Solid beverage with skin whitening function, and preparation method thereof

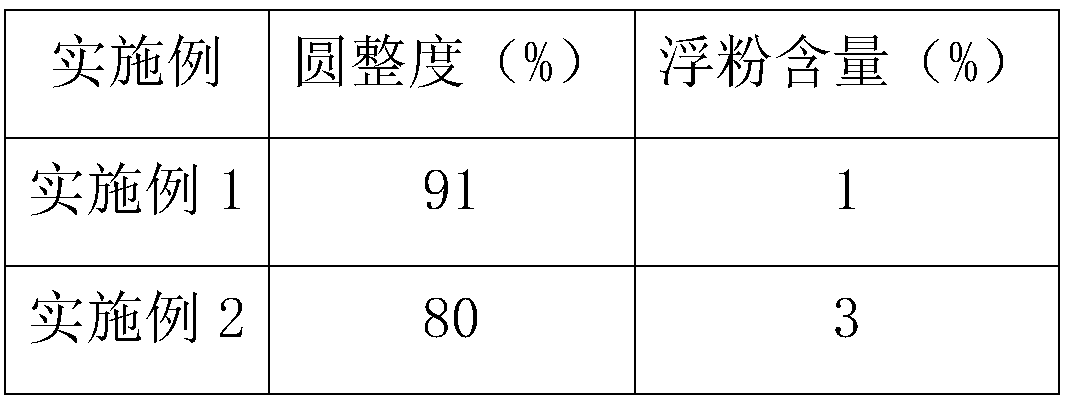

A technology of solid beverage and skin, which is applied in the field of solid beverage with white skin function and its preparation, which can solve the problems of irregular beverage particles, poor roundness, and easy crushing, and achieve less floating powder, high roundness, and increased The effect of viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

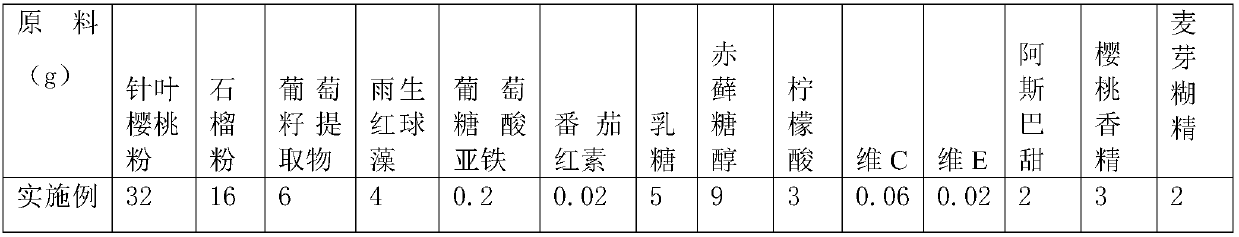

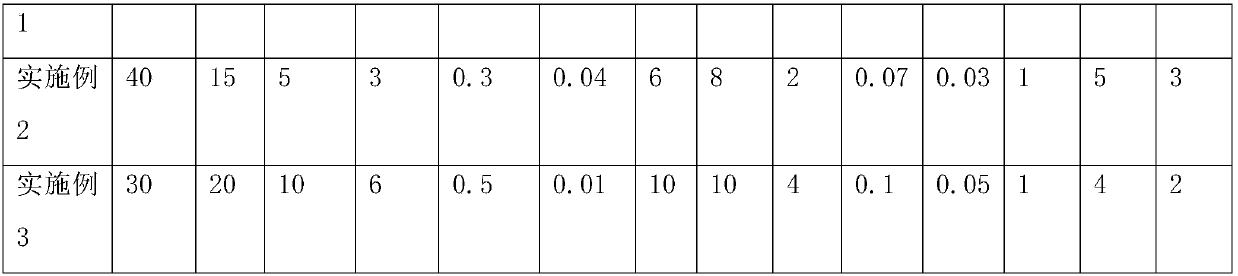

[0029] Embodiment 1: solid beverage preparation one:

[0030] Mixing: Weigh raw materials according to the weight of Example 1 in Table 1, mix Haematococcus pluvialis, ferrous gluconate, lycopene, lactose, citric acid, vitamin C, vitamin E, aspartame, cherry essence, Mix maltodextrin evenly, then put it into the mixture of acerola cherry powder, pomegranate powder, grape seed extract, and erythritol, and stir evenly. Mix a small amount of raw materials and then put them into the remaining large amount of raw materials, so that the raw materials can be fully mixed together.

[0031] High-pressure homogenization: Prepare the mixed raw materials into a suspension with a solid content of 80%, divide it into 3 parts, put the first part into the high-pressure homogenization machine, take 20 minutes as a cycle T, and use it in 0-4 / 20 cycles 15MPa pressure for high-pressure milk uniformity, 25Mpa pressure for high-pressure milk homogenization in the 4 / 20-8 / 20 cycle, 35MPa pressure fo...

Embodiment 2

[0037] Embodiment 2: solid beverage preparation two:

[0038] Mixing: Weigh the raw materials according to the weight of Example 2 in Table 1, and mix grape seed extract, Haematococcus pluvialis, ferrous gluconate, lycopene, citric acid, vitamin C, vitamin E, aspartame, Mix the cherry essence and maltodextrin evenly, then put them into the mixture of acerola cherry powder, pomegranate powder, lactose and erythritol, and stir evenly.

[0039]High-pressure homogenization: Prepare the mixed raw materials into a suspension with a solid content of 75%, put it into a high-pressure homogenization machine, take 20 minutes as a cycle T, and go through four cycles T of high-pressure homogenization, and follow the steps in each cycle T Parameter setting: 0-4 / 20T adopts a pressure of 15MPa for high-pressure creaming, 4 / 20-8 / 20T uses a pressure of 25Mpa for high-pressure milking, and 8 / 20-12 / 20T uses a pressure of 35MPa for high-pressure milking Milk homogenization, 12 / 20-15 / 20T uses 20MP...

Embodiment 3

[0042] Embodiment 3: solid beverage preparation three:

[0043] Mixing: Weigh the raw materials according to the weight of Example 3 in Table 1, mix ferrous gluconate, lycopene, citric acid, vitamin C, vitamin E, aspartame, cherry essence, and maltodextrin evenly, and then put in In the mixture of acerola cherry powder, pomegranate powder, grape seed extract, Haematococcus pluvialis, lactose, and erythritol, stir well.

[0044] Dry granulation: Put the uniformly stirred raw materials into the hopper of the dry granulator, and send them into the room between the two rollers through the feeding system. The pressure between the two rollers is 10.5MPa, and the speed is 15Hz. The granulation system is crushed into granules, and passed through a sieve with a sieve aperture of 0.8 mm to obtain a solid beverage.

[0045] During the whole preparation process, keep the ambient humidity at about 30%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com