Preparation method for film printing coating

A coating and film technology, which is applied in the field of film printing coating preparation, can solve the problems of poor image and text adhesion, unsatisfactory printing clarity, etc., and achieves easy paper jams, good image color reproduction, and simple coating process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

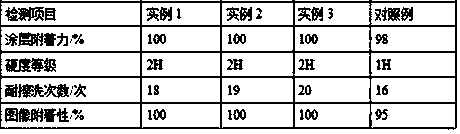

Examples

example 1

[0024] Seal the gas-phase explosion tube and evacuate it to 100Pa, then inject 420g of silicon tetrachloride into the explosion tube, and preheat it to 120°C, then introduce 19.2g of hydrogen and 76.8g of oxygen in sequence, and detonate it with a detonator after standing for 5 minutes. Stand still for 1 hour after the explosion, open the valve to discharge the gas and open the explosion tube to collect the explosion products in the tube, wash the explosion products twice with deionized water, put them in a drying oven, and dry them at 105°C to constant weight to obtain spherical carbon dioxide Silicon, take 2.4g aluminum chloride, 50g absolute ethanol, 10g mass fraction of 37% hydrochloric acid solution, add 500mL deionized water, stir at 100r / min for 20min, add 72g spherical silica, stir at 4000r / min for 40min, then Add 7.2g of silane coupling agent, 100g of 5% hydrochloric acid solution by mass fraction, continue to stir for 40min, stand and age for 1 day to obtain a dispers...

example 2

[0026] Seal the gas-phase explosion tube and evacuate it to 50Pa, then inject 500g of silicon tetrachloride into the explosion tube, and preheat it to 130°C, then pass in 25g of hydrogen and 80g of oxygen in sequence, let it stand for 8 minutes and detonate it with a detonator, and the explosion is over After standing still for 1 hour, open the air valve to discharge the gas and open the explosion tube to collect the explosion products in the tube, wash the explosion products twice with deionized water, put them in a drying oven, and dry them at 108°C to constant weight to obtain spherical silica. Take 3g of aluminum chloride, 60g of absolute ethanol, and 12g of 37% hydrochloric acid solution in 600mL of deionized water, stir at 150r / min for 25min, then add 90g of spherical silica, stir at 4500r / min for 50min, then add 9g of silane Coupling agent, 150g mass fraction of 5% hydrochloric acid solution, continue to stir for 50min, stand and age for 2 days to obtain a dispersion, st...

example 3

[0028]Seal the gas-phase explosion tube and evacuate it to 10Pa, then inject 600g of silicon tetrachloride into the explosion tube, and preheat it to 150°C, then pass in 28.8g of hydrogen and 115.2g of oxygen in sequence, let it stand for 10min, and detonate it with a detonator. Stand still for 2 hours after the explosion, open the valve to discharge the gas and open the explosion tube to collect the explosion products in the tube, wash the explosion products with deionized water for 3 times, put them in a drying oven, and dry them at 110°C to constant weight to obtain spherical carbon dioxide For silicon, take 3.6g of aluminum chloride, 75g of absolute ethanol, and 15g of 37% hydrochloric acid solution in 750mL of deionized water, stir at 200r / min for 30min, add 108g of spherical silica, stir at 5000r / min for 60min, and then Add 10.8g of silane coupling agent, 200g of 5% hydrochloric acid solution by mass fraction, continue to stir for 60min, stand and age for 2 days to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com