A method for manufacturing lead-acid storage battery plates that reduces the powder shedding rate on the surface of the plates

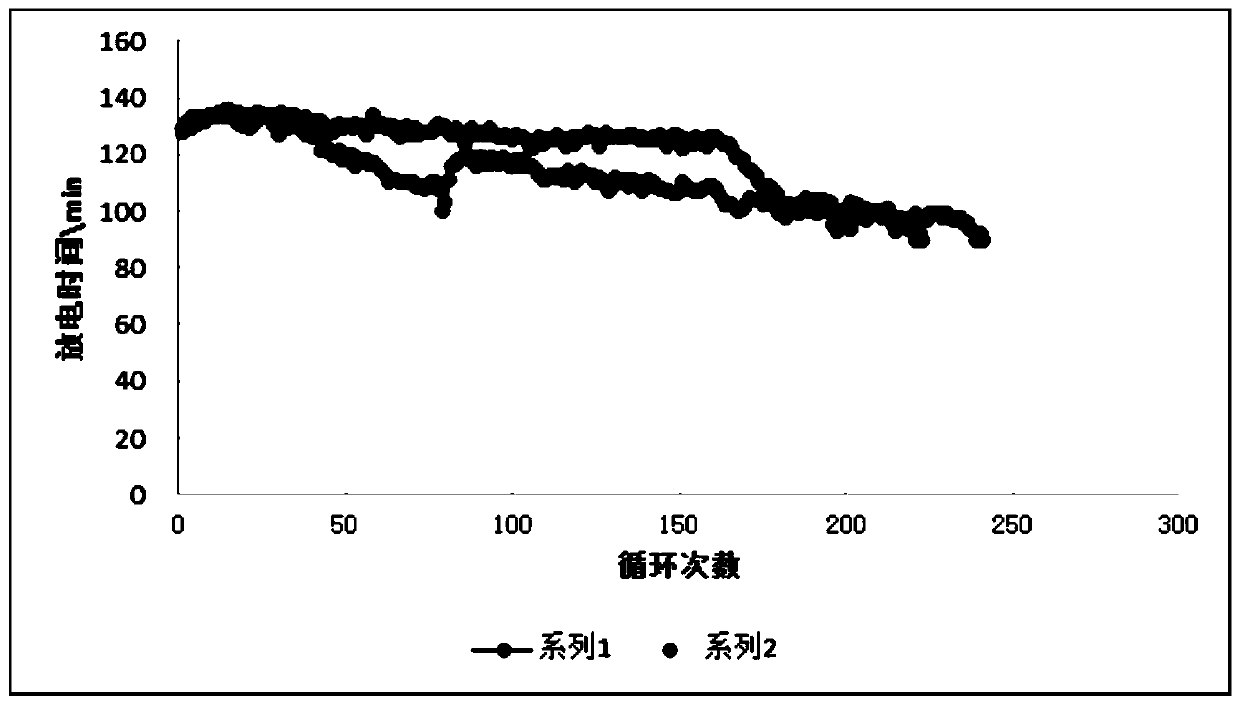

A lead-acid battery and production method technology, applied in the direction of lead-acid battery electrodes, etc., can solve the problems of cycle life attenuation and low battery capacity, and achieve the effects of reducing floating powder, enhancing internal binding force, and solving low battery capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for manufacturing a lead storage battery pole plate for reducing the powder shedding rate on the surface of the pole plate, comprising the following steps:

[0031] 1. Blending process

[0032] After mixing 1000 parts by mass of lead oxide powder and additives in the paste machine, add 5 parts by weight of acrylic resin binder polyethylene glycol diacrylate and stir slowly for a period of time, then add deionized water and sulfuric acid solution, To prepare lead paste, slowly add the prepared sulfuric acid to the above-mentioned wet-mixed positive and negative lead pastes for acid mixing, and the mixing is carried out in four stages:

[0033] A. When the temperature of the lead paste is below 48°C, control the addition rate of sulfuric acid at 0.17%L / s, where the above-mentioned L represents the volume of the sulfuric acid solution,

[0034] B. When the temperature of the lead paste is between 48 and 57°C, adjust the addition rate of sulfuric acid to 70% of th...

Embodiment 2

[0045] 1. Blending process

[0046] After mixing 1000 parts by mass of lead oxide powder and additives in the paste machine, add 15 parts by weight of acrylic resin binder polyethylene glycol diacrylate and slowly stir for a period of time, then add deionized water and sulfuric acid solution, prepared as lead paste

[0047] Slowly add the prepared sulfuric acid into the positive and negative electrode pastes after wet mixing, respectively, for acid mixing, and the mixing is carried out in four stages:

[0048] A. When the temperature of the lead paste is below 48°C, control the addition rate of sulfuric acid at 0.22%L / s, where the above-mentioned L represents the volume of the sulfuric acid solution,

[0049] B. When the temperature of the lead paste is between 48 and 57°C, adjust the addition rate of sulfuric acid to 85% of the original flow rate,

[0050]C. When the temperature of the lead paste is between 57 and 68°C, adjust the addition rate of sulfuric acid to 60% of th...

Embodiment 3

[0060] 1. Blending process

[0061] In the paste machine, 1000 parts by mass of lead oxide powder and additives are mixed evenly, then add 20 parts by weight of acrylic resin binder polyethylene glycol dimethacrylate and stir slowly for a period of time, then add deionized water and sulfuric acid The solution is prepared into a lead paste, and the sulfuric acid of the prepared material is slowly added to the above-mentioned wet-mixed positive and negative lead pastes for acid mixing, and the mixing is carried out in four stages:

[0062] A. When the temperature of the lead paste is below 48°C, control the addition rate of sulfuric acid at 0.2%L / s, where the above-mentioned L represents the volume of the sulfuric acid solution,

[0063] B. When the temperature of the lead paste is between 48 and 57°C, adjust the addition rate of sulfuric acid to 80% of the original flow rate,

[0064] C. When the temperature of the lead paste is between 57 and 68°C, adjust the addition rate of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com