Garbage feeding device

A technology for feeding device and garbage, applied in the direction of combustion method, combustion type, incinerator, etc., can solve the problems of arching, complex shape and size, clogging, etc., to prevent clogging or arching and ensure stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

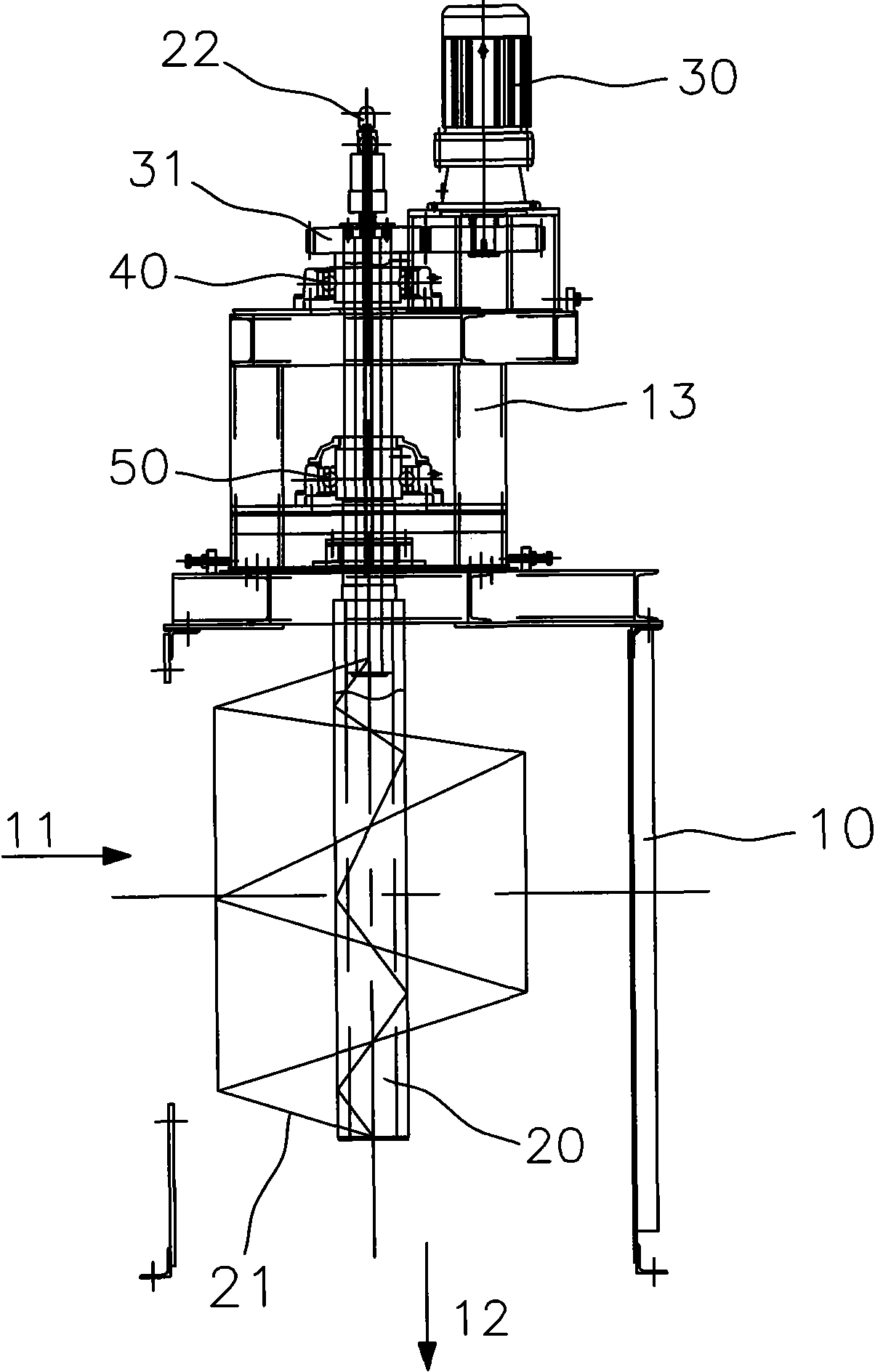

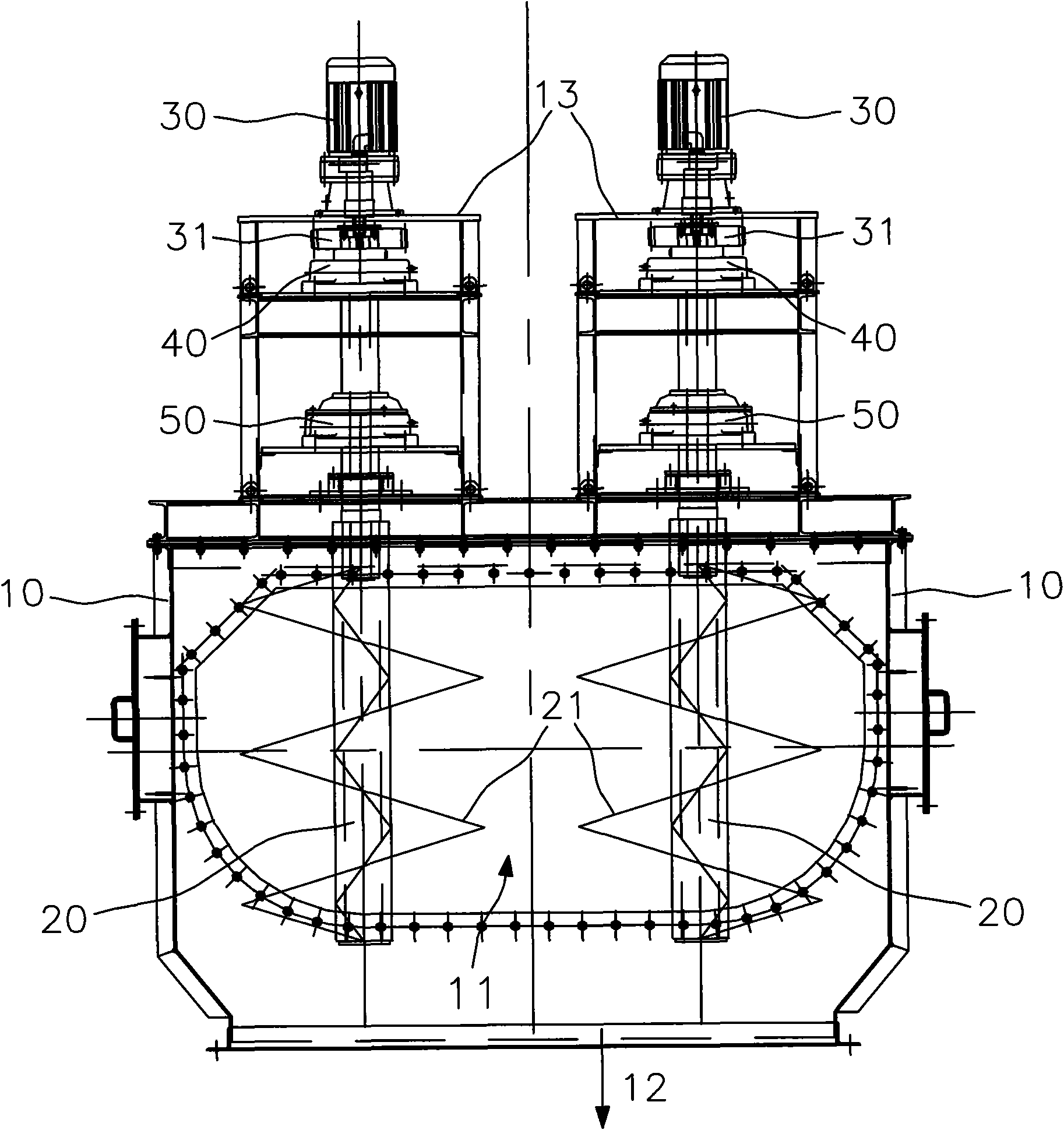

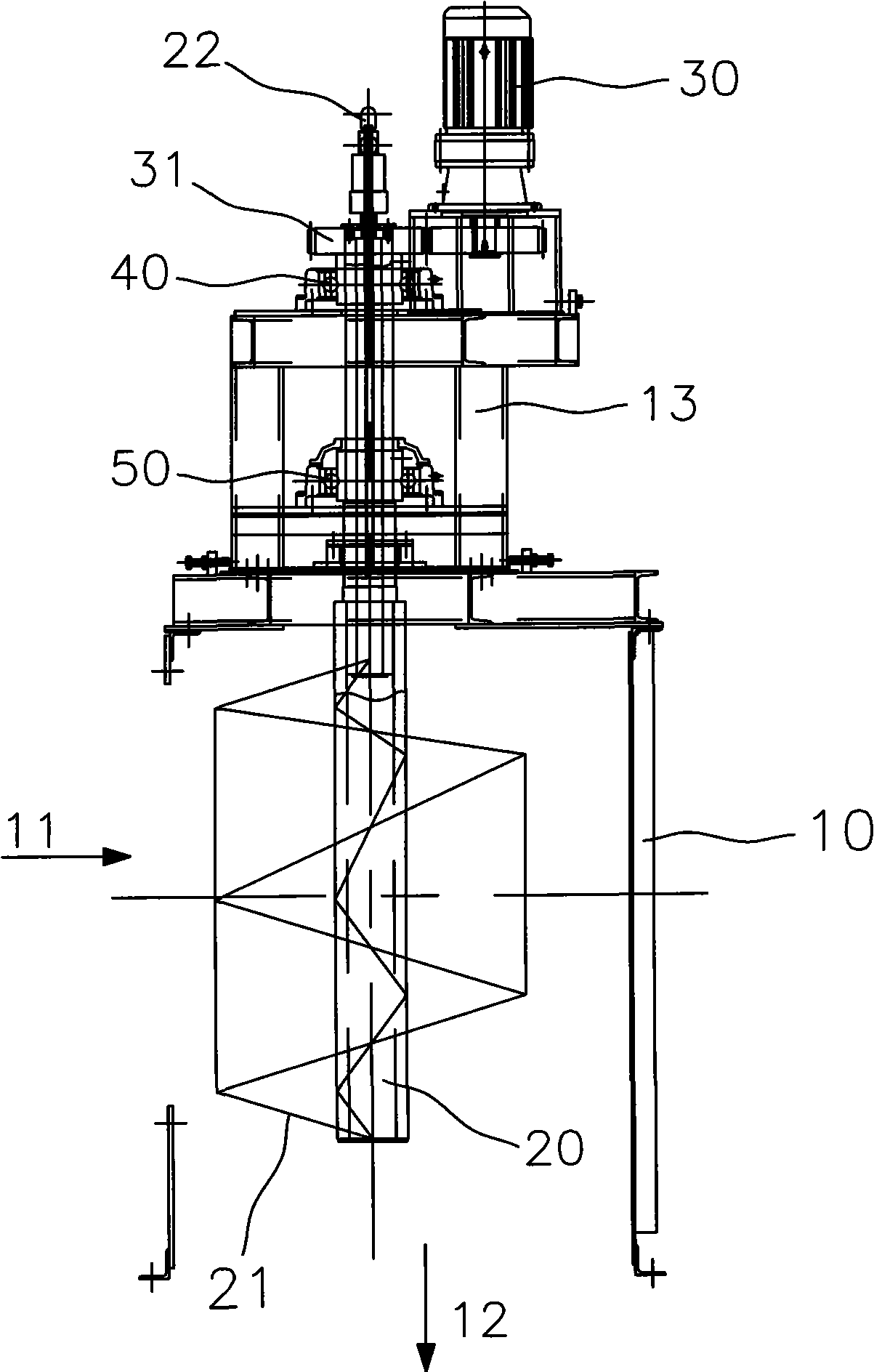

[0008] Such as figure 1 , 2 As shown, a garbage feeding device, the garbage feeding device includes a housing 10 with a cavity inside, the upper part of the outer surface of the housing 10 is provided with a feed port 11, and the lower side of the housing 10 is provided with a discharge Port 12, the cavity of the casing 10 is provided with a garbage crushing and conveying mechanism, and the garbage crushing and conveying mechanism is connected with the power mechanism arranged on the casing 10.

[0009] During actual operation, the housing 10 is fixed on the upper side of the garbage incinerator, and the garbage is input from the feed port 11 on the upper part of the housing. The crushed garbage enters the garbage incinerator for combustion through the discharge port 12 on the lower side of the housing.

[0010] Such as figure 1 , 2 As shown, the power mechanism includes a deceleration motor 30 arranged on the upper side of the housing 10. The deceleration motor 30 drives ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com