Substrate processing apparatus

一种基板处理装置、基板的技术,应用在气态化学镀覆、加热元件材料、涂层等方向,能够解决膜厚增加等问题,达到防止污染、提高生产率、防止裂纹的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

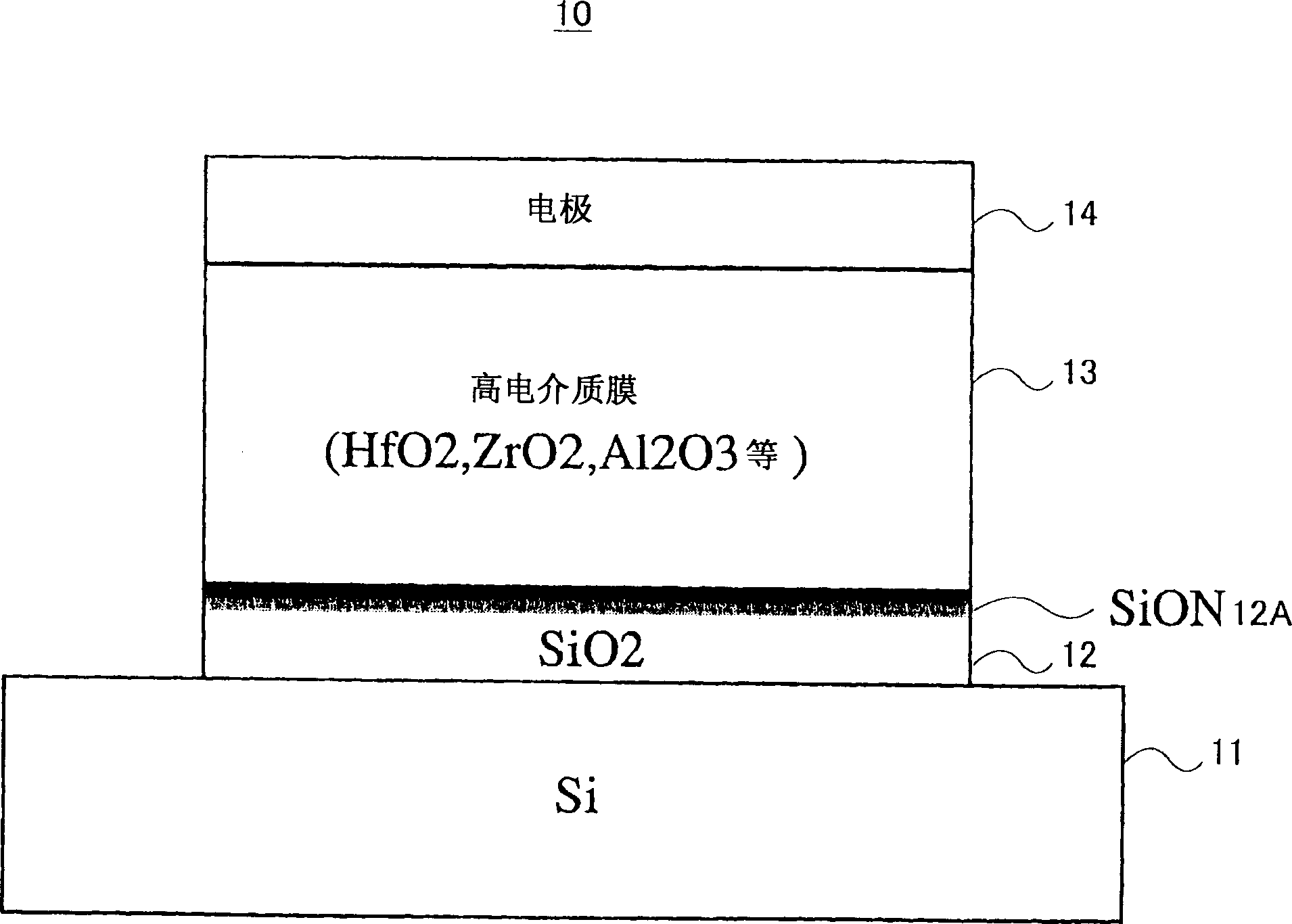

[0114] with the following Figure 1 Embodiments of the present invention will be described first.

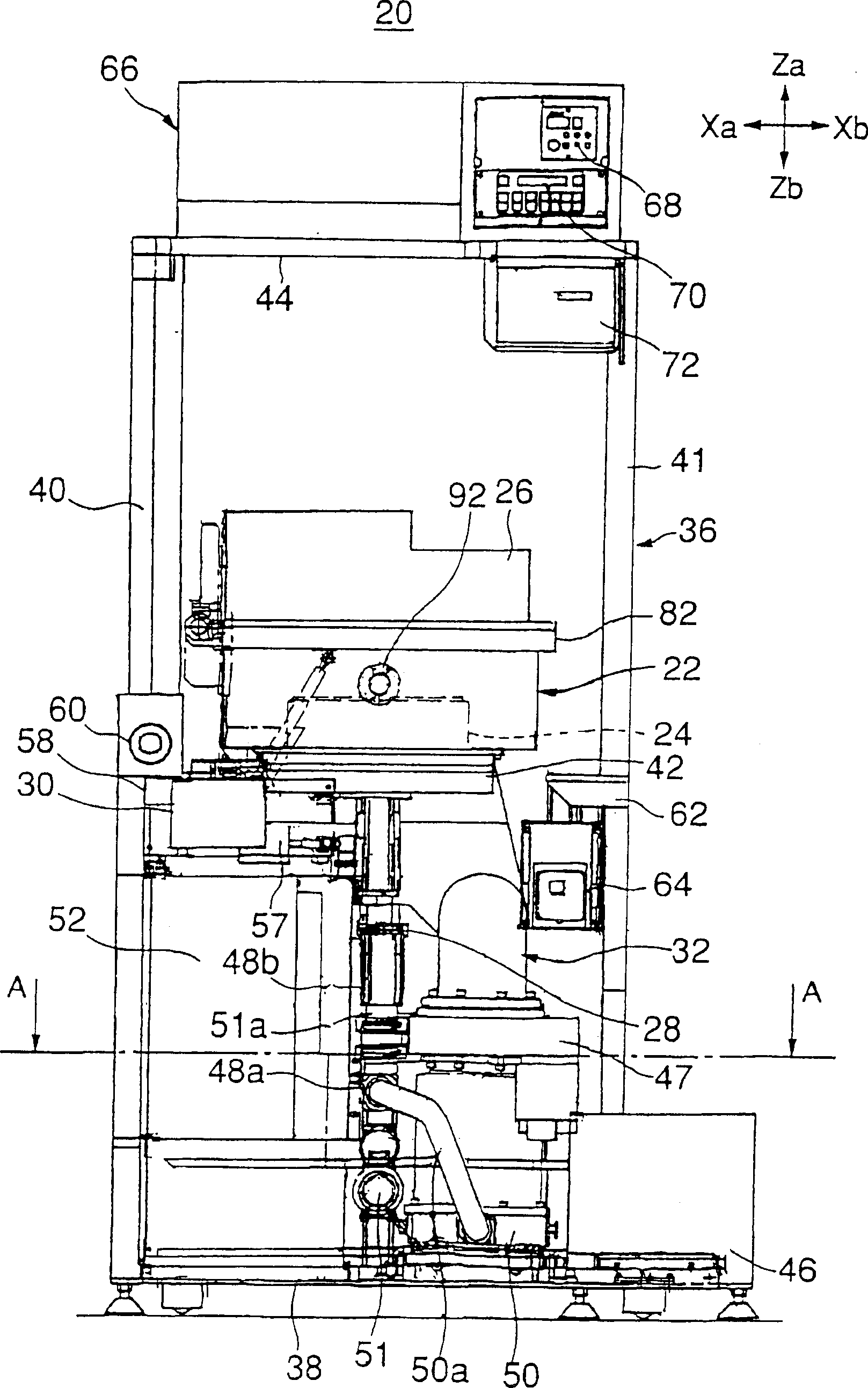

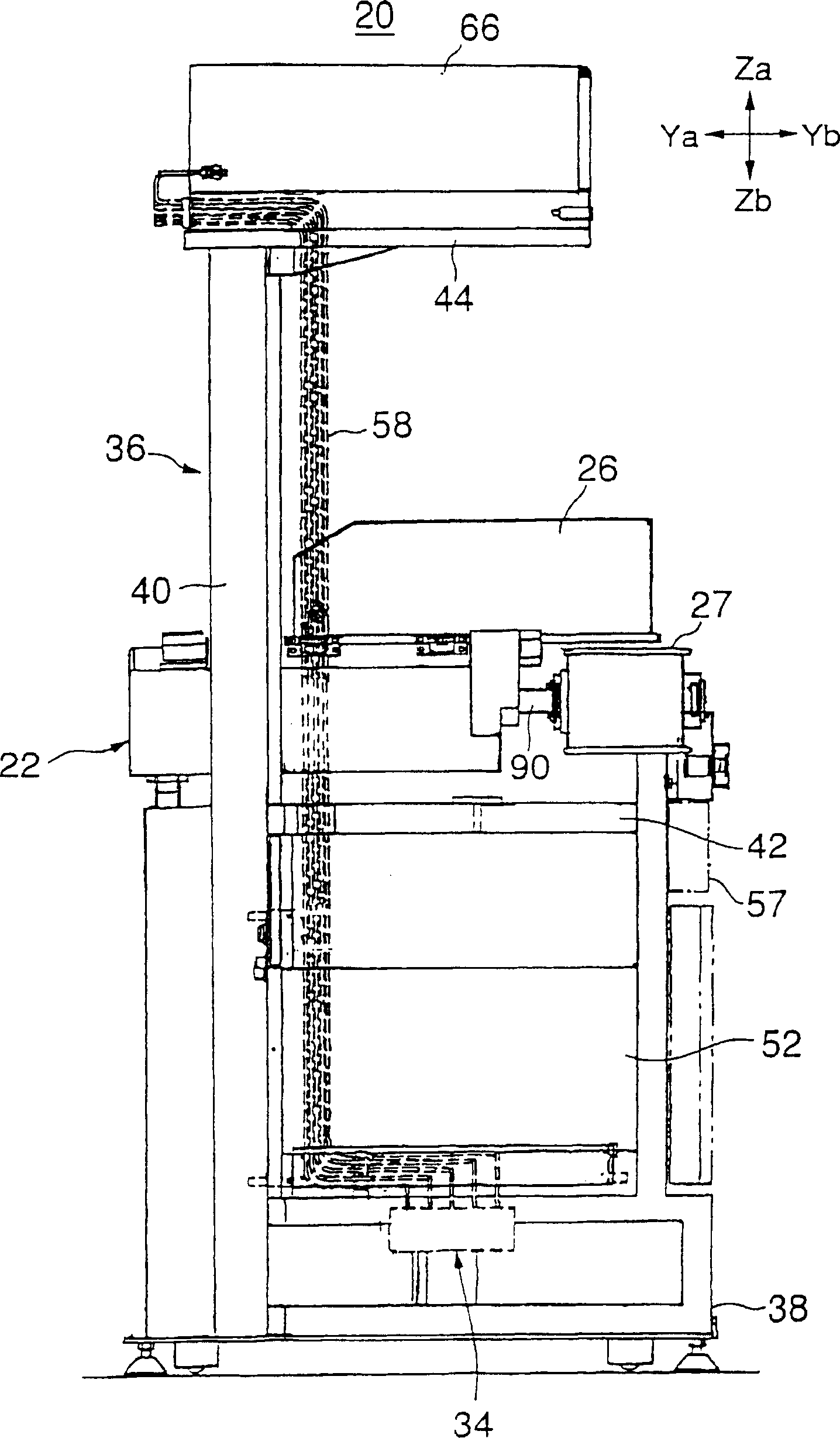

[0115] figure 2 It is a front view showing the structure of an embodiment of the substrate processing apparatus of the present invention. image 3 It is a side view showing the structure of one embodiment of the substrate processing apparatus of the present invention. Figure 4 for along figure 2 A cross-sectional view of line A-A in the center.

[0116] Such as Figure 2 to Figure 4As shown, the substrate processing apparatus 20 can continuously carry out the ultraviolet light radical oxidation treatment of the silicon substrate and the free radical oxidation film formed by such ultraviolet light radical oxidation treatment using a high-frequency remote plasma as described later. The method of base nitriding treatment constitutes.

[0117] The main structure of the substrate processing apparatus 20 includes a processing container 22 forming a processing space inside, a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com