Patents

Literature

32results about How to "Control warping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

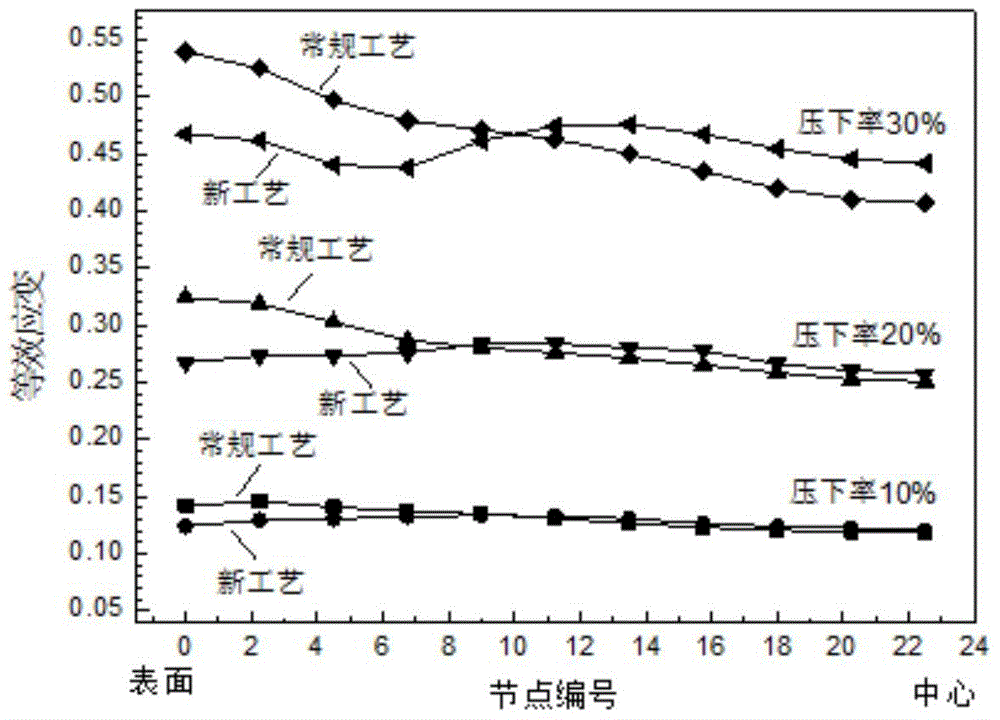

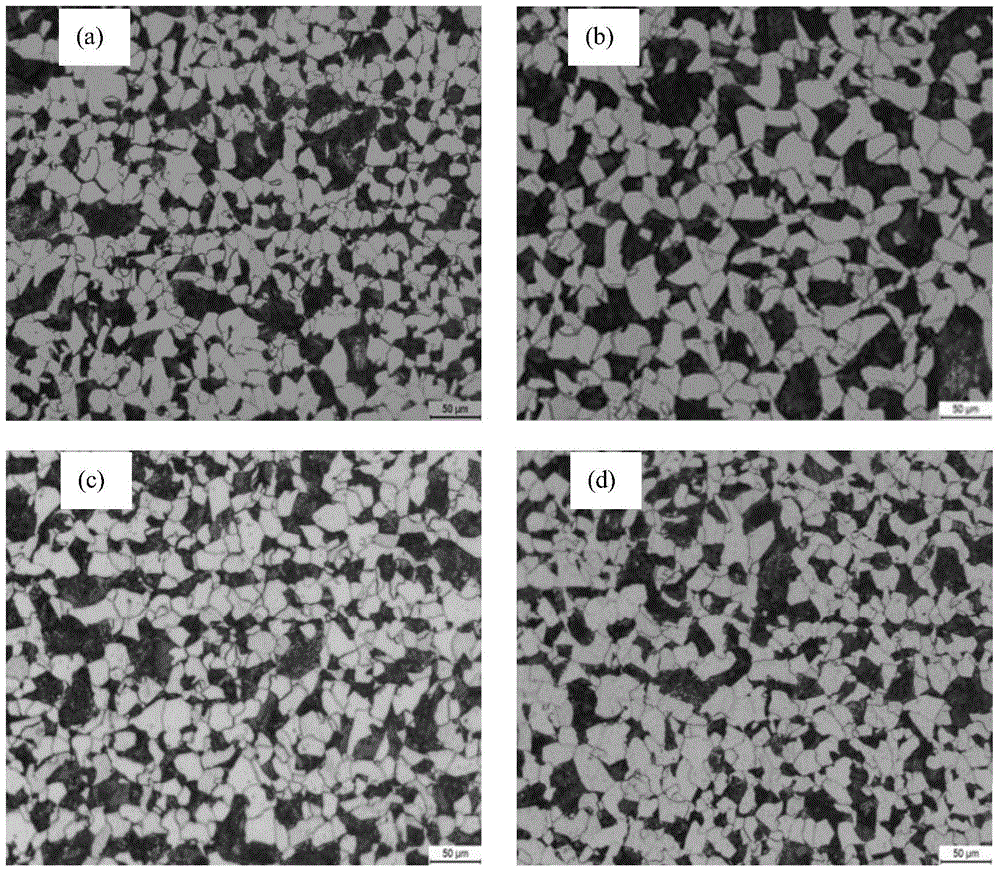

Method for improving deformation and permeability in high-thickness standard steel plate hot rolling process

ActiveCN104525588AEvenly distributedIncreased deformation resistanceWork treatment devicesMetal rolling arrangementsCryogenic hardeningSteel ball

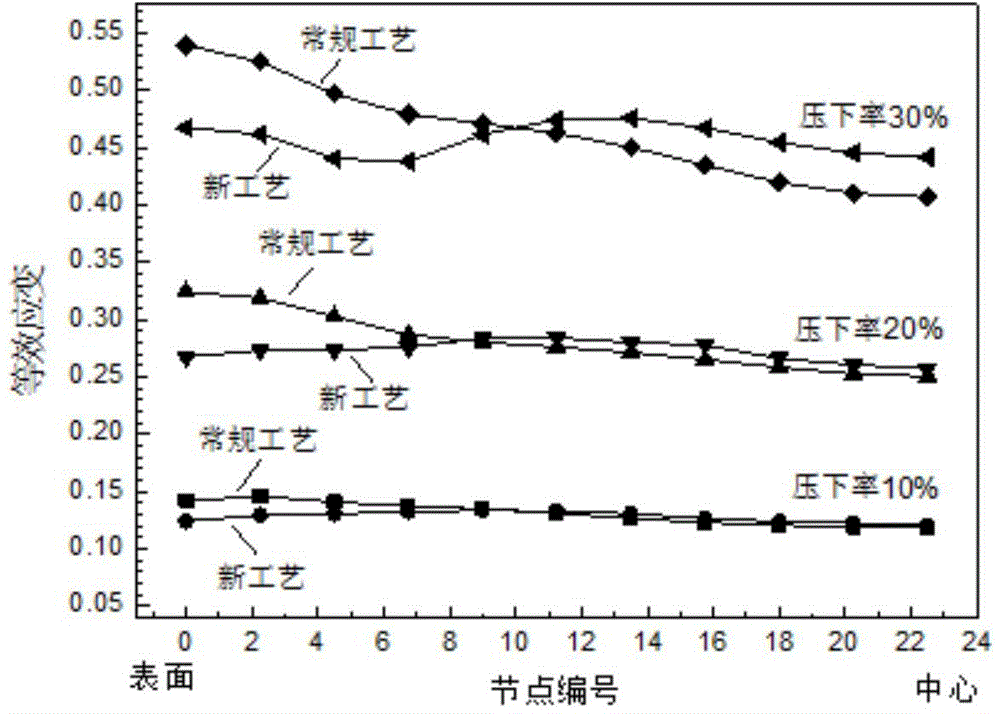

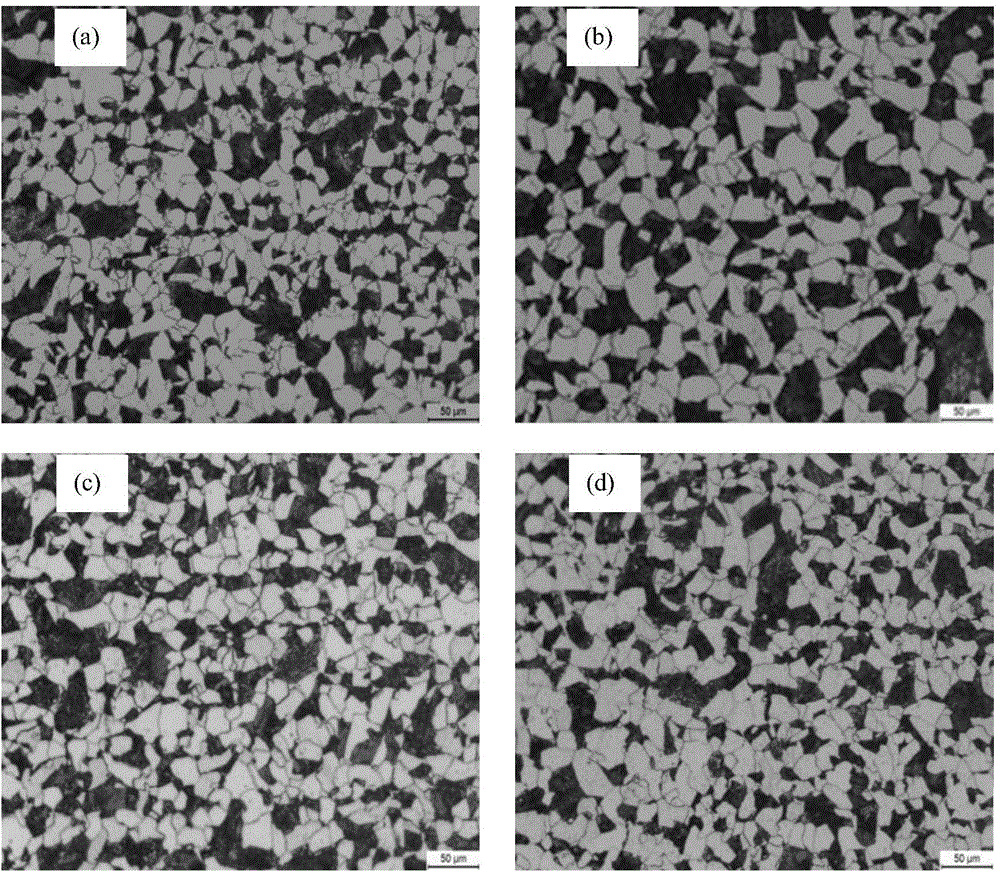

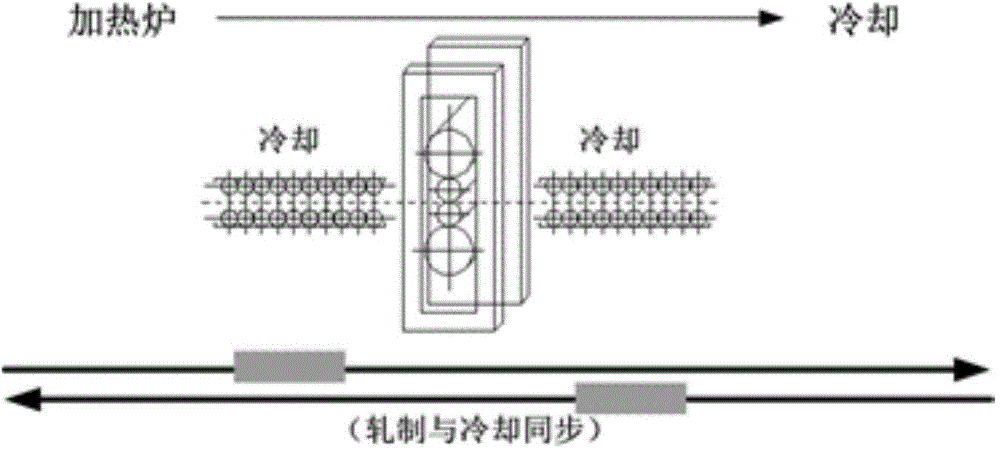

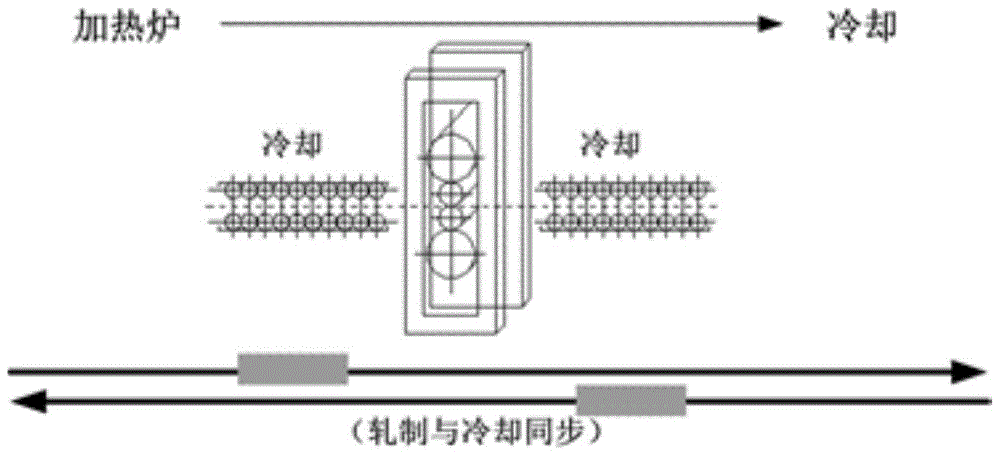

A method for improving deformation and permeability in the high-thickness standard steel plate hot rolling process is characterized in that a uniform fast cooling device is arranged at a position close to the opening of a heavy and medium plate mill or hot strip roughing mill with the length being 5 to 15 meters and the cooling total water being 3,000 to 6,000 cubic meters per hour respectively; before rolling, the cooling device conducts asymmetrical uniform fast cooling to the upper and lower surfaces of a plate blank, a low-temperature hardened layer is formed on the surface of the plate blank, the temperature gradient of a core reaches 2 to 3 DEG C per millimeter, before the cooling returns red, the cooling device can quickly enter the mill to conduct differential temperature rolling, and plate blank core deformation is improved; the cooling device is further combined with asymmetrical rolling, while deepening the plate blank core deformation, the cooling device solves the warping problem caused by the asymmetrical rolling through the asymmetrical cooling of the upper and lower surfaces of the plate blank before rolling. For a steel ball needing two-stage control, the uniform fast cooling device can replace a middle cooling device, shortens or even eliminates the temperature waiting time of swinging steel, and improves the production efficiency.

Owner:NORTHEASTERN UNIV

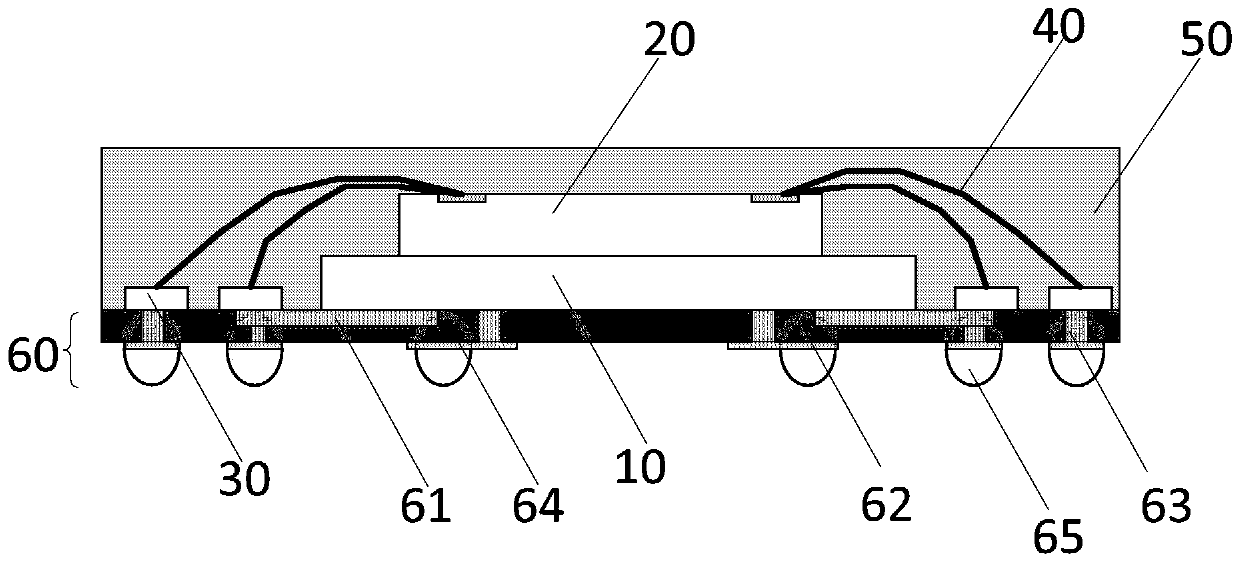

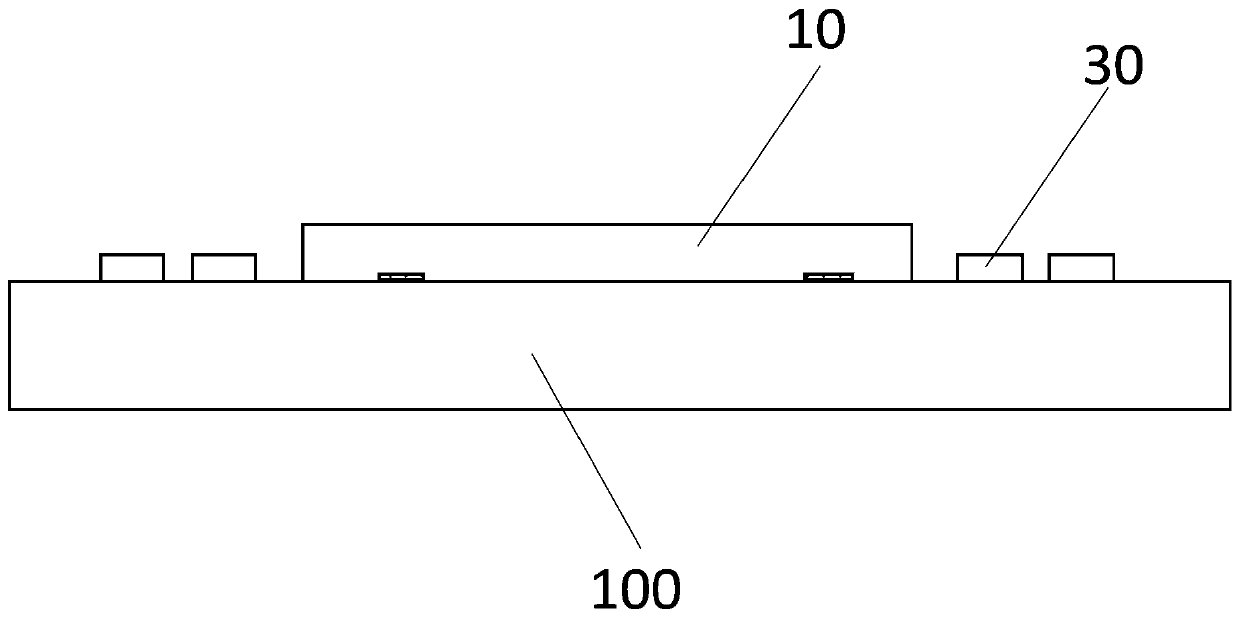

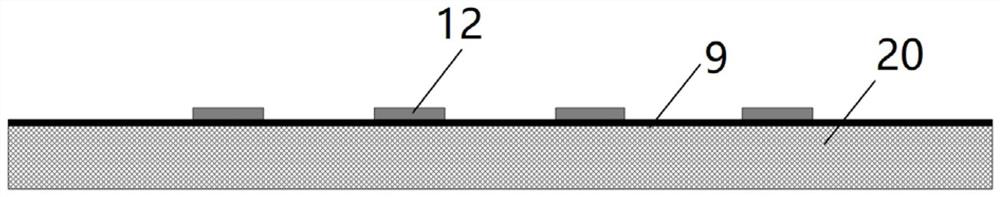

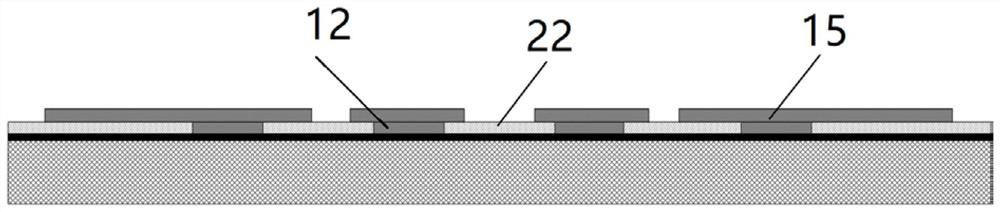

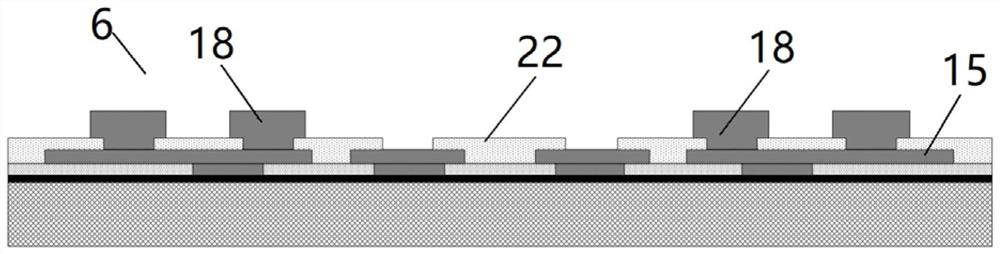

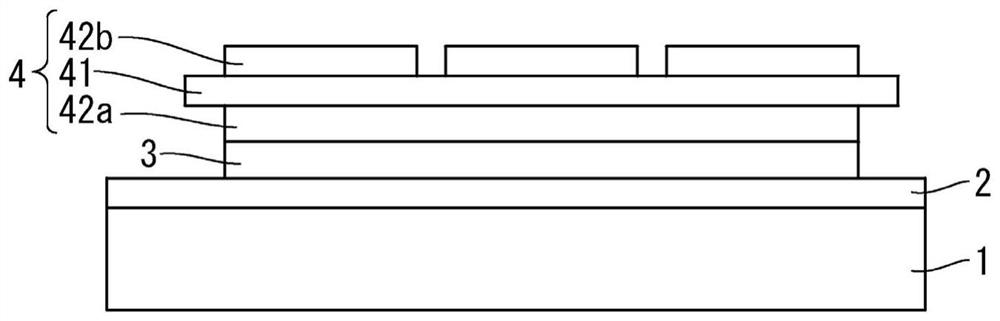

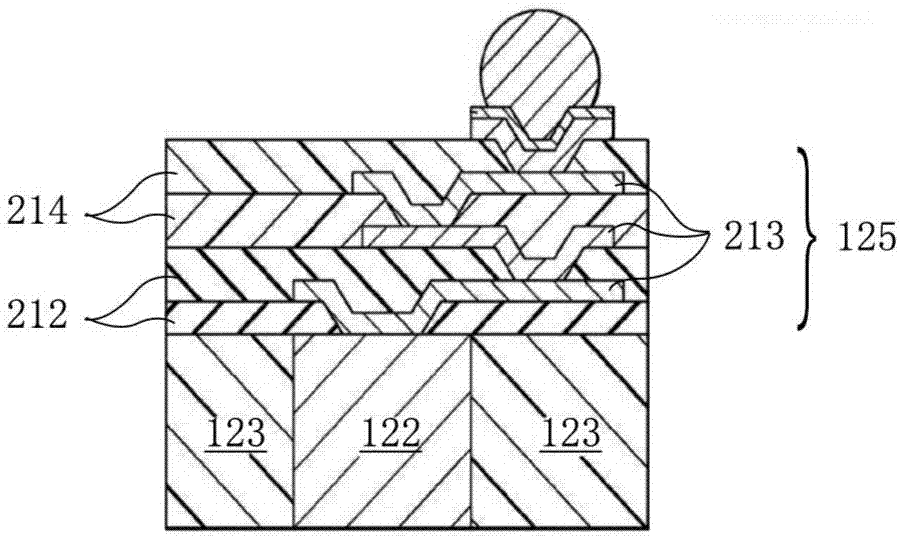

Chip packaging structure and preparation method thereof

InactiveCN106531642AAvoid risks during processingReduce riskSemiconductor/solid-state device detailsSolid-state devicesOperabilityEngineering

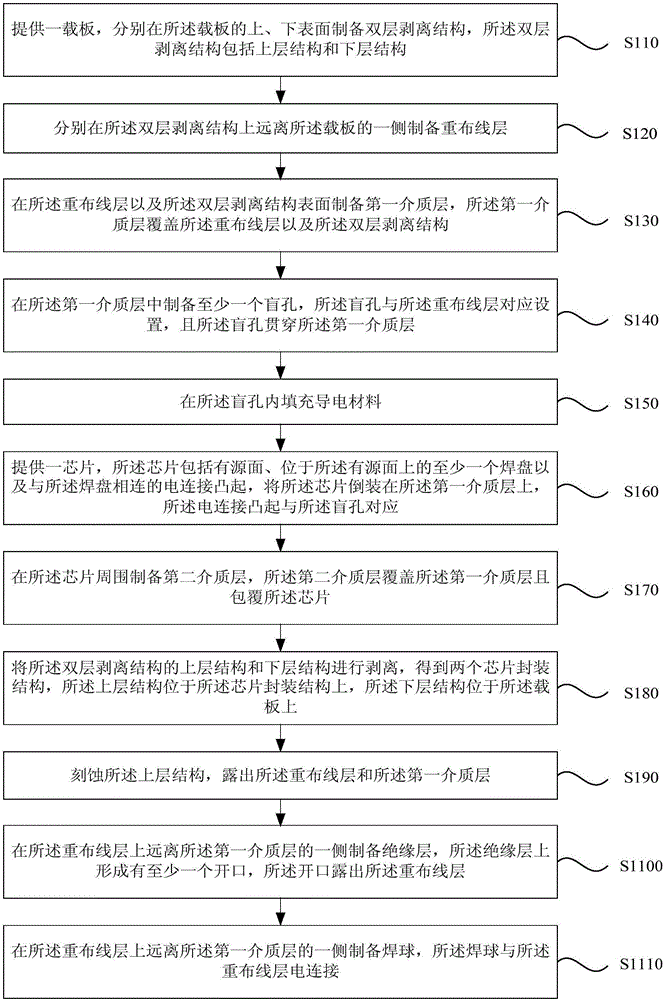

The invention discloses a chip packaging structure and a preparation method thereof. The preparation method comprises the following steps: providing a support plate, and preparing double-layer peeling structures on the upper surface and the lower surface of the support plate; preparing a rewiring layer on the side, away from the support plate, of each double-layer peeling structure; preparing first dielectric layers on each rewiring layer and the surface of each double-layer peeling structure; preparing at least one blind hole in each first dielectric layer; filling a conducting material in the blind holes; providing a chip, and arranging the chip on each first dielectric layer; preparing a second dielectric layer on the periphery of each chip, wherein each first dielectric layer is covered with the corresponding second dielectric layer, and each chip is wrapped by the corresponding second dielectric layer; peeling off the double-layer peeling structures; etching an upper-layer structure of each double-layer peeling structure so as to expose the corresponding rewiring layer and the corresponding first dielectric layer; and preparing a welded ball on the side, away from each first dielectric layer, of the corresponding rewiring layer, wherein each welded ball is electrically connected with the corresponding rewiring layer. To sum up, the preparation method is simple, high in operability and low in cost, and can avoid chip damage; and moreover, preparation technology is carried out on two sides of the support plate simultaneously, so that the efficiency is high, and warping is avoided.

Owner:NAT CENT FOR ADVANCED PACKAGING

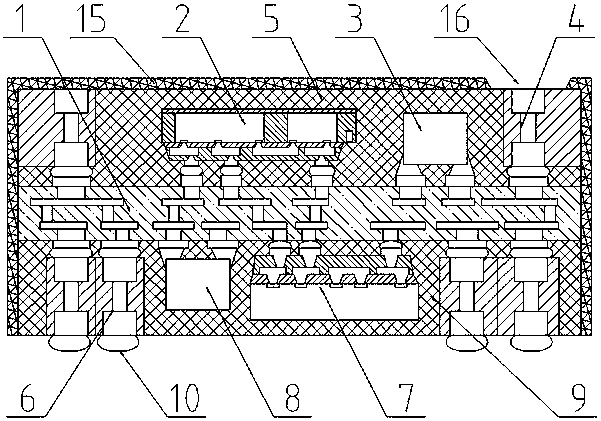

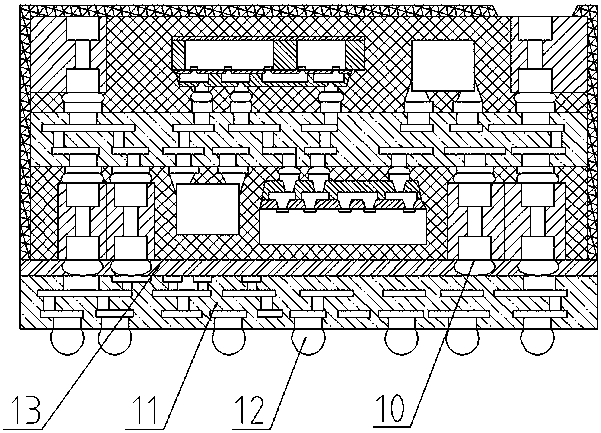

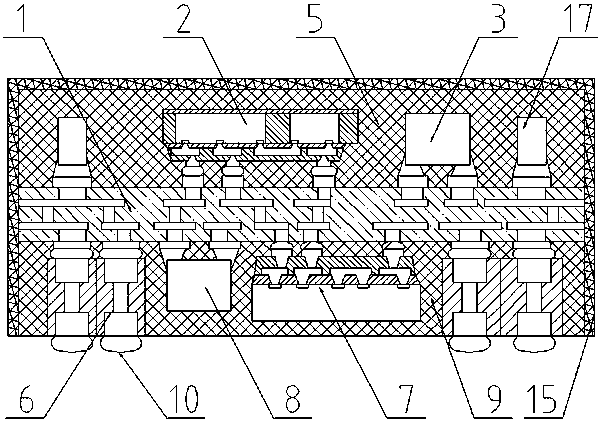

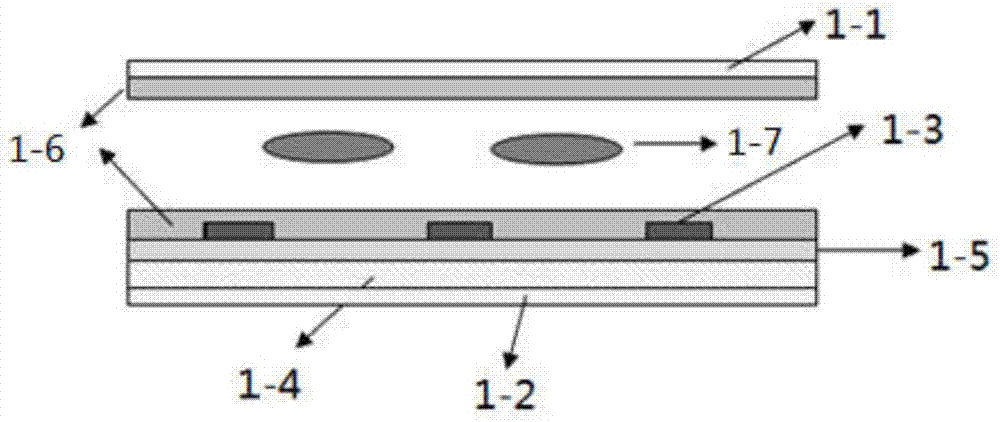

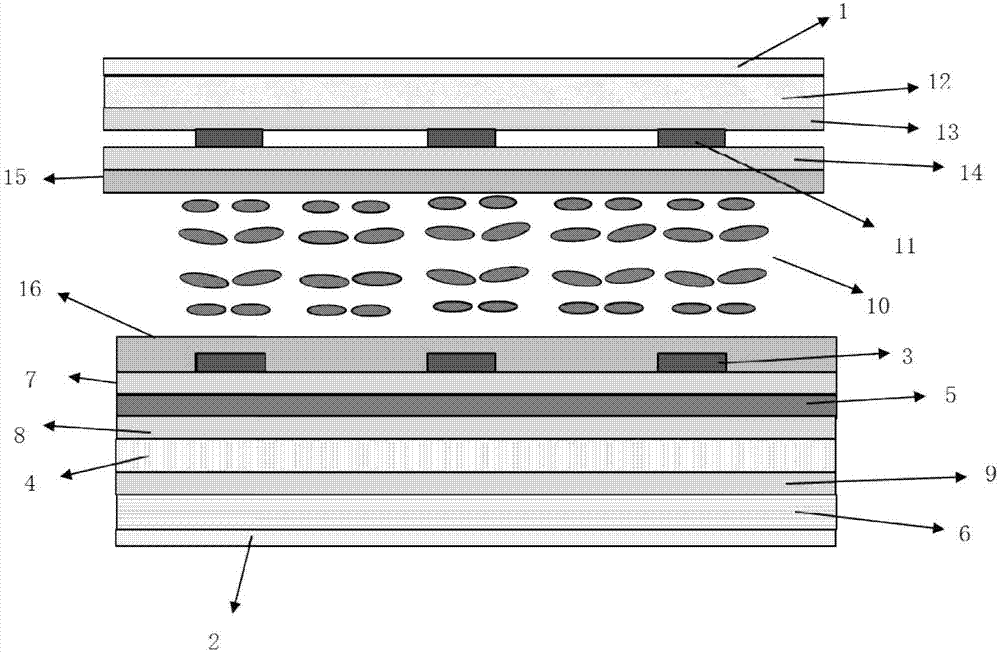

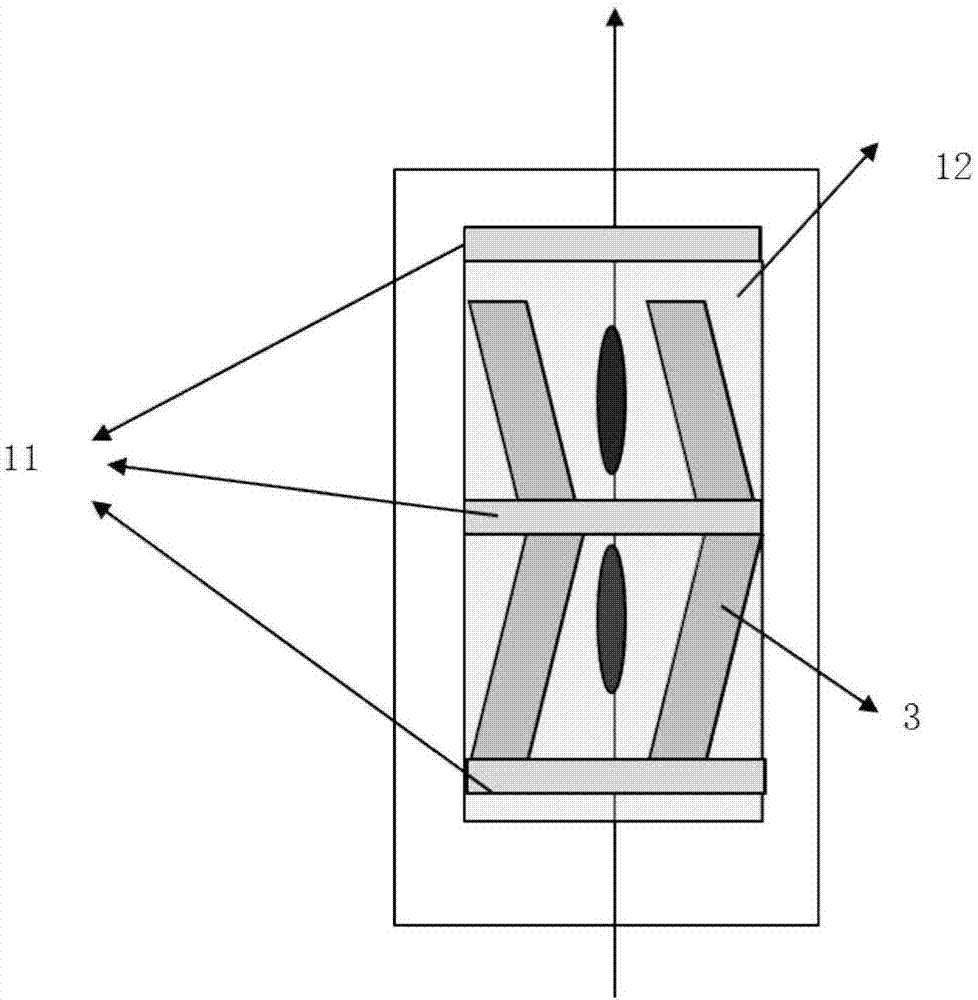

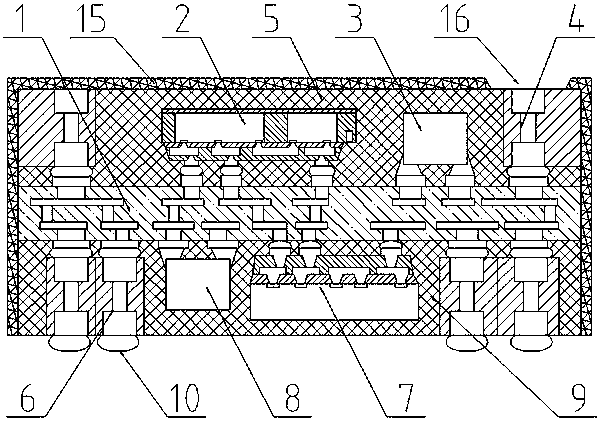

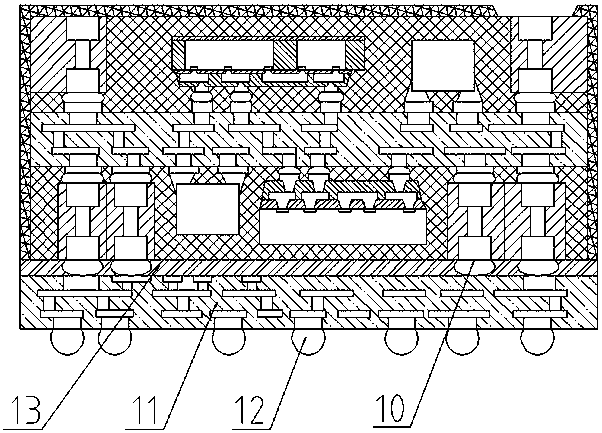

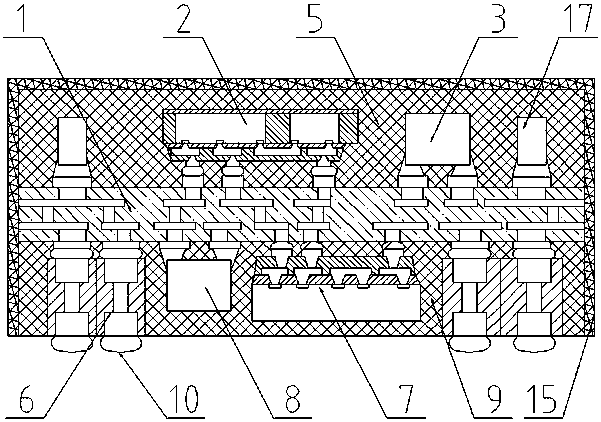

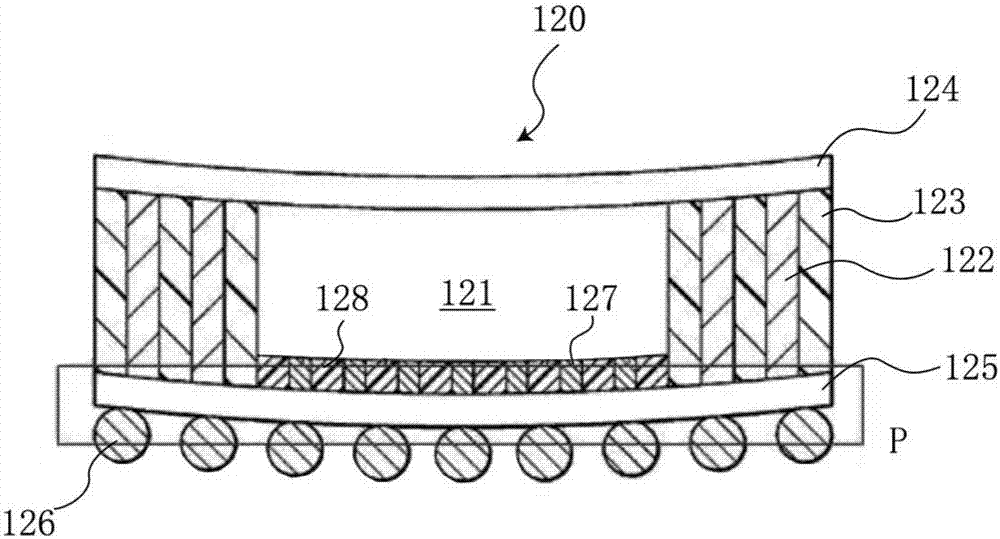

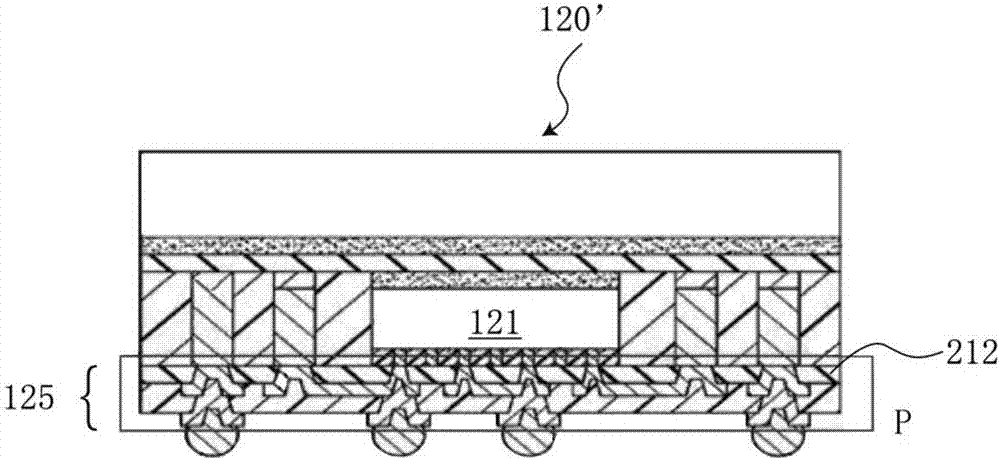

Dual-side SiP three-dimensional package structure

ActiveCN107768349AImprove high frequency performanceReduce chip lossSemiconductor/solid-state device detailsSolid-state devicesWafer-level packagingElectromagnetic interference

The invention relates to a dual-side SiP three-dimensional package structure. The dual-side SiP three-directional package structure comprises a core pinboard (1), wherein a fan-out wafer-level packagestructure (2), a first passive component (3) and a first three-dimensional (3D) conductive part (4) are mounted on a front surface of the core pinboard (1), a chip (7), a second passive component (8)and a second 3D conductive part (6) are mounted on a back surface of the core pinboard (1), a first welding ball (10) is arranged on a back surface of the second 3D conductive part (6), shielding layers (15) are arranged on a front surface and a side surface of the package structure, and an opening (16) is formed in the shielding layer (15) on a front surface of the first 3D conductive part (4).By the dual-side SiP three-dimensional package structure, a pre-fabricated 3D conductive part can be used as a support structure for lamination and package, the 3D conductive part is used as a grounding end of electromagnetic shielding, the size height of a package module can be reduced, the high-frequency performance of the package module is improved, and electromagnetic interference is effectively prevented.

Owner:JCET GROUP CO LTD

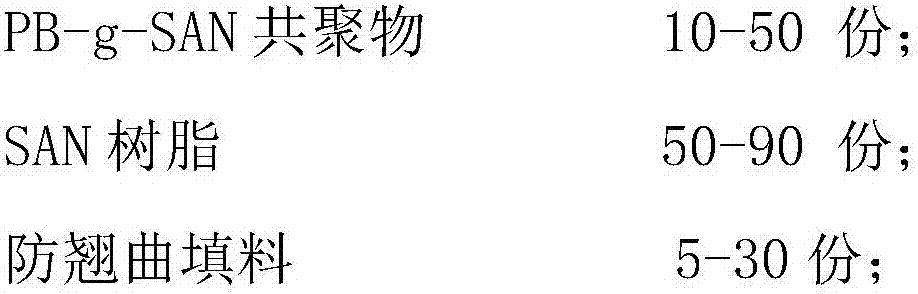

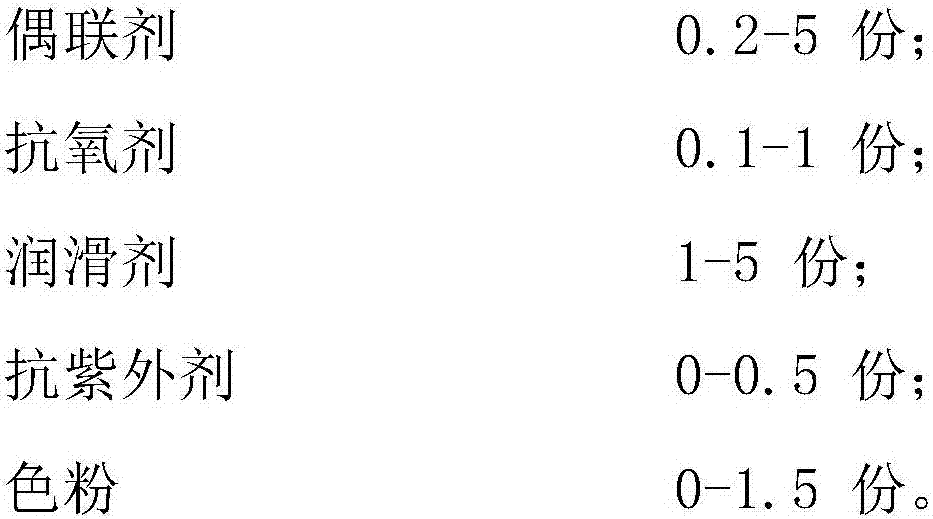

Low warpage ABS material for 3D printing, and preparation method thereof

InactiveCN107163426APrint controlRealize printingAdditive manufacturing apparatusAntioxidantMixed materials

The invention discloses a low warpage ABS material for 3D printing, and a preparation method thereof, wherein the low warpage ABS material comprises, by weight, 10-50 parts of a PB-G-SAN copolymer, 50-90 parts of a SAN resin, 5-30 parts of an anti-warpage filler, 0.2-5 parts of a coupling agent, 0.1-1 part of an antioxidant, 1-5 parts of a lubricant, 0-0.5 part of an anti-ultraviolet agent, and 0-1 part of toner. The preparation method comprises: weighing various raw materials according to the ratio, carrying out uniform mechanical mixing, extruding the mixed material through a twin-screw extruder, carrying out normal temperature cooling, carrying out air drying, granulating to prepare a modified ABS particle, and extruding the modified ABS particle by using a 3D printing material extruder to produce the low warpage ABS material for 3D printing. According to the present invention, with the application of the prepared ABS material for 3D printing in printing, the advantages of uniform and smooth printing, no drawing, strong adhesion between the layers, low warpage and high size precision of the product, and printing of the large-size product can be provided.

Owner:HUIZHOU RES INST OF SUN YAT SEN UNIV

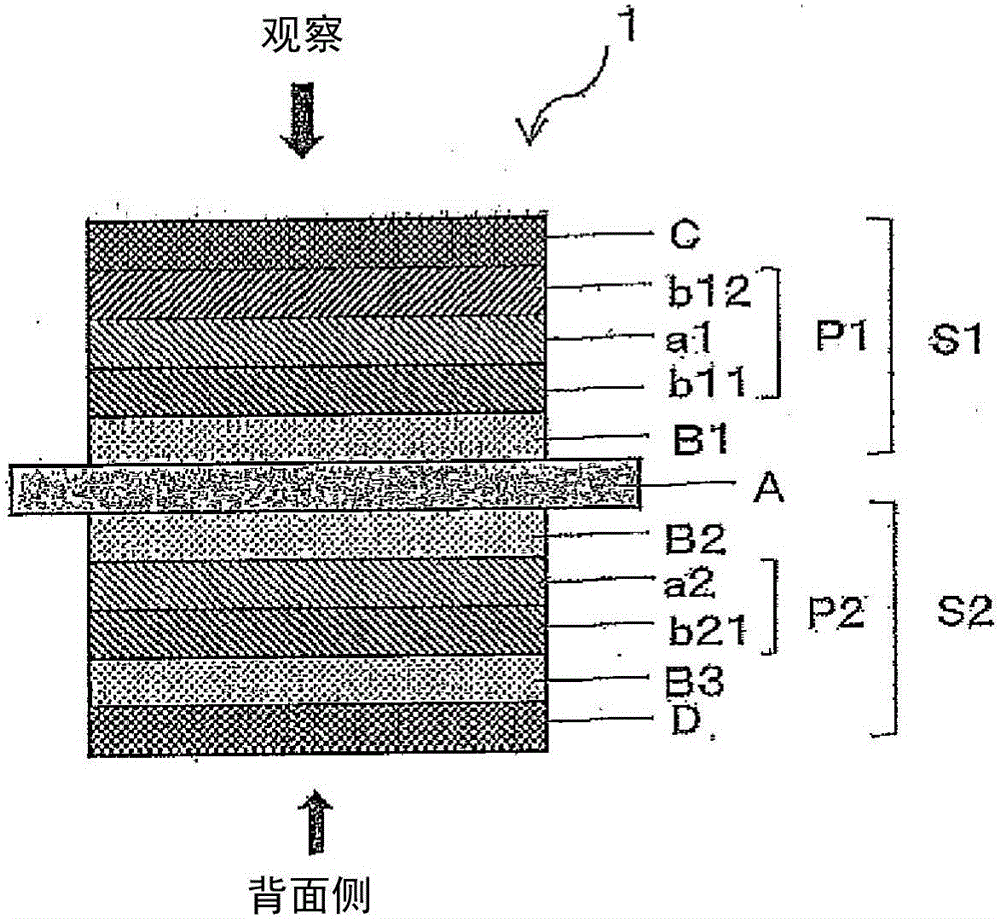

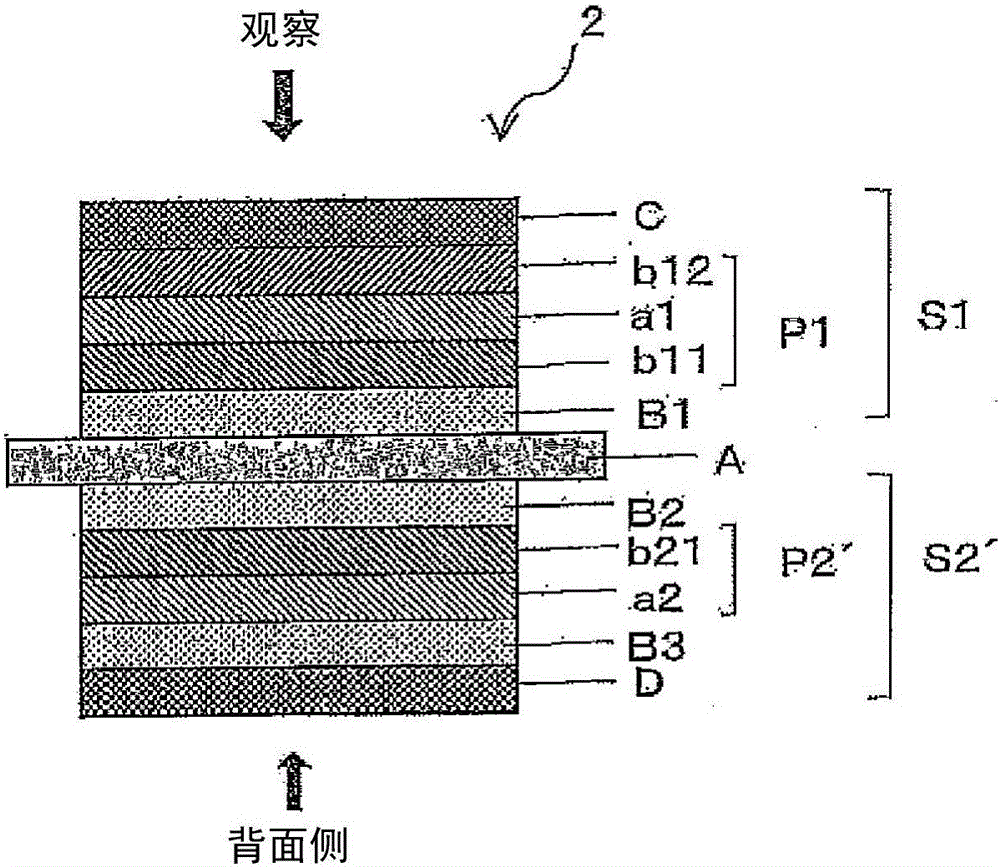

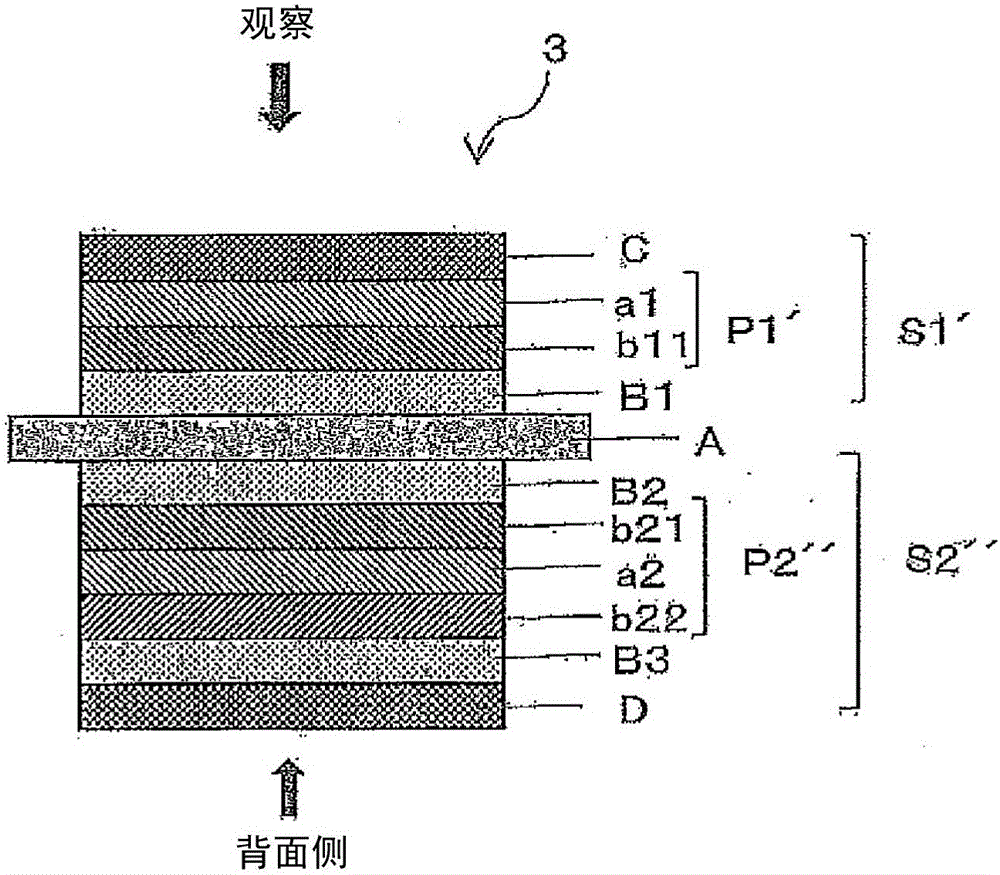

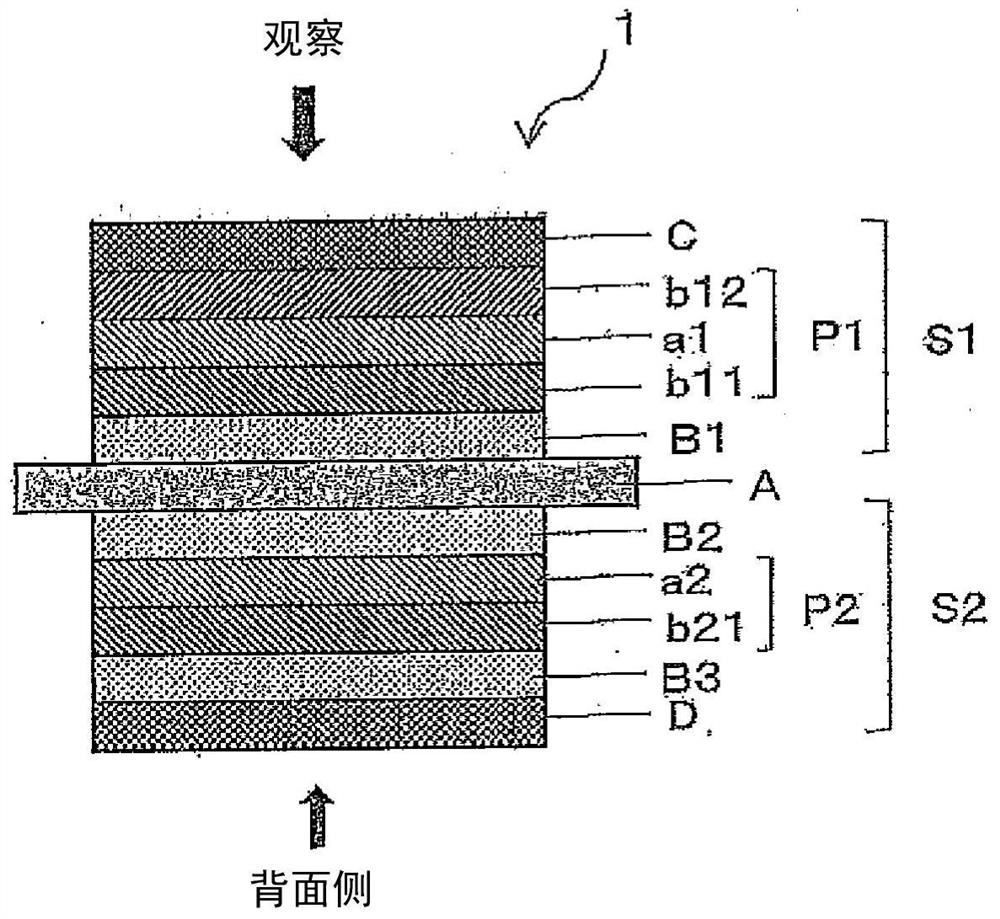

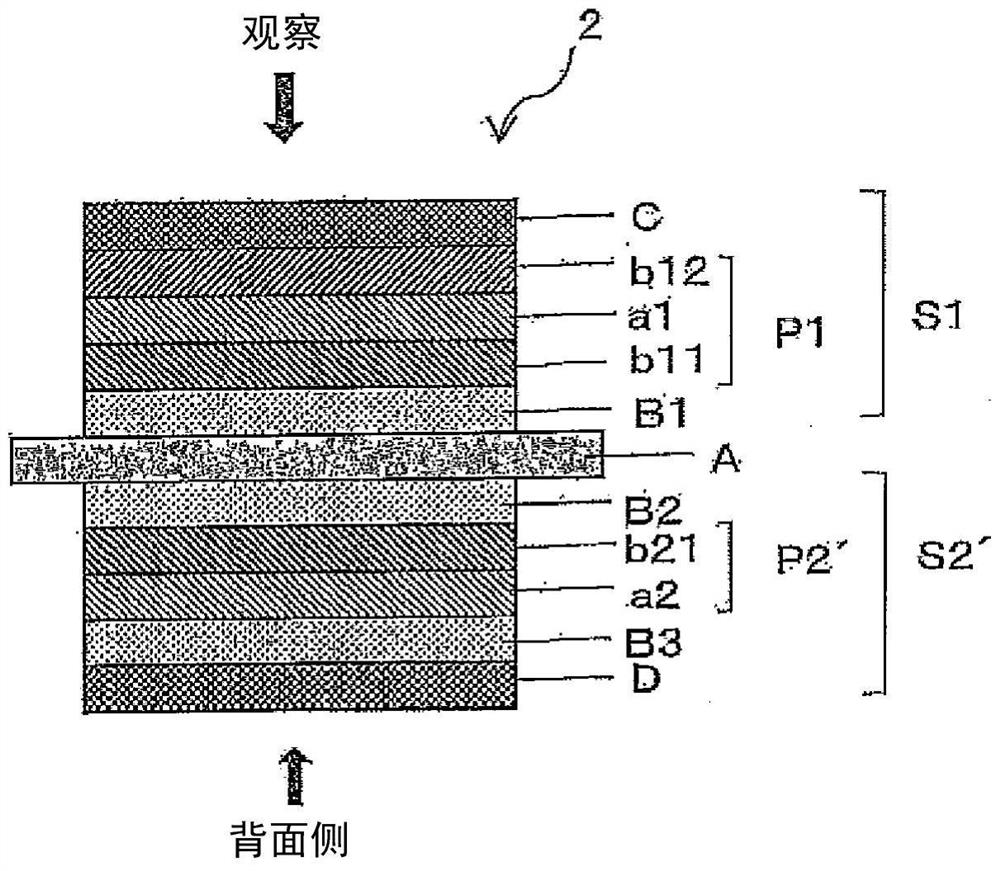

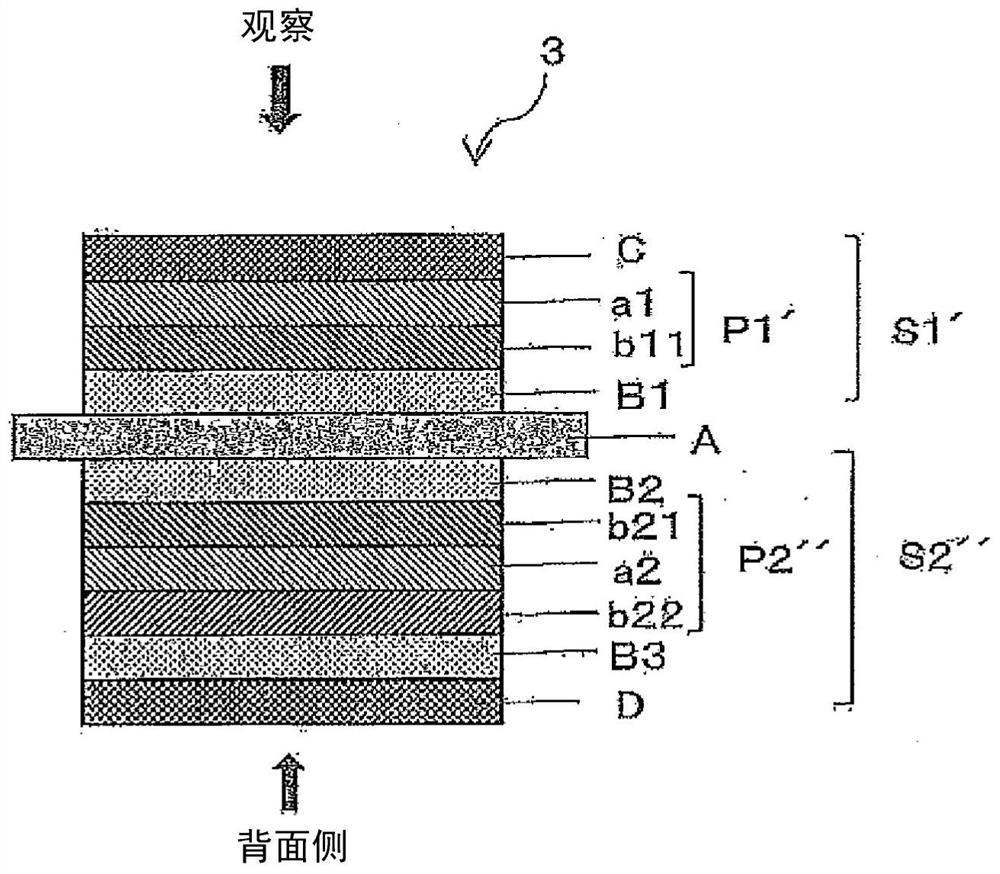

Pressure-sensitive adhesive layer attached polarizing film set, liquid crystal panel and liquid crystal display device

ActiveCN106054437ASmall Humidity Expansion CoefficientSuppress changesNon-linear opticsOptical elementsLiquid-crystal displayPolarizer

The invention provides a polarizing film set which is used for controlling the decrease of warping under normal temperature and humidity. The polarizing film set is provided with a polarizing film with a first adhesive layer, and a polarizing film with a second adhesive layer, wherein the polarizing film with the first adhesive layer is configured at an observation side of a liquid crystal unit in an IPS mode, and the polarizing film with the second adhesive layer is configured at a back side of the liquid crystal unit. The first polarizing film of the polarizing film with the first adhesive layer is a first transparent protection film (b11) which is located at one side of a first polaroid with the thickness being less than 25 microns, and has the humidity expansion coefficient (1.0*10<-6> / %RH). The other side is provided with a surface treatment layer, and the first transparent protection film (b11) is configured at the liquid crystal unit side.

Owner:NITTO DENKO CORP

Fan-out type packaging structure and packaging method of chip

PendingCN109786347AReduce the valueReduce package warpageSemiconductor/solid-state device detailsSolid-state devicesElectricityInterconnection

The invention discloses a fan-out type packaging structure and packaging method of a chip; the fan-out type packaging structure comprises a first chip, a second chip, a plurality of metal terminals, alead, a packaging layer, and an extraction layer; the bottom surface of the first chip and the bottom surface of the second chip are oppositely attached to each other; the plurality of metal terminals are distributed on the periphery of the first chip, one face of the metal terminal is located on the same plane as the front surface of the first chip; the lead is connected between the front face of the second chip and the other face of the metal terminal; the packaging layer is used for packaging the first chip, the second chip, the lead and the metal terminals; and the extraction layer is arranged on a first surface of the packaging layer and is respectively electrically connected with one face of the metal terminal and / or the front face of the first chip. Compared with the fan-out type packaging structure packaged by using a slide glass whole surface, a plurality of metal terminals are arranged in a distributed mode, the packaging structure is balanced by utilizing the volume ratio of the metal terminals, for example, the numerical value of the equivalent thermal expansion coefficient of the packaging body is reduced, so that warping of the product is controlled, and packaging deformation warping is reduced. In addition, signal interconnection of multi-chip stacked in the Z direction can be realized through the plurality of metal terminals.

Owner:NAT CENT FOR ADVANCED PACKAGING

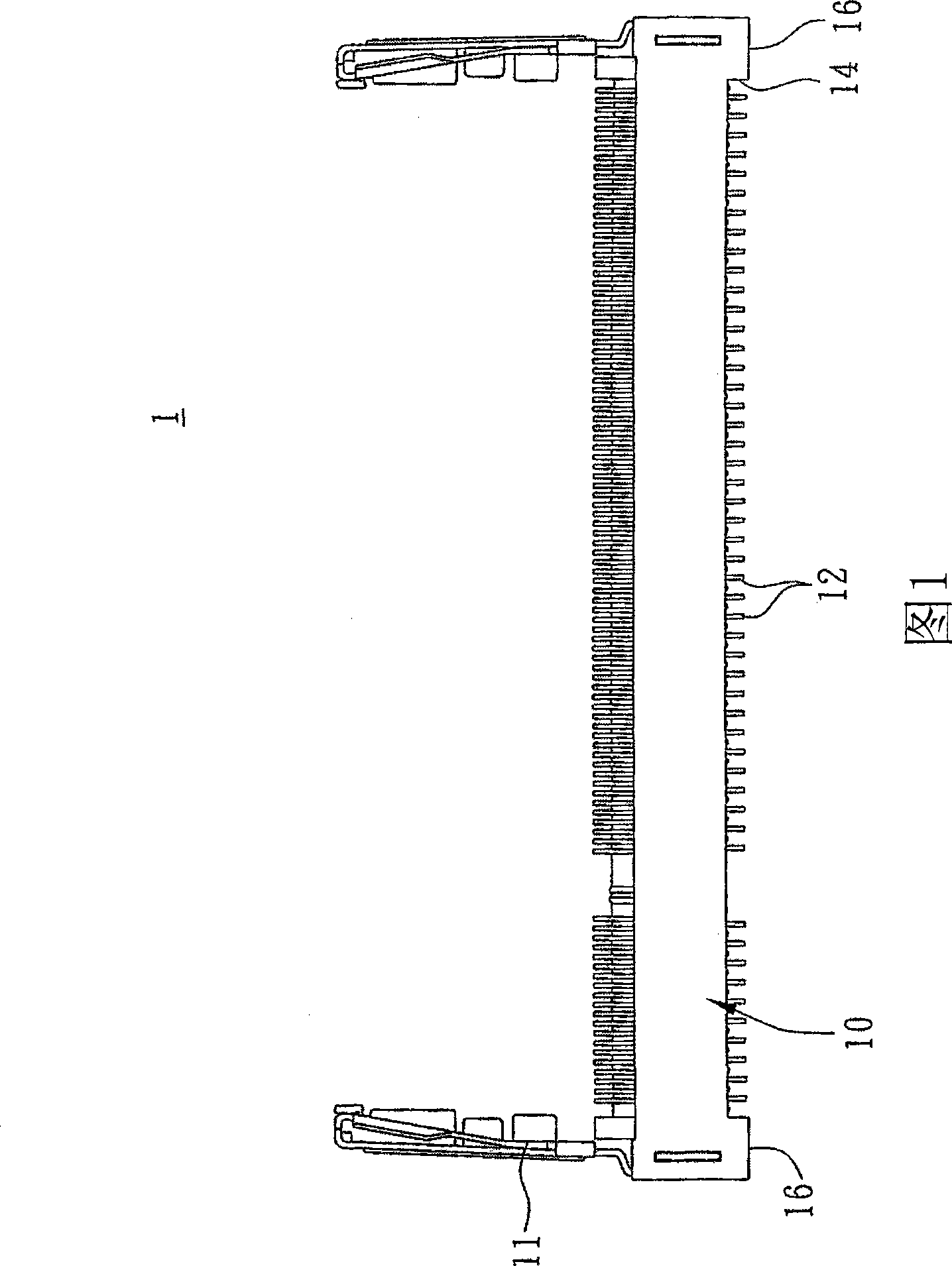

Liquid crystal display device

InactiveCN107272278ALow refractive indexScatter constant reductionNon-linear opticsRefractive indexBrightness perception

The invention discloses a liquid crystal display device which comprises an upper substrate, a lower substrate and liquid crystal molecules, wherein the liquid crystal molecules are arranged between the upper substrate and the lower substrate. The lower substrate comprises a first counter electrode, the upper substrate comprises a second counter electrode corresponding to the first counter electrode, the first counter electrode comprises a first pixel electrode and a first common electrode, the second counter electrode comprises a second pixel electrode and a second common electrode, and insulating layers are arranged between the first pixel electrode and the second common electrode and between the second pixel electrode and the second common electrode. According to the liquid crystal display device, warping of the liquid crystal molecules can be controlled when the device is in an opening state, penetration rate is increased, opening of the liquid crystal molecules is accelerate, response time of the liquid crystal molecules is shortened when the device is in a closing state, refractive index of liquid crystals is reduced based on invariant box thickness, so that the brightness of a dark state is reduced, and the contrast ratio of liquid crystal display is finally increased.

Owner:NANJING CEC PANDA FPD TECH CO LTD +2

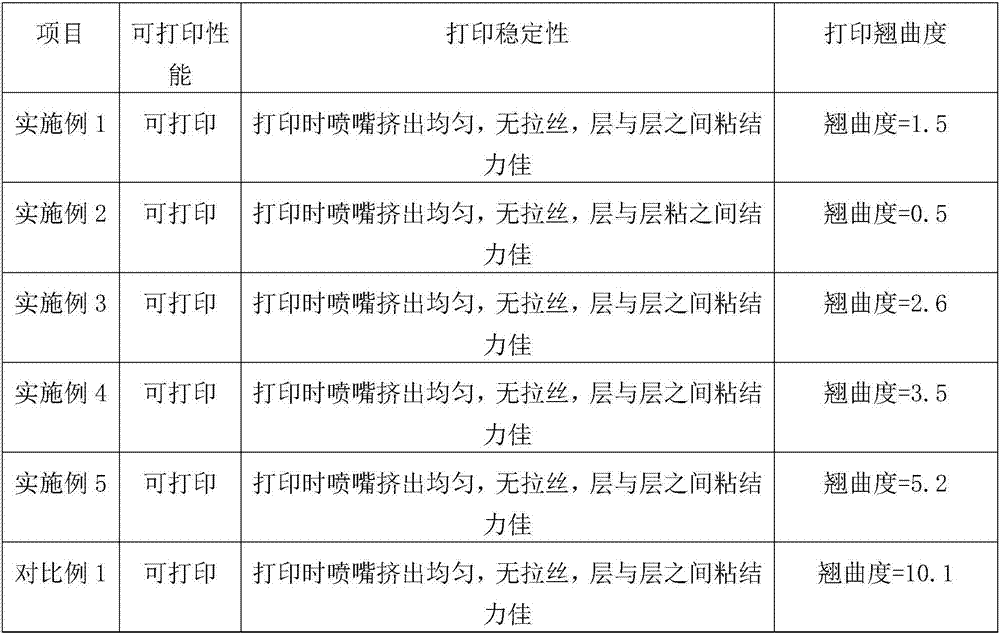

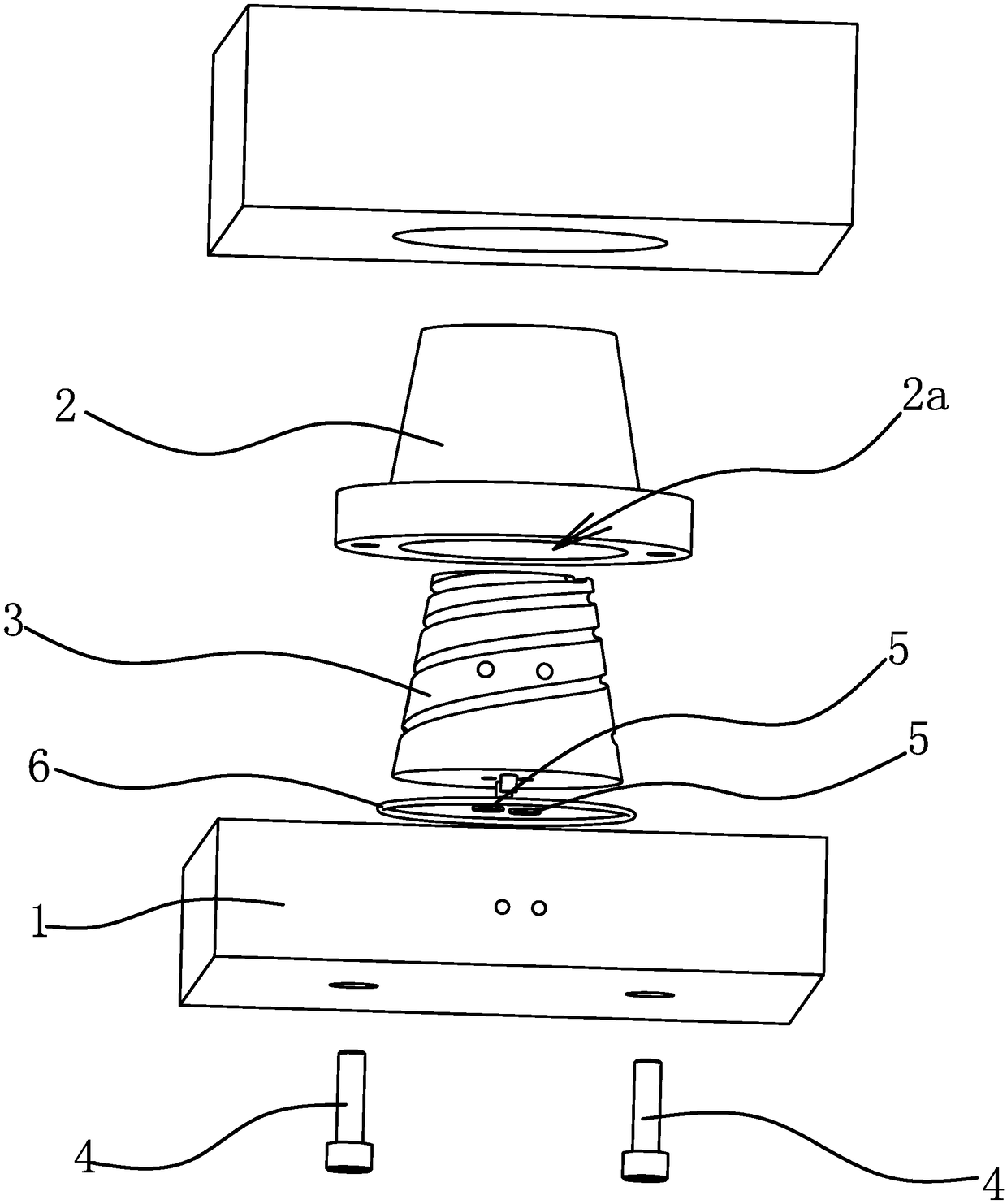

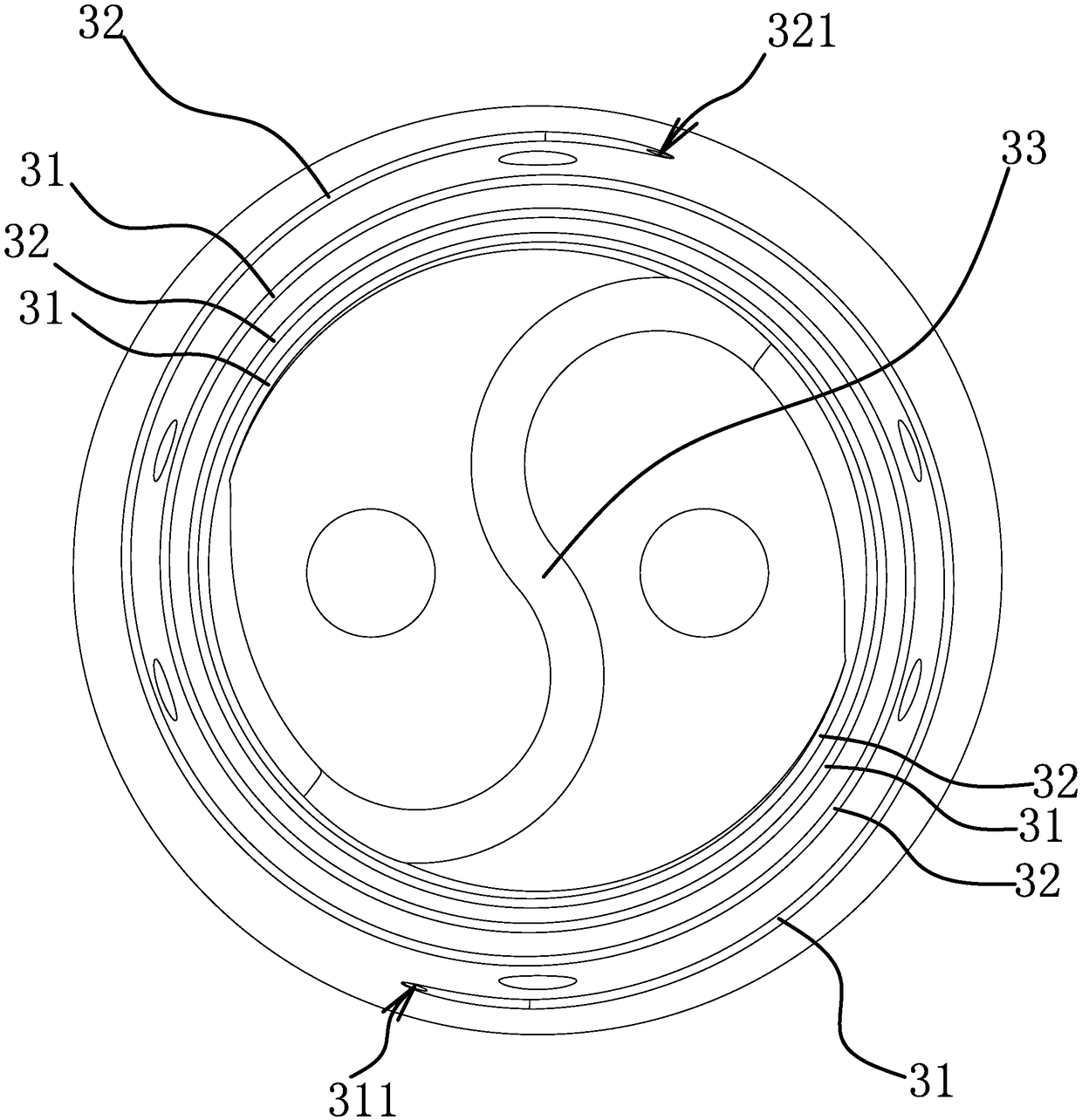

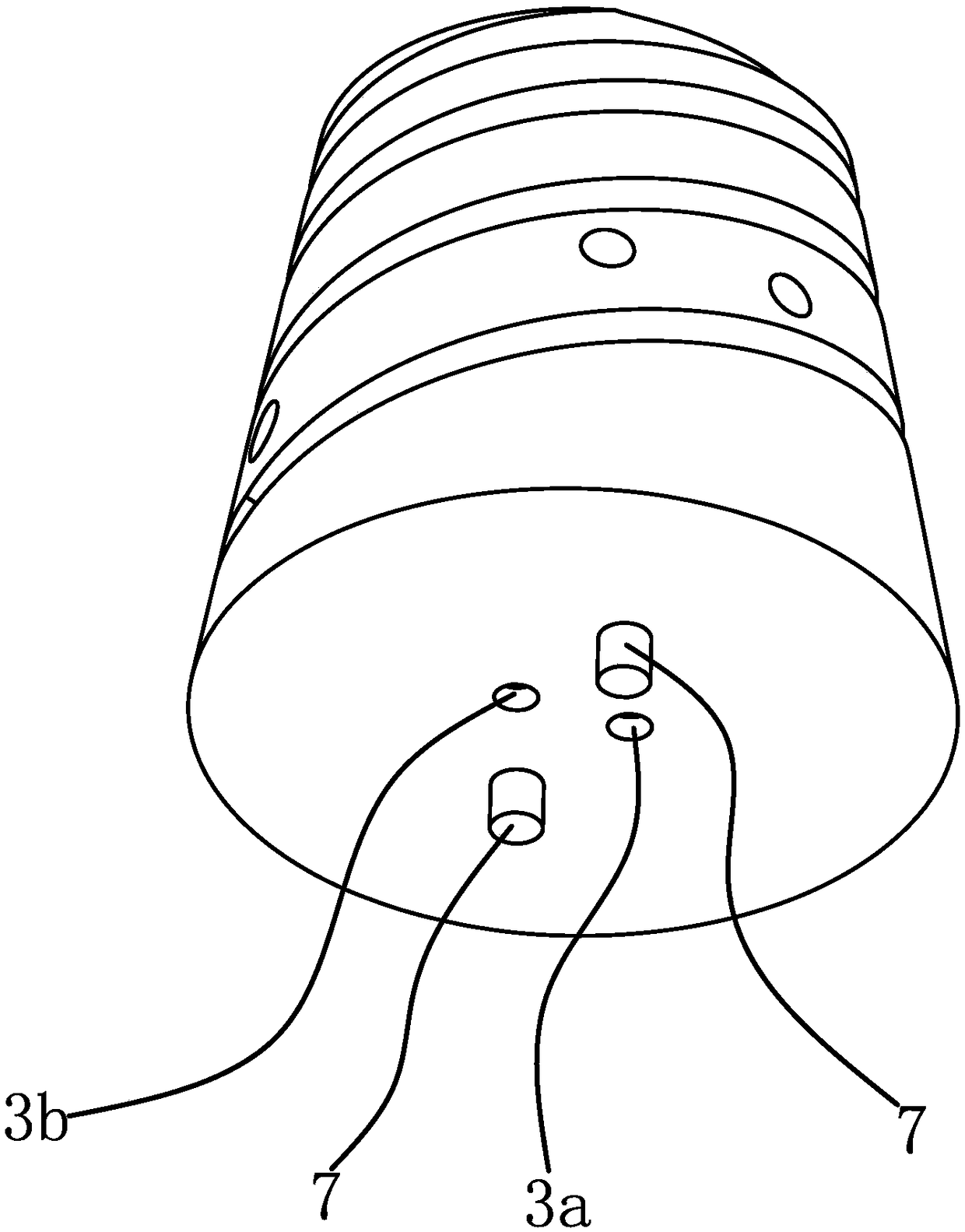

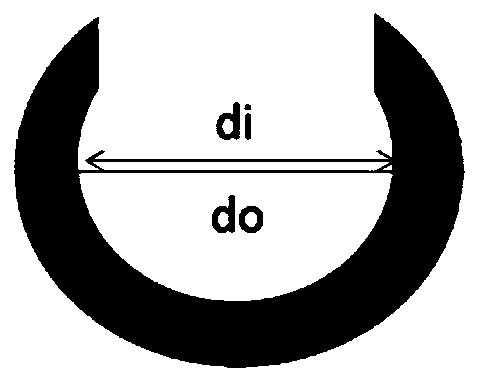

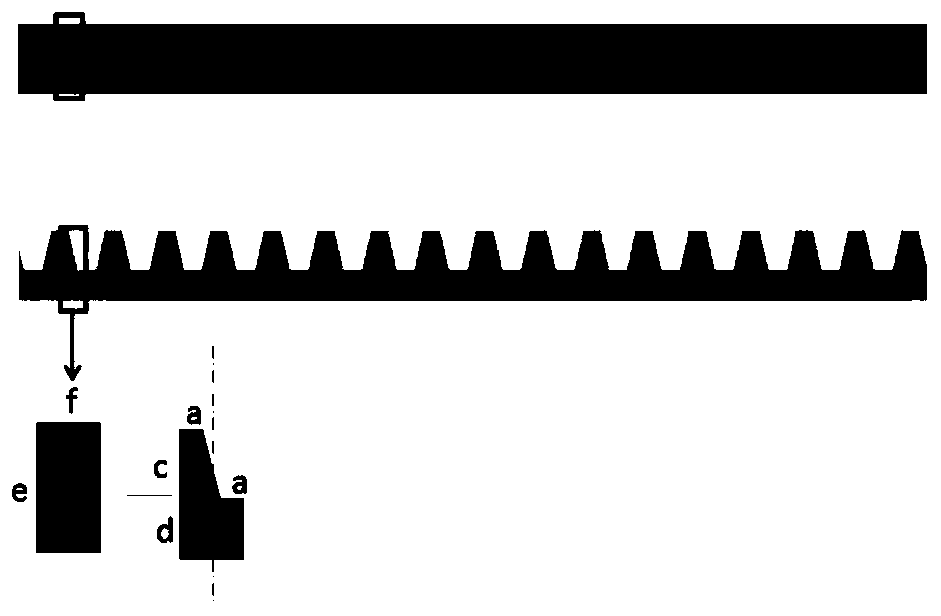

Cold and hot loop alternate mold conformal cooling system

The invention provides a cold and hot loop alternate mold conformal cooling system and belongs to the technical field of mold cooling. The cold and hot loop alternate mold conformal cooling system achieves the effects of keeping the temperature of a cooled mold core balanced and improving the cooling effect. The conformal cooling system comprises a cooling cavity formed in a mold core and a cooling core. An inflow cooling groove and a backflow cooling groove are spirally and alternately formed in the peripheral surface of the cooling core. The bottom of the cooling core is provided with a water inlet and a water outlet. The top end of the cooling core is provided with a communicating flow channel. The water inlet end of the inflow cooling groove is provided with a water inlet hole communicating with the water inlet. The water outlet end of the inflow cooling groove communicates with one end of the communicating flow channel. The water inlet end of the backflow cooling groove communicates with the other end of the communicating flow channel. The water outlet end of the backflow cooling groove is provided with a water outlet hole communicating with the water outlet. The cold and hotloop alternate mold conformal cooling system can make the temperature of the cooled mold core keep balanced, has the high cooling effect and can improve the production quality of plastic products.

Owner:TAIZHOU VOCATIONAL & TECHN COLLEGE

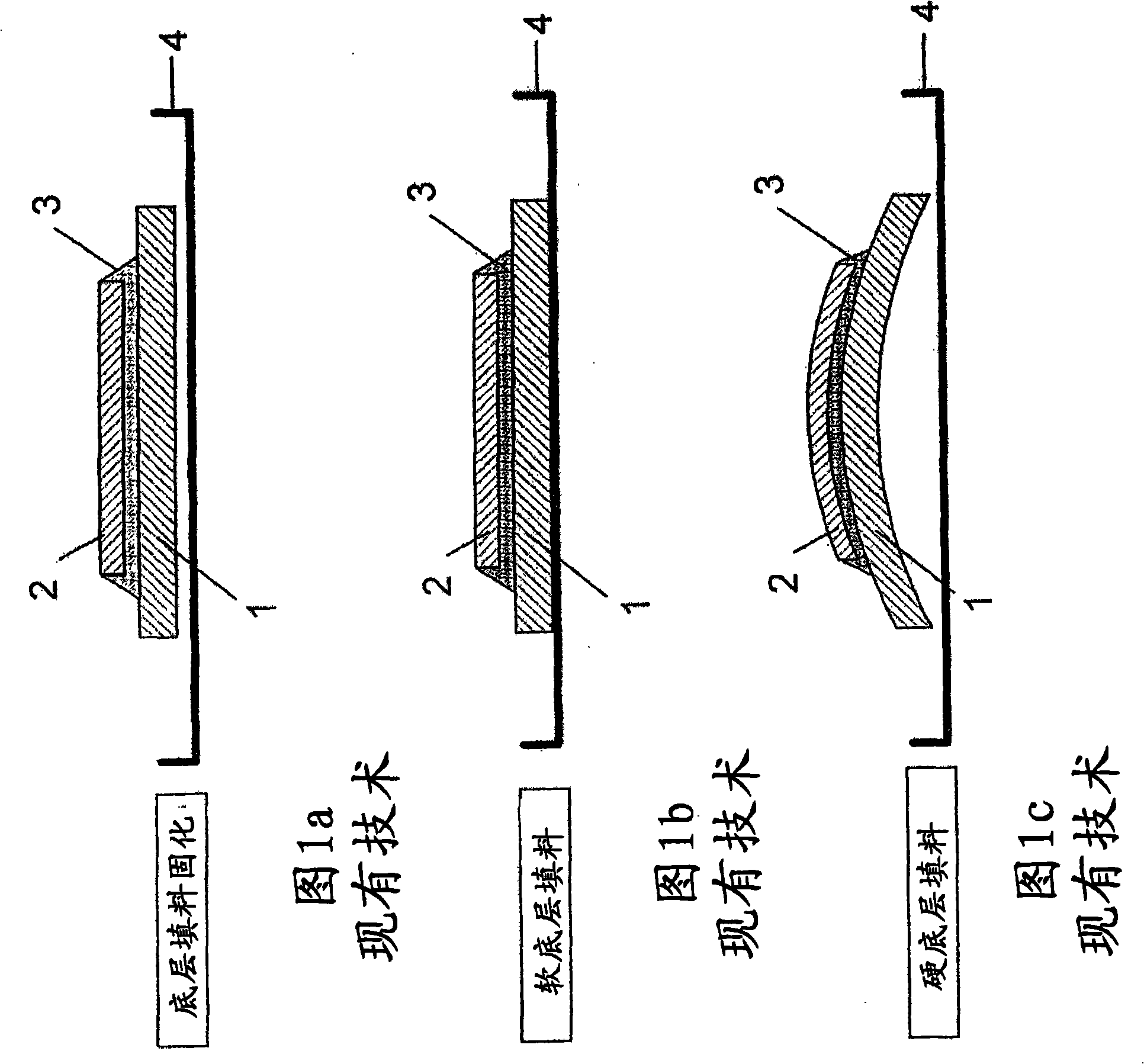

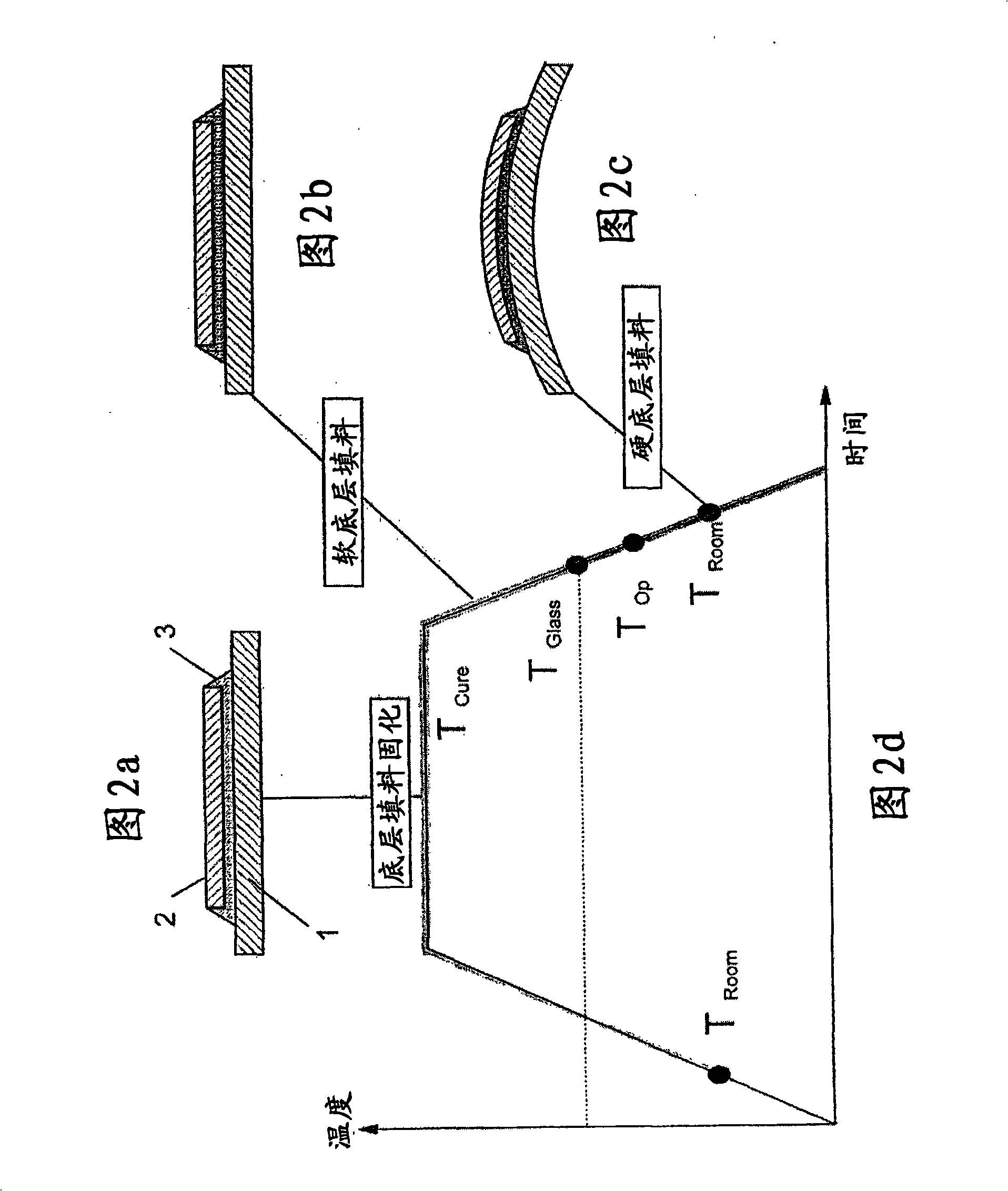

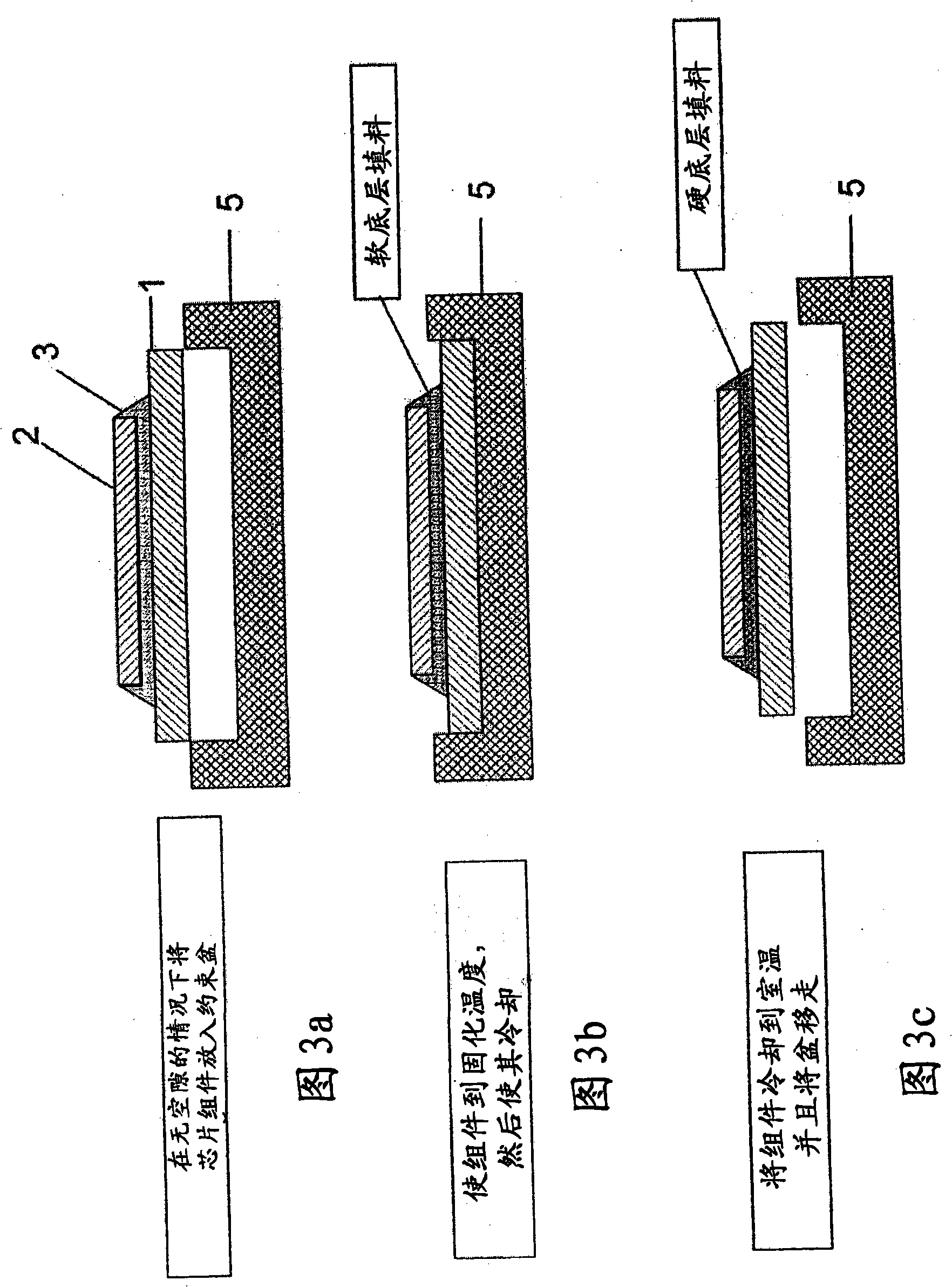

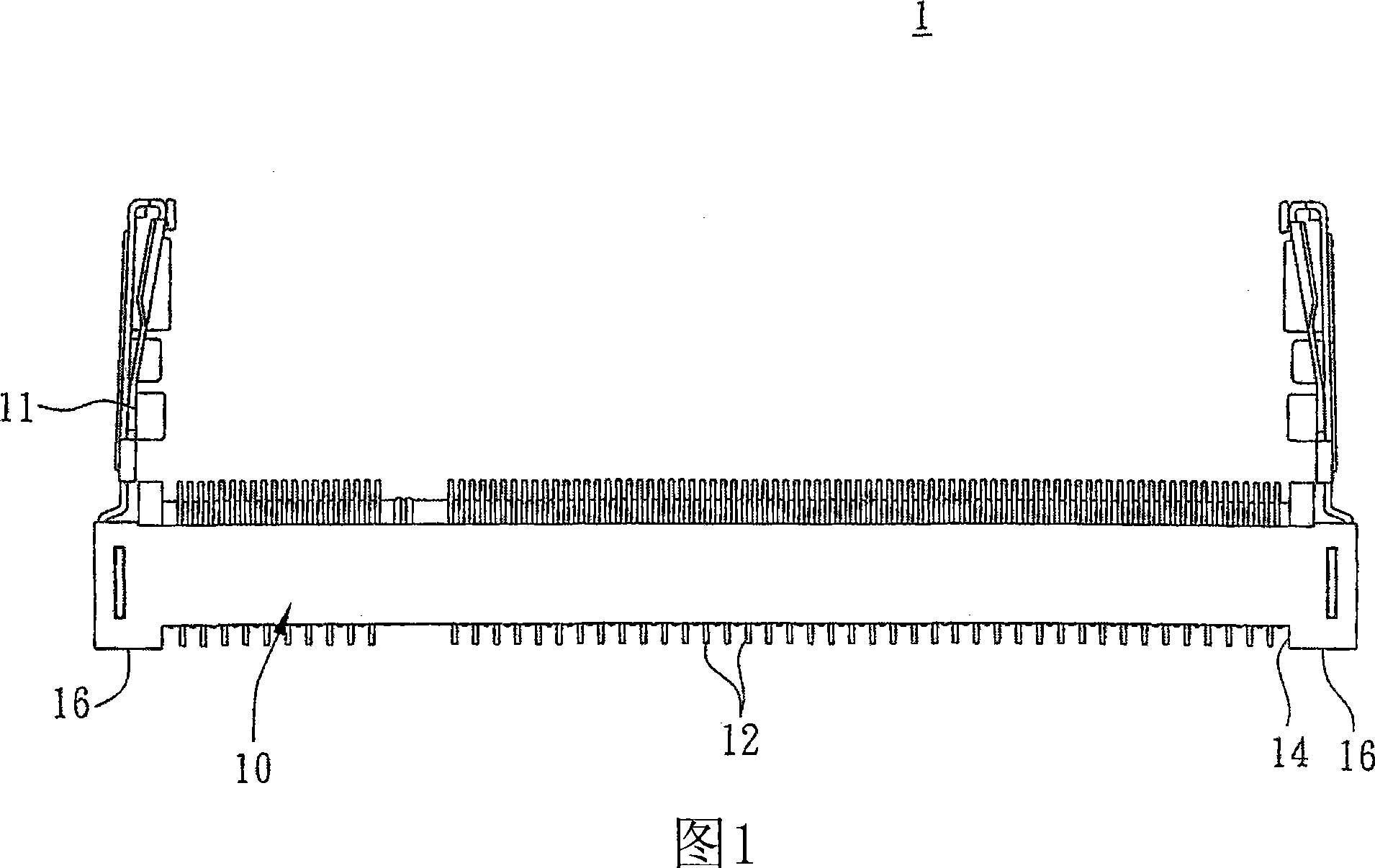

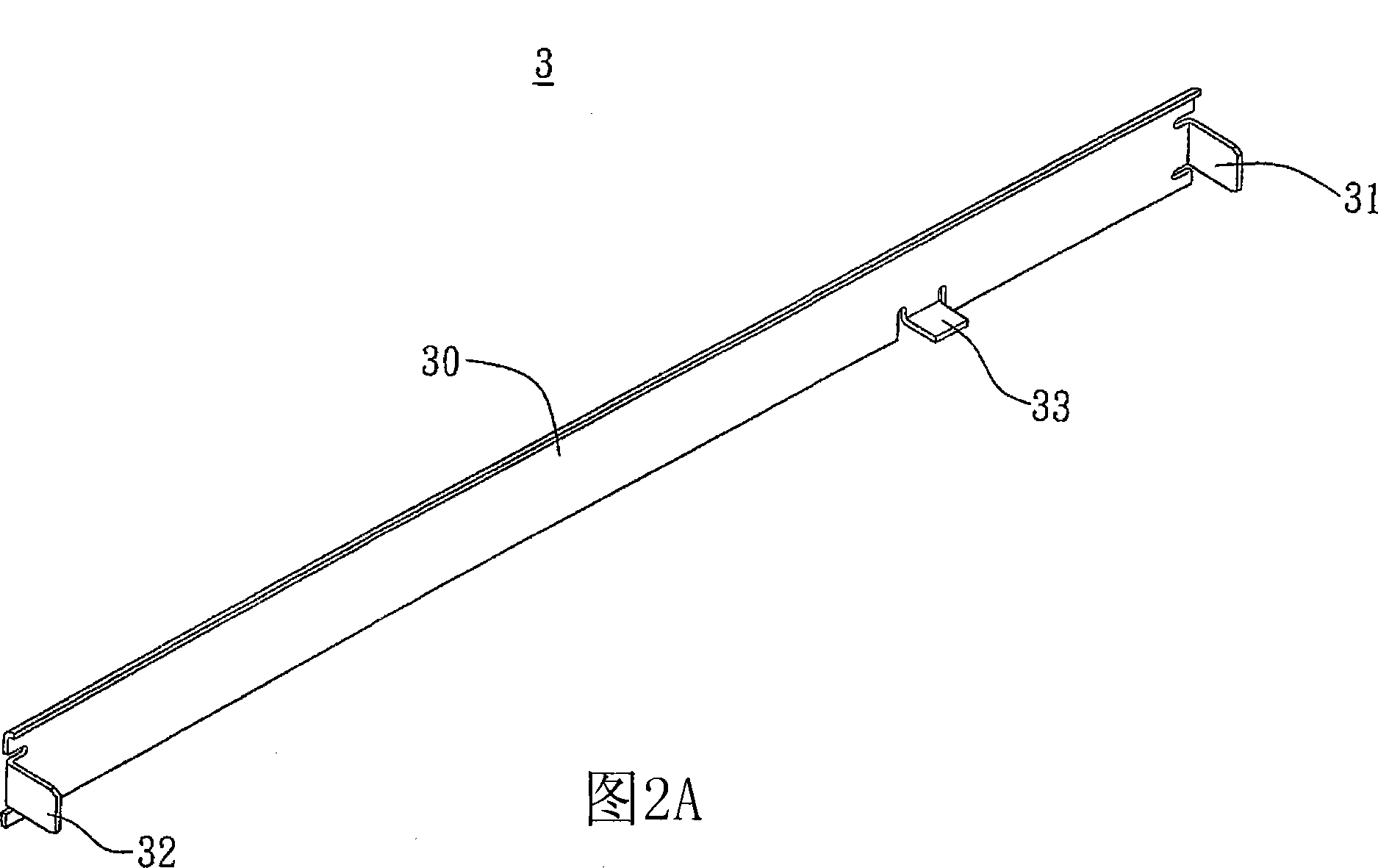

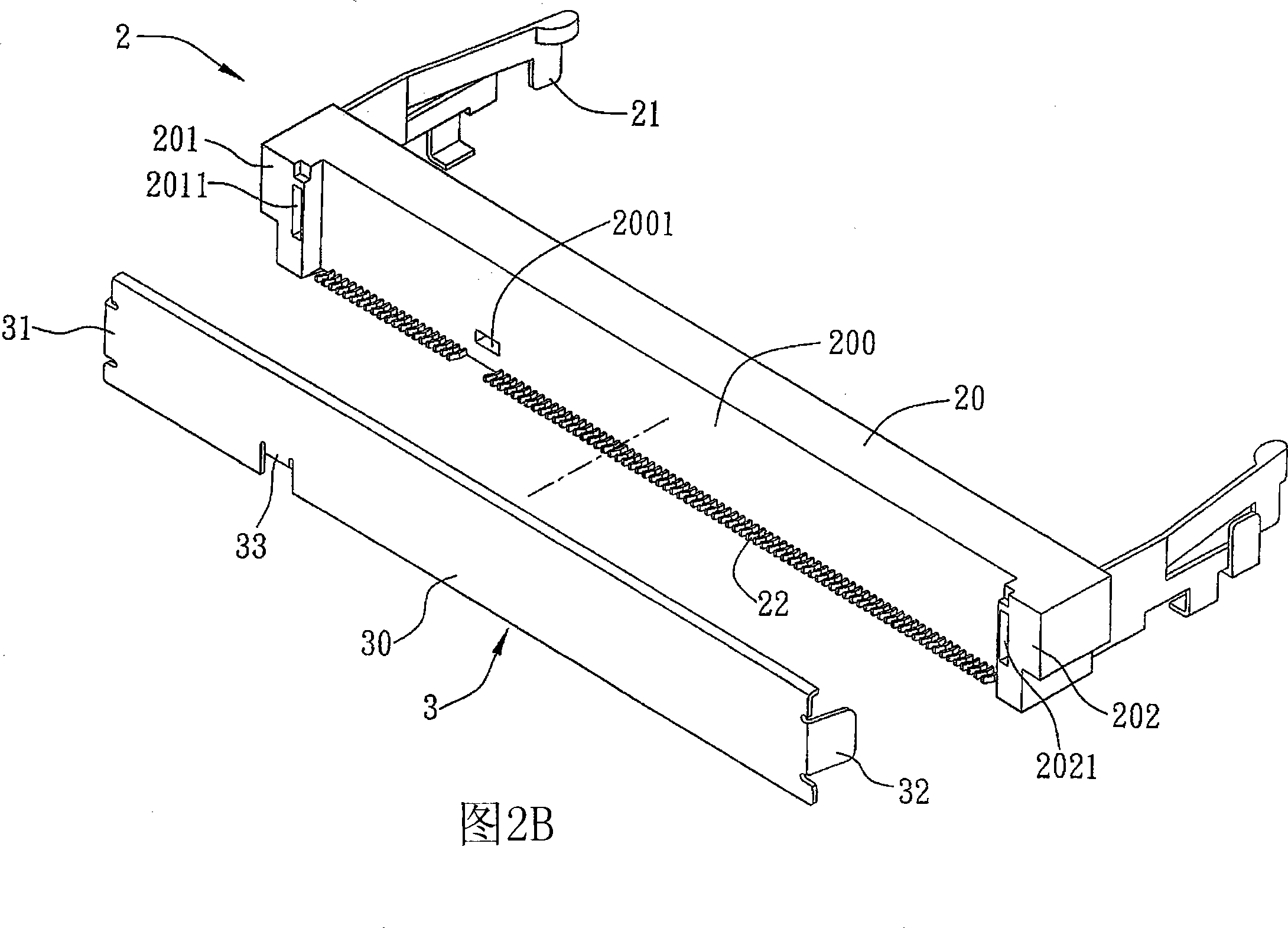

Method and apparatus for assembling die on electronic substrate

InactiveCN101256967AControl warpingAvoid damageSolid-state devicesSemiconductor/solid-state device manufacturingPre stressPre stressing

A method (and apparatus) of assembling a die on an electronic substrate, includes processing an assembly including a substrate and a die, and during the processing, introducing a pre-stress to the assembly during a cure process.

Owner:GLOBALFOUNDRIES INC

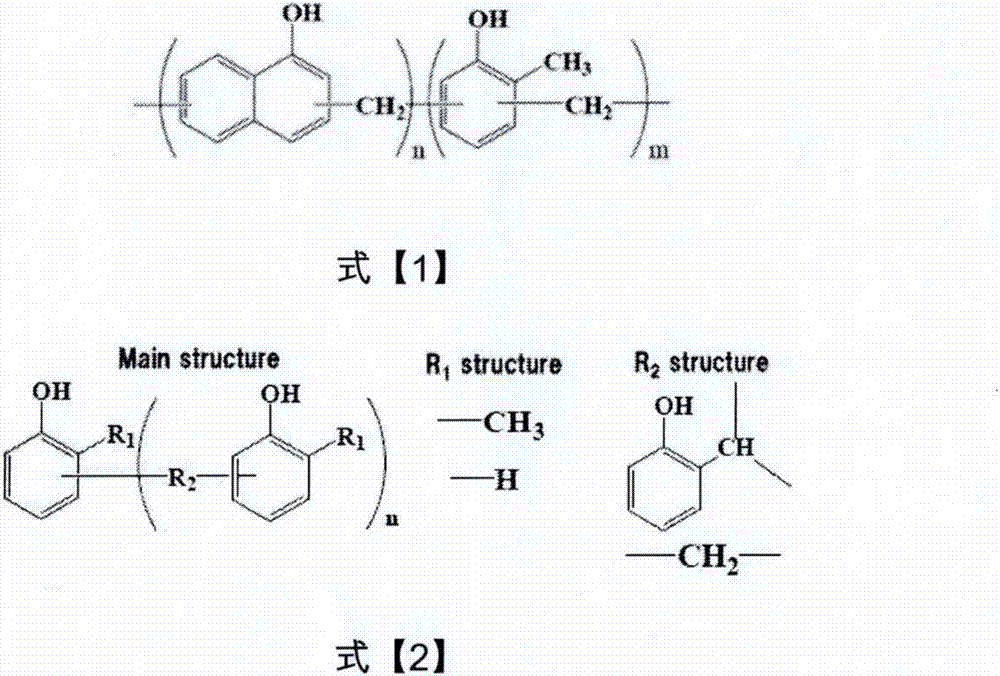

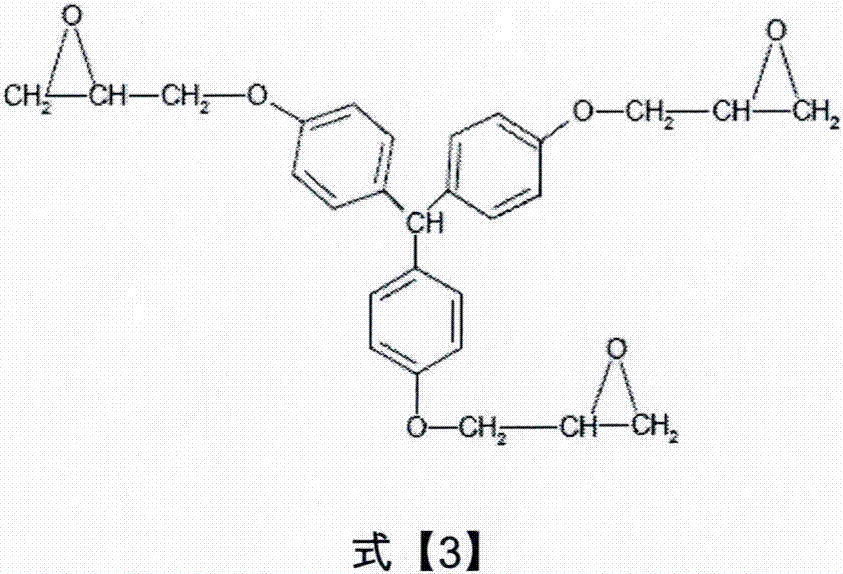

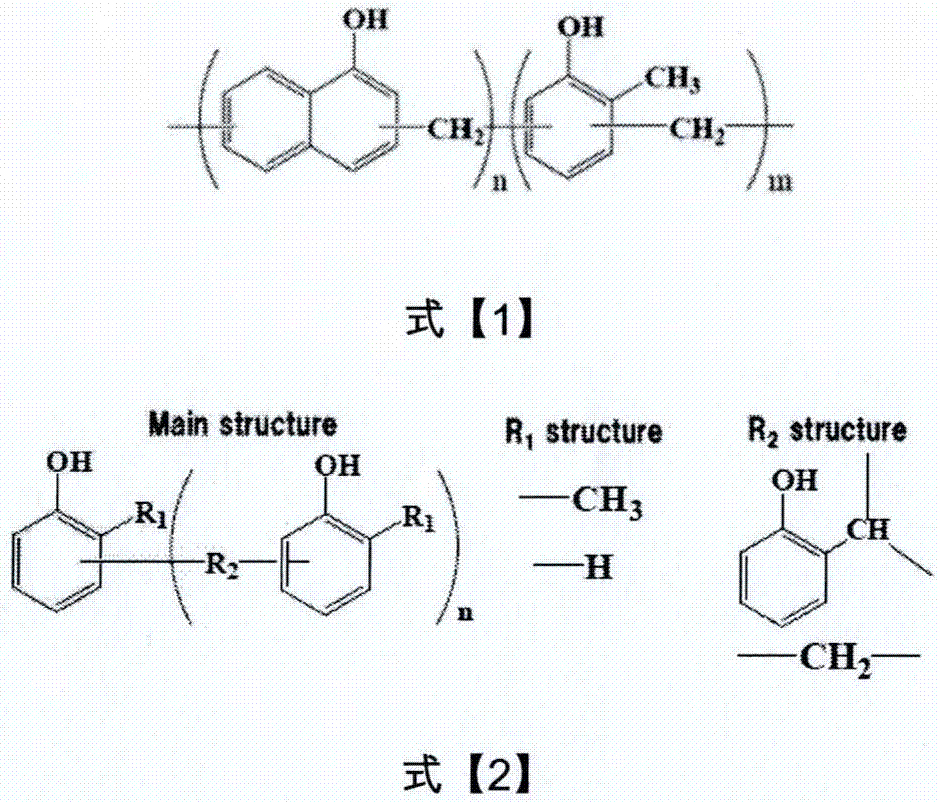

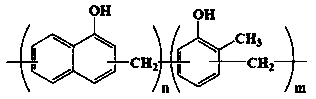

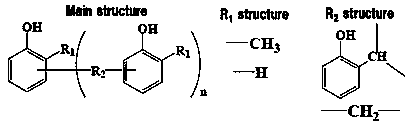

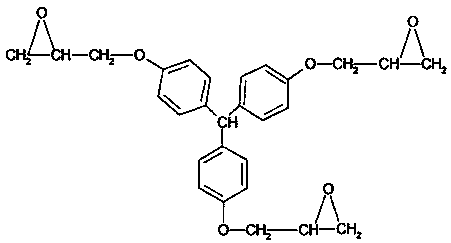

Epoxy resin composition suitable for fan-out wafer level package

ActiveCN107216614AControl warpingHigh glass transition temperatureSemiconductor/solid-state device detailsSolid-state devicesEpoxyGlass transition

The invention discloses an epoxy resin composition suitable for fan-out wafer level package. The epoxy resin composition is prepared from the following main components of epoxy resin, silica powder, curing agent and flow aid, wherein the content of the silica powder accounts for 89 to 93 percent of the total mass of the epoxy resin composition; the curing agent is one or a mixture of components shown in a formula (1) and a formula (2), and accounts for 3 to 8 percent of the total mass of the epoxy resin composition; the epoxy resin is shown as a formula (3), and accounts for 2 to 6 percent of the total mass of the epoxy resin composition; the flow aid is a methoxyl-containing organic silicon resin which accounts for 0.5 to 1 percent of the total mass of the epoxy resin composition. The epoxy resin composition can further contain a proper amount of catalyst, coloring agent, demolding agent, ion catching agent, coupling agent, stress absorbent and the like. The epoxy resin composition has the advantages that the glass transition temperature is remarkably raised, and the bending modulus is lowered. The problems of warping and insufficient liquidity under a large filling amount can be solved, so that continuous production can be realized by using a conventional extruder of the epoxy resin composition.

Owner:JIANGSU HHCK NEW MATERIAL CO LTD

Modular packaging structure and method

InactiveCN111900155AHighly integratedImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesComputer hardwareComputer architecture

The invention provides a modular packaging structure and method. The modular packaging structure comprises: at least one first module arranged in a stacked manner, each comprising a first chip and a second chip arranged opposite to each other, the first chip being electrically led out to a first surface and / or a second surface of the first module, and the second chip being electrically led out tothe first surface and / or the second surface of the first module; and a second module which is attached to the first module and comprises a third chip, wherein the third chip is electrically led out tothe first surface and / or the second surface of the second module, and the second module is electrically connected with the first module.

Owner:SHANGHAI XIANFANG SEMICON CO LTD +1

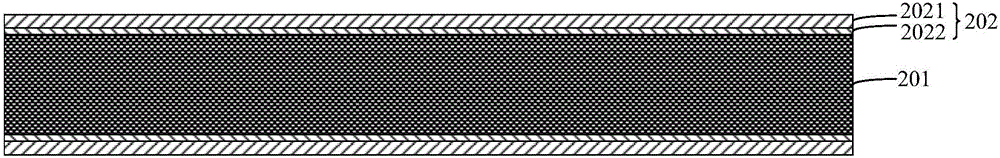

Manufacturing method of substrate used for low-warping polycrystalline silicon solar cell

ActiveCN108807595AAvoid defectsControl warpingFinal product manufacturePhotovoltaic energy generationSand blastingSolar cell

The invention belongs to the technical field of polysilicon substrates, and specifically relates to a manufacturing method of a substrate used for a low-warping polycrystalline silicon solar cell. Theinvention provides a surface sand-blasting texturing mode of the polycrystalline silicon solar cell, and the warping degree of the polycrystalline silicon after texturing can be controlled by using the mode. The two-faced texturing degree of the silicon wafer is adjusted through wet process sand-blasting so as to obtain the silicon wafer with texturing structures on two faces, then the damage degree of the band-blasting processing procedure on two faces of the silicon wafer is judged through the glossiness after texturing on the two faces of the silicon wafer, and then the warping degree of the silicon wafer is controlled so as to reduce the probability of fragment occurrence.

Owner:苏州澳京光伏科技有限公司

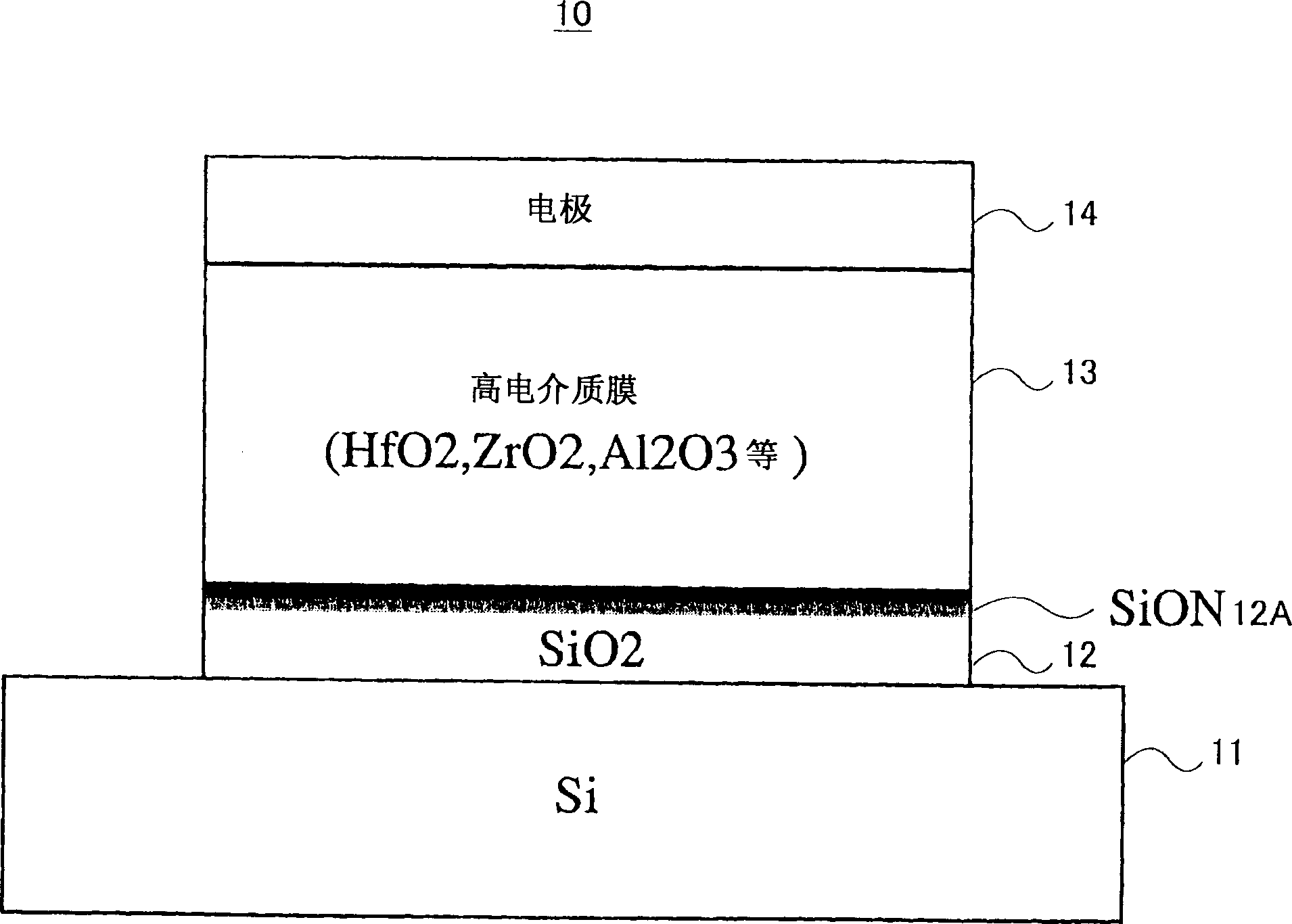

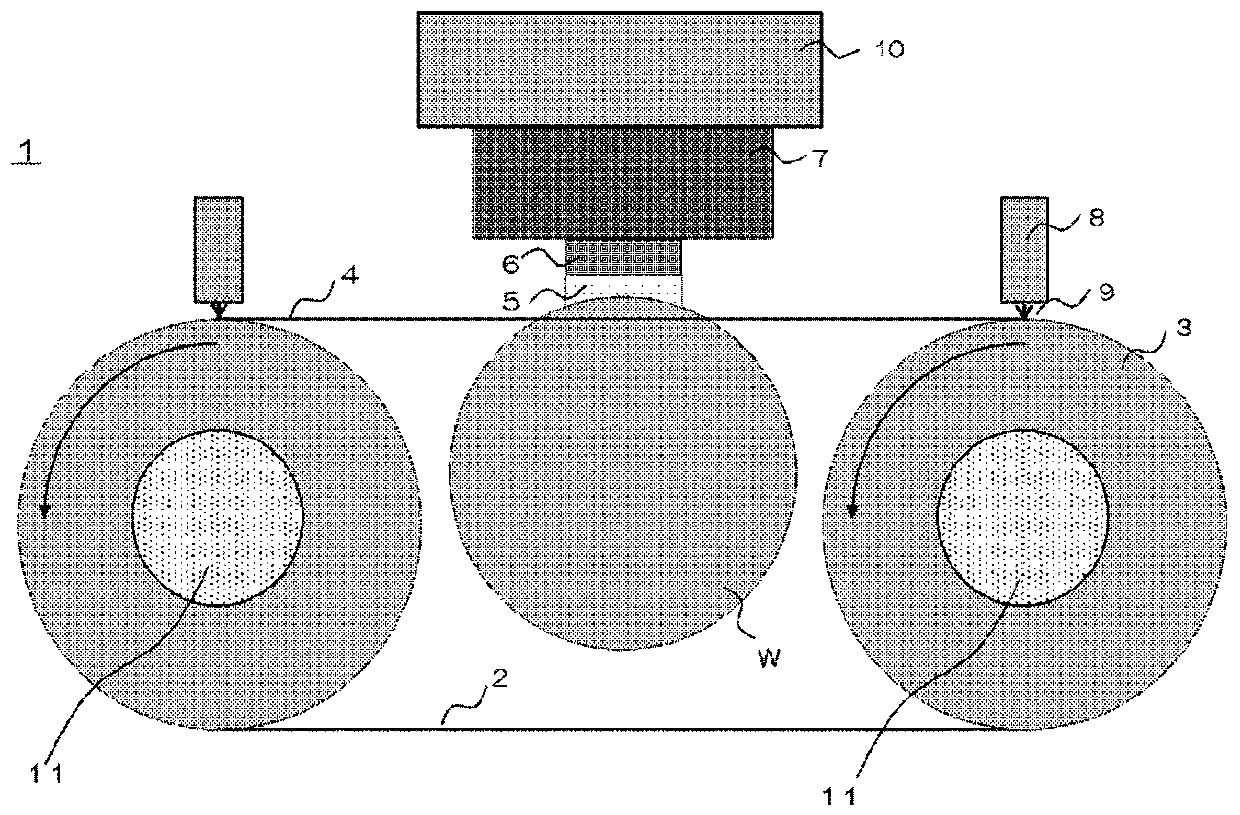

Substrate processing apparatus

InactiveCN1685485AUniform temperature distributionControl warpingSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringDeposition process

The substrate processing apparatus according to the present invention is aimed to stably and efficiently perform a deposition process on a substrate W. The substrate processing apparatus supports the substrate W in a position facing a heater portion and thus rotates a holding member holding the substrate W. Furthermore, the heating portion houses a SiC heater and a heat reflecting member in an internal portion of a quartz bell jar made of transparent quartz, and depressurizes an internal space of a processing vessel and an internal space of the quartz bell jar at the same time; thereby allowing the thickness of the quartz bell jar to be thinner, and thus improving thermal conductivity of heat from the SiC heater and preventing contamination by the SiC heater.

Owner:TOKYO ELECTRON LTD

Double-sided sip three-dimensional packaging structure

ActiveCN107768349BReduce the overall heightSmall sizeSemiconductor/solid-state device detailsSolid-state devicesSolder ballElectromagnetic interference

The invention relates to a double-sided SiP three-dimensional packaging structure, which includes a core adapter board (1). The core adapter board (1) is mounted on the front with a fan-out wafer-level packaging structure (2), a first passive component (3) and the first 3D conductive component (4). The core adapter board (1) is mounted on the back with the chip (7), the second passive component (8) and the second 3D conductive component (6), so A first solder ball (10) is provided on the back of the second 3D conductive component (6), a shielding layer (15) is provided on the top and side surfaces of the packaging structure, and the shielding layer on the front of the first 3D conductive component (4) The layer (15) is provided with openings (16). The present invention can use prefabricated 3D conductive components to become the support structure of the stacked package, and use the 3D conductive components as the grounding end of the electromagnetic shielding, which can reduce the size and height of the package module, improve the high-frequency performance of the package module, and effectively prevent electromagnetic interference. .

Owner:JCET GROUP CO LTD

Warpage control structure for metal base plate, semiconductor module, and inverter device

PendingCN113906553AControl warpingSemiconductor/solid-state device detailsSolid-state devicesPhysical chemistryInverter

Owner:MITSUBISHI ELECTRIC CORP

Semiconductor packaging part and manufacturing method therefor

InactiveCN106876364AOffset stressAvoid warpingSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipSemiconductor package

The invention provides a semiconductor packaging part and a manufacturing method therefor. The semiconductor packaging part comprises a substrate, a dielectric layer, a rewiring structure, a semiconductor chip, and an encapsulating layer, wherein the substrate comprises a first surface, a second surface back to the first surface, and conductive columns which extend in the substrate to connect the first surface and the second surface; the dielectric layer is positioned on the first surface of the substrate; the rewiring structure is arranged in the dielectric layer and electrically connected to the conductive columns; the semiconductor chip is arranged on the dielectric layer and electrically connected to the rewiring structure; and the encapsulating layer is positioned on the dielectric layer and encapsulates the semiconductor chip, wherein each of the substrate and the encapsulating layer is formed by a moulding material.

Owner:SAMSUNG SEMICON CHINA RES & DEV +1

Aqueous solution for surface treatment of tin films and method for preventing discoloration of a tin film surface

ActiveCN1924091BGood solder wettabilityControl warpingSemiconductor/solid-state device detailsSolid-state devicesTin platingAqueous solution

To provide a solder-plating film which has good solder wettability and with which discoloration and twisting of the tin film after heat treatment are prevented. A method and a solution for surface treating a tin film are disclosed. The aqueous solution contains specific compounds and is brought into contact with a tin-plating film before reflow treatment of the tin film.

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

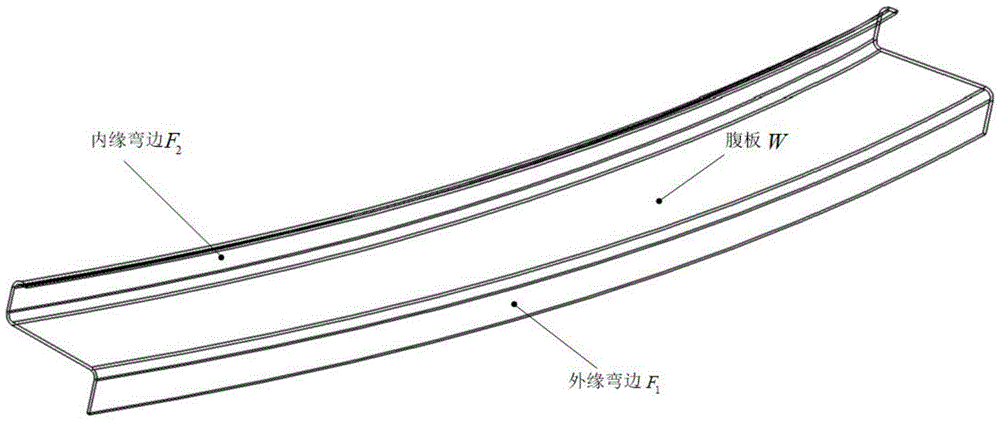

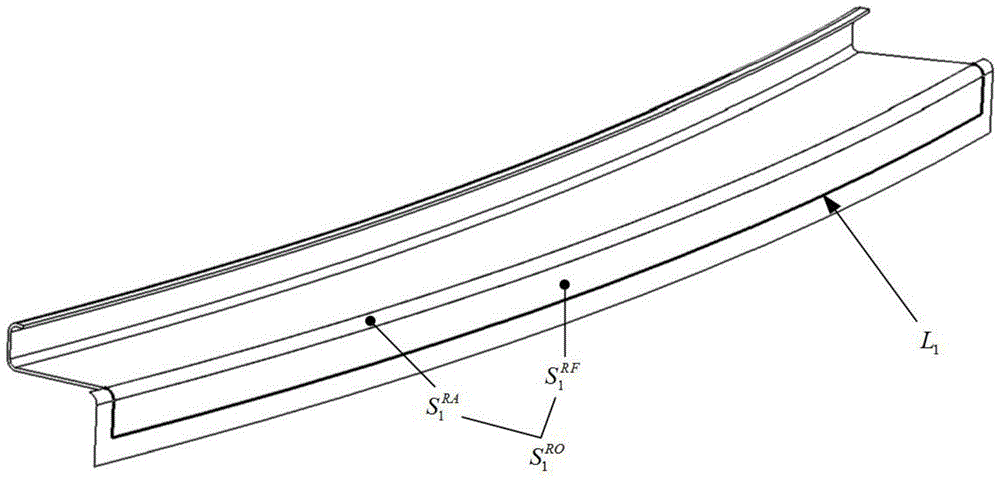

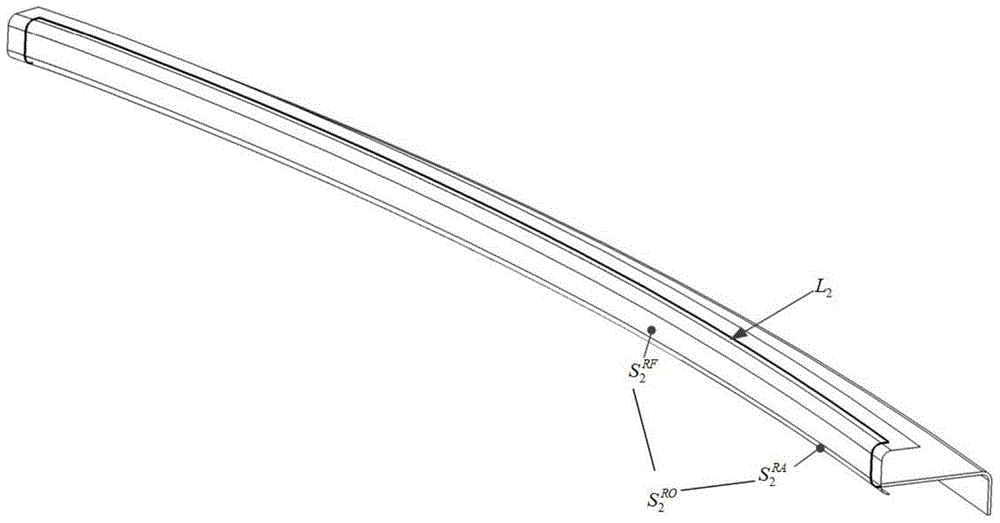

A Web Warpage Control Method for Large Frame Sheet Metal Parts

ActiveCN105081133BControlled reboundControl warpingAircraft componentsEngineeringMechanical engineering

The invention provides a method for controlling warping of a web of a large frame type sheet metal part, and belongs to the technical field of aircraft manufacturing. For a large frame type sheet metal part of which the variable curvature, the variable section and the length are more than 1m, the method is that a technological rib groove structure is added to the outer flank of bent edge of the outer side of frame type rib part, so as to enable uniform distribution of the stress on the bent edge of the outer side of such parts after forming. The method is applicable to further control of the warping of the web of the large frame type part of which the bent edge section is complex and the curvature and the sectional linear dimension are changed constantly according to the bent edge line after forming and unloading, on the basis of springback compensation. With the adoption of the method, the springback of the part can be controlled, and the warping of the web of the part can be effectively controlled; after being formed, the part can simply meet the requirement on accurate formation without or with little manual repair by tapping, so that the forming quality and the production efficiency of the large frame type part can be obviously improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

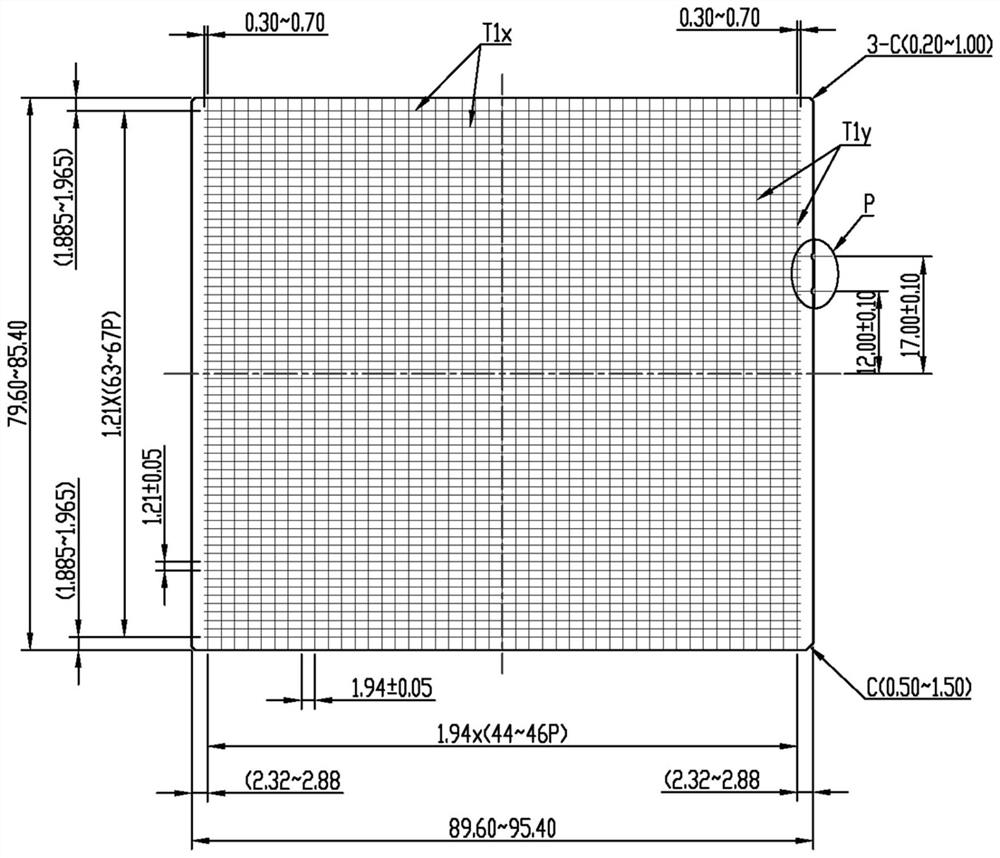

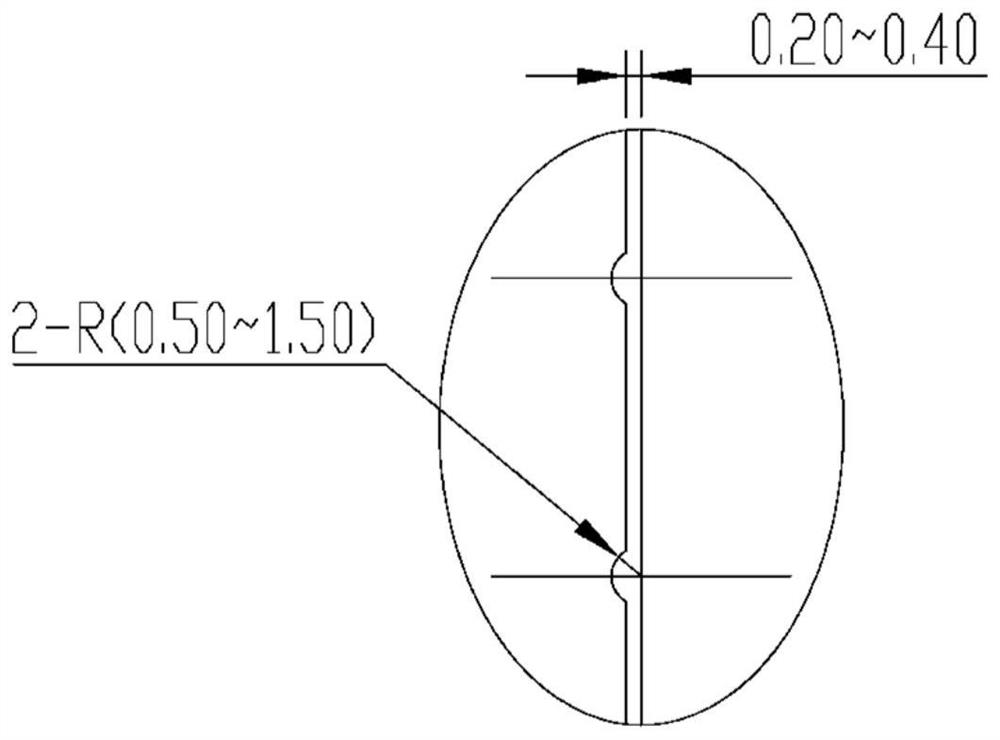

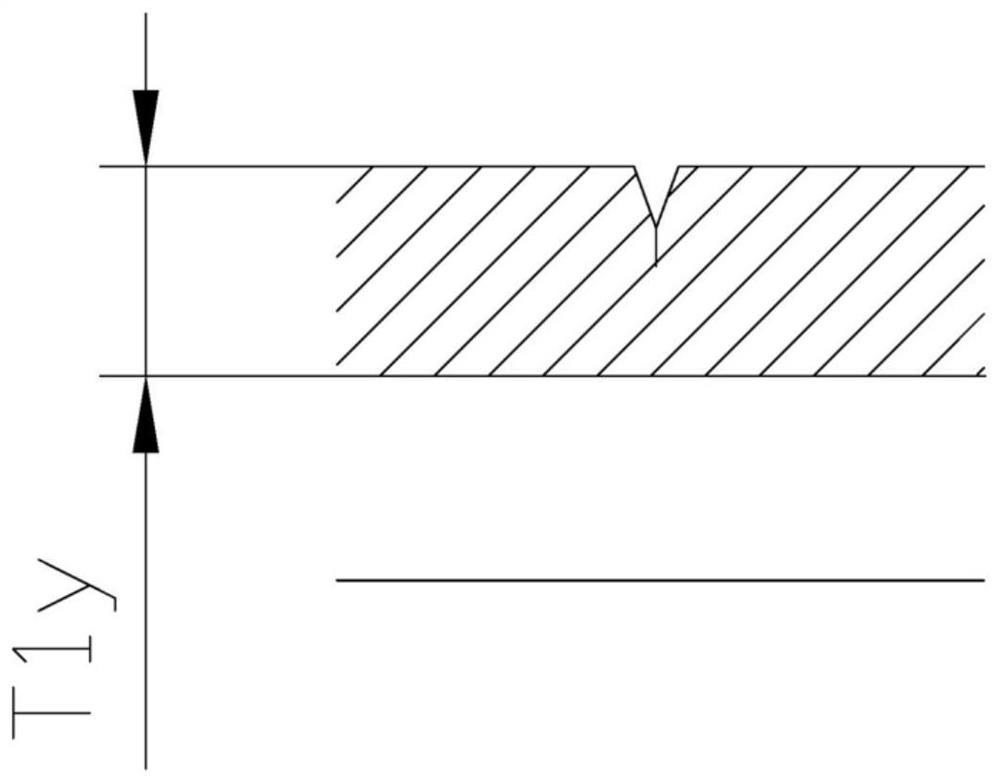

A large size ceramic substrate

ActiveCN112863793BIncrease productivityControl warpingResistor manufactureNon-adjustable resistorsCeramic substrateComposite material

The invention discloses a large-sized ceramic substrate. This large-sized ceramic substrate includes a ceramic substrate body; a sheet-forming area, which is arranged on the surface of the ceramic substrate body; a white edge, which is arranged around the sheet-forming area; the sheet-forming area is provided with There are several primary dents and secondary dents formed on the surface of the ceramic substrate body; the primary dents and the secondary dents intersect vertically; the depth of the primary dents is greater than the depth of the secondary dents; The outer dimensions of the ceramic substrate are as follows: length≥89.60mm, width≥79.60mm, thickness≥0.43mm. The invention greatly increases the production efficiency of the substrate by increasing the length and width of the ceramic substrate, and can effectively control the occurrence of warpage, which is conducive to large-scale automatic production and reduces the cost of materials, labor and time.

Owner:NANCHONG THREE CIRCLE ELECTRONICS +1

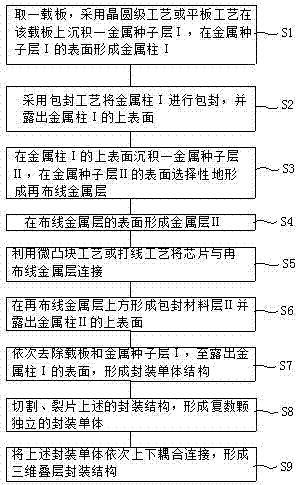

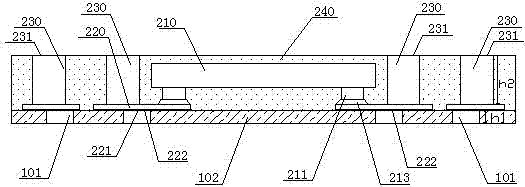

A three-dimensional stacked packaging structure and packaging method thereof

ActiveCN104576579BSimple processImprove efficiencySemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageSolder ball

The invention discloses a three-dimensional laminated packaging structure and a packaging method thereof, belonging to the technical field of semiconductor packaging. It includes a plurality of packaging monomers packaged up and down. The packaging monomer includes a chip package and a lower package. The chip package includes at least one chip and a rewiring metal layer. The lower surface of the rewiring metal layer is provided with the chip package. The lower input / output terminal is on the same side of the chip, and the far chip end of the rewiring metal layer is provided with metal pillar II, and the metal pillar II is fixedly connected with the rewiring metal layer to form the upper input / output end of the chip package; the lower package The metal pillar I is fixedly connected to the lower input / output end of the chip package, and the encapsulation material layer I encapsulates the metal pillar I, and exposes the lower surface of the metal pillar I, forming the input / output end of the lower package body; adjacent up and down The two package monomers are connected by solder balls / solder bumps. The three-dimensional stacked packaging structure formed by the invention does not need a carrier board to carry chips, has a simple structure, and conforms to the development trend of miniaturization.

Owner:JIANGYIN CHANGDIAN ADVANCED PACKAGING CO LTD

A Method for Improving Deformation Penetration of Thick Gauge Steel Plate in Hot Rolling Process

ActiveCN104525588BImprove deformation resistanceAvoid deformationWork treatment devicesMetal rolling arrangementsThick plateSheet steel

A method for improving the deformation permeability of thick-sized steel plates during hot rolling, which is characterized by setting up uniform and rapid cooling devices immediately adjacent to the mouth of the medium-thick plate rolling mill or the hot-band roughing mill, with a length of 5 to 15 m and a total cooling water volume of 3000 to 6000 m3 / h; Before rolling, the slab is uniformly and asymmetrically cooled on the upper and lower surfaces, forming a low-temperature hardened layer on the surface of the slab, and the temperature gradient with the core reaches 2~3°C / mm, and before the slab returns to red after cooling Quickly enter the rolling mill for differential temperature rolling to improve the deformation of the core of the slab; and further combine it with asynchronous rolling to deepen the deformation of the core of the slab and solve the problem of asynchronous rolling through asymmetric cooling of the upper and lower surfaces of the slab before rolling. warping problem caused by manufacturing. For steel types that require two-stage controlled rolling, the uniform rapid cooling equipment involved in the present invention can replace the intermediate cooling equipment, shorten or even eliminate the waiting time for the swing steel to warm up, and improve production efficiency.

Owner:NORTHEASTERN UNIV LIAONING

A method for manufacturing a substrate for low warpage polysilicon solar cells

ActiveCN108807595BAvoid defectsControl warpingFinal product manufacturePhotovoltaic energy generationCrystallographySand blasting

The invention belongs to the technical field of polysilicon substrates, and specifically relates to a manufacturing method of a substrate used for a low-warping polycrystalline silicon solar cell. Theinvention provides a surface sand-blasting texturing mode of the polycrystalline silicon solar cell, and the warping degree of the polycrystalline silicon after texturing can be controlled by using the mode. The two-faced texturing degree of the silicon wafer is adjusted through wet process sand-blasting so as to obtain the silicon wafer with texturing structures on two faces, then the damage degree of the band-blasting processing procedure on two faces of the silicon wafer is judged through the glossiness after texturing on the two faces of the silicon wafer, and then the warping degree of the silicon wafer is controlled so as to reduce the probability of fragment occurrence.

Owner:苏州澳京光伏科技有限公司

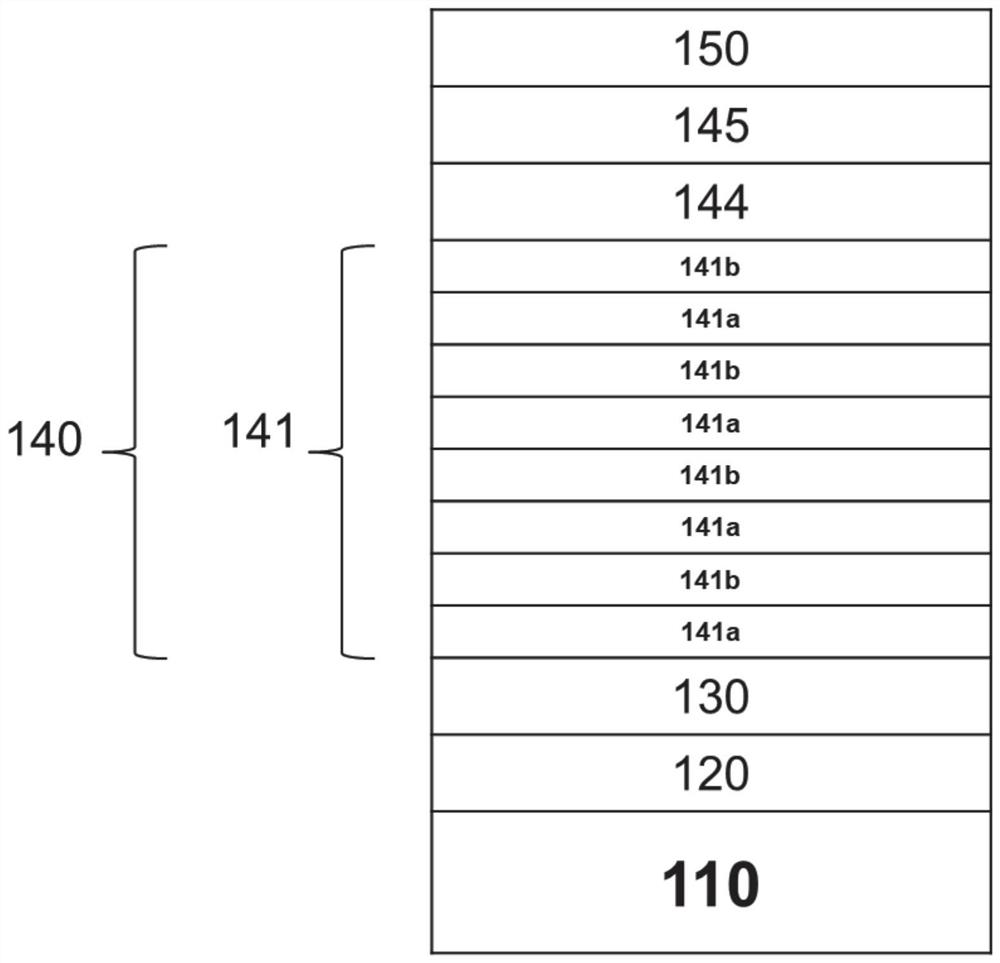

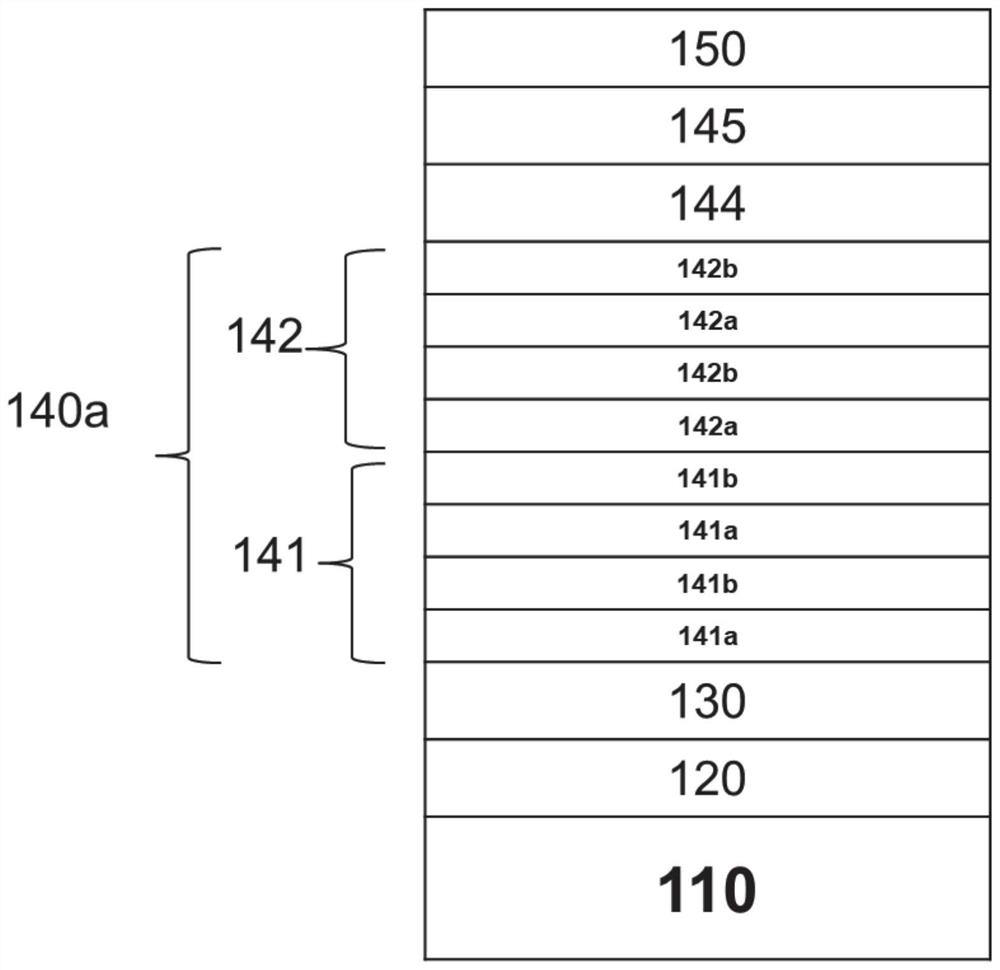

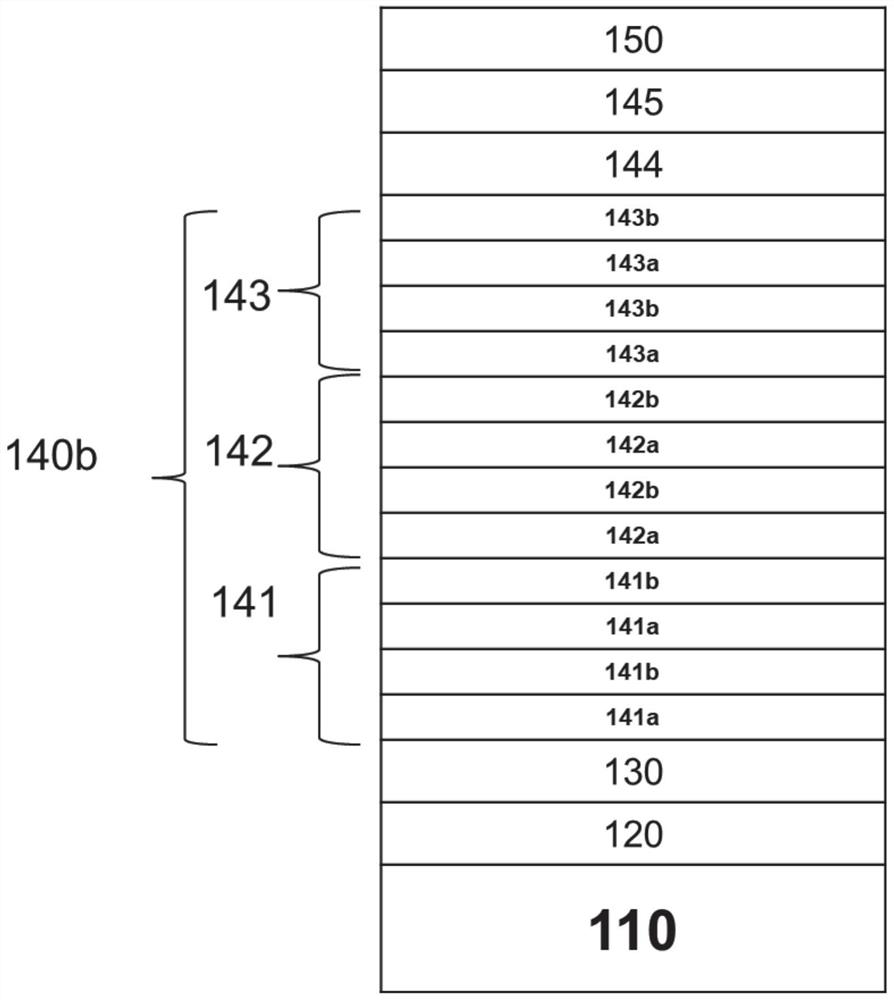

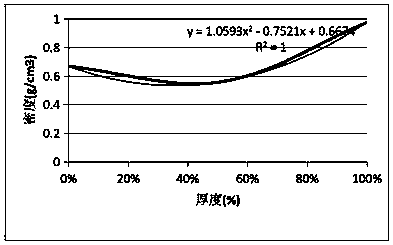

Nitride semiconductor epitaxial structure

PendingCN114823853AReduce stressImprove qualitySemiconductor devicesFinal product manufactureCrystallographyGallium nitride

The invention discloses a nitride semiconductor epitaxial structure, which comprises a substrate, a nucleating layer, a transition layer, a composite buffer layer, a top gallium nitride layer and a coating layer are sequentially arranged on the substrate, the transition layer is an AlxGaN layer, the composite buffer layer comprises a first composite buffer layer, the first composite buffer layer comprises a plurality of Aly1GaN layers and a plurality of GaN layers which are mutually overlapped, y1 is greater than x, and y2 is greater than x. The Aly1GaN layers in the first composite buffer layer are the same in thickness, and the first GaN layers are the same in thickness. According to the method, the epitaxial layer is grown through superlattices, warping can be effectively controlled, the quality of gallium nitride is improved, defects are reduced, the product yield is increased, in the growth method of the superlattice composite buffer structure, different aluminum content growth modes are added, warping can be further effectively improved, and the product yield is increased.

Owner:南京百识电子科技有限公司

Flattened bamboo high-strength composite laminate with sawtooth interlocking structure and manufacturing method thereof

ActiveCN107984581BImprove compactnessImprove stabilityPlywood pressesWood compressionComposite laminatesSingle plate

The invention discloses a sawtooth-interlocking-structure flattened bamboo high-strength composite laminated board and a manufacturing method thereof. A flattened bamboo veneer is manufactured througha sawtooth interlocking structure, so that the tensile stress generated by flattening among tabasheer tissues can be effectively released. In the tooth pressing process, the compactness of the tabasheer surface is improved to a certain extent, the density of the inner wall of a bamboo is increased, and warping and cracking caused by uneven internal stress and density distribution after the bamboois flattened can be effectively controlled. A composite laminated board basic unit is formed by gluing two flattened bamboos in a sawtooth occlusion mode, in the composite laminated board made of thesawtooth interlocking structure, the gluing area is increased due to the sawtooth structure, and the shear resistance is greatly enhanced. The density distribution of the cross section of the composite laminated board unit is balanced, the strength of the upper surface and the lower surface of the composite laminated board unit is high, and the anti-shearing capacity of the middle part is high, so that the structural design requirements of bending-resistant components are met; and the composite laminated board subjected to sawtooth occlusion treatment can effectively control deformation generated by internal stress of the bamboo, and the stability and the durability of the composite laminated board are greatly improved.

Owner:INT CENT FOR BAMBOO & RATTAN

An epoxy resin composition suitable for fan-out wafer level packaging

ActiveCN107216614BControl warpingHigh glass transition temperatureSemiconductor/solid-state device detailsSolid-state devicesEpoxyGlass transition

The invention discloses an epoxy resin composition suitable for fan-out wafer level package. The epoxy resin composition is prepared from the following main components of epoxy resin, silica powder, curing agent and flow aid, wherein the content of the silica powder accounts for 89 to 93 percent of the total mass of the epoxy resin composition; the curing agent is one or a mixture of components shown in a formula (1) and a formula (2), and accounts for 3 to 8 percent of the total mass of the epoxy resin composition; the epoxy resin is shown as a formula (3), and accounts for 2 to 6 percent of the total mass of the epoxy resin composition; the flow aid is a methoxyl-containing organic silicon resin which accounts for 0.5 to 1 percent of the total mass of the epoxy resin composition. The epoxy resin composition can further contain a proper amount of catalyst, coloring agent, demolding agent, ion catching agent, coupling agent, stress absorbent and the like. The epoxy resin composition has the advantages that the glass transition temperature is remarkably raised, and the bending modulus is lowered. The problems of warping and insufficient liquidity under a large filling amount can be solved, so that continuous production can be realized by using a conventional extruder of the epoxy resin composition.

Owner:JIANGSU HHCK NEW MATERIAL CO LTD

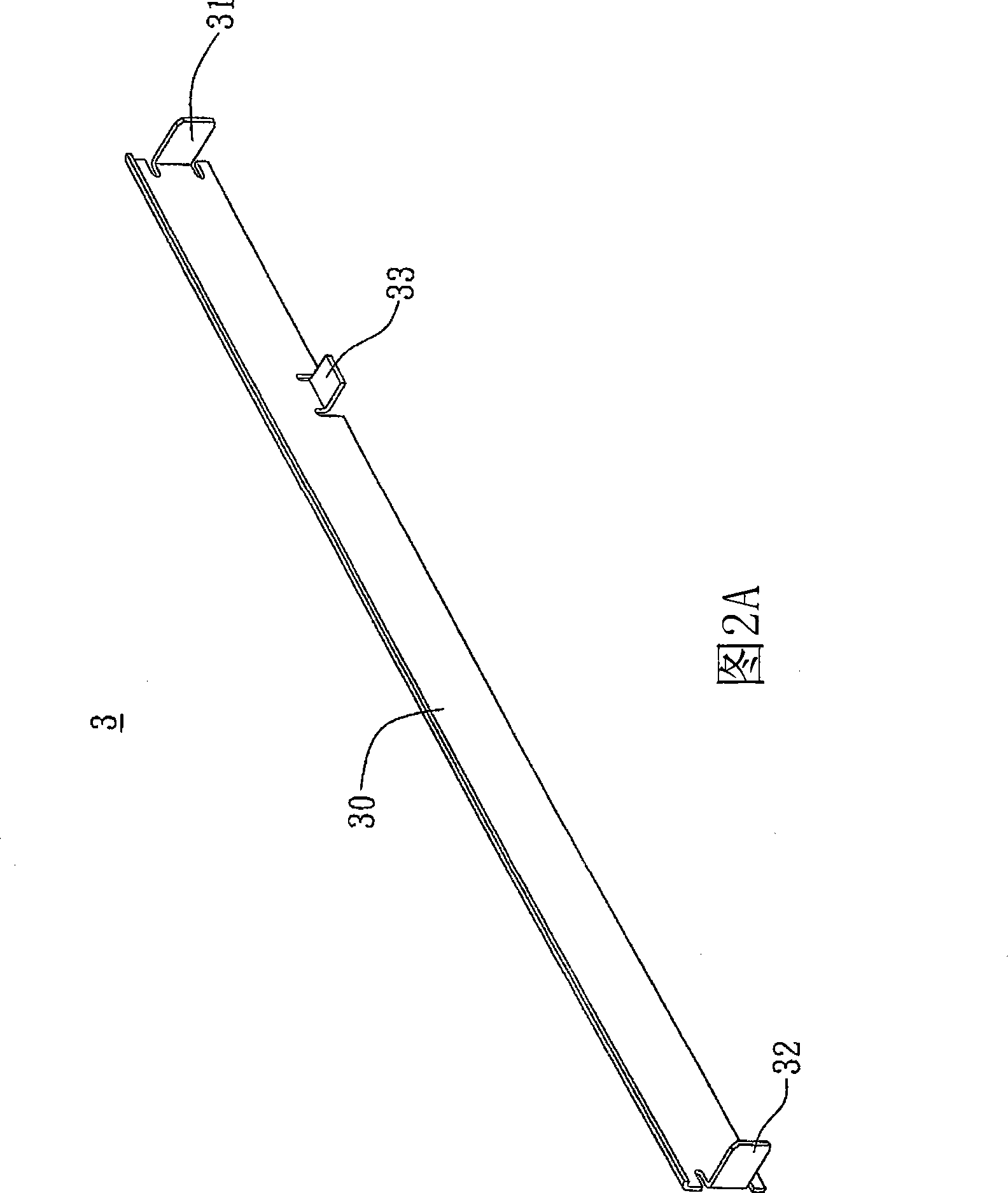

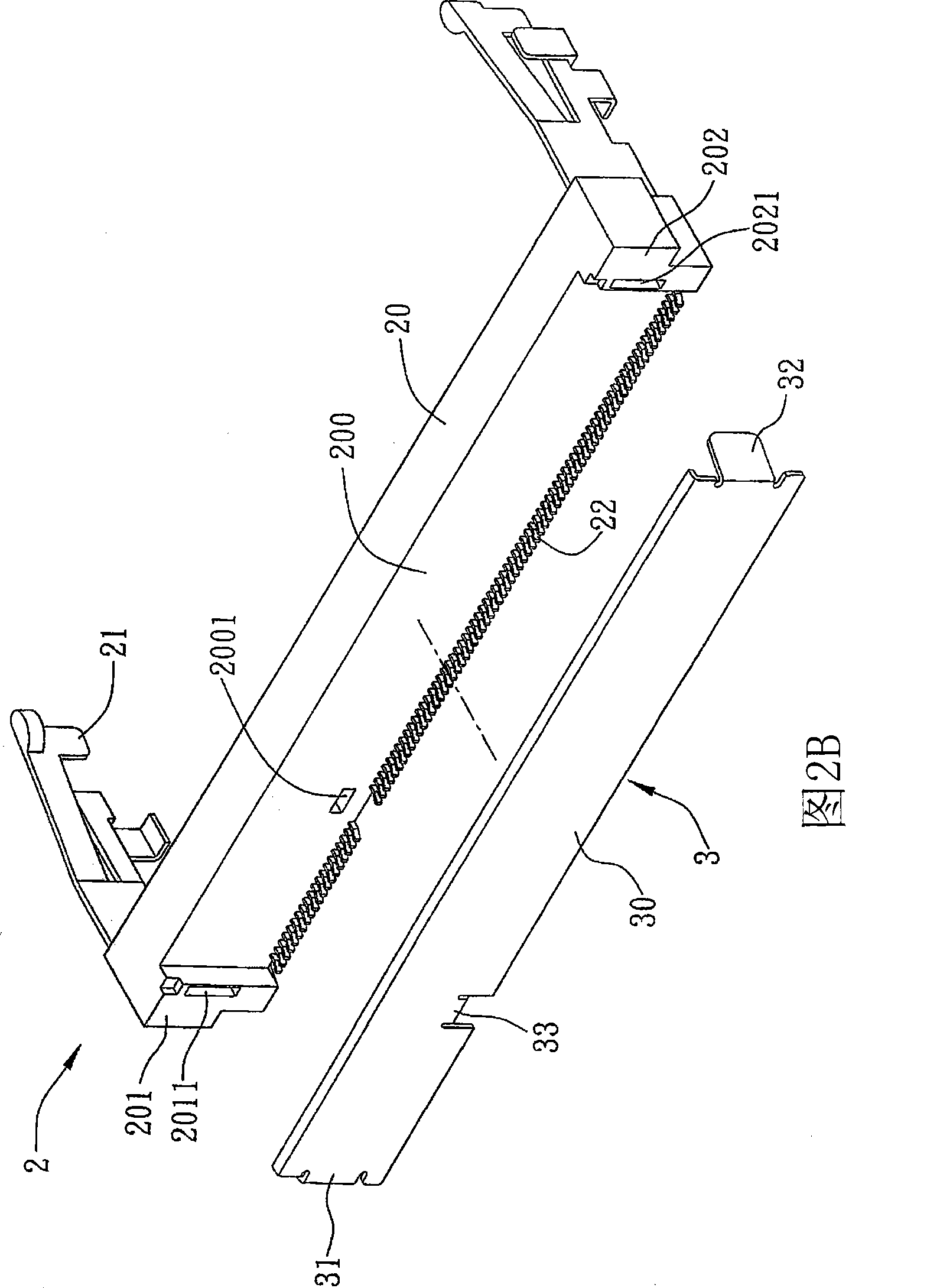

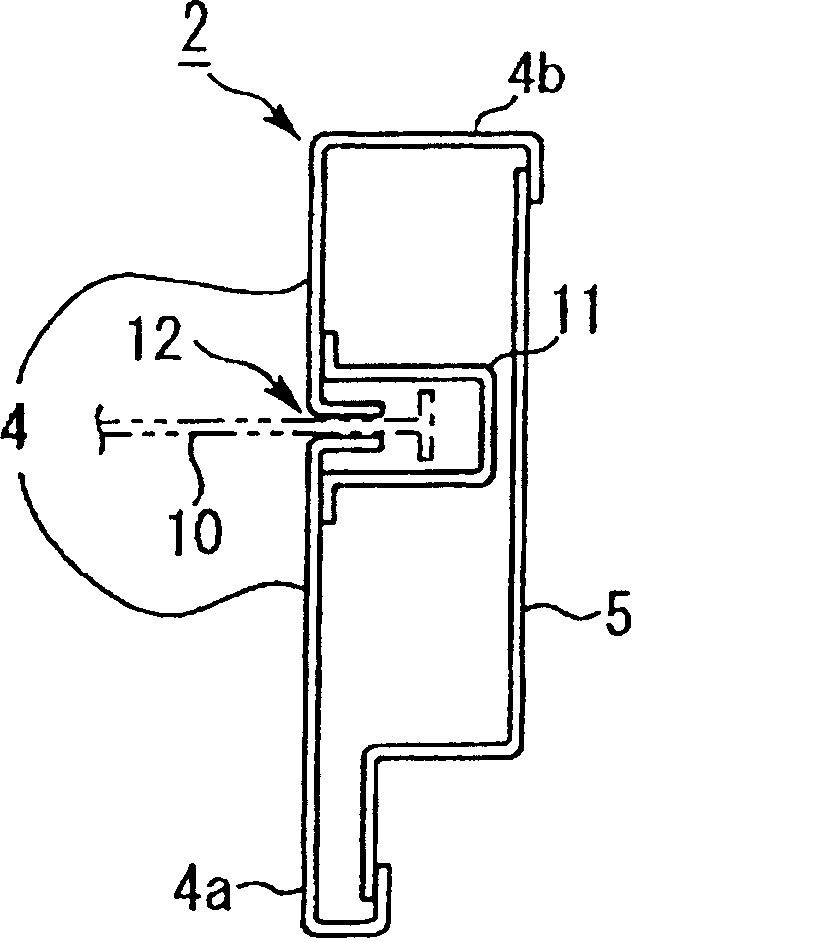

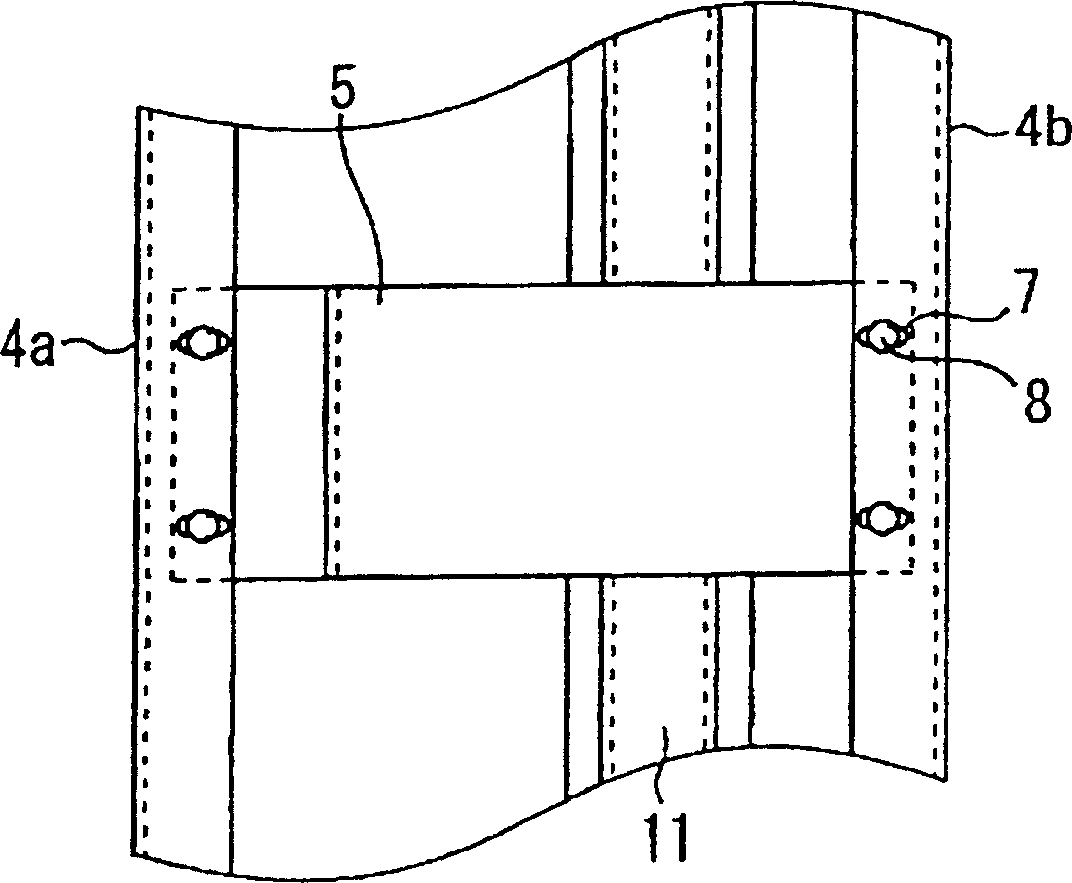

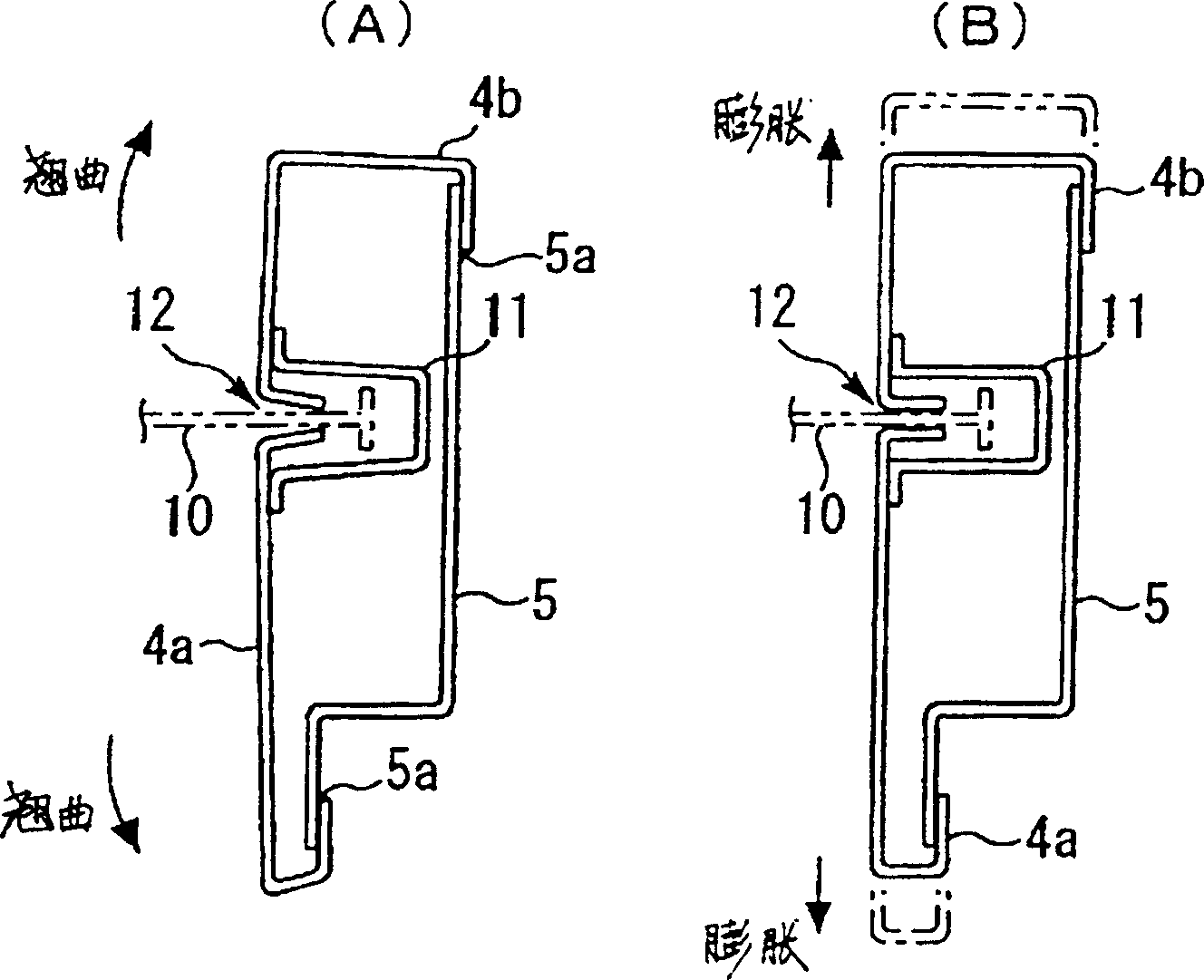

Floor entvance device for elevator

This elevator landing entrance device comprises a surface plate 4 constituting a decorated face of a vertical frame 2 of a jamb; a reinforcing member 5 enabling the surface plate 4 to slide at a joint part in a horizontal direction at the time of thermal expansion of the surface plate 4; and a fire protecting shutter 10 guided by a rail groove 12 and lowered by an upper frame 3 of the jamb. As another constitution of this invention, the reinforcing member 5 is composed of a material having a linear expansion coefficient larger than the surface plate 4, or ends are rotatably jointed to both ends of the surface plate 4 at stepped positions against a horizontal direction, bridging both ends of the surface plate 4. The rear plate 6 is separated from the surface plate 4 and jointed with the reinforcing member 5.

Owner:MITSUBISHI ELECTRIC CORP

Polarizing film group with adhesive layer, liquid crystal panel and liquid crystal display device

ActiveCN106054437BSmall Humidity Expansion CoefficientSuppress changesNon-linear opticsOptical elementsAdhesivePolarizer

The present invention provides a polarizing film set with an adhesive layer which is controlled so that warpage at normal temperature and normal humidity is reduced when used in a liquid crystal panel. The polarizing film set with an adhesive layer has a polarizing film with a first adhesive layer disposed on the observation side of an IPS mode liquid crystal cell and a polarizing film with a second adhesive layer disposed on the back side of the liquid crystal cell. The first polarizing film of the polarizing film with the first adhesive layer has a humidity expansion coefficient of 1.0×10 on one side of the first polarizer with a thickness of 25 μm or less. ‑6 The first transparent protective film (b11) below / % RH has a surface treatment layer on the other side, and the first transparent protective film (b11) side is arranged on the polarizing film on the side of the liquid crystal cell, and the above-mentioned second adhesive The second polarizing film of the polarizing film of the agent layer has a first transparent protective film (b21) on at least one side of the second polarizing plate with a thickness of 10 μm or less, and a brightness is attached to the side where the second adhesive layer is not provided. Raise the membrane.

Owner:NITTO DENKO CORP

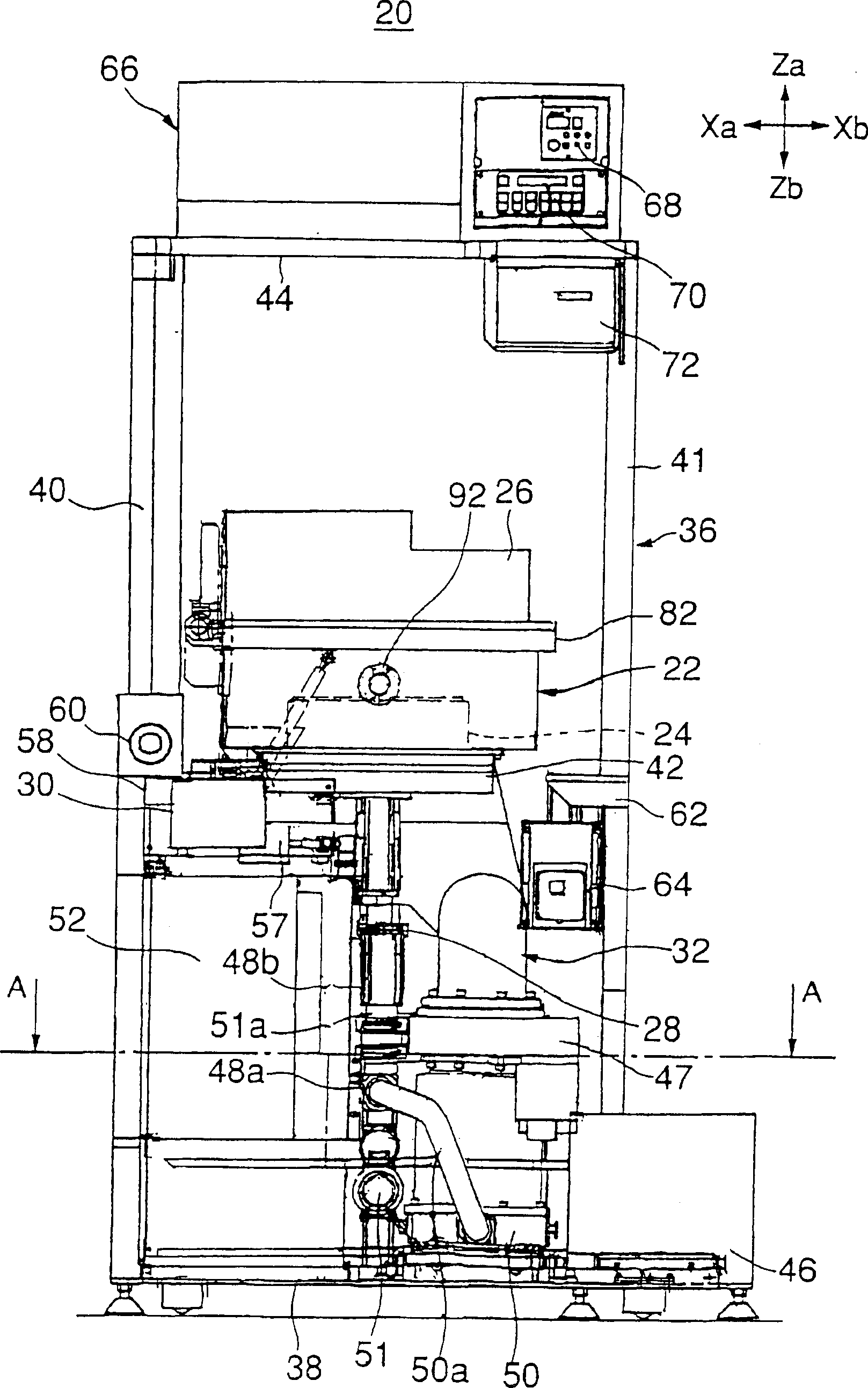

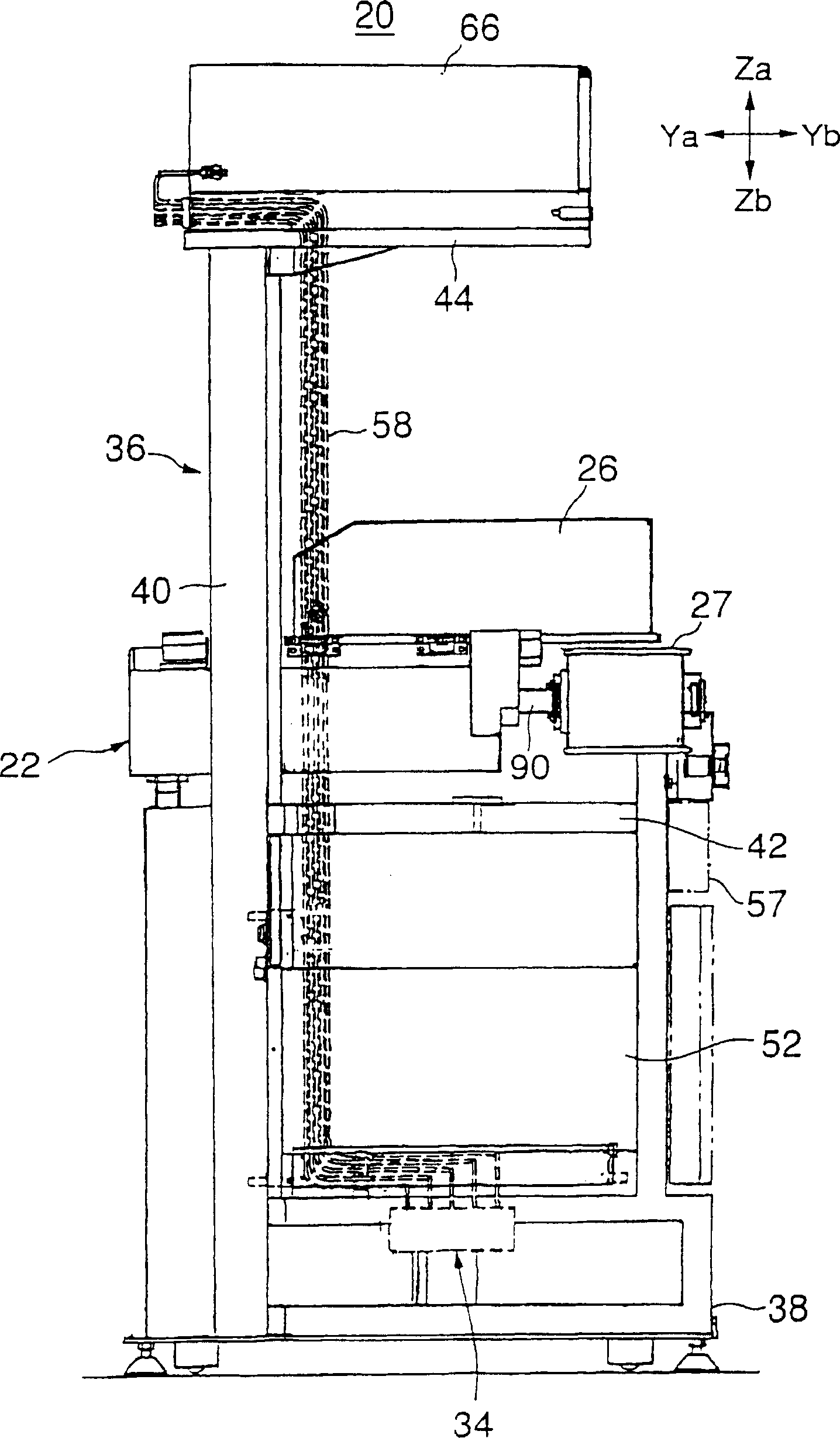

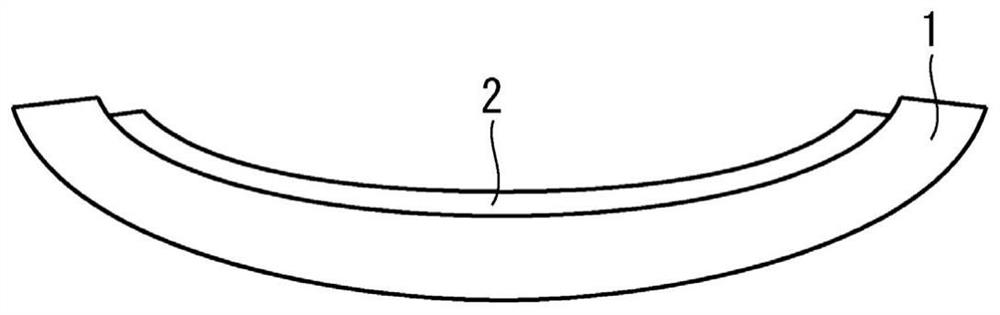

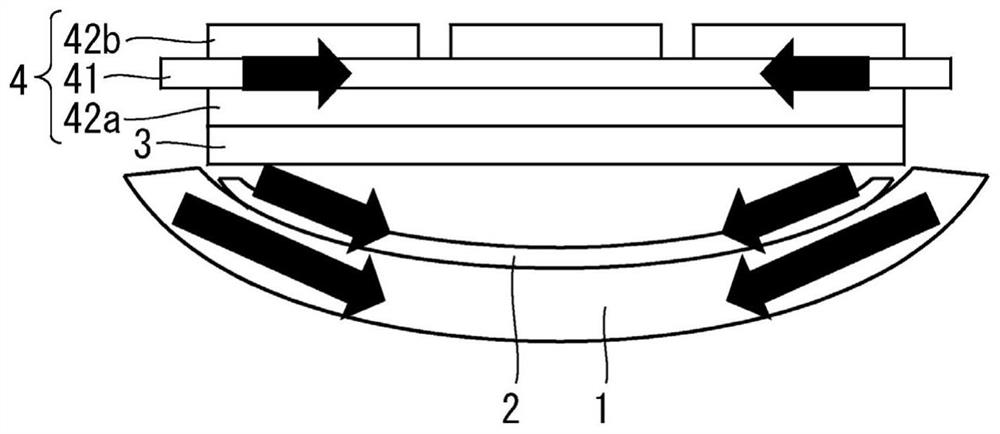

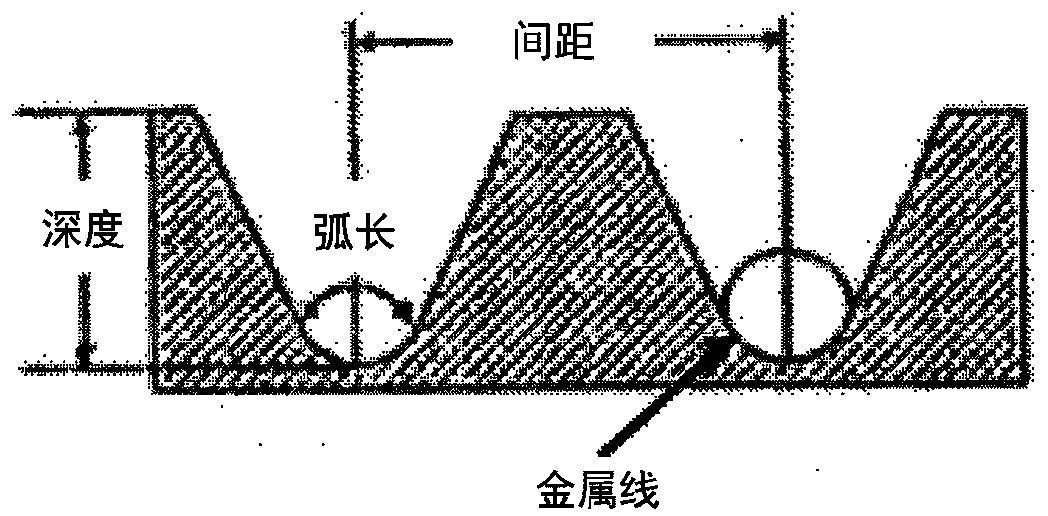

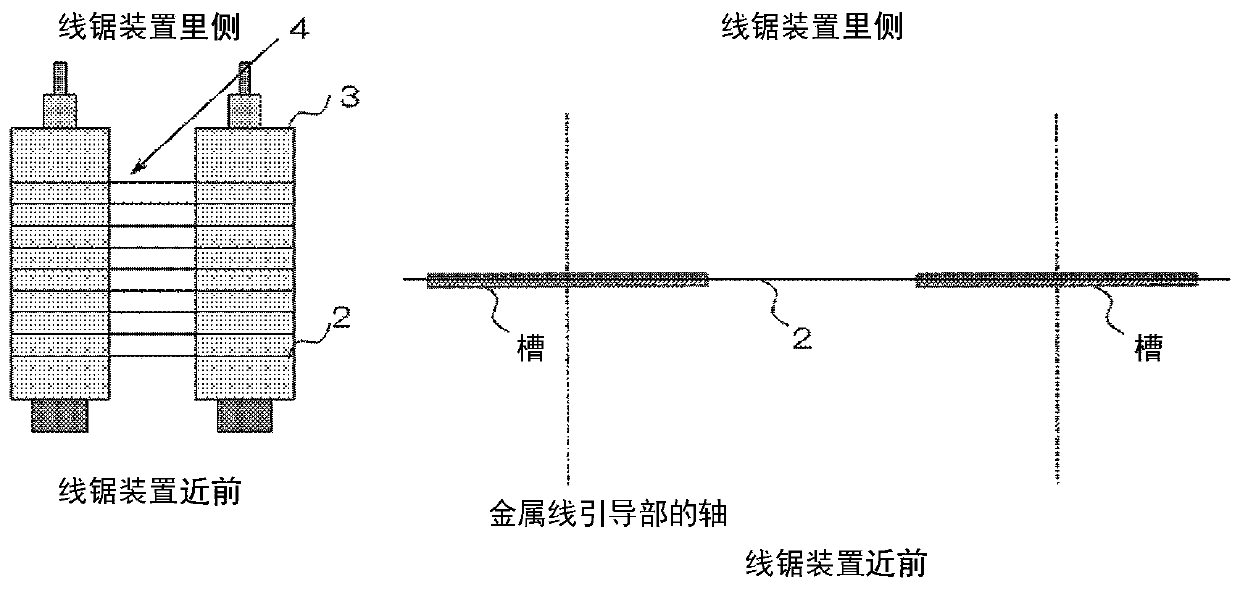

Wire saw device and wafer manufacturing method

ActiveCN111418045AArbitrary warping shapeControl warpingSemiconductor/solid-state device manufacturingGrinding machinesWaferStructural engineering

This wire saw device comprises: a plurality of wire guides; a wire row that is formed by a wire wound onto the plurality of wire guides and travels reciprocally in the axial direction; a nozzle that supplies coolant or slurry to the wire; a workpiece holding part that suspends and holds, via a beam, a workpiece plate on which a workpiece is attached; and a workpiece feeding mechanism that pressesthe workpiece against the wire row. The wire saw device is characterized by being provided with a mechanism for adjusting the degree of parallelism of the axes of the plurality of wire guides formingthe wire row. Due to this configuration, a wire saw device and a wafer manufacturing method are provided with which the warp of the workpiece in the wire movement direction after cutting is controlledand a wafer having any warp shape can be manufactured.

Owner:SHIN-ETSU HANDOTAI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com