Preparing method of water system capacitor battery positive electrode

A technology for capacitor batteries and positive plates, which is applied to the field of preparation of positive plates of water-based capacitor batteries, can solve the problems of uneven dispersion of water-based mixed emulsions, difficulty in meeting power quality requirements, serious production dust, etc., and can meet the requirements of ultra-long life and Ultra-high power input and output requirements, the effect of improving the operating environment of employees and improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

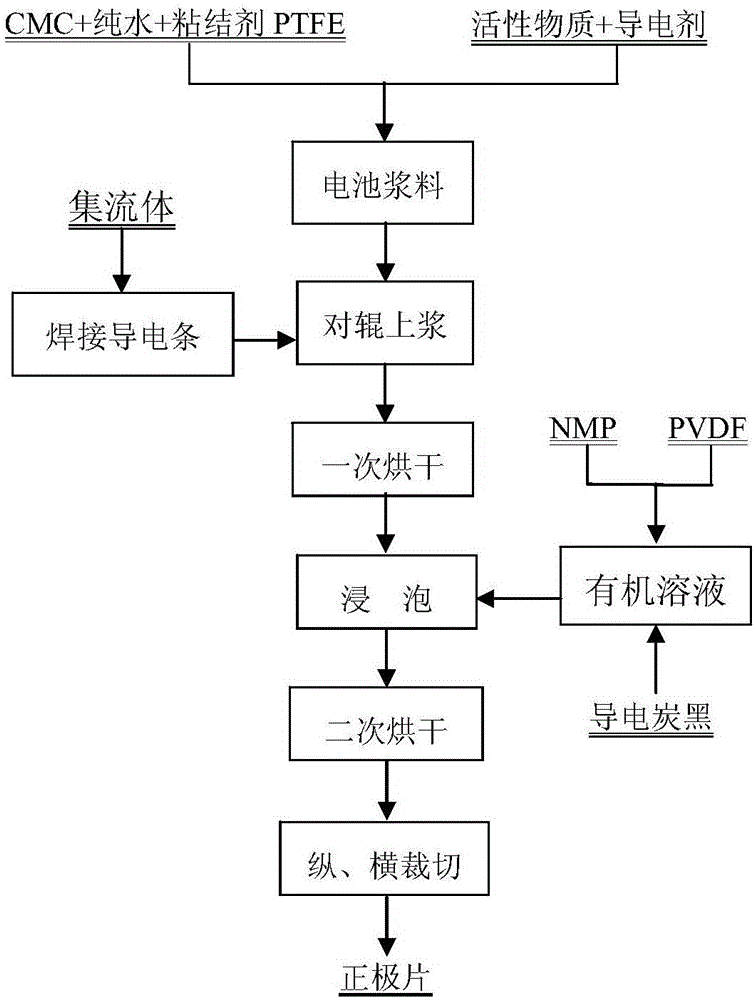

[0030] A kind of preparation method of water-system capacitance battery positive plate, such as figure 1 As shown, specifically:

[0031] a. Use CMC, conductive agent, binder PTFE, active material and pure water to prepare battery slurry, and use NMP, conductive carbon black and PVDF to prepare organic solution;

[0032] Preparation of battery slurry: Add battery-grade CMC and binder PTFE into pure water, wherein the content of CMC is 2% of the total mass of battery slurry, and the content of binder PTFE is 1% of the total mass of battery slurry %. Stir at normal pressure for 3 hours, and then leave it statically at room temperature for 12 hours to become CMC glue. Spherical nickel hydroxide and conductive agent are uniformly mixed through a rotary mixer, wherein the content of spherical nickel hydroxide is 65% of the total mass of the battery slurry, and the content of conductive agent composed of nickel powder and cobalt oxyhydroxide is the mass of active material spherica...

Embodiment 2

[0037] A kind of preparation method of water-system capacitance battery positive plate, such as figure 1 As shown, specifically:

[0038] a. Use CMC, conductive agent, binder PTFE, active material and pure water to prepare battery slurry, and use NMP, conductive carbon black and PVDF to prepare organic solution;

[0039] Preparation of battery slurry: Add battery-grade CMC and binder PTFE into pure water, wherein the CMC content is 5.5% of the total mass of the slurry, and the binder PTFE content is 3.2% of the total mass of the slurry. Stir at normal pressure for 6 hours, then leave it statically at room temperature for 24 hours to become CMC glue. The zinc-doped spherical nickel hydroxide and the conductive agent are uniformly mixed through a rotary mixer, wherein the content of the zinc-doped spherical nickel hydroxide is 65% of the total mass of the slurry, and the content of the conductive agent composed of nickel powder and cobalt oxyhydroxide is the active substance do...

Embodiment 3

[0044] A kind of preparation method of water-system capacitance battery positive plate, such as figure 1 As shown, specifically:

[0045] a. Use CMC, conductive agent, binder PTFE, active material and pure water to prepare battery slurry, and use NMP, conductive carbon black and PVDF to prepare organic solution;

[0046] Preparation of battery slurry: Add battery-grade CMC and binder PTFE into pure water, wherein the CMC content is 3.5% of the total mass of the slurry, and the binder PTFE content is 2.5% of the total mass of the slurry. Stir at normal pressure for 5 hours, and then leave it statically at room temperature for 18 hours to become CMC glue. The cobalt-coated zinc-doped spherical nickel hydroxide and the conductive agent are uniformly mixed by a rotary mixer, wherein the content of the cobalt-coated zinc-doped spherical nickel hydroxide is 76% of the total mass of the slurry, and the content of the conductive agent composed of nickel powder and cobalt oxyhydroxide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com