Lithium ion battery pole sheet making method and lithium ion battery pole sheet surface treatment device

A technology for surface treatment devices and lithium-ion batteries, which is applied to battery electrodes, circuits, electrical components, etc., can solve problems such as floating powder, improve cycle life, reduce short-circuit and micro-short-circuit rates of batteries, and improve comprehensive electrochemical performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

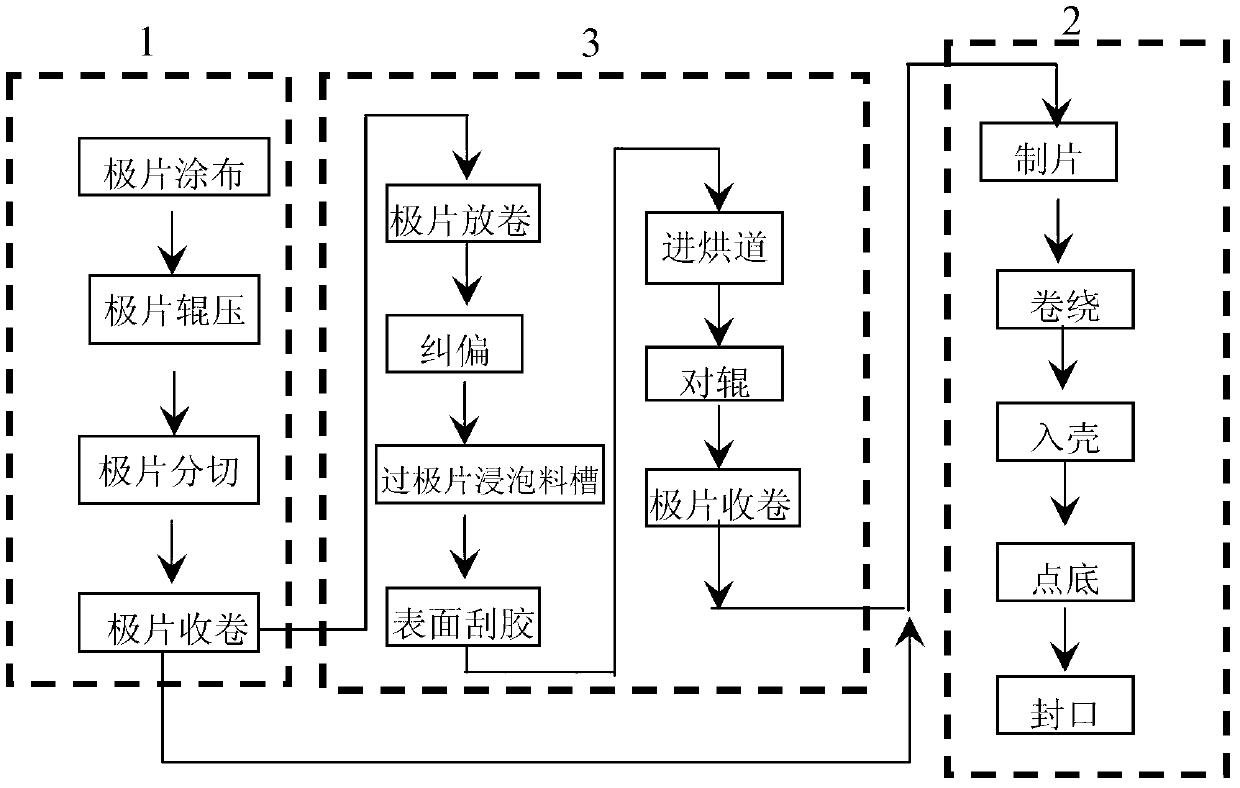

[0037] Such as figure 1 Shown is the process flow of the preparation method of the lithium ion battery pole piece of the present invention, including:

[0038] 1) In frame 1 is the pole piece coating and cutting process, which is followed by pole piece coating, pole piece rolling, pole piece slitting, and pole piece winding;

[0039] 2) In frame 3 is the pole piece surface treatment process, which is followed by pole piece unwinding, deviation correction, pole piece soaking chute, surface squeegee, drying tunnel, pair of rollers, pole piece winding, and the coated and slitting The latter pole piece is immersed in a water-soluble polymer treatment solution and then dried to form a polymer film (ie, polymer film) on the surface of the pole piece, soaked in the pole piece soaking trough, and dried in a drying tunnel;

[0040] The water-soluble polymer treatment solution includes water and water-soluble polymer compounds. The water-soluble polymer compounds are gelatin, carboxymethyl cel...

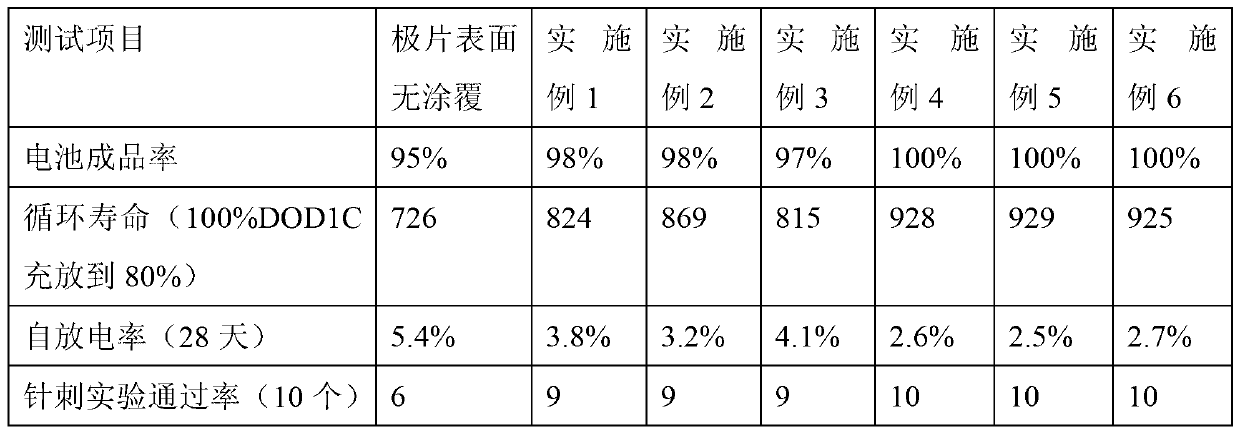

Embodiment 1

[0048] The method for preparing a pole piece of a lithium ion battery in a specific embodiment includes: 1) a pole piece coating and cutting process; 2) a pole piece surface treatment process; 3) a sheet production and packaging process.

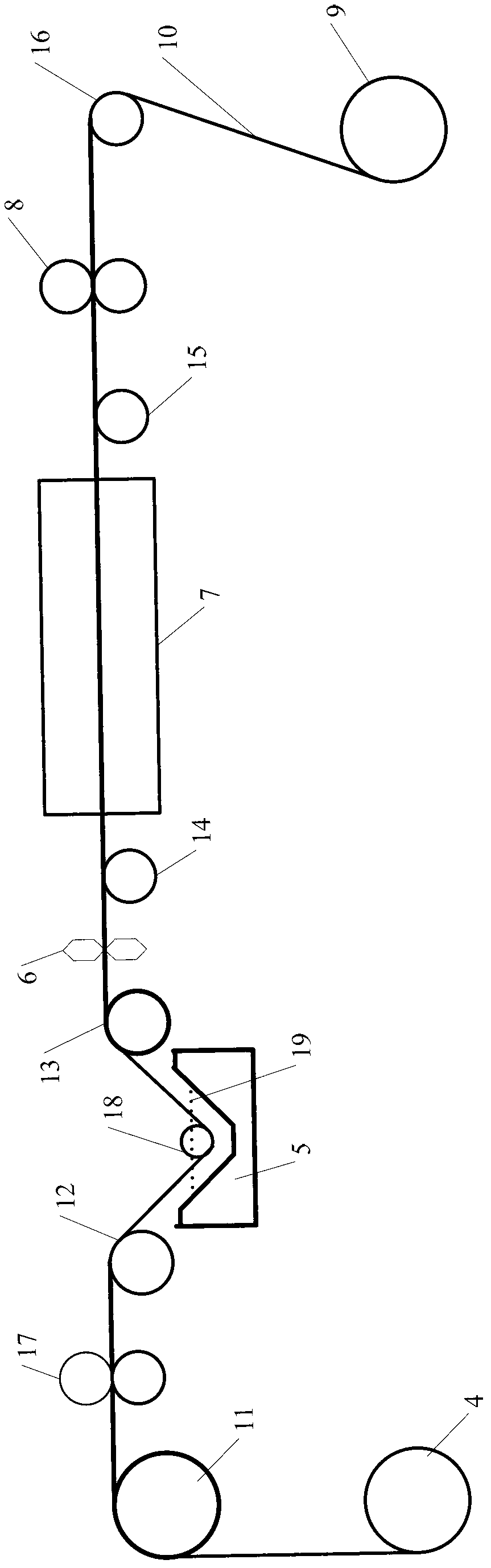

[0049] The pole piece surface treatment procedures are successively pole piece unwinding, correction, soaking, squeegee, drying, rolling, and winding. The surface treatment device of the lithium ion battery pole piece of the present invention in the specific embodiment is used, which depends on the release The reel 4, the correction guide wheel 17, the pole piece soaking trough 5, the doctor blade 6, the drying tunnel 7, the roller counter 8 and the take-up wheel 9 are realized. The pole piece soaking trough 5 contains a water-soluble polymer treatment liquid 19, which is soaked in the pole piece soaking trough 5, and drying is performed in the drying tunnel 7.

[0050] Preparation of water-soluble polymer treatment solution: stir and mix deioniz...

Embodiment 2

[0053] The method for preparing a pole piece of a lithium ion battery in a specific embodiment includes: 1) a pole piece coating and cutting process; 2) a pole piece surface treatment process; 3) a sheet production and packaging process.

[0054] The pole piece surface treatment procedures are successively pole piece unwinding, correction, soaking, squeegee, drying, rolling, and winding. The surface treatment device of the lithium ion battery pole piece of the present invention in the specific embodiment is used, which depends on the release The reel 4, the correction guide wheel 17, the pole piece soaking trough 5, the doctor blade 6, the drying tunnel 7, the roller counter 8 and the take-up wheel 9 are realized. The pole piece soaking trough 5 contains a water-soluble polymer treatment liquid 19, which is soaked in the pole piece soaking trough 5, and drying is performed in the drying tunnel 7.

[0055] Preparation of water-soluble polymer treatment solution: Stir and mix deioniz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com