A kind of preparation method of lead-acid storage battery raw electrode plate reducing floating powder

A technology for lead-acid batteries and raw plates, which is applied in the direction of lead-acid battery electrodes and electrode manufacturing, and can solve the problems of increasing equipment, increasing waste acid containing lead, and consuming energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Use the following raw materials to prepare 1.13g / cm 3 Acid solution: 20 parts of sulfuric acid, 2 parts of fumed silica, 0.6 parts of sodium lauryl sulfate, and 77.4 parts of water.

[0019] Described leaching acid solution preparation method, comprises the steps:

[0020] (1) First take parts by weight of sulfuric acid and add it to water, and stir while adding, until the temperature of the sulfuric acid solution is lower than 35°C;

[0021] (2) Add parts by weight of fumed silica and sodium lauryl sulfate in sequence to the sulfuric acid solution, and stir for 25-40 minutes to obtain a density of 1.13 g / cm 3 The acid solution, the temperature of the acid solution is controlled at 5-35°C.

[0022] The paste uses lead powder with a lead oxide content of 76%, and the apparent density of the paste is 4.35g / cm 3 , use 1.13g / cm2 in paste 3 Carry out acid-leaching and rolling treatment, dry in a surface drying kiln at 170°C for 15 seconds, and enter the curing drying roo...

Embodiment 2

[0024] Use the following raw materials to prepare 1.11g / cm 3 Acid solution: 16 parts of sulfuric acid, 4 parts of fumed silica, 0.6 parts of sodium lauryl sulfate, 79.4 parts of water. The paste uses lead powder with a lead oxide content of 78%, and the apparent density of the paste is 4.50g / cm 3 , 1.11g / cm2 is used for the raw plate in the paste 3 Carry out acid-leaching and rolling treatment, dry in a surface drying kiln at 140°C for 15 seconds, and enter the curing drying room within 10 minutes. The curing temperature is 70°C and the humidity is 95%. All the other are as embodiment 1.

Embodiment 3

[0026] Use the raw materials of the following parts by weight to prepare 1.08g / cm 3 Acid solution: 13 parts of sulfuric acid, 4 parts of fumed silica, 0.8 parts of sodium lauryl sulfate, and 82.2 parts of water. The paste uses lead powder with a lead oxide content of 80%, and the apparent density of the lead paste is 4.60g / cm 3 , 1.08g / cm2 is used for the raw plate in the paste 3 Carry out acid-leaching and rolling treatment, pass through a surface drying kiln at 120°C for 15 seconds, and enter the curing drying room within 10 minutes. The curing temperature is 78°C and the humidity is 95%.

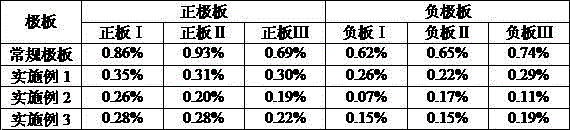

[0027] According to conventional dilute sulfuric acid immersion acid rolling and embodiment 1 to 3 to prepare green plates, use 4-EVF-150 battery plates to test, each group includes three positive plates and three negative plates respectively, the positive and negative The polar plates were horizontally free-falled from a height of 1m on a flat concrete floor, and the loss ratio of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com