Ceramic powder preparation process and system

A ceramic manufacturing and process technology, which is applied in the field of ceramic pulverizing process and its system, can solve the problems such as the large difference in water content between the surface and the core of the mud block, the large size of the drying equipment, and the long drying time, so as to reduce the dry mud block. time, reduce energy consumption, and improve drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

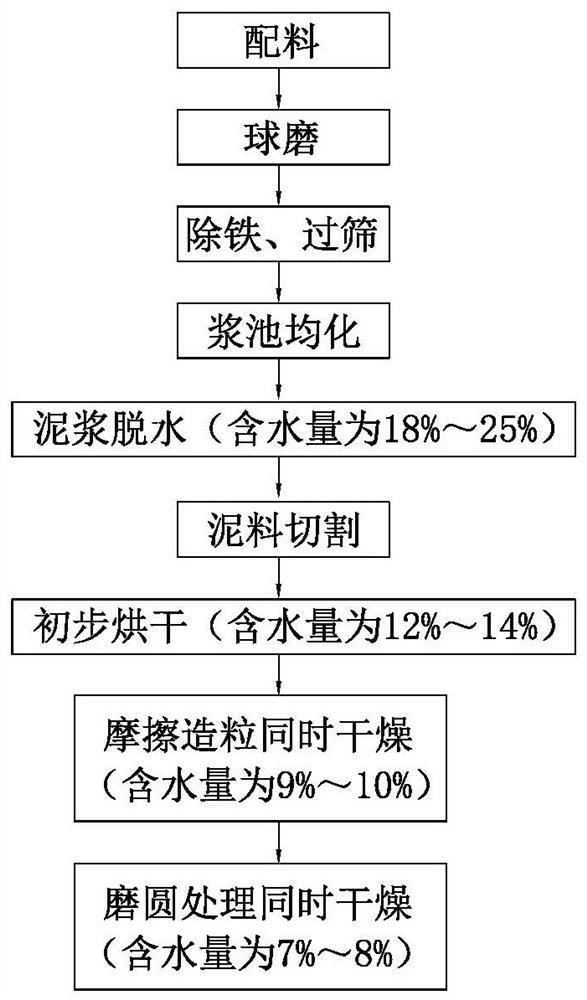

[0043] Such as figure 1 A ceramic powder-making process shown includes the steps of batching, ball milling, sieving, iron removal, and slurry pool homogenization in order to obtain slurry with a water content of 30% to 40%, and then pass through filter presses and other equipment Dehydrate the mud to obtain a blocky mud (filter cake) with a water content of 18% to 25%, and then cut the blocky mud into pieces with a length of about 5cm and a water content of 18% to 25% by high-speed mud cutting equipment Mud.

[0044] The above process can be processed with reference to the existing equipment and technology. No more details are given in this embodiment.

[0045] Technology of the present invention also comprises following step to mud drying treatment:

[0046] Step S1, drying the mud material to obtain mud lumps with a water content of 12% to 14%;

[0047]Step S2, rubbing the mud block layer by layer with more than 2 screens arranged in sequence, the apertures of the screen...

Embodiment 2

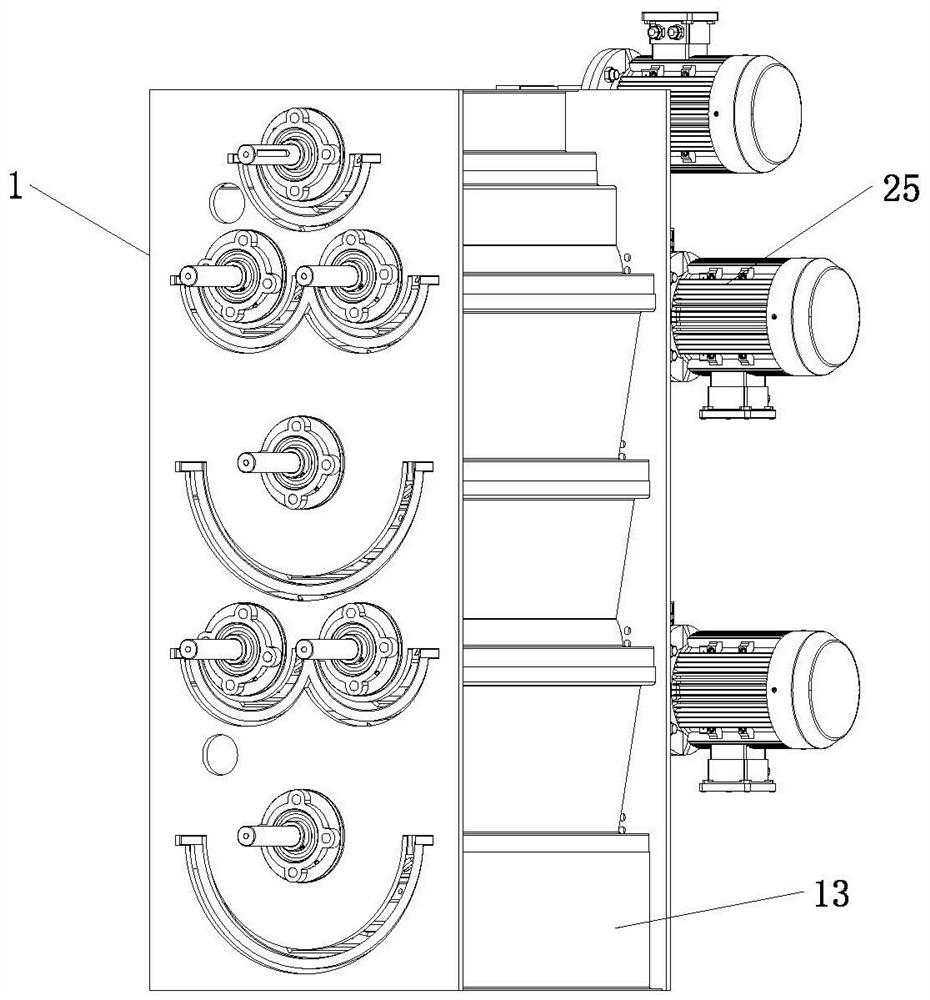

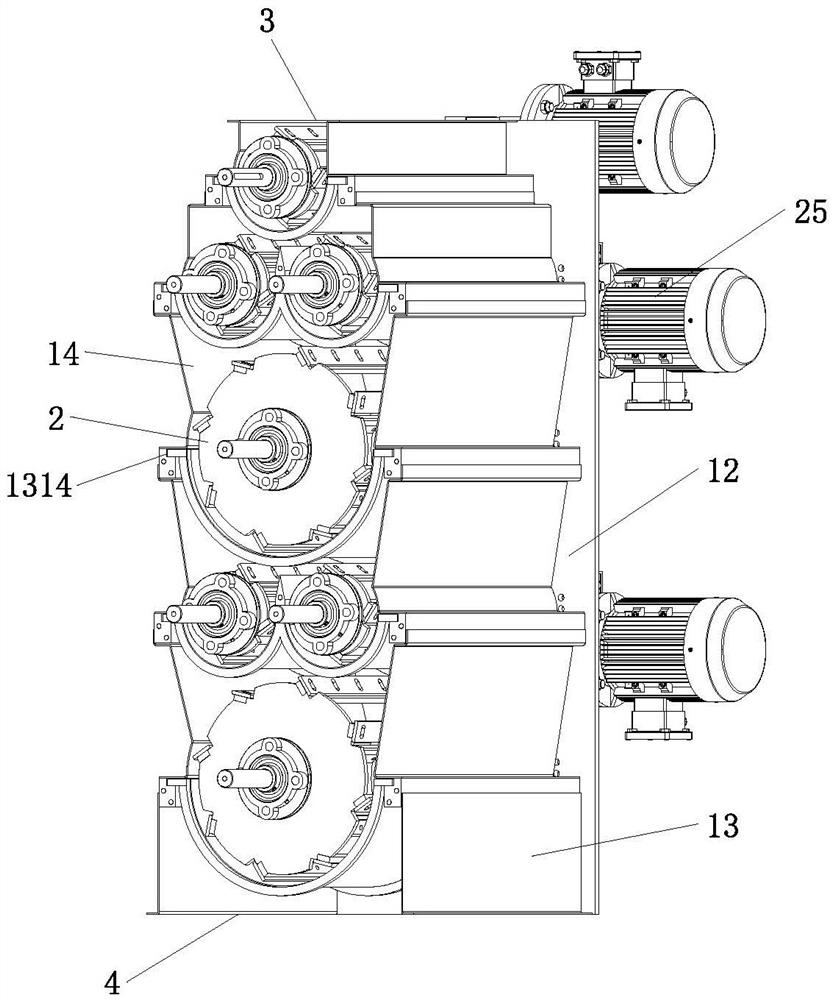

[0083] The present invention also provides a kind of ceramic powder making system that adopts above-mentioned technology simultaneously, as Figure 7 As shown, it includes filter press 10 , mud cutting equipment 20 , ceramic mud drying equipment 30 and ceramic mud multistage granulation equipment 40 connected in sequence. In addition, in order to obtain more rounded powder particles, a rounding device 50 may also be included in the ceramic powder making system. Wherein, filter press 10, mud cutting equipment 20, ceramic mud material drying equipment 30 are existing equipment; Figure 2 ~ Figure 6 . The filter press 10, the mud cutting equipment 20, the ceramic mud drying equipment 30, the ceramic mud multi-stage granulation equipment 40 and the rounding equipment 50 are respectively connected in sequence by a conveyor belt between the discharge port and the feed port. In addition, at the front end of the feeding port of the ceramic mud drying equipment 30 and the ceramic mud...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com