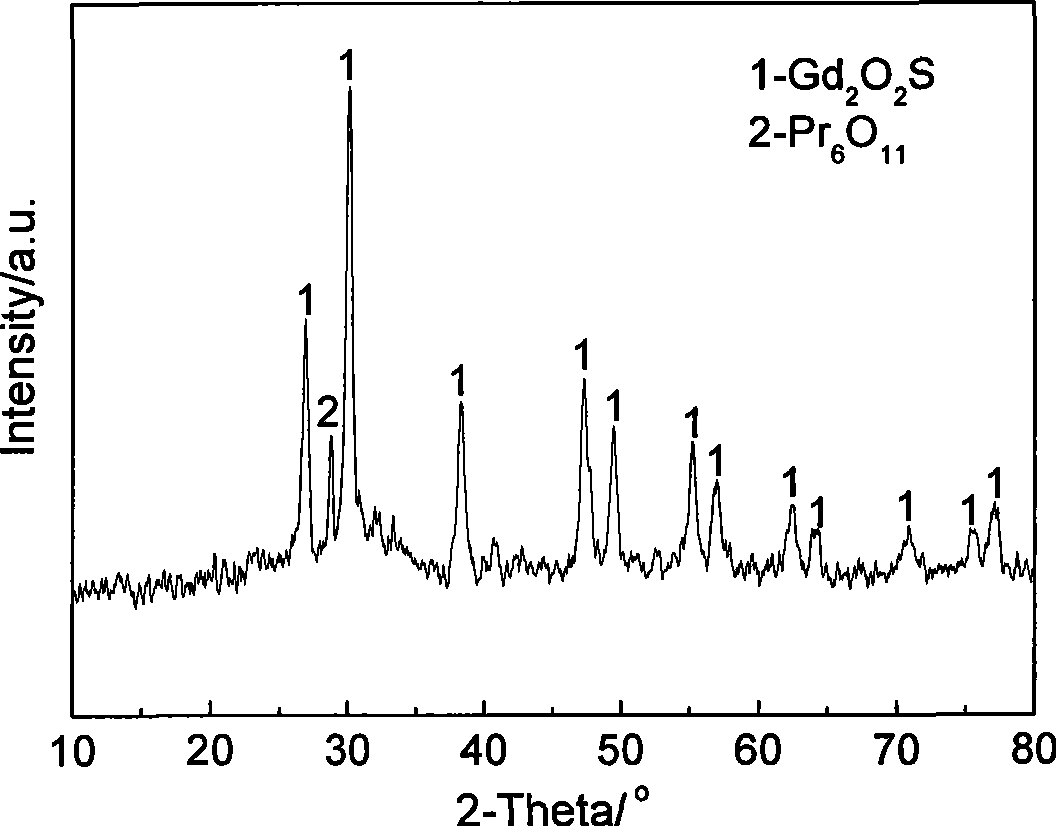

[0021] figure 1 It is the ceramic scintillator powder Gd synthesized in Example 1 2 o 2 XRD spectrum of S:Pr. from figure 1 It can be seen that the resulting Gd 2 o 2 S: Pr powder is polycrystalline.

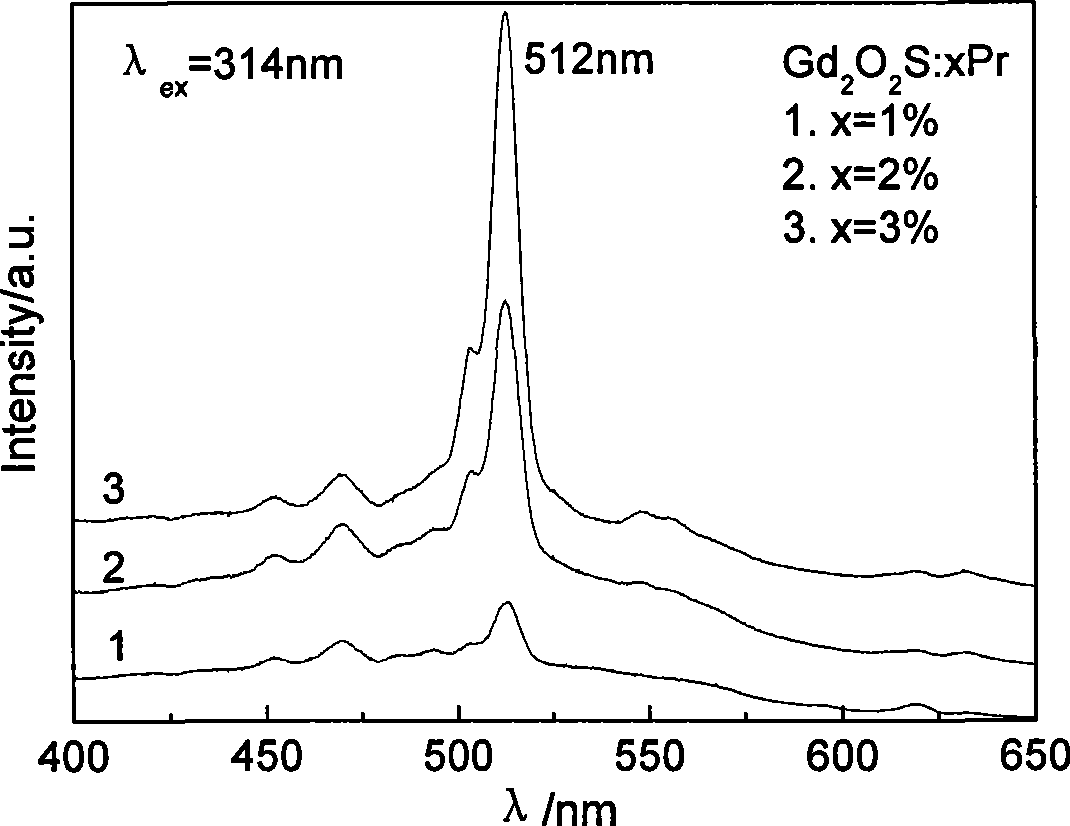

[0022] figure 2 It is the Gd synthesized in Examples 1, 2, and 3 2 o 2 S: Emission spectra of Pr p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com