Method for improving deformation and permeability in high-thickness standard steel plate hot rolling process

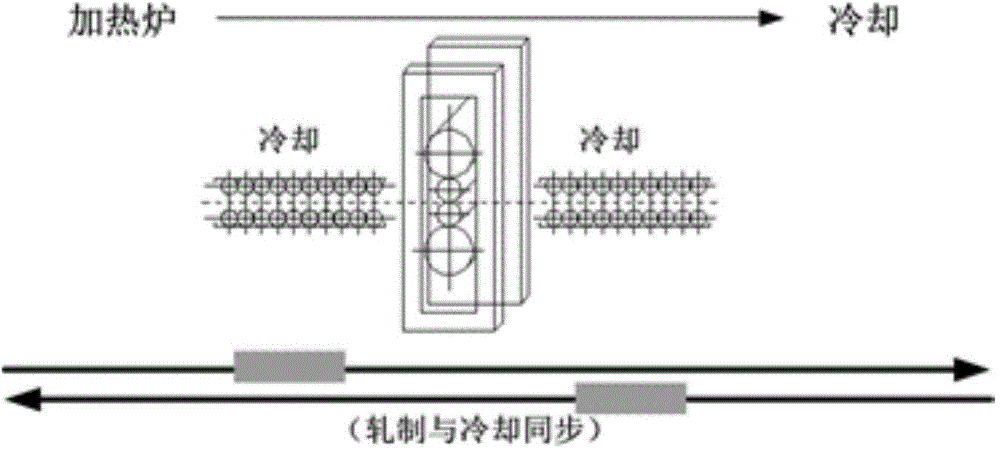

A hot rolling process and permeability technology, applied in metal rolling, metal rolling, metal processing equipment, etc., can solve the problem that the cooling device does not give a corresponding solution, eliminate core defects, control slab warpage The effect of bending and improving the quality of the core

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

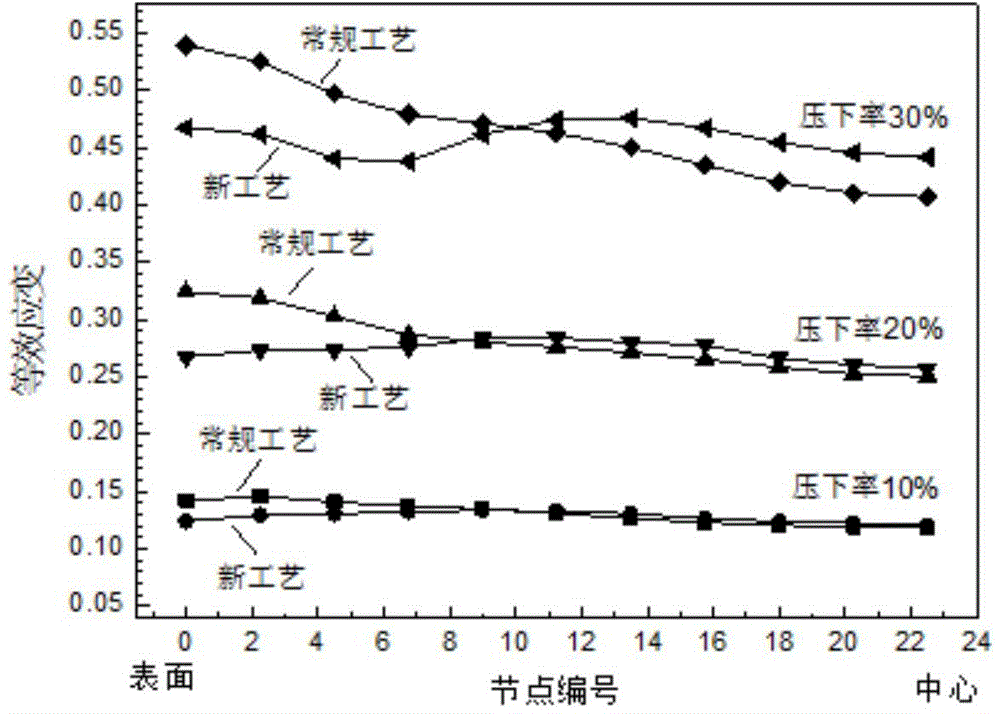

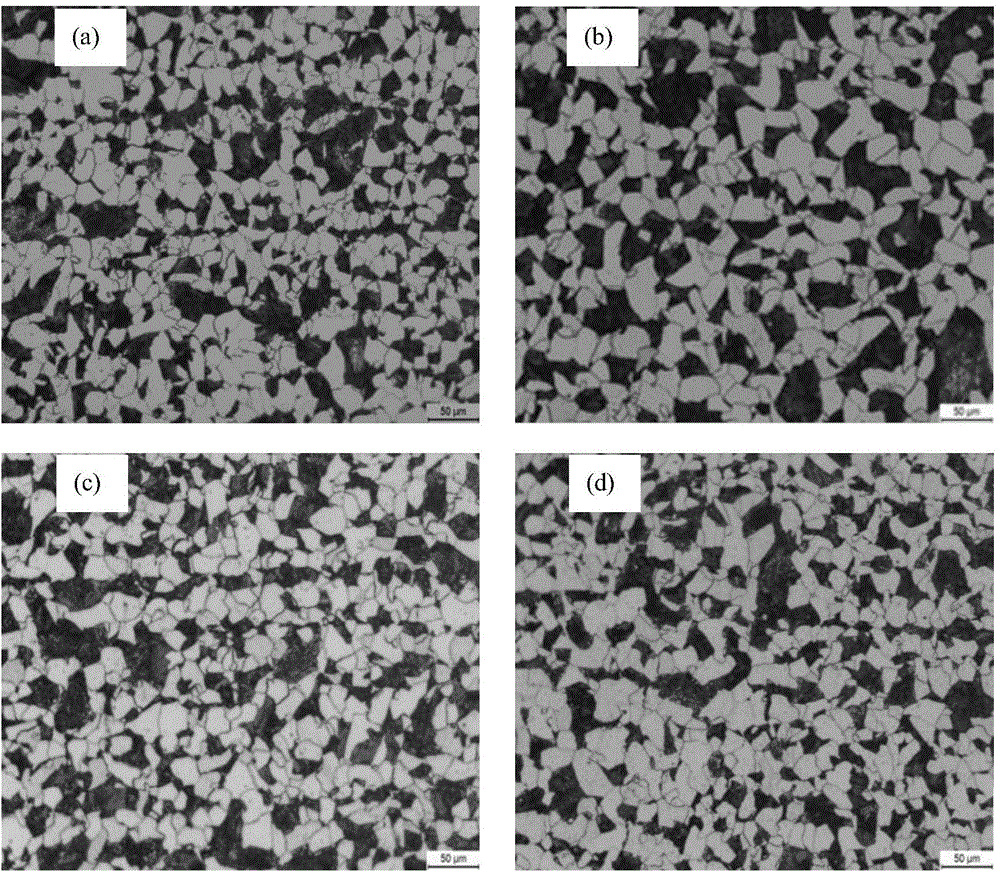

[0021] Example 1: Pipeline steel X80 is rolled using the method proposed by the present invention in the first pass. The thickness of the slab is 240mm, the furnace temperature is 1170℃, the inlet temperature of the cooling zone before the machine is 1138℃, and the water consumption of the cooling equipment is 5000m 3 / hr, the heat transfer coefficient ratio of the upper and lower surfaces is 1.18~1.22, the upper surface temperature of the mill entrance is 850°C, the lower surface temperature is 800°C, the core temperature is 1138°C, the temperature gradient is 2.4~2.8°C / mm, and the average temperature is 1110°C; while cooling, enter the rolling mill for synchronous rolling, the reduction rate is 10%, and the rolling speed is 1.2m / s~1.5m / s, and then, on the basis of the original speed specification, fine-tune the upper and lower working rolls of the rolling mill The speed ratio enters asynchronous rolling, and the speed ratio of the work rolls in asynchronous rolling is 1.003~...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com