A kind of rapid solidification and drying process of negative raw electrode plate

A rapid curing and raw plate technology, applied in the direction of lead-acid battery electrodes, etc., can solve the problems of long cycle, high process production cost, and low efficiency of curing chamber, so as to reduce the amount of floating powder, improve the drop strength, and reduce steam and the effect of electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0088] Specific embodiments of the present invention will be described in detail below.

[0089] A process for rapid solidification and drying of a negative raw electrode plate, comprising the following program steps:

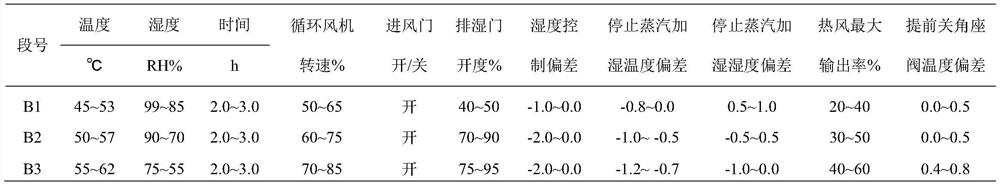

[0090] (1) Curing constant temperature and high humidity maintenance stage, process parameters:

[0091]

[0092] (2) In the stage of curing temperature rise and dehumidification at a constant speed, the parameters of the process program:

[0093]

[0094] (3) In the stage of curing temperature rise and rapid dehumidification, process parameters:

[0095]

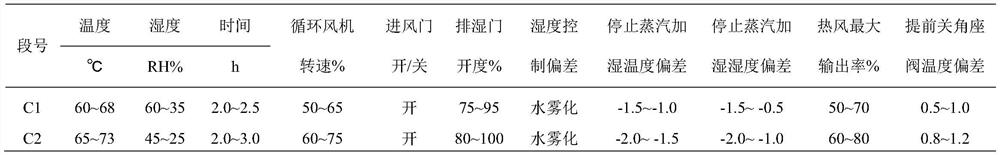

[0096] (4) In the stage of drying, heating and rapid dehumidification, process parameters:

[0097]

[0098] (5) Drying high temperature rapid enhancement stage, process parameters:

[0099]

[0100] (6) Drying and cooling fast and stable stage, process parameters:

[0101]

[0102] Fast curing drying program data comparison table

[0103]

[0104] The above-mentioned embodiments ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com