High-density PCB

A high-density, solder pad technology, which is applied in the direction of electrical connection of printed components, printed circuit components, and assembly of printed circuits with electrical components, can solve the problems of difficult layout of solder pads on printed boards, pin adhesion, and high scrap rate. Reach the effect of reducing sticking rate, improving yield and reducing solder fluid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, the present invention will be further described in detail through specific embodiments in conjunction with the accompanying drawings.

[0027] Such as figure 1 As shown, the three-in-one LED lamp 11 has 4 pins. In the LED display application scenario, a large number of components are arranged on the PCB board 13. The density of the pins 12 of the device is very high. During the processing, Especially when wave soldering is used, solder often sticks between the pins, resulting in a very low yield of product production, and large-scale production cannot be carried out. This is particularly prominent in the production process of LED displays.

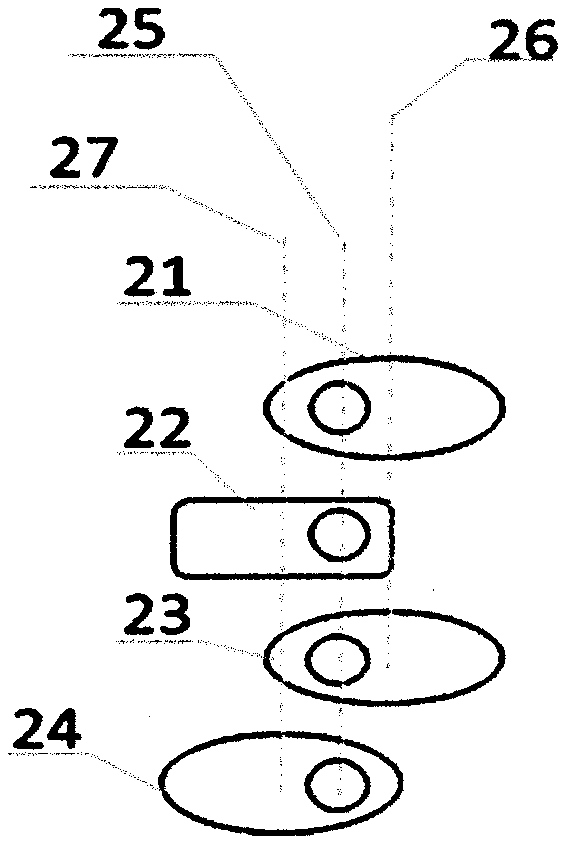

[0028] Such as figure 2 , A specific implementation technical solution of the present invention to solve the technical problem, the center line 26 or 27 of the set pad is not in a straight line with the center 25 of the solder hole, and the centers of adjacent pads are located on both sides of the center line of the solder h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com