Advanced purification process for secondary effluent from municipal wastewater treatment plant

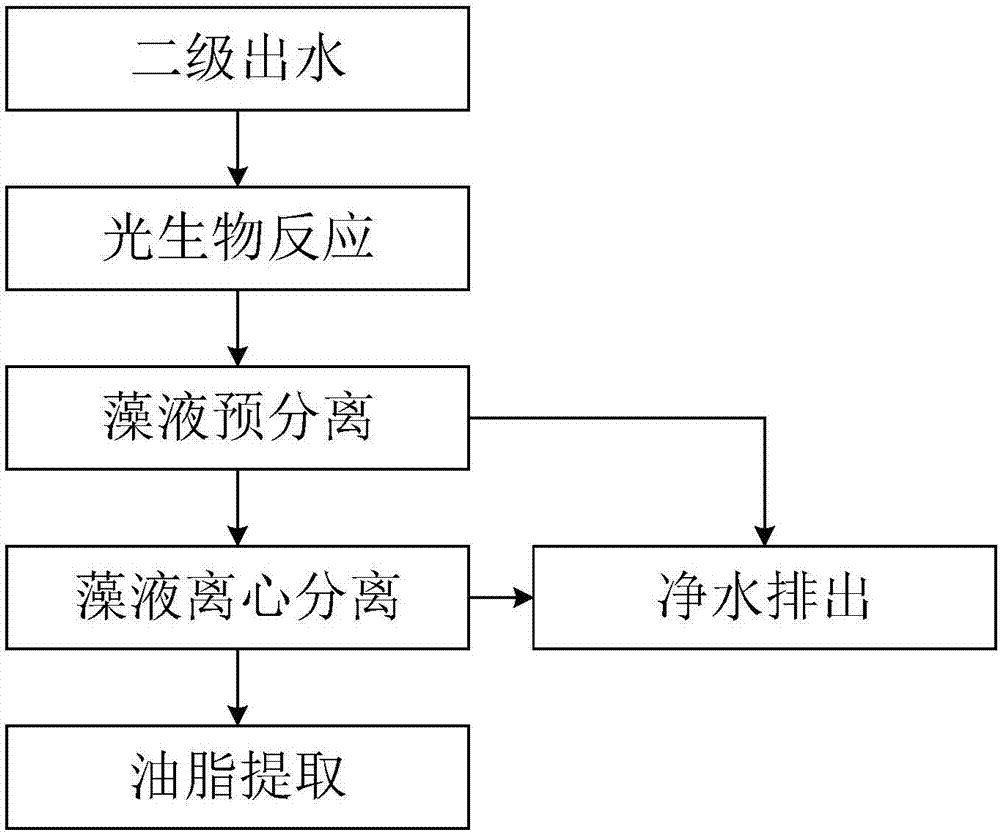

A technology of two-stage water outlet and deep purification, which is applied in biological water/sewage treatment, light water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of high cost, high operating cost, and unreachable, and achieve the realization of The effect of continuous production, short hydraulic retention time and huge economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0026] Except following data change, other processing steps and conditions are with embodiment 1:

[0027] The temperature of the photobioreactor is controlled at 10°C to 20°C, the pH is controlled at 7 to 8, and the aeration rate is controlled at 15% of the sewage volume; The volume ratio of chlorella and activated sludge bacteria in the algae-bacteria symbiont is 9:1, the hydraulic retention time is 1h, and the average daily replacement water sample accounts for 50% of the liquid volume in the tank.

[0028] After the above process, the naturally discharged upper supernatant and centrifugal supernatant are effluent water quality indicators TN: 1.98mg / L, TP: 0.26mg / L, COD cr : 37.22mg / L, ammonia nitrogen: 1.20mg / L. The water quality indicators of the effluent are all lower than the standard limit value of the basic item standard of the environmental quality standard of category V (mainly applicable to agricultural water areas and water areas with general landscape requiremen...

Embodiment 3

[0031] Except following data change, other processing steps and conditions are with embodiment 1:

[0032]The temperature of the photobioreactor is controlled at 20°C to 30°C, the pH is controlled at 7 to 8, and the aeration rate is controlled at 15% of the sewage volume; The volume ratio of chlorella and activated sludge bacteria in the algae-bacteria symbiont is 11:1, the hydraulic retention time is 0.5h, and the average daily replacement water sample accounts for 60% of the liquid volume in the tank.

[0033] After the above process, the water quality indicators of the naturally discharged upper supernatant and centrifugal supernatant are: TN: 1.89mg / L, TP: 0.30mg / L, COD cr : 36.72mg / L, ammonia nitrogen: 1.87mg / L. The water quality indicators of the effluent are all lower than the standard limit of the basic items of the environmental quality standard of the V category (mainly applicable to agricultural water areas and waters with general landscape requirements) in GB3838-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com