Patents

Literature

44results about How to "Controlled rebound" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

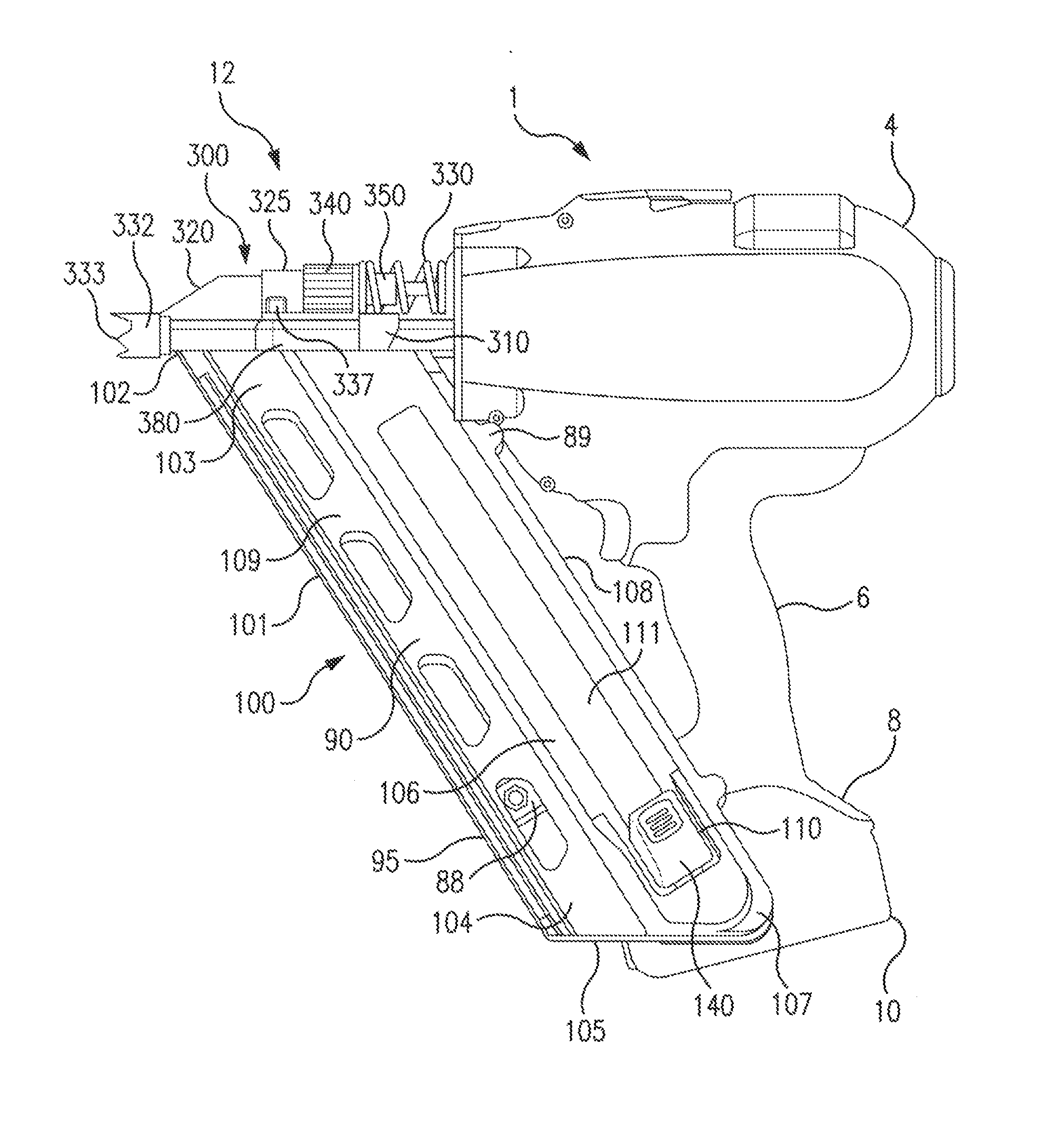

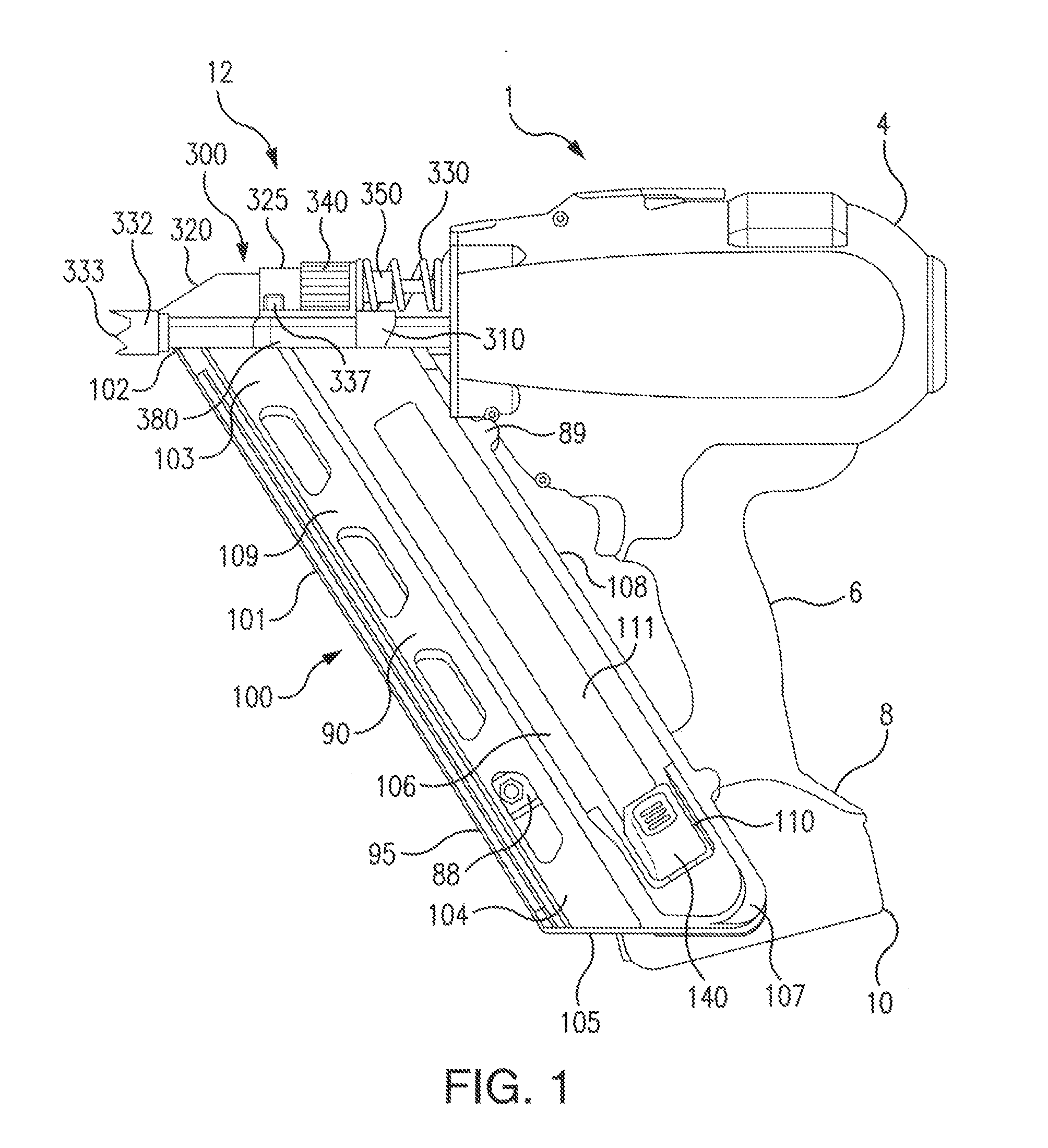

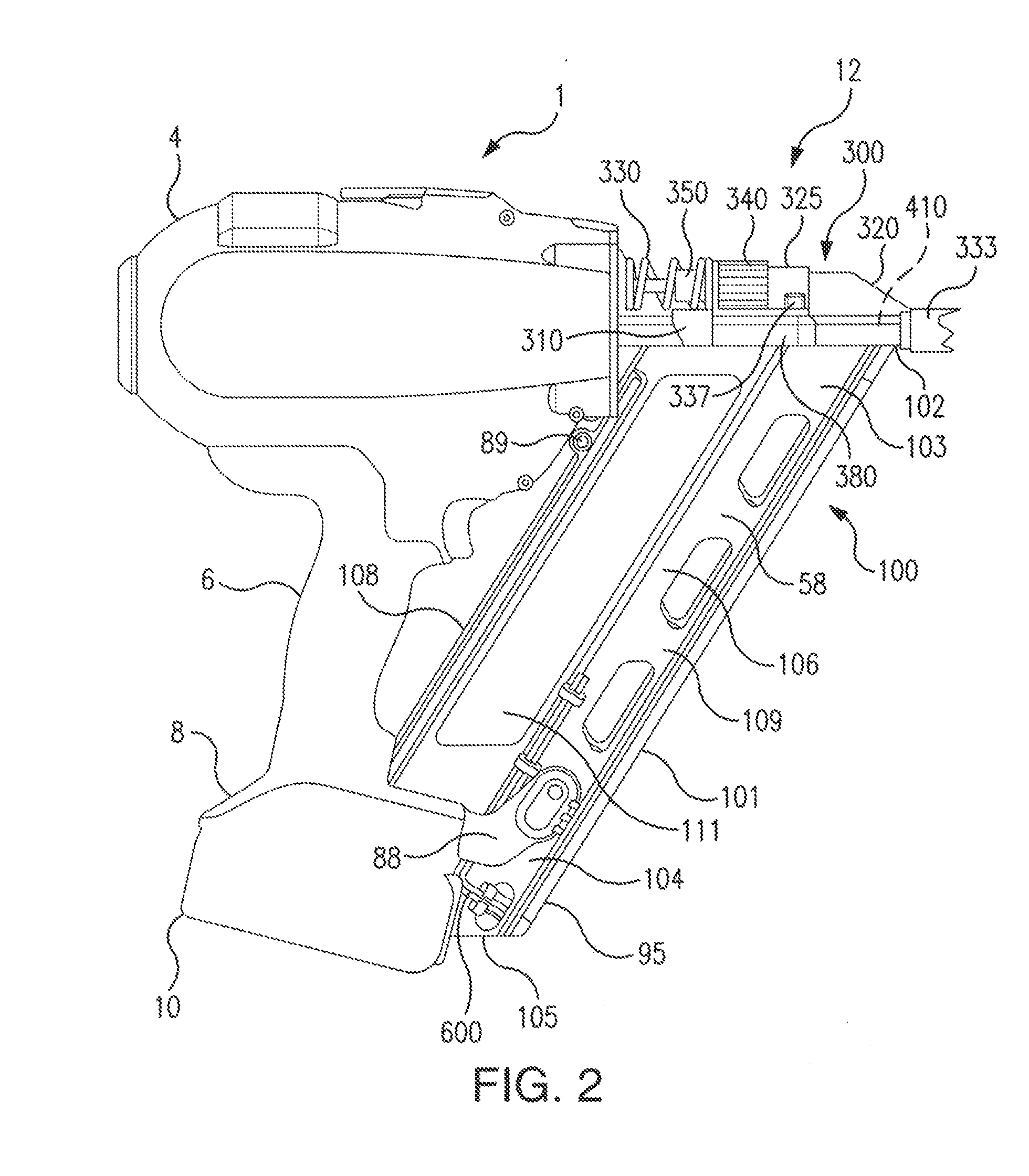

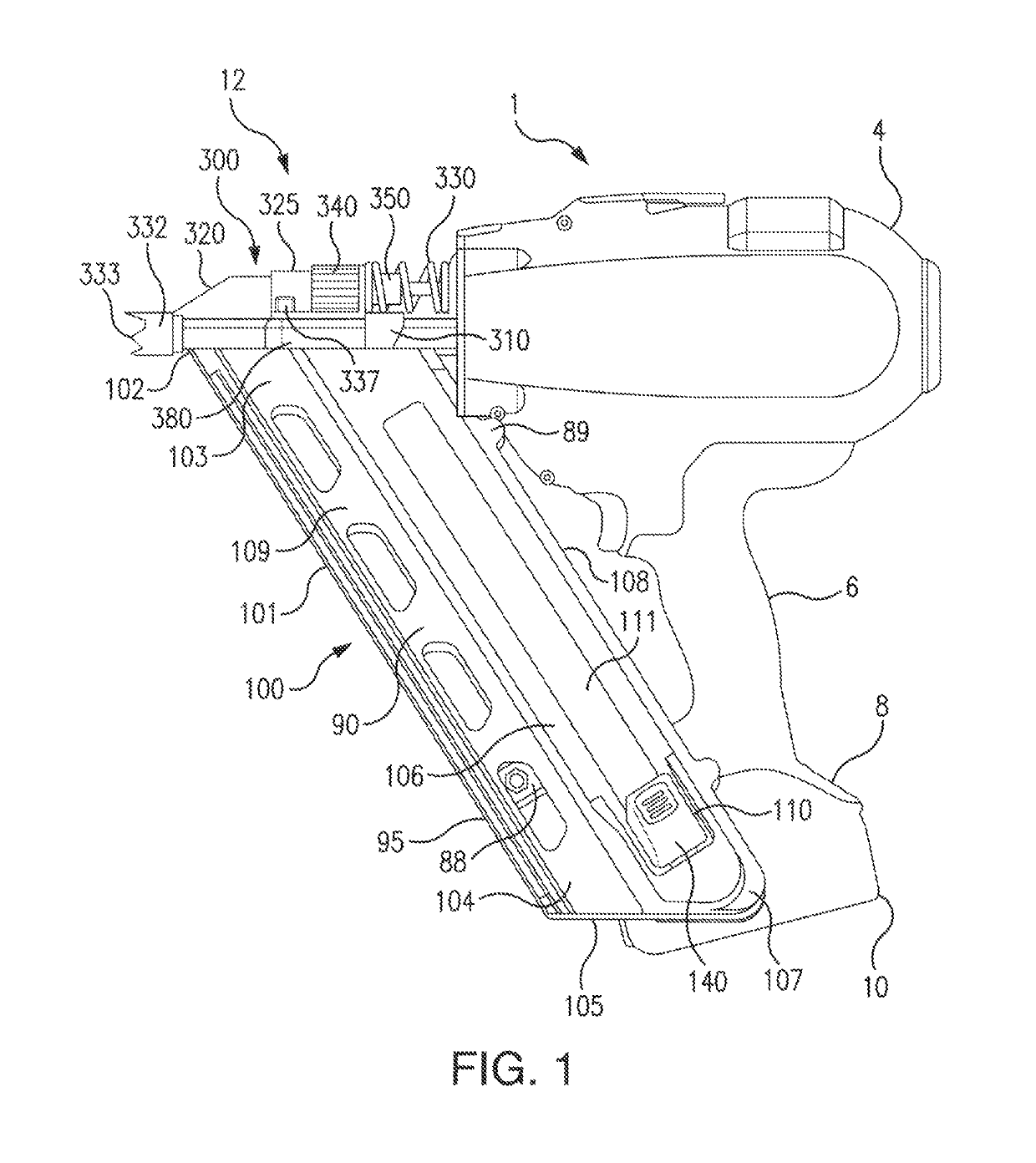

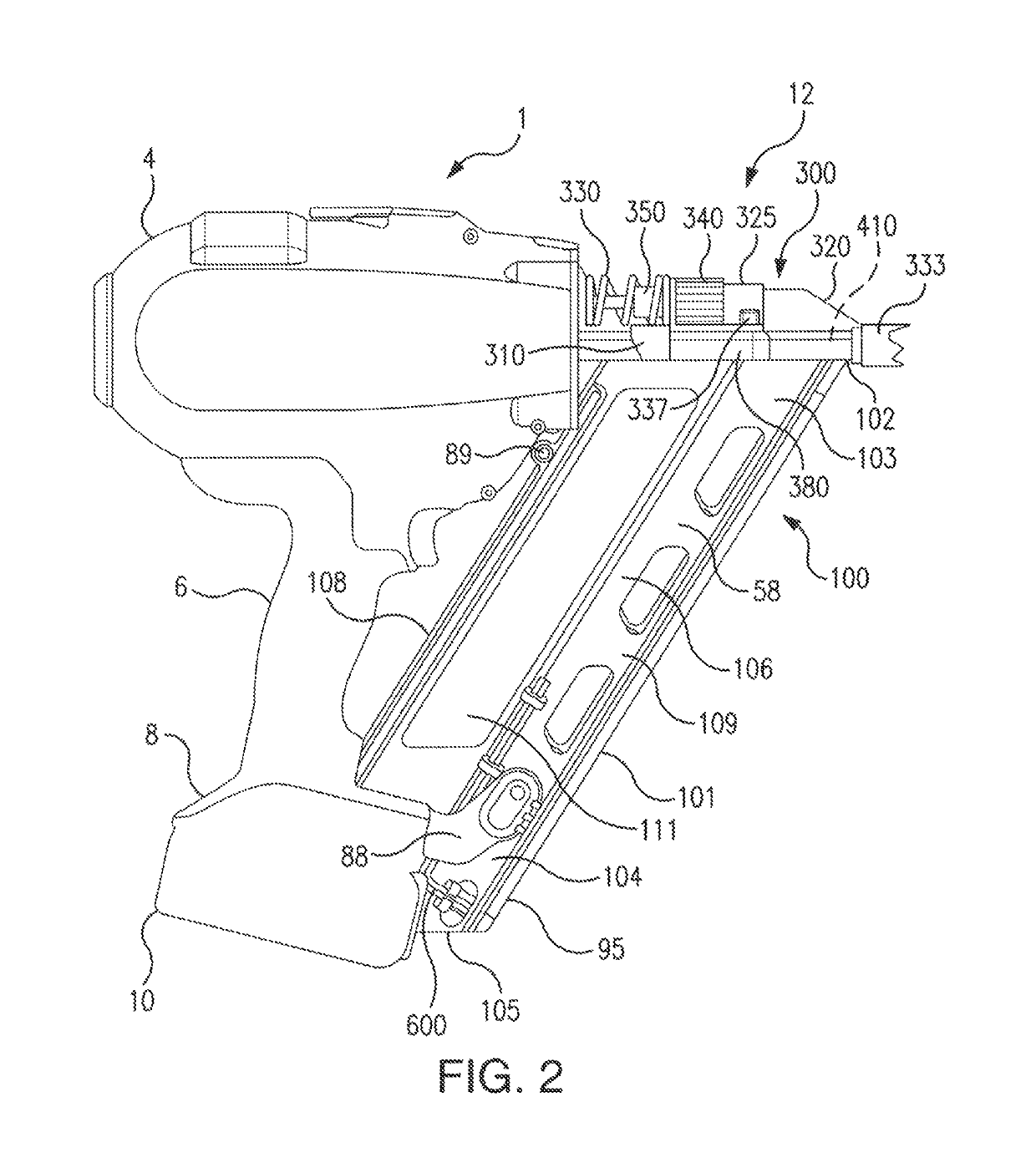

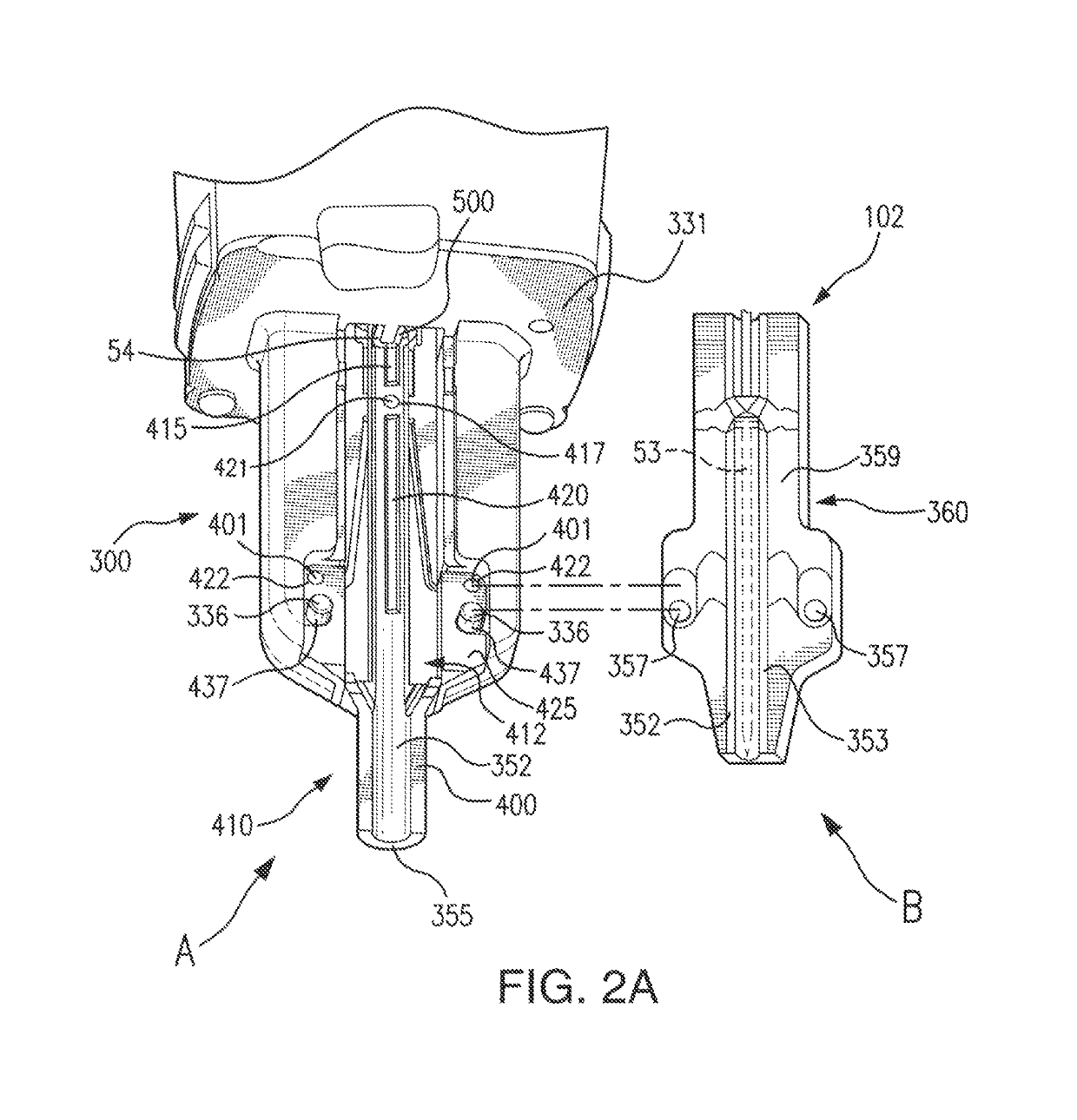

Nailer Driver Blade Stop

ActiveUS20150096776A1Reduces and eliminates misfireControlled reboundStapling toolsPower driven toolsEmbedded systemFastener

A fastening tool which controls the return behavior of a driver blade by using a blade stop and / or a bumper. The fastening tool can remove the driver blade from the drive path upon its return after driving a fastener into a workpiece and bring the driver blade to a resting state by using a bumper to orient the driver blade out of alignment with the drive path and into contact the driver blade stop.

Owner:BLACK & DECKER INC

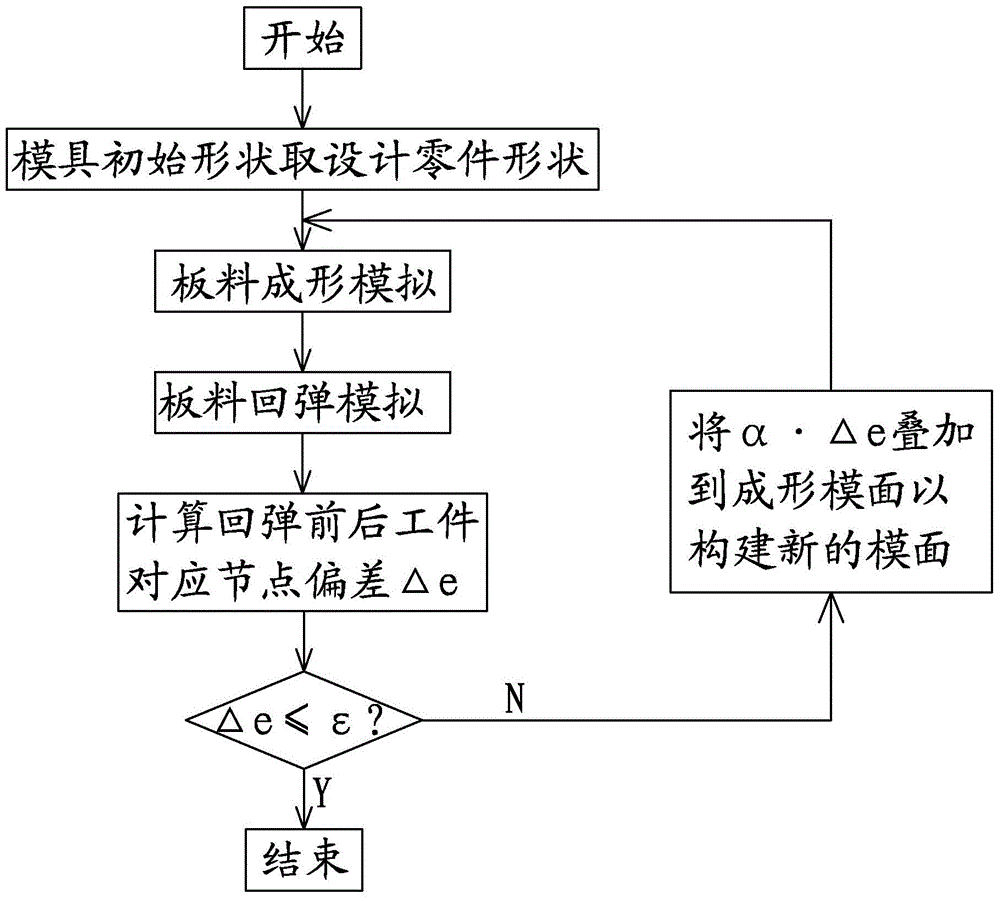

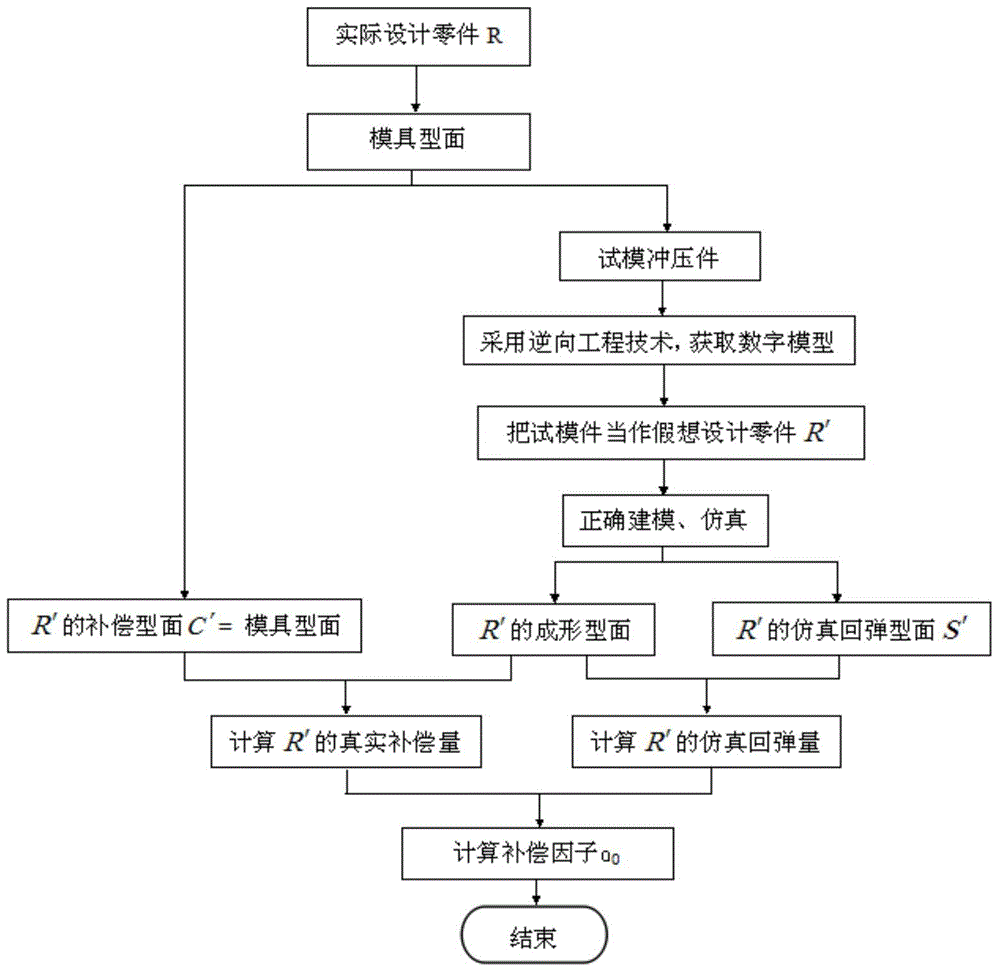

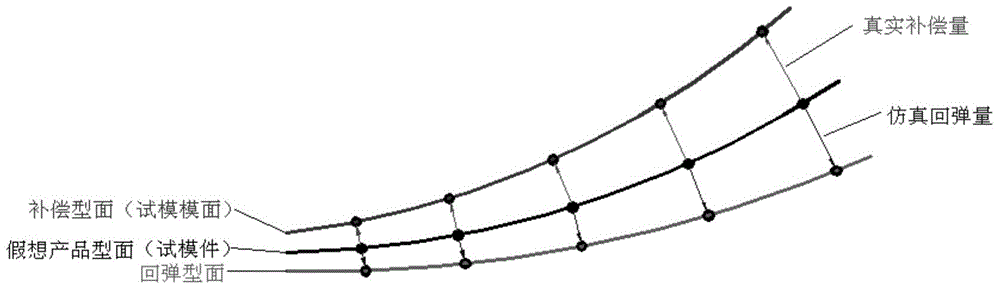

Spring-back compensation method working out factor reversely

ActiveCN104615809AImprove compensation efficiencyReduce the number of trialsSpecial data processing applicationsProduct PartElectrical and Electronics engineering

The invention provides a spring-back compensation method working out factor reversely. A test die stamping part is regarded as an imaginary product part and subjected to forming and spring-back simulation, and a simulated spring-back value is worked out; through a forcing-deformation simulation method, the difference value between a test die surface and a test die is calculated and used as an actual compensation value, and a compensation factor is worked out; the compensation factor is applied to die surface compensation of an actual designed part. When the spring-back compensation method is applied to forming of a two-dimensional bent part, spring-back can be well controlled only through once compensation, the compensation efficiency is greatly improved, the die testing frequency is reduced, and reference and basis are provided for spring-back compensation of the two-dimensional bent part.

Owner:HUAQIAO UNIVERSITY

Method for preparing weight-reducing yoghurt beverage

InactiveCN101642165AMaintain ecological balanceInhibitionMilk preparationFood preparationNutritive valuesBad mouth taste

The invention belongs to the field of nutritional health-care foods, which in particular relates to a method for preparing a weight-reducing yoghurt beverage. The weight-reducing yoghurt beverage comprises the main components of green tea, cassia seed, rivier giantarum, lotus leaf and yoghurt. The method comprises the following steps: mixing, adding into hot water, refluxing, clarifying, filtering, adding yoghurt according to a certain proportion, mixing, sterilizing, packaging in vacuum, obtaining a product and mixing. The product has abundant nutritive value and is easy to absorb, lactobacilli in the yoghurt also has the function of health care, can promote digestion and absorption and maintain the ecological equilibrium of intestinal tract florae, and the green tea containing tea polyphenol and caffeine in the product not only has the effects of thinning the body and reducing fat, but also has the functions of refreshing oneself, restoring consciousness, preventing dental caries and clearing away halitosis.

Owner:HANGZHOU LIUYI TECH

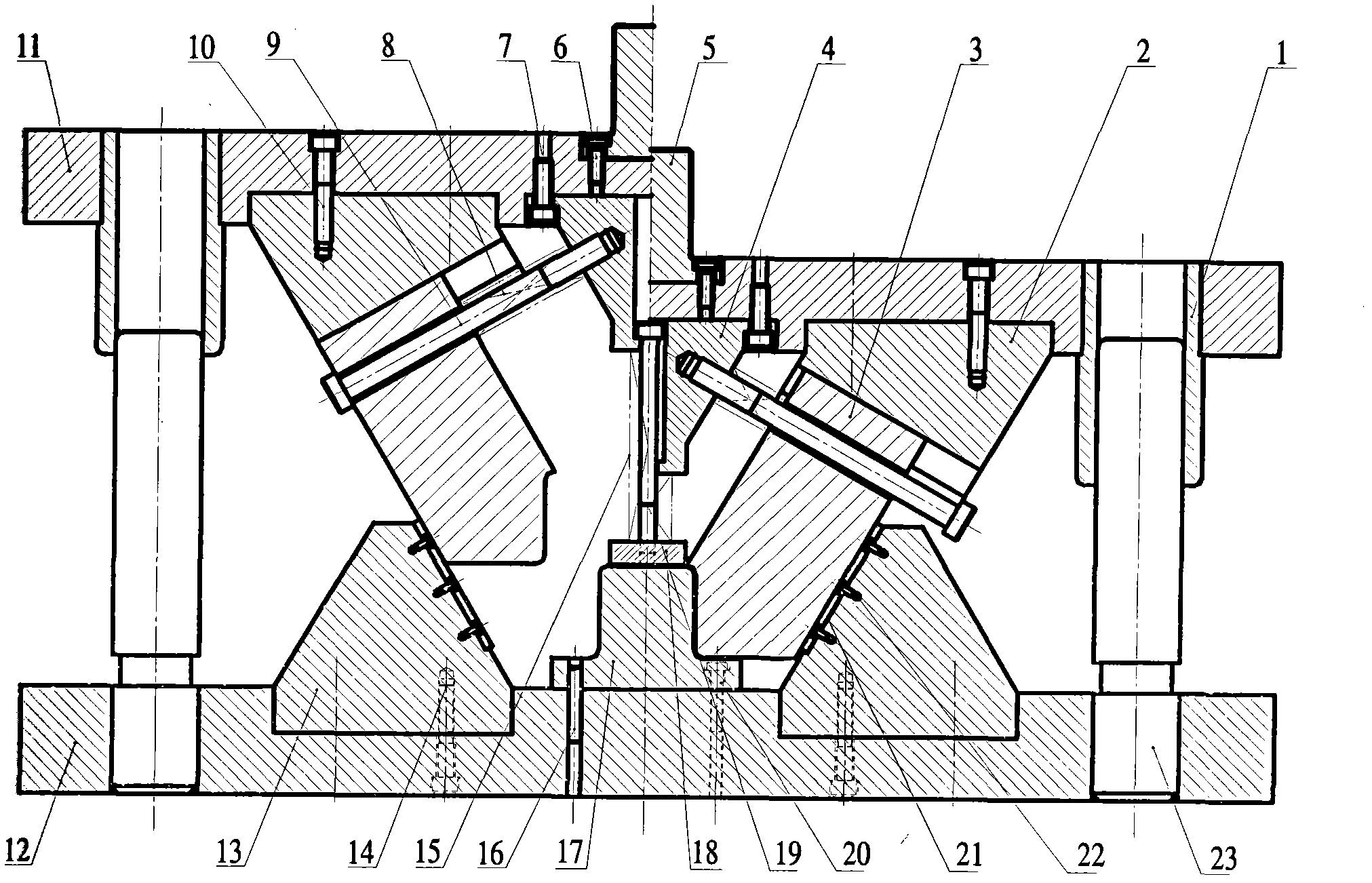

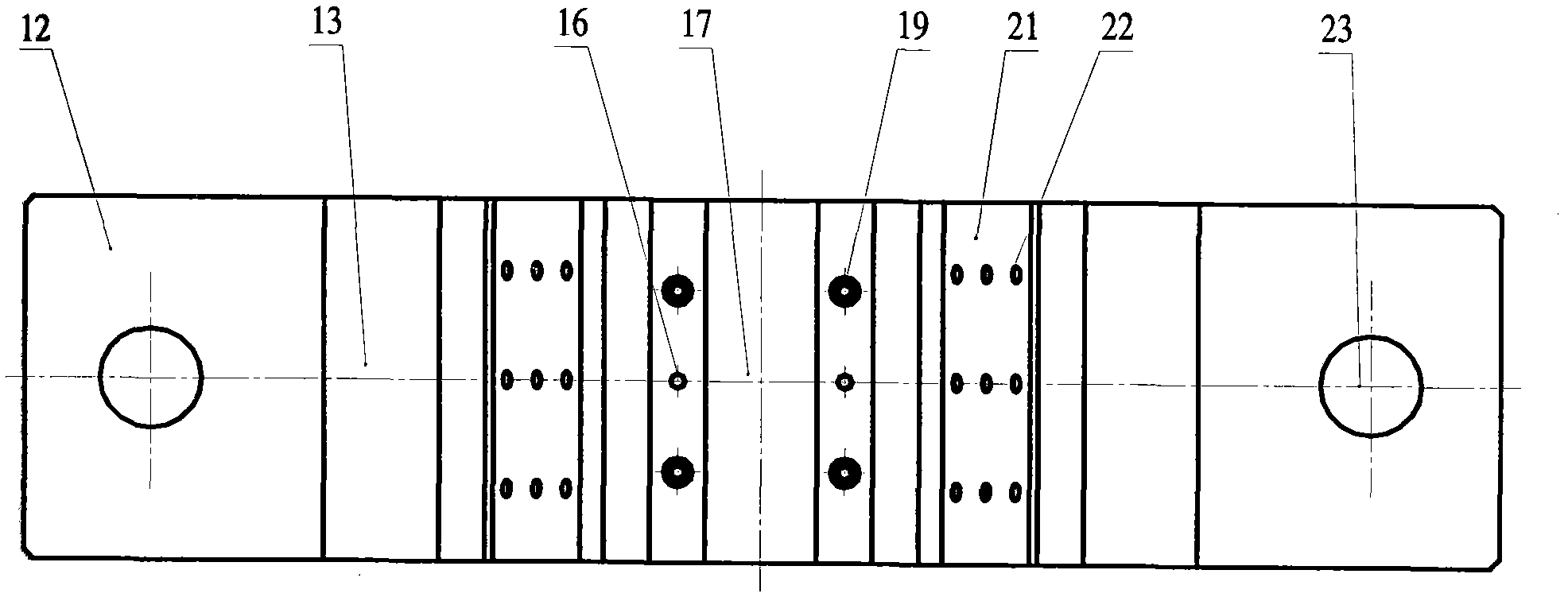

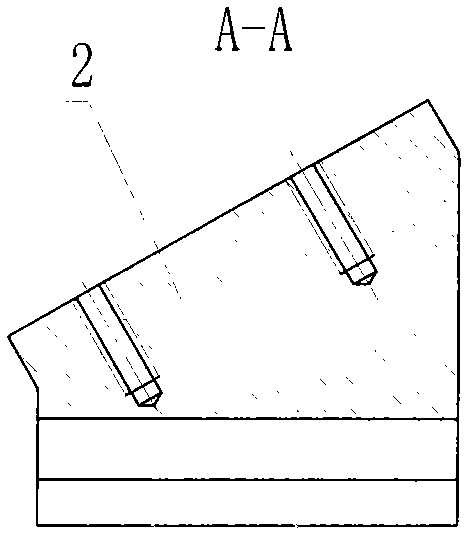

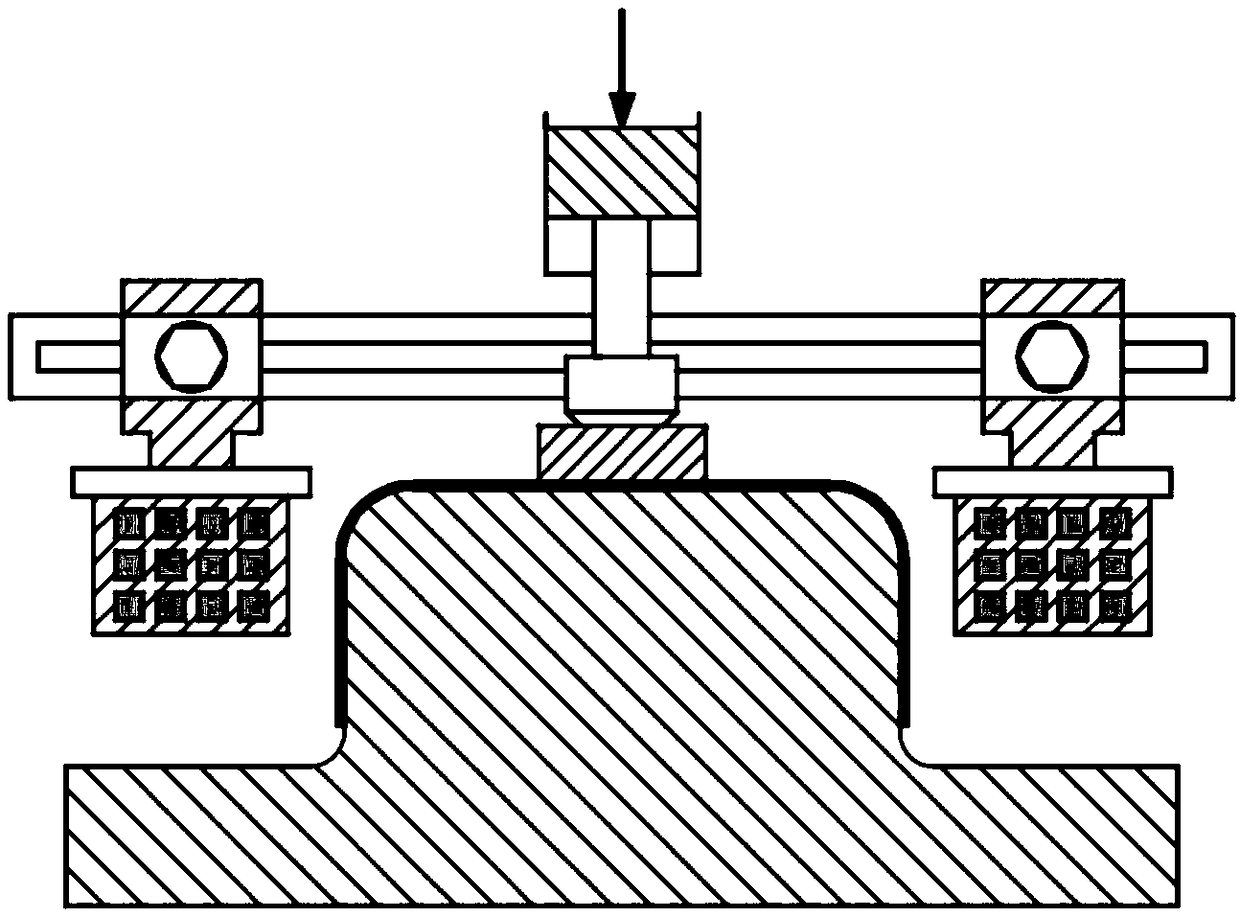

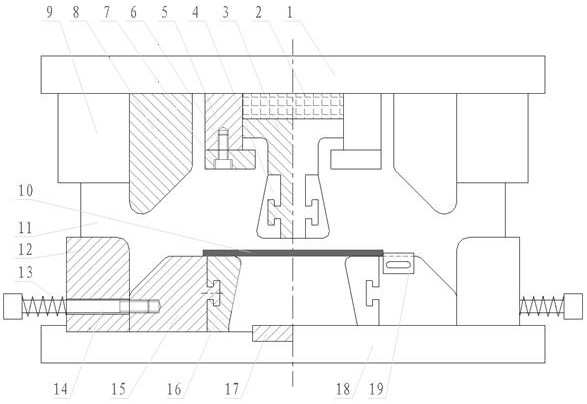

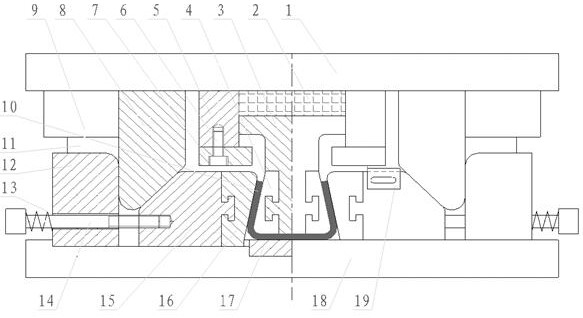

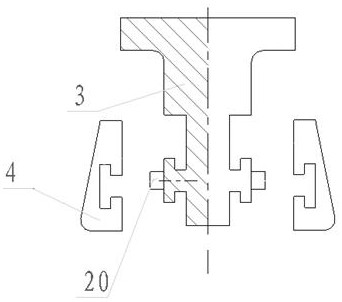

Composite Die for Slanted Wedge Bending and Reshaping of U-like Section Stamping Parts

A compound mold for oblique wedge bending and shaping of U-shaped cross-section stamping parts, including a mold handle, an upper mold plate, an upper pressure block, an upper mold insert, a slider, a lower pressure plate, a guide sleeve and a spring. The upper mold part, and the lower mold plate , oblique wedge, wear plate, punch, guide post and pin are the lower part of the die. There are three open shallow grooves on the bottom surface of the upper formwork, and the cross-section of the upper pressing block is isosceles trapezoidal, which is connected with the lower pressing plate through screws covered with springs outside. One side of the two bar-shaped block-shaped upper mold inserts is an inclined plane, and the surface opposite to the inclined plane has a T-shaped groove. The bottom of the slider is V-shaped, and the upper end is a T-shaped boss embedded in the T-shaped groove of the upper mold insert. During production, the lower platen presses the sheet, and the slider bends the sheet from both sides from outside to inside and from top to bottom under the action of the upper die insert, wedge and wear plate, and finally the slider and the punch are aligned. Bending corner shaping not only reduces springback, but also prevents the upper die from scratching the straight wall of the blank. It can bend parts of various widths and can be used on various general-purpose presses.

Owner:CHONGQING UNIV

Lotus leaf and balsam pear lipid-lowering tea and production technique thereof

The present invention discloses a lotus leaf and balsam pear lipid-lowering tea which is composed of the following components: 50-60 parts of lotus leaf and 40-50 parts of balsam pear. A production technique of the lipid-lowering tea comprises the following steps: soaking the collected lotus leaf and balsam pear for 3-5 hours; after water flushing, cutting to sheets; chopping; drying with microwave at a temperature of 90-100 DEG C and a power of 10-15 kw; mixing according to the above proportion; and finally performing vacuum packaging. The lotus leaf and balsam pear lipid-lowering tea has a good lipid lowering effect.

Owner:兴义市东泰天然果蔬开发有限公司

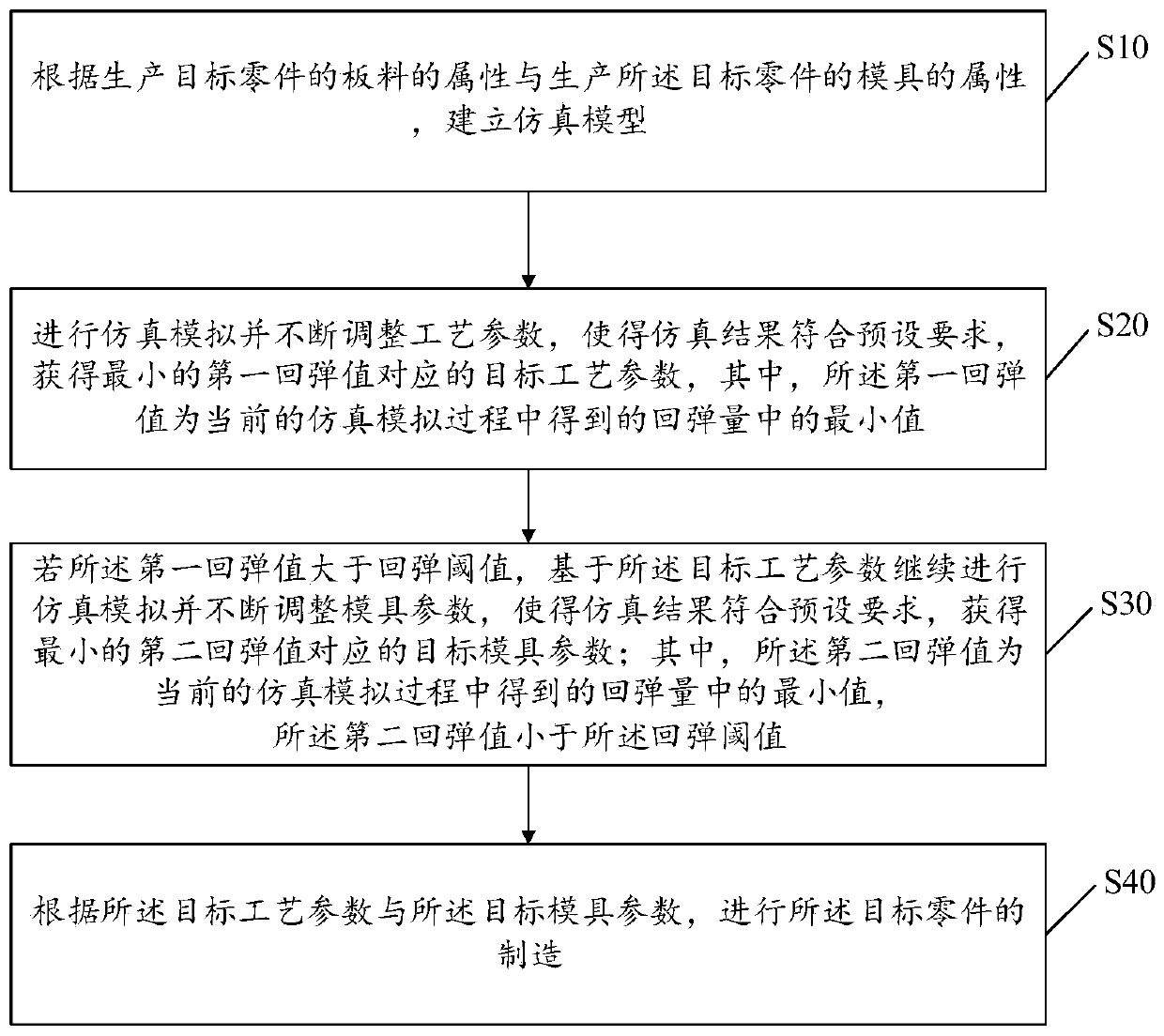

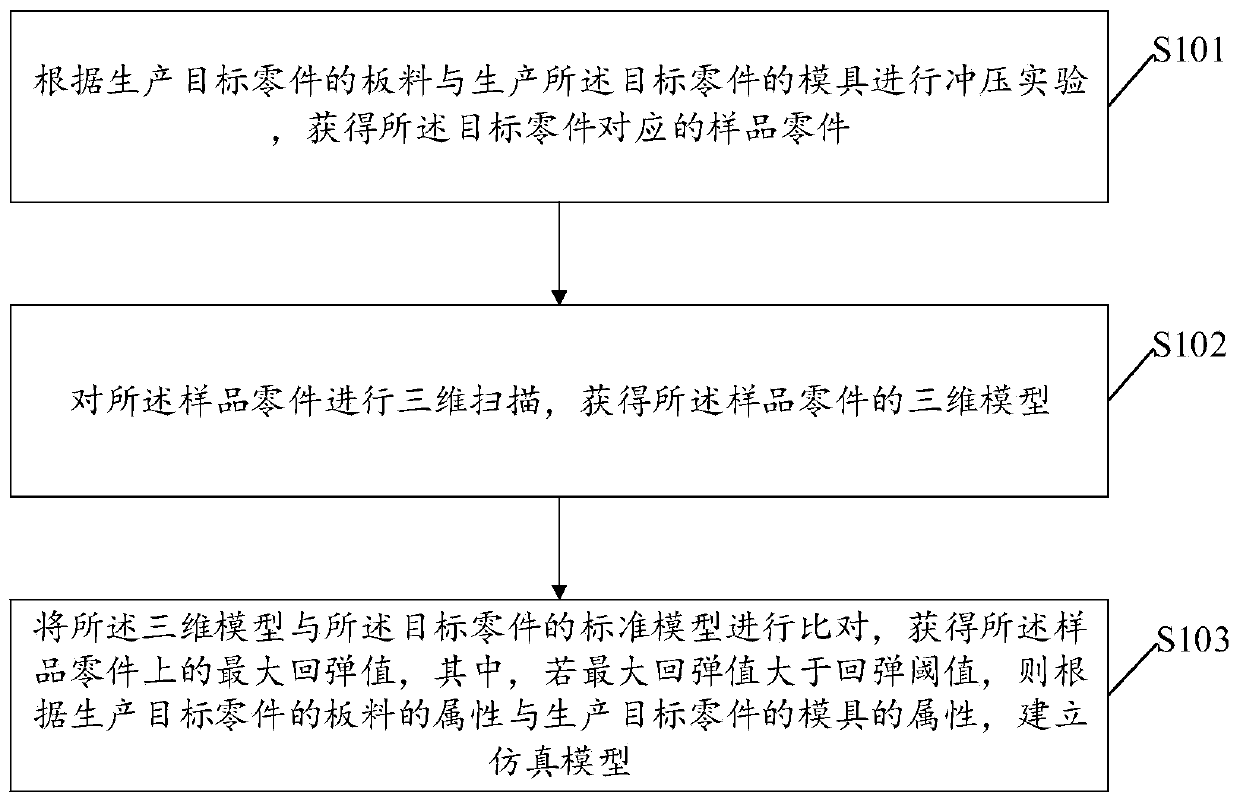

Stamped part rebound optimization method

ActiveCN110059426AControlled reboundGuarantee processing qualityDesign optimisation/simulationSpecial data processing applicationsComputer science

The embodiment of the invention provides a stamped part rebound optimization method, which comprises the following steps of establishing a simulation model according to the attributes of a plate for producing a target part and the attributes of a mold for producing the target part; carrying out simulation and continuously adjusting process parameters to enable a simulation result to meet a presetrequirement, and obtaining a target process parameter corresponding to the minimum first rebound value; if the first rebound value is larger than a rebound threshold value, continuing simulation simulation on the basis of the target process parameters, continuously adjusting mold parameters, so that a simulation result meets a preset requirement, and a target mold parameter corresponding to a minimum second rebound value is obtained; and manufacturing the target part according to the target process parameters and the target mold parameters. The method solves the problems that in the prior art,the optimal parameters of rebound optimization are difficult to find, and rebound of a stamping part is difficult to restrain.

Owner:SHOUGANG CORPORATION

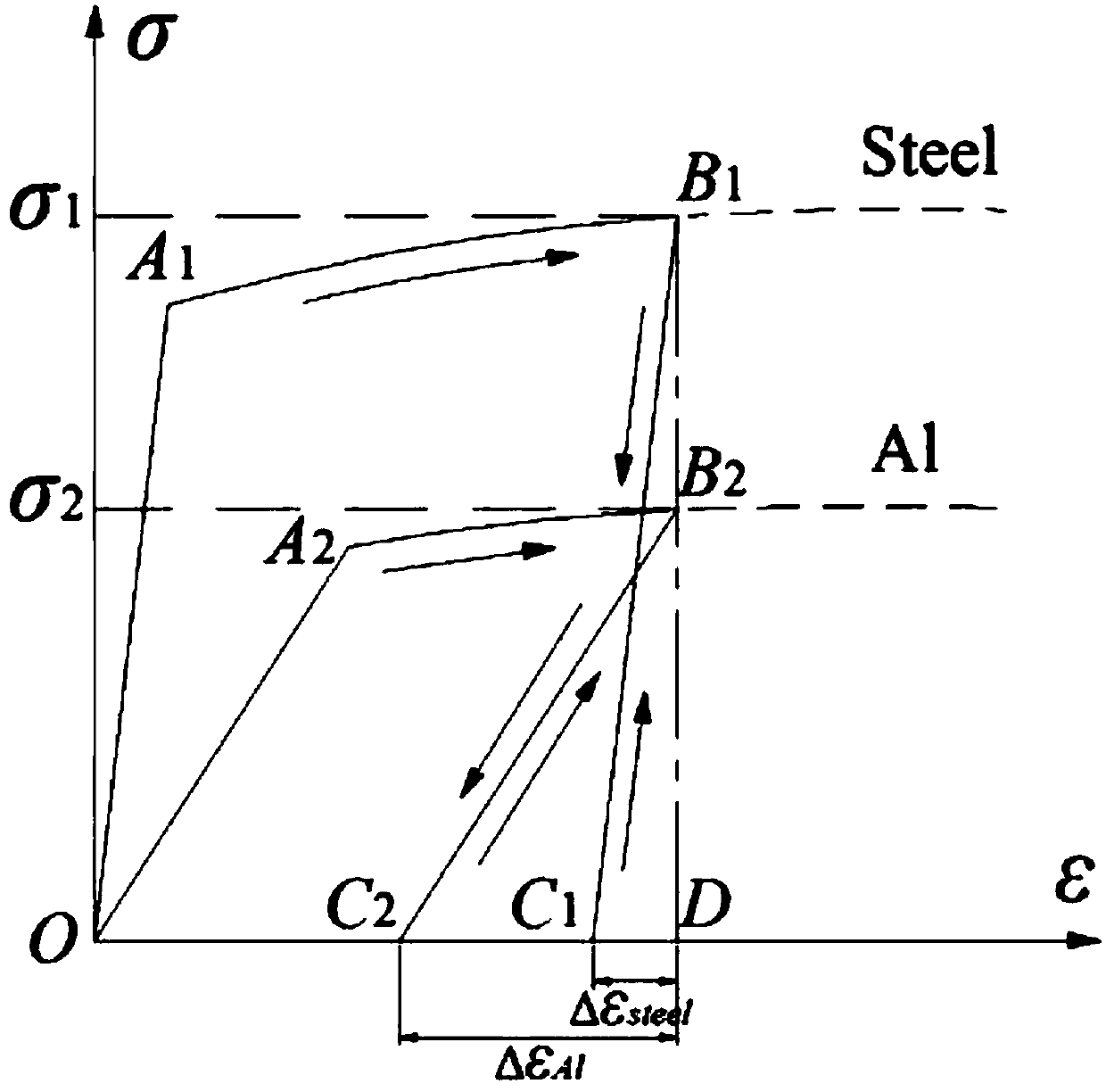

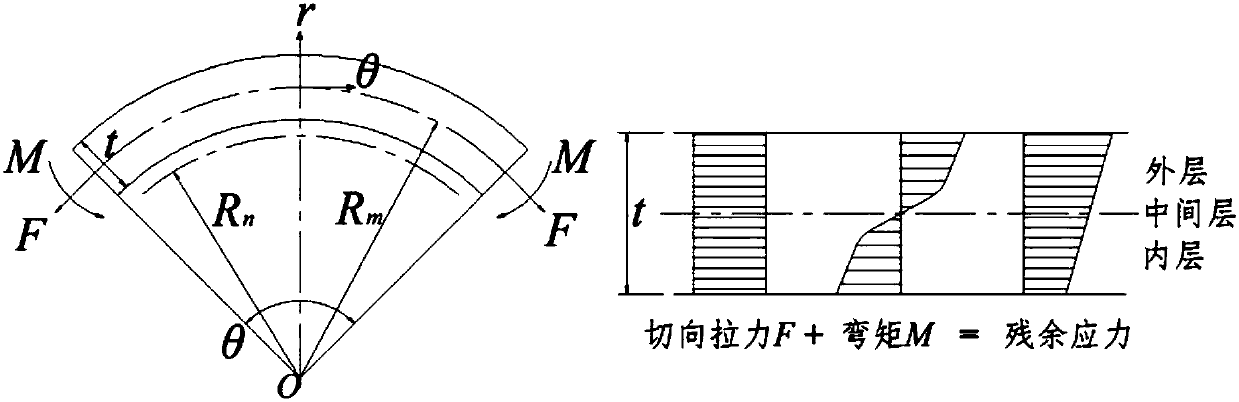

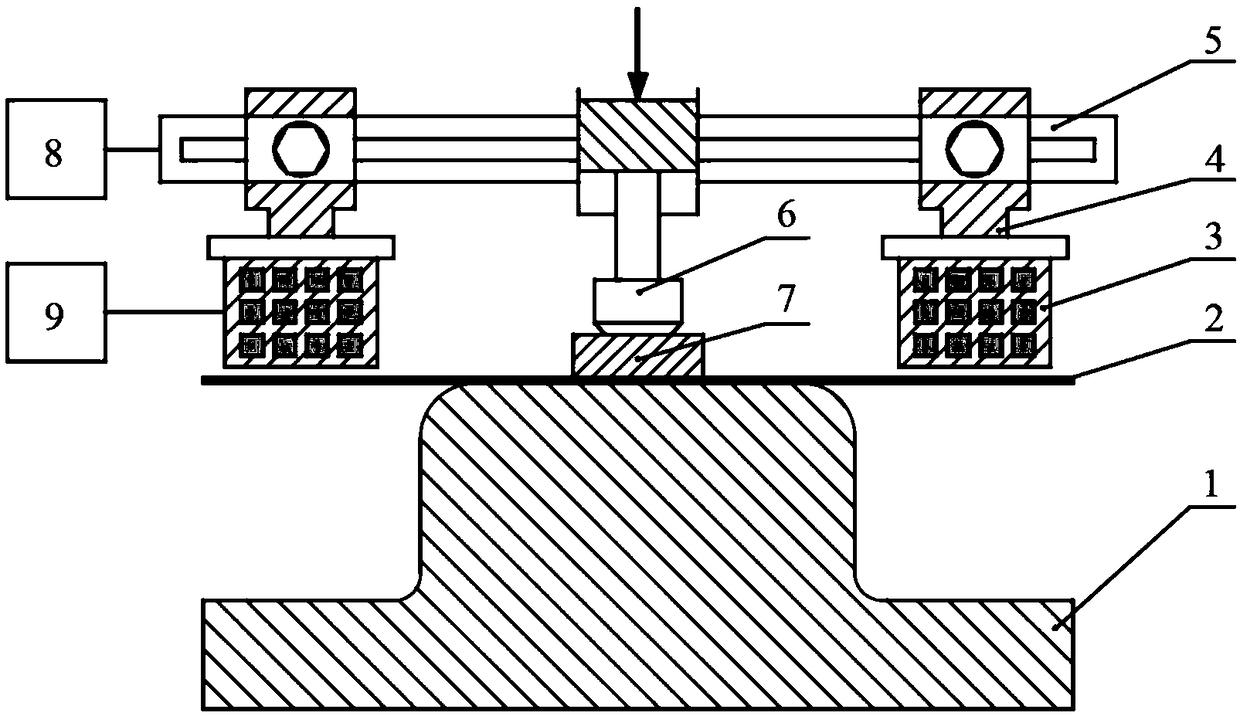

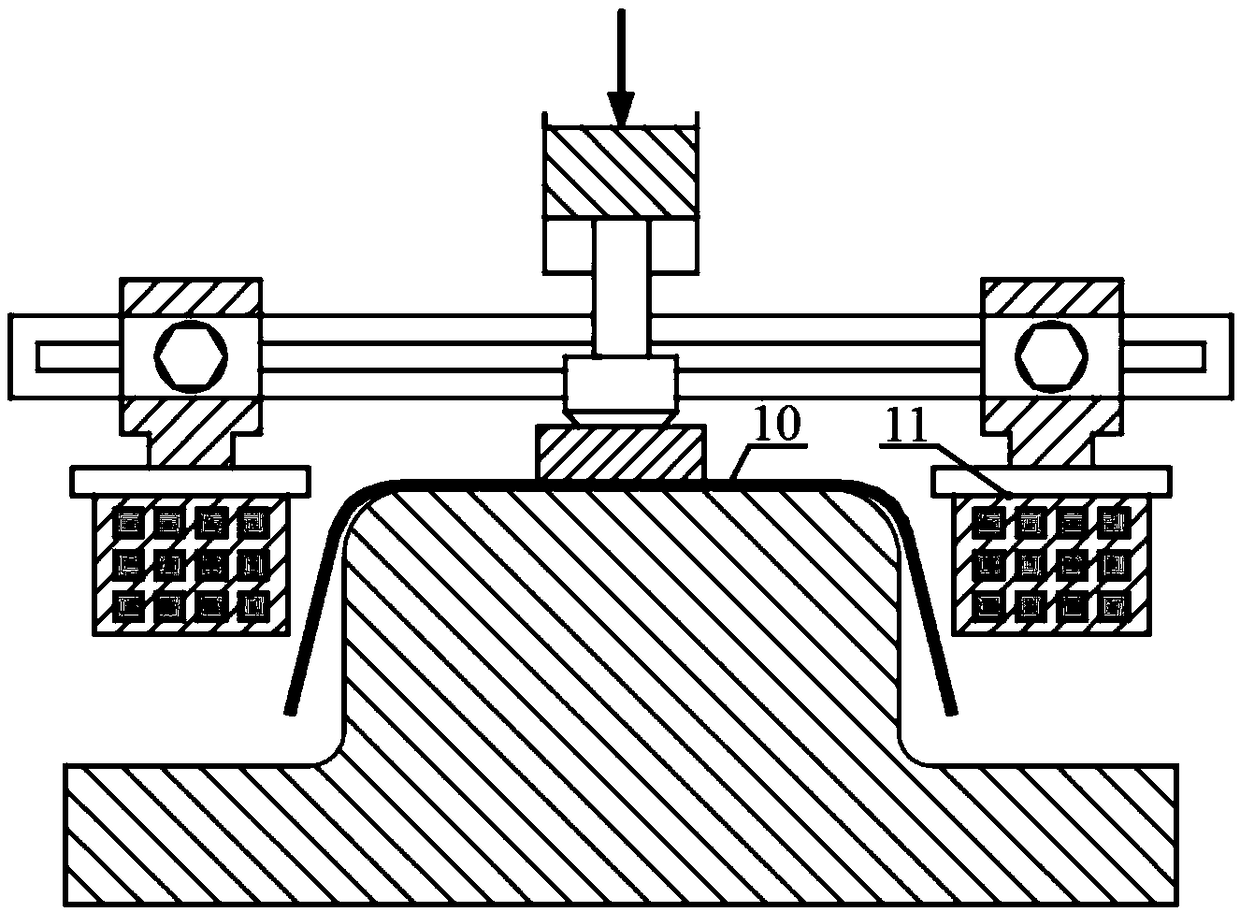

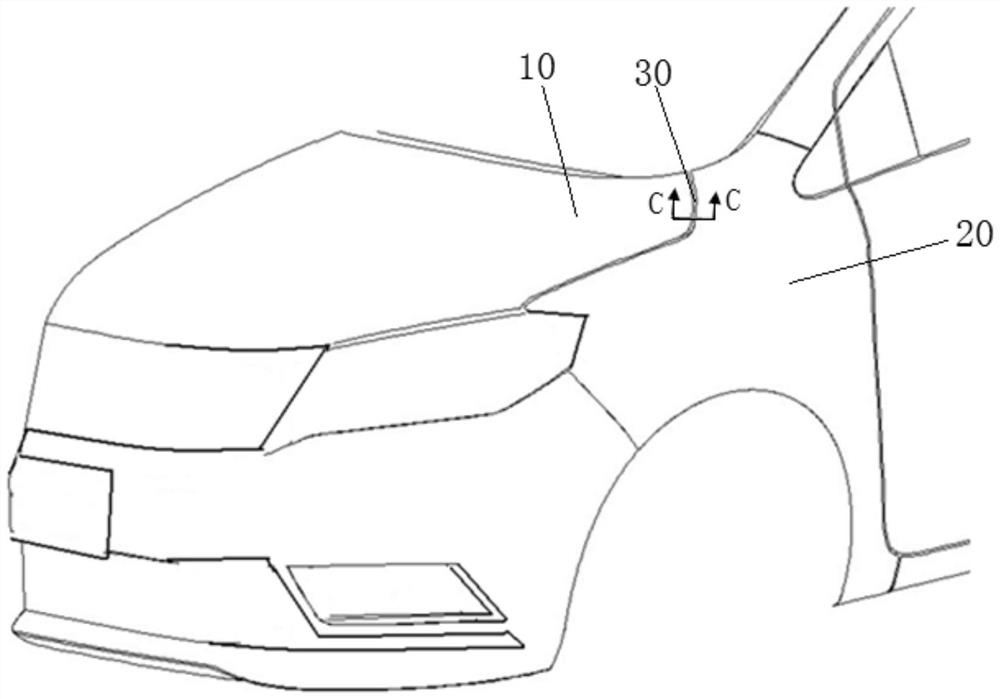

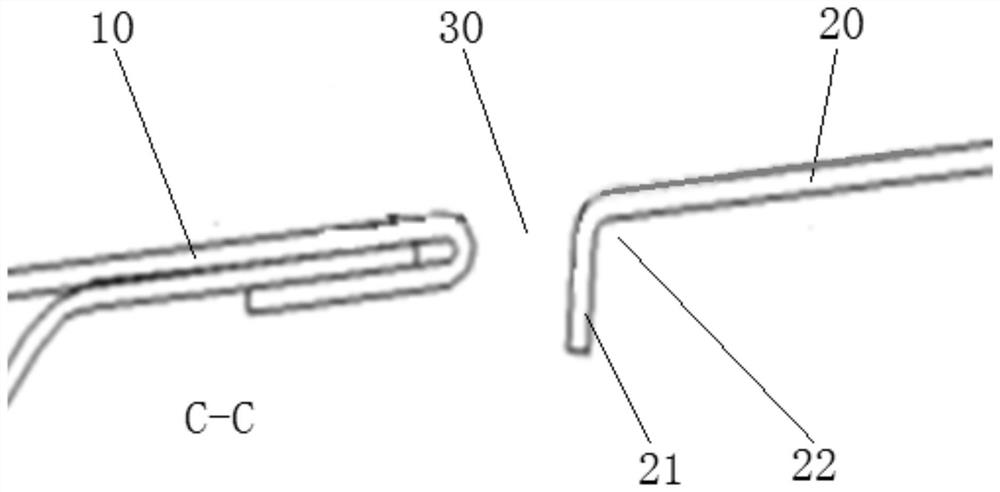

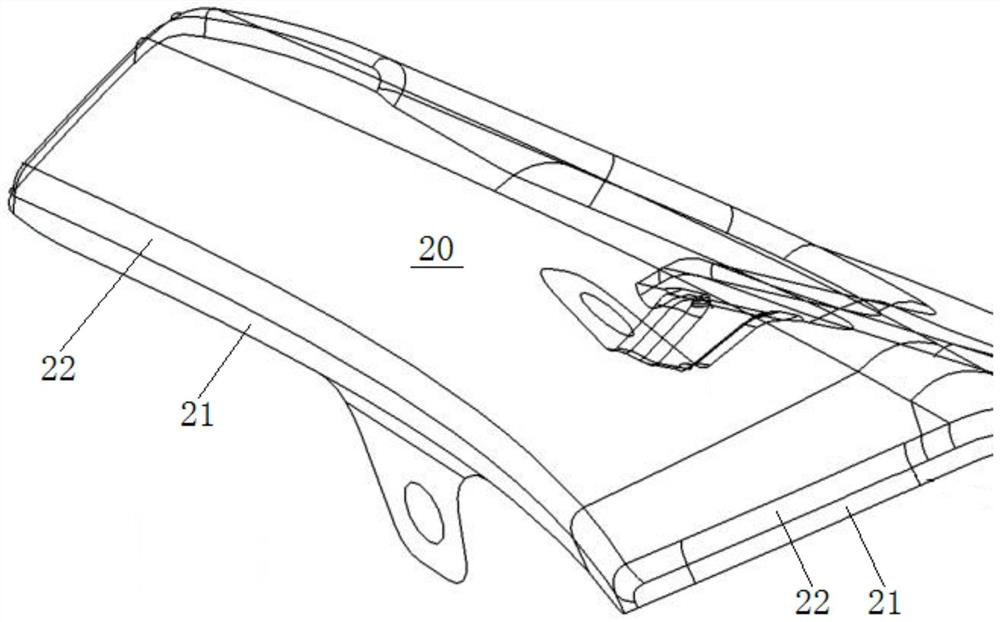

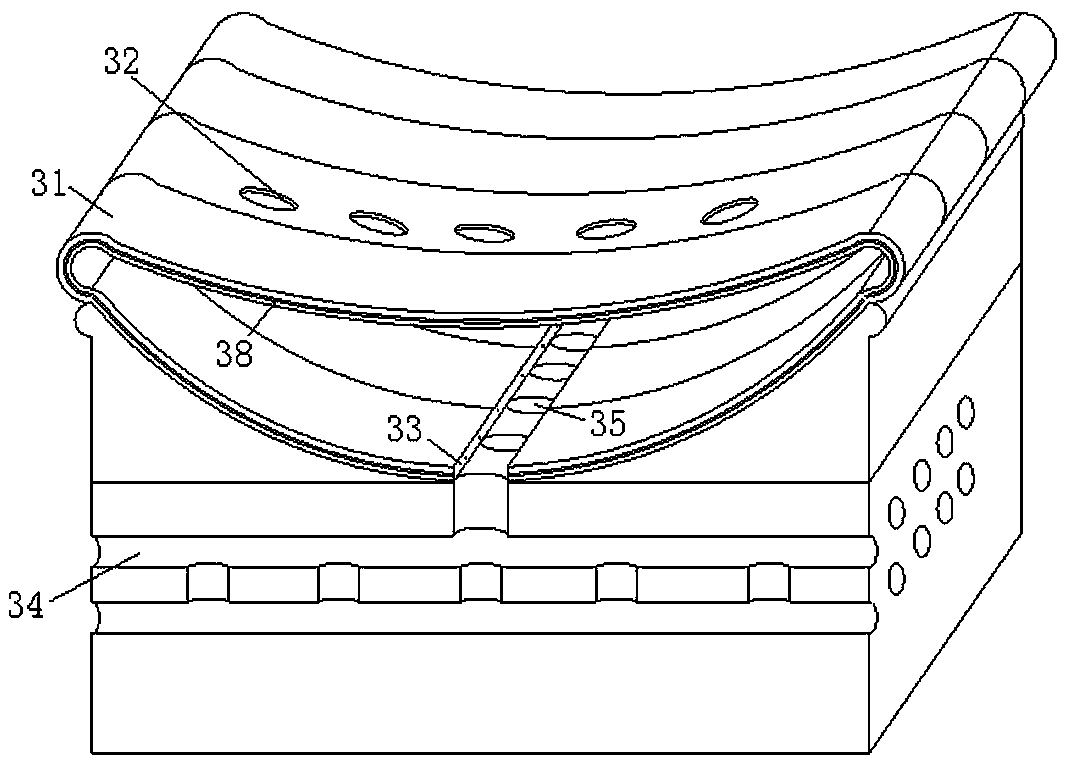

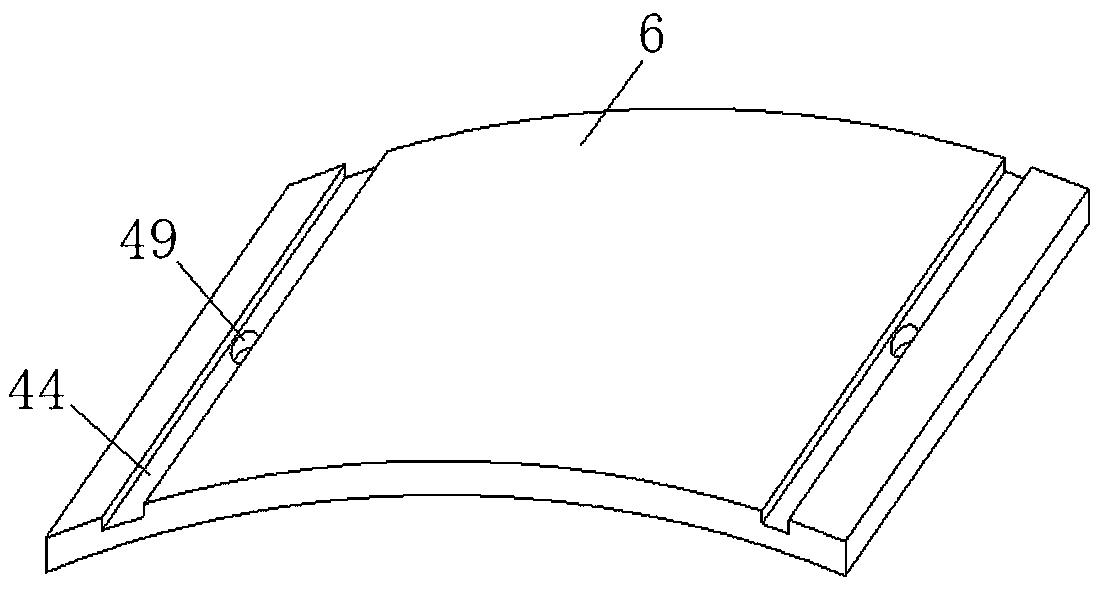

Stamping forming die of aluminum car door outside plate and rebound control method

InactiveCN107855413AControlled reboundRealize pull-shaped clampingShaping toolsVehicle componentsFlangingEngineering

The invention provides a stamping forming die of an aluminum car door outside plate and a rebound control method. The stamping forming die comprises an upper die part and a lower die part, wherein theupper die part comprises an upper die holder, a flanging insert and a pressing core, the flanging insert is fixedly connected with the upper die holder, and the pressing core is elastically connectedwith the upper die holder; the lower die part comprises a lower die holder, a flanging male die and a support core, the flanging male die is fixedly connected with the lower die holder, and the support core is elastically connected with the lower die holder. The stamping forming die and the rebound control method have the beneficial effects that according to the rebound control method, stretch forming is introduced to the flanging procedure, so that secondary stretching is performed on materials in a car door product area, and the rebound of the product area is effectively controlled; the structure of the die is simple, the support core is convenient to disassemble, and the traditional flanging and the flanging of the introduced stretch forming can be realized at the same time by one die,so that the cost of the die is effectively reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

Fat-reducing slimming tea and preparation process thereof

InactiveCN105560655AAvoid absorptionPromote excretionMetabolism disorderTea substituesTraditional medicineReduced fat

The invention relates to a traditional Chinese medicine health care tea, and in particular to a fat-reducing slimming tea and a preparation process thereof. The fat-reducing slimming tea is prepared from the following raw materials by weight: 12-15 parts of lotus leaf, 10-20 parts of cassia seed, 9-20 parts of hawthorn and 9-20 parts of rhizoma alismatis. The tea employs a pure traditional Chinese herbal prescription, which has no toxic or side effect on the human body, can reduce fat and help lose weight, and is applicable to the obese people with elevated blood lipids.

Owner:HENAN QIANFANG PHARMA

Health care oatmeal with function of loosing weight, and preparation method of health care oatmeal

InactiveCN104000097AImprove immunityPromote secretionNatural extract food ingredientsFood ingredient functionsFlavorDigestion

The invention belongs to the technical field of food processing, and particularly relates to health care oatmeal with a function of loosing weight, and a preparation method of the health care oatmeal. The health care oatmeal is prepared by the following raw materials: oatmeal, Chinese wampee fruits, rhodomyrtus tomentosa, mulberries, lotus leaves, herba lycopi and xylitol. The health care oatmeal with the function of loosing weight is prepared by combining the effective extraction components of natural fruits and plant extract components with effect of homology of medicine and food, thus having the effects of loosing weight, lubricating the intestines, relaxing the bowels, helping digestion, inhibiting appetite, removing fat and reducing blood pressure, balancing nutrition, beautifying and protecting skin, and the like; the health care oatmeal also has the characteristics that the raw materials are easily available, the operation is simple, the flavor is unique, the taste is good, the taking is convenient, etc.

Owner:陈国勇

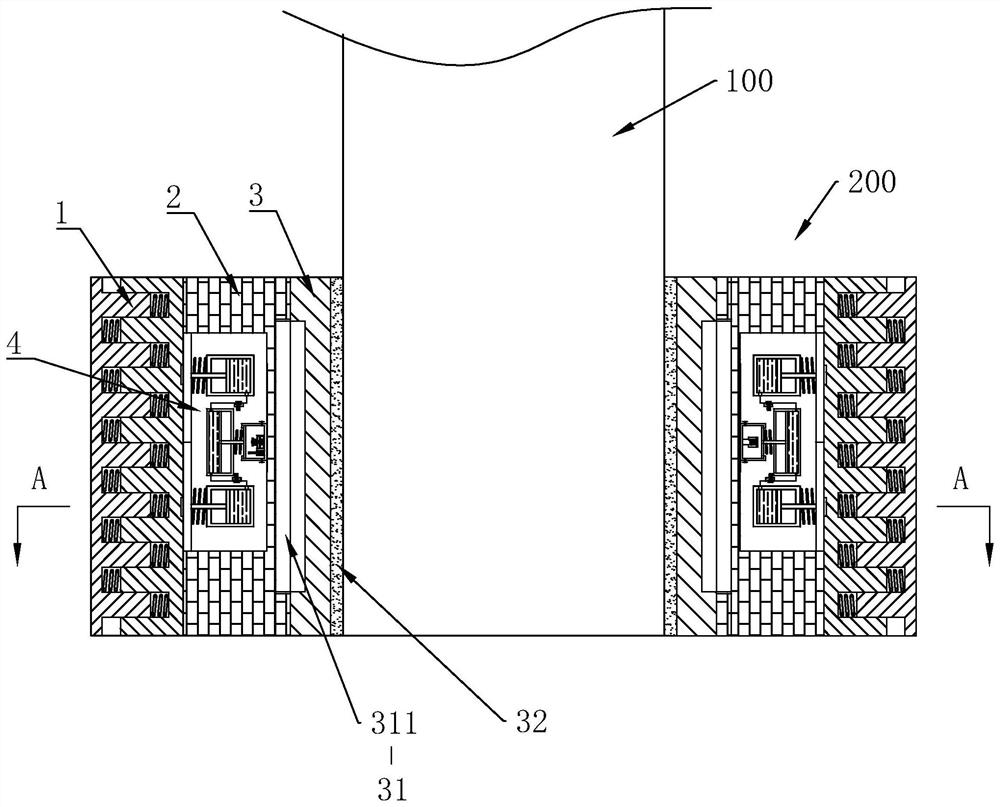

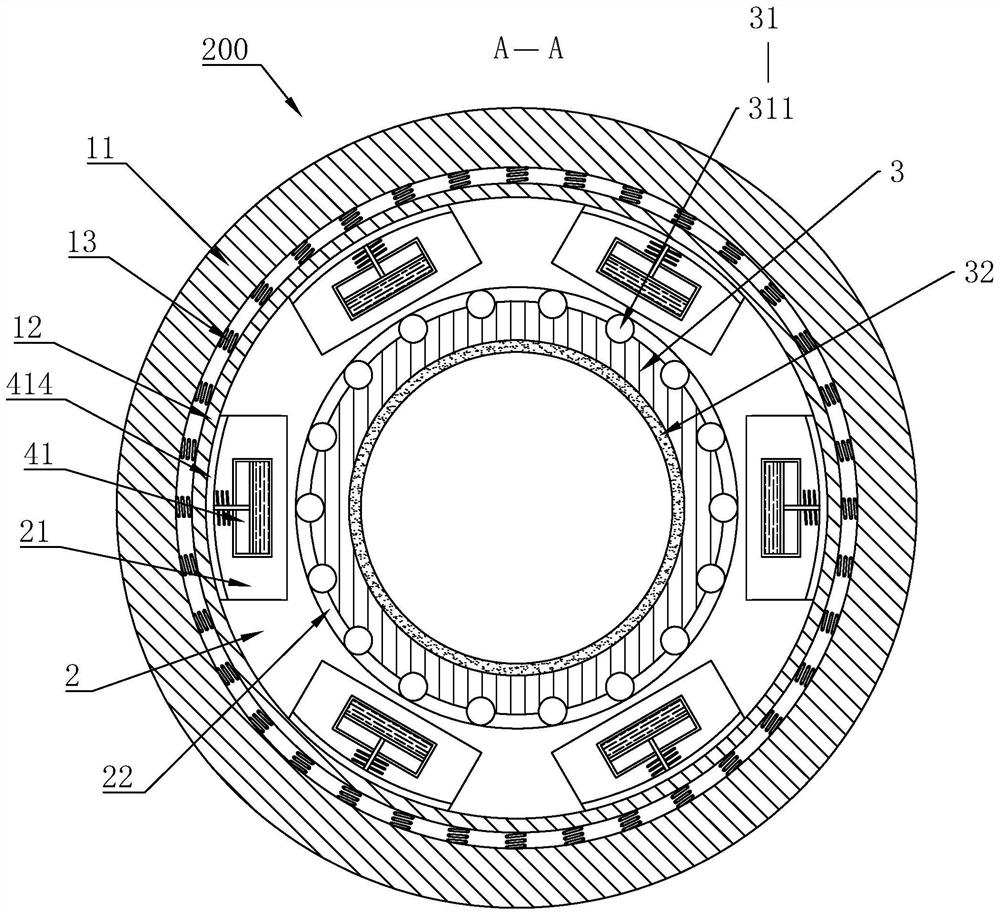

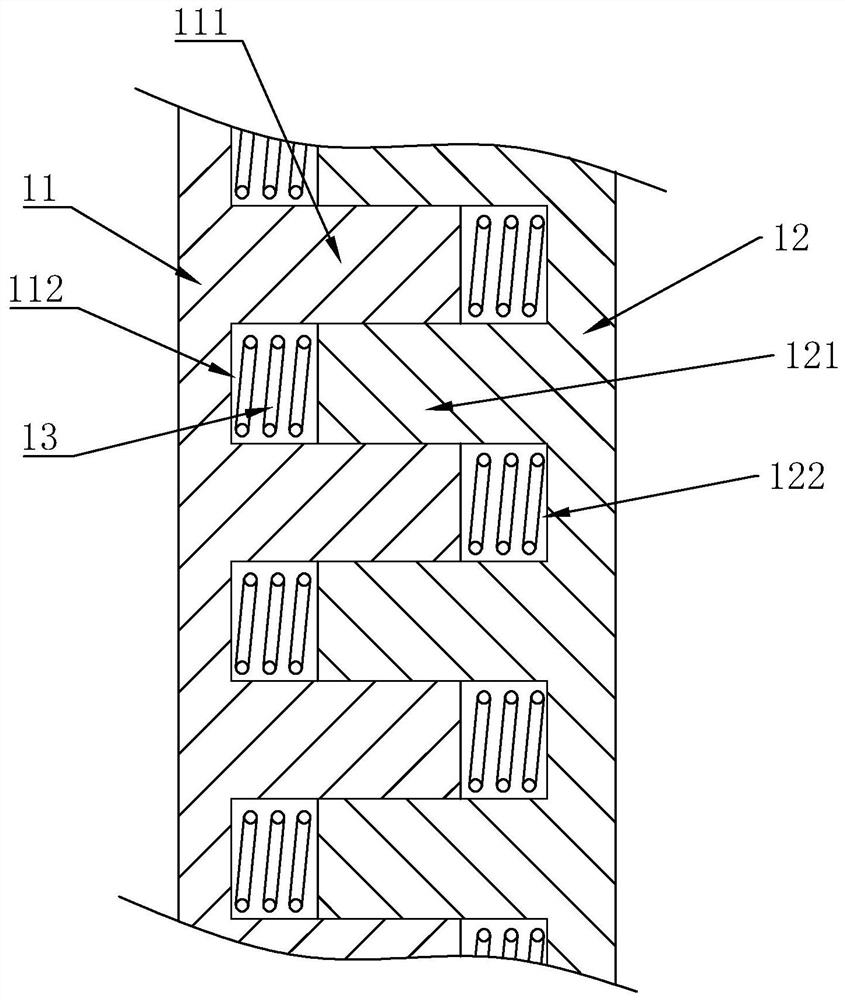

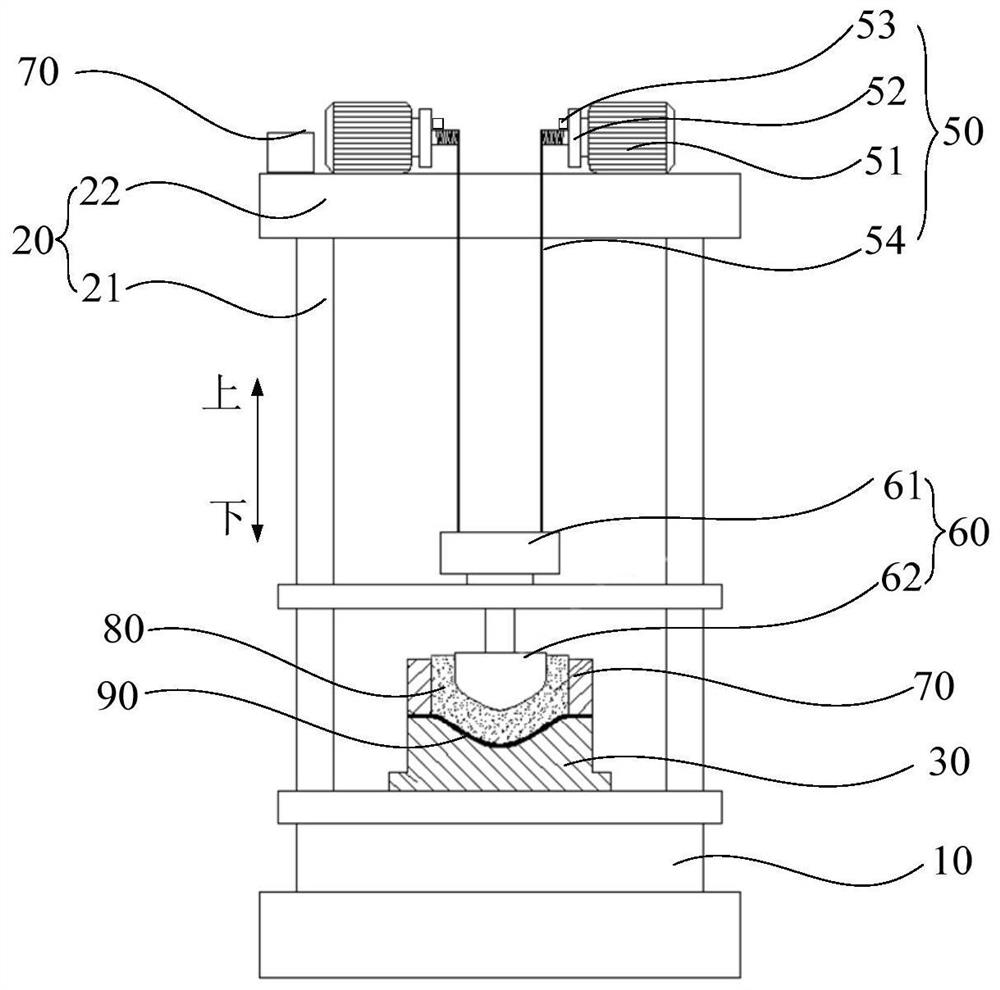

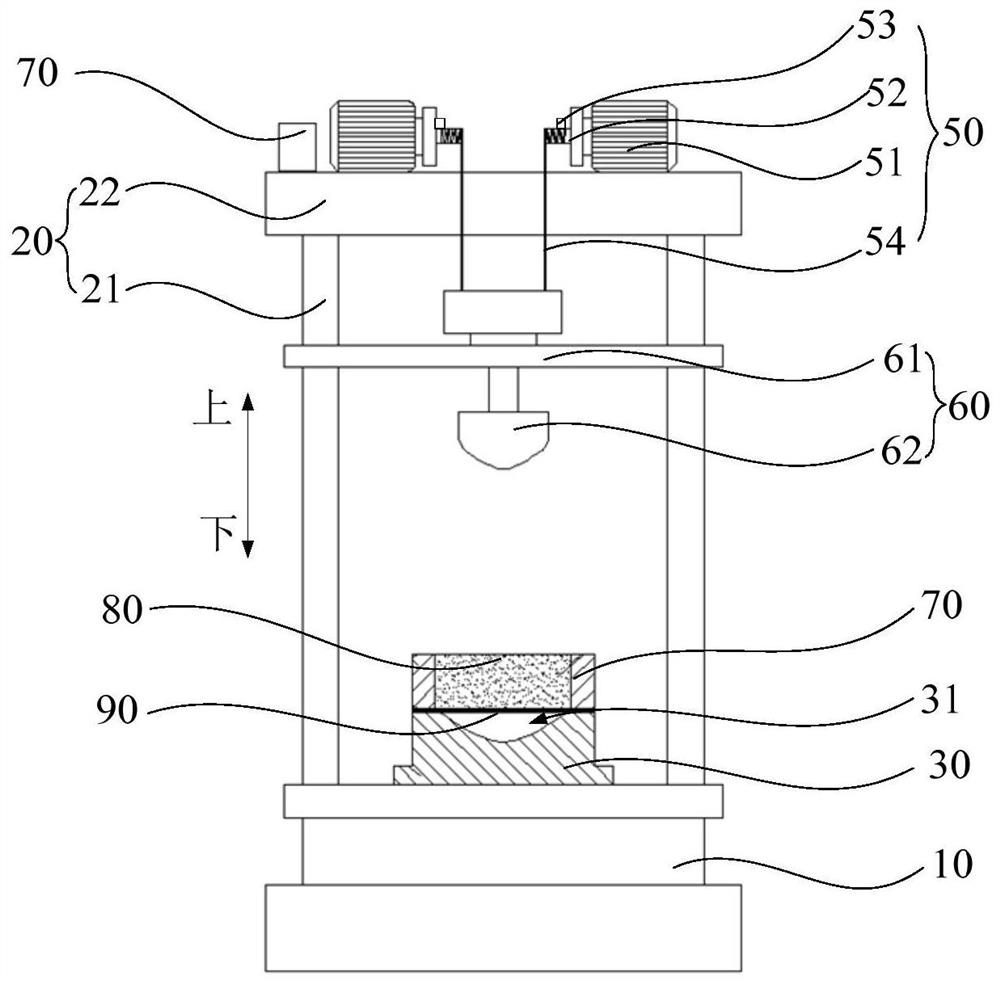

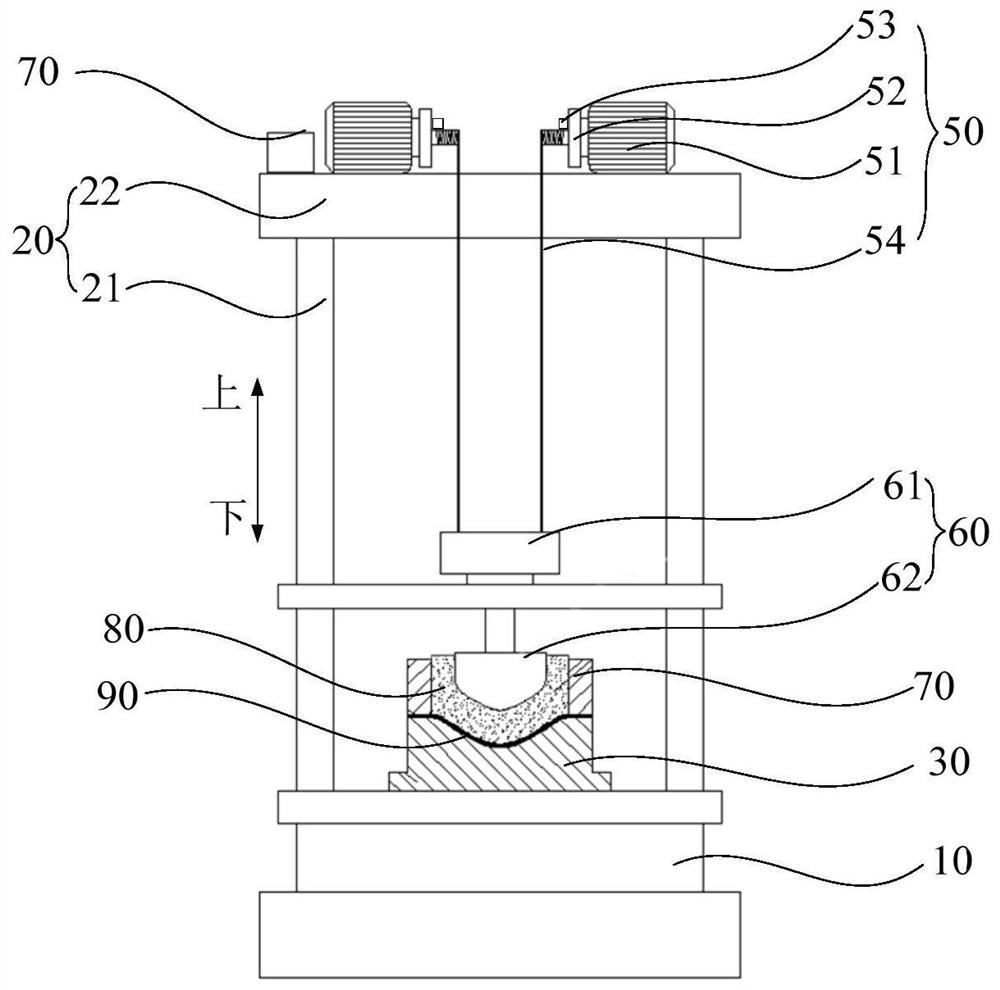

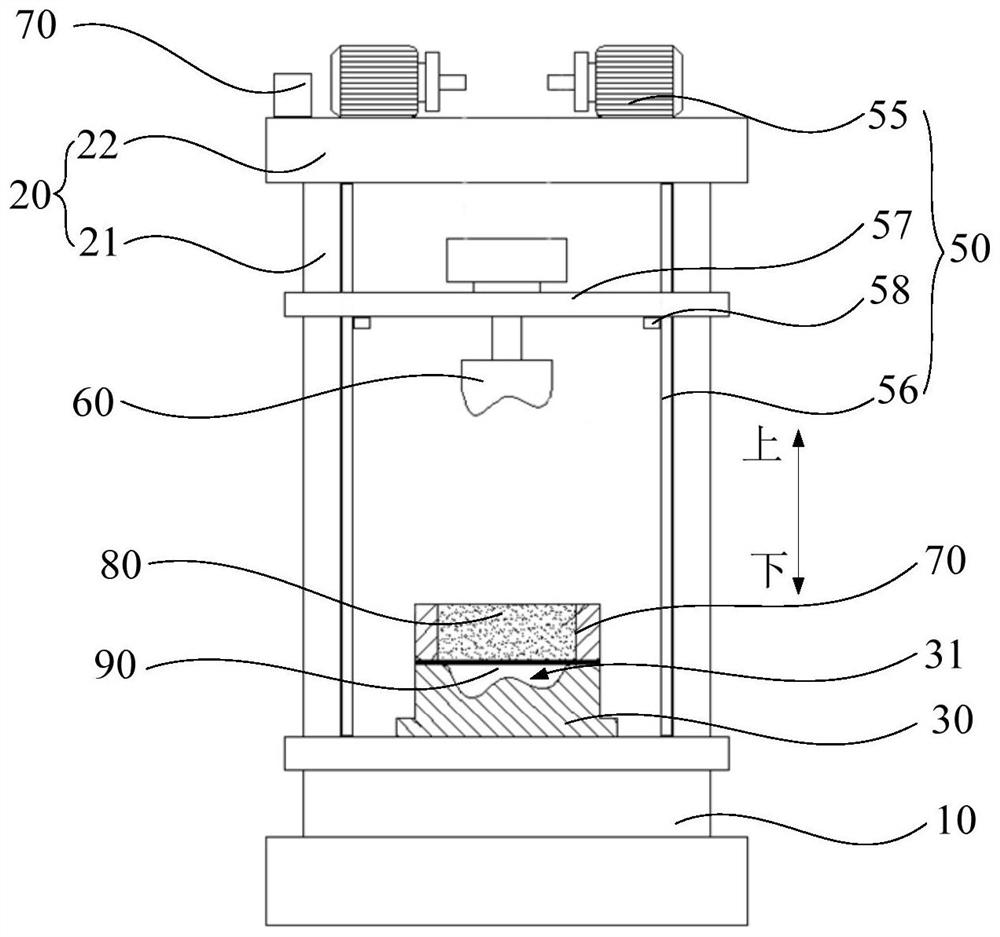

Magnetic pulse bending device for controlling U-shaped piece springback and forming method

The invention belongs to the field of metal plate forming, and particularly discloses a magnetic pulse bending device for controlling U-shaped piece springback and a forming method. The bending devicecomprises a forming unit, a compression unit and an adjusting unit, the forming unit comprises a male die and an electromagnetic forming assembly, the male die is used for controlling the bending shape of a to-be-formed plate material, and the electromagnetic forming assembly is used for conducting magnetic pulse bending forming on the plate material; the compression unit is used for applying compression force to a center zone of the bottom of a U-shaped piece; and the adjusting unit is used for adjusting the position of the electromagnetic forming assembly relative to the to-be-formed platematerial. According to the forming method, the magnetic pulse bending device is used for conducting two-step magnetic pulse bending forming, and bending forming of the U-shaped piece is completed. Bymeans of the device and method, the springback phenomenon generated after bending forming of the U-shaped piece can be effectively controlled, and the die structure and the technological flow are greatly simplified.

Owner:HUAZHONG UNIV OF SCI & TECH

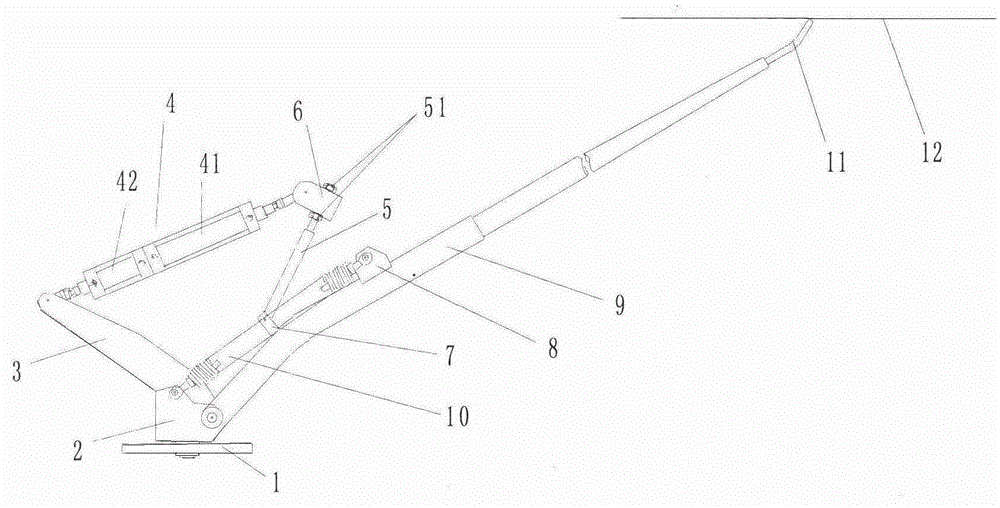

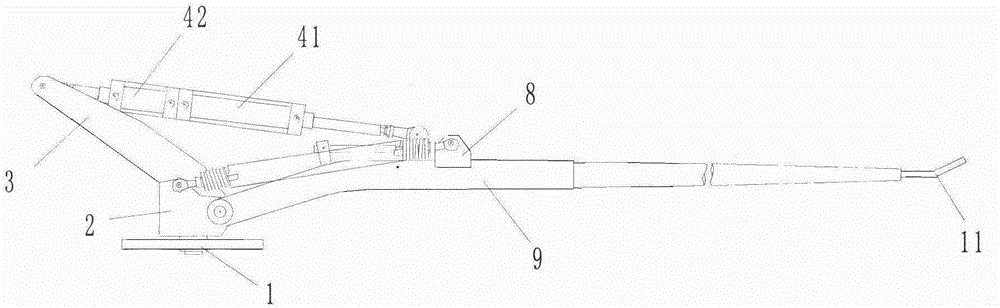

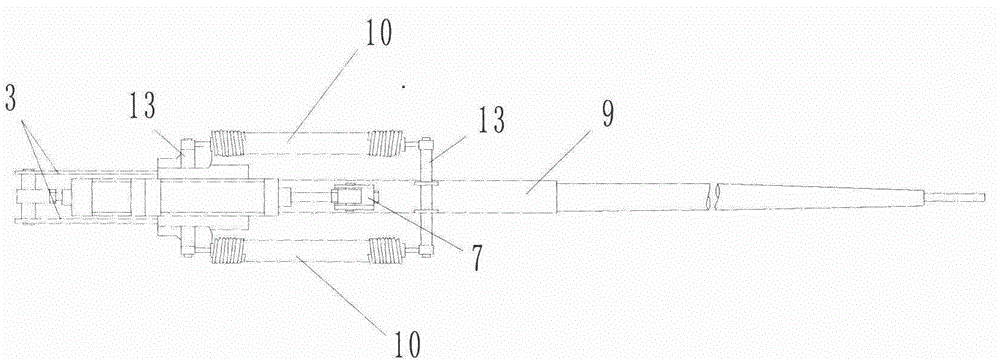

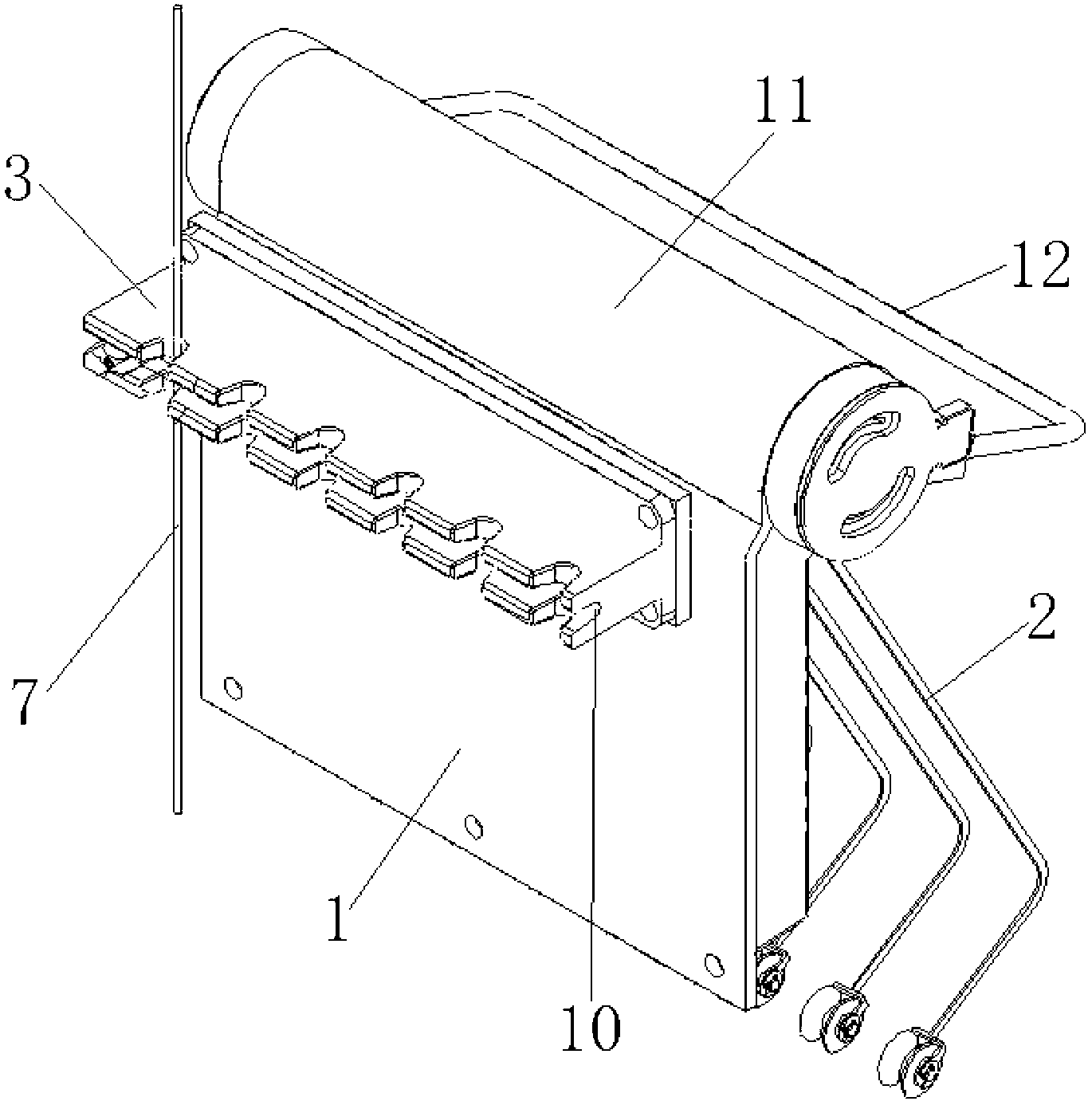

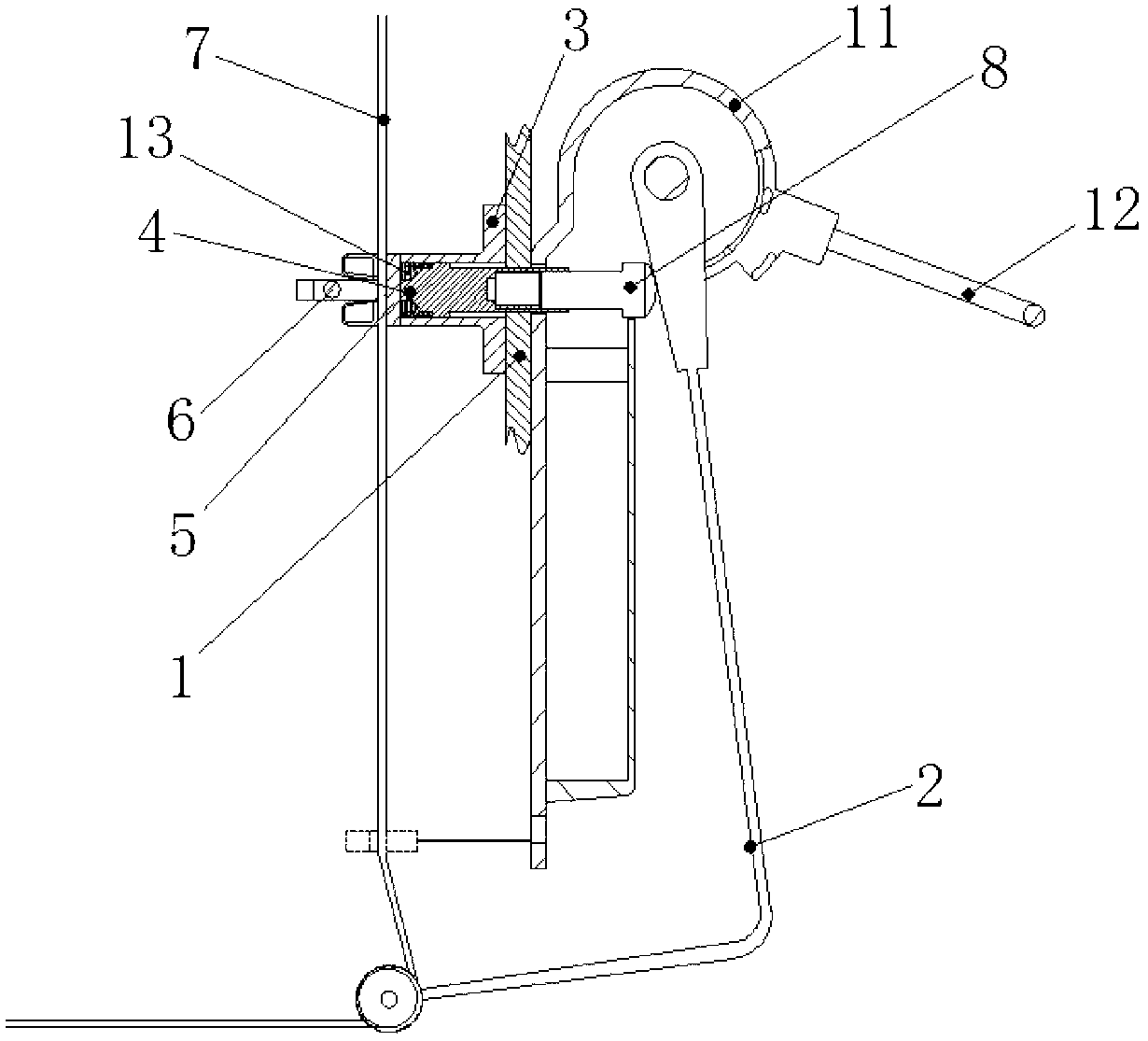

Four-connecting-rod mechanism for trolley pole

ActiveCN105034816AEasy to control speedControlled reboundPower current collectorsFour-bar linkageEngineering

The invention discloses a four-connecting-rod mechanism for a trolley pole, and relates to the technical field of trolley buses. The four-connecting-rod mechanism comprises a base plate and a supporting base connected with the base plate. A large arm and a first connecting rod are connected to the supporting base. The first connecting rod is connected with a second connecting rod. A third connecting rod is connected between the second connecting rod and the large arm. A spring is connected between the large arm and the supporting base. Due to the fact that force applied by the spring on the large arm can be controlled by adjusting the lengths of the second and third connecting rods, the large arm can ascend and descend at different speeds to carry out active net touch and active net disengagement work, and meanwhile a trolley bus can be effectively prevented from being disengaged from a net in the driving process.

Owner:SUZHOU KAIBO YIKONG DRIVE TECH CO LTD

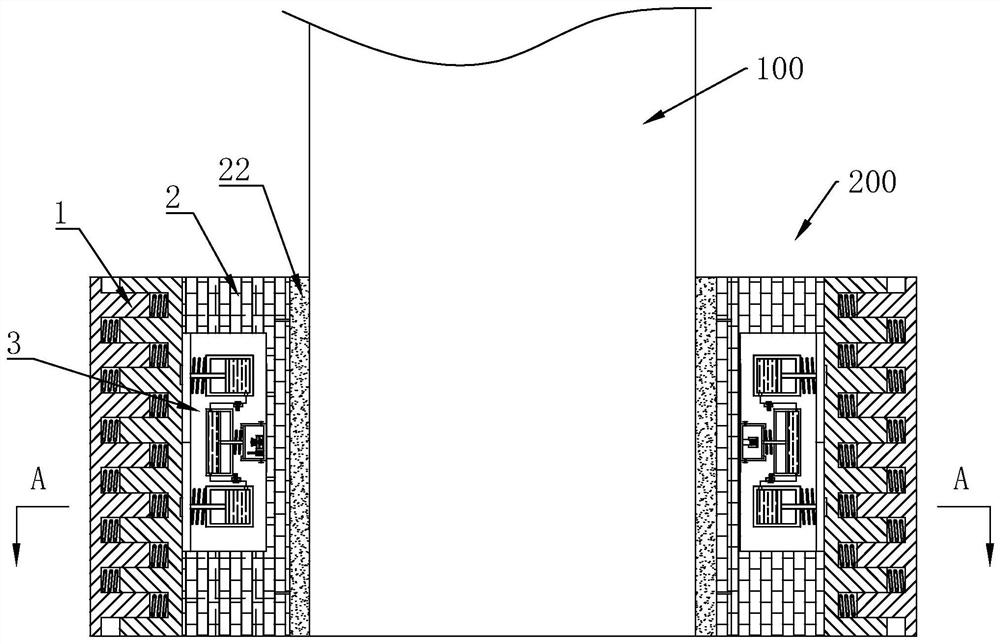

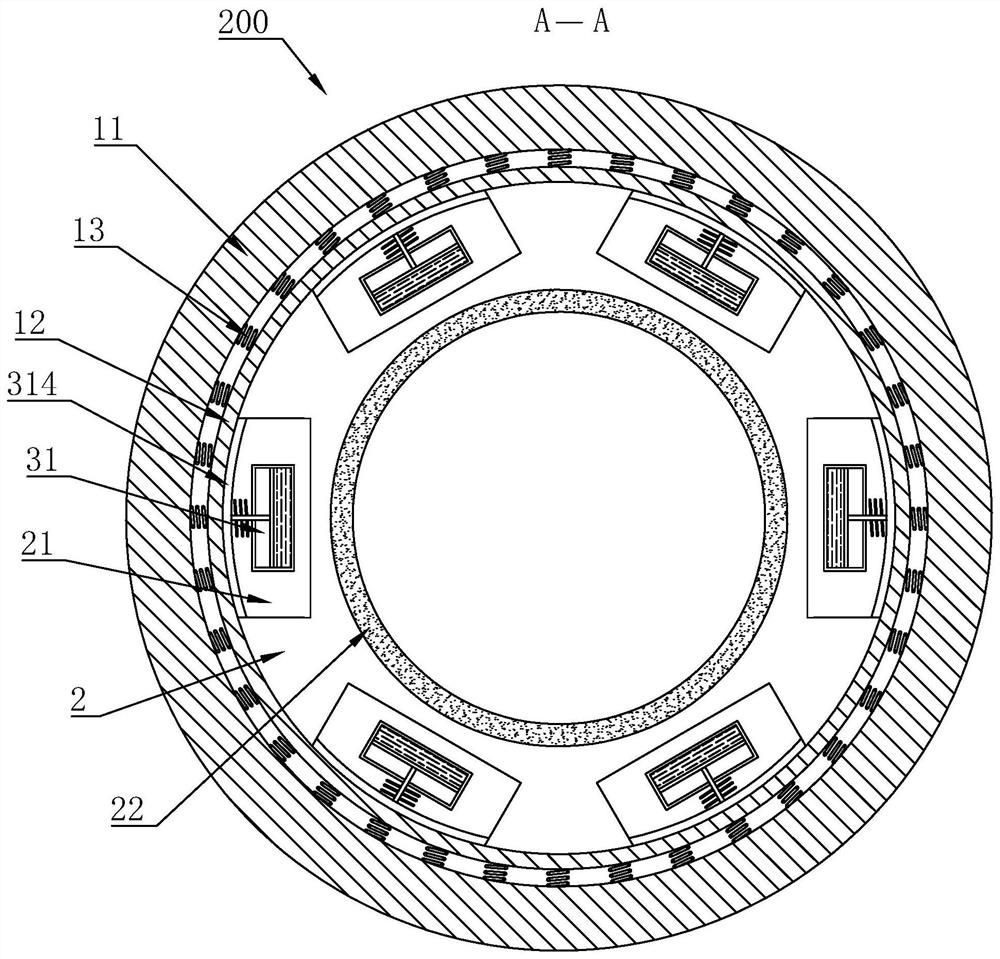

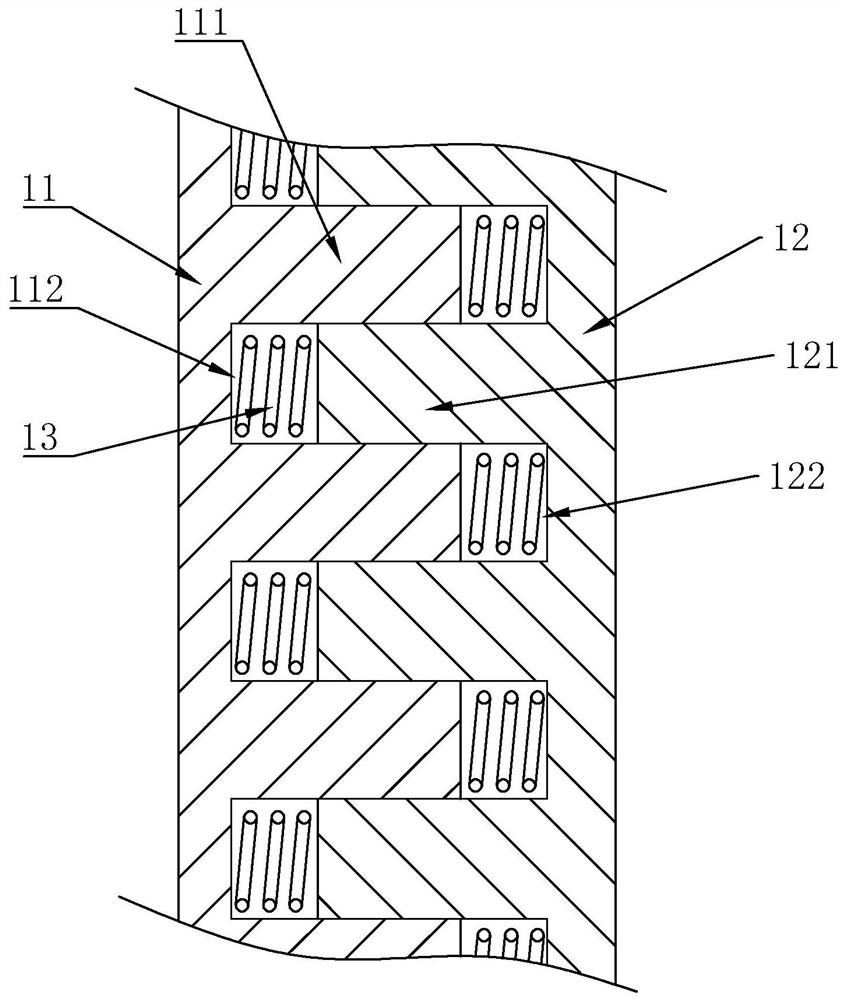

Multi-stage buffer anti-collision pier

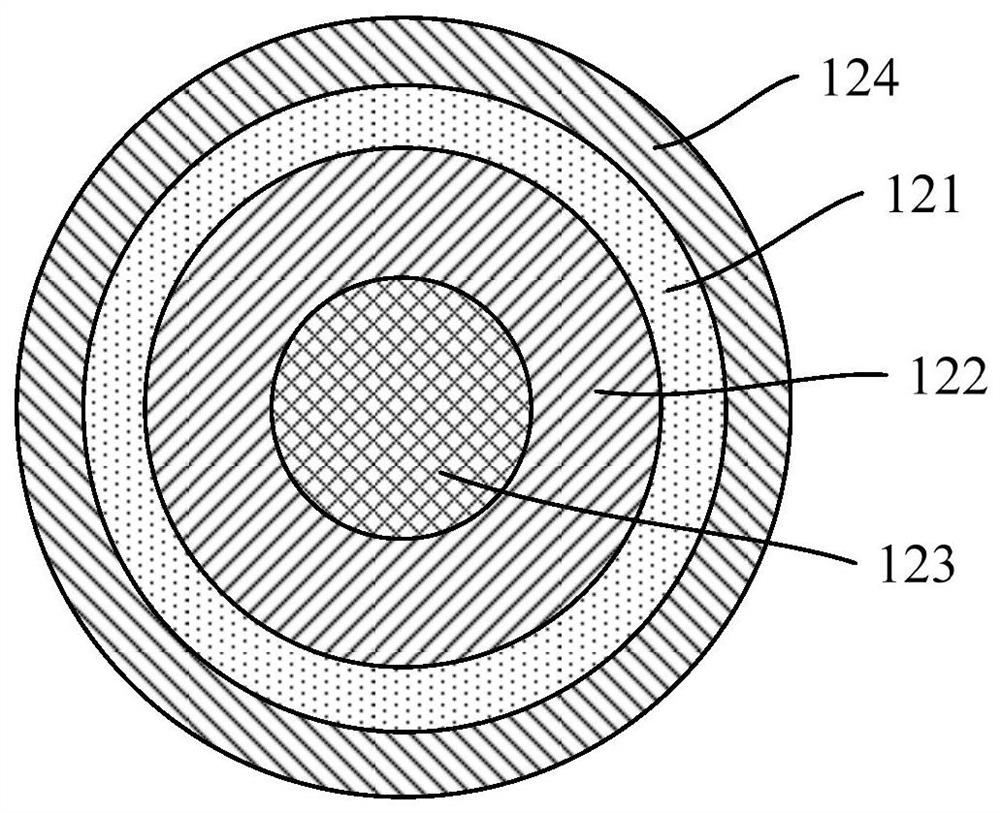

ActiveCN112144386AReduce damageGood cushioning effectBridge structural detailsRoadway safety arrangementsPierEnergy absorption

The invention belongs to the technical field of bridge protection devices, and particularly relates to a multi-stage buffer anti-collision pier. The multi-stage buffer anti-collision pier comprises apier body and an anti-collision body surrounding the pier body; the anti-collision body comprises a first-stage protection cylinder, a second-stage protection cylinder and a third-stage protection cylinder, wherein the first-stage protection cylinder surrounding the pier body, and the first-stage protection cylinder comprises the outer cylinder body and the inner cylinder body which are sequentially arranged from outside to inside; the outer wall of the second-stage protection cylinder abuts against the inner wall of the inner cylinder body of the first-stage protection cylinder; and the outerwall of the third-stage protection cylinder abuts against the inner wall of the inner cylinder body of the first-stage protection cylinder, a guide mechanism is arranged on the outer wall of the third-stage protection cylinder, and after the first-stage protection cylinder is impacted, the guide mechanism can drive the first-stage protection cylinder to rotate, so that an impacted object deviates. After a vehicle collides with the anti-collision pier, the first-stage protection cylinder absorbs a small part of energy firstly, then the remaining energy is completely absorbed by the second-stage protection cylinder, or the second-stage protection cylinder absorbs a part of energy, the remaining energy is discharged by the third-stage protection cylinder, and through multi-stage energy absorption, it can be effectively guaranteed that the pier body is not damaged, and damage to the vehicle can be reduced.

Owner:绍兴其顺桥梁设备有限公司

Tea for reducing weight and making method of tea

InactiveCN107114528AAdjust absorptionStay in shapeMetabolism disorderTea substituesLicorice rootsSemen

The invention discloses tea for reducing weight. The tea comprises the following components in parts by mass: 105-115 parts of semen cassiae, 100-115 parts of rhizoma alismatis, 100-110 parts of mulberry leaves, 70-75 parts of rose flowers, 70-80 parts of mulberries, 70-80 parts of lily bulbs, 55-65 parts of poria cocos, 60-65 parts of haws, 55-65 parts of red jujubes, 33-39 parts of lotus leaves, 45-60 parts of radix asparagi, 25-37 parts of peach kernels, 25-39 parts of chrysanthemums, 10-20 parts of licorice roots, 20-28 parts of dried orange peel, 20-27 parts of ginseng, 15-28 parts of radix puerariae, and 15-25 parts of coix seeds. The invention further discloses a preparation method of the tea for reducing weight. According to the tea and the preparation method thereof, various relevant components are used for regulating the metabolism of human bodies, so that the function of various organs of the human bodies can be maintained harmonious, the metabolism function of various organs are reinforced, and the condition that superfluous fat is stored in bodies is avoided. After conditioning for some time, the conditioning function of organism is strengthened, the weight of the human bodies can be maintained to fluctuate within a healthy range, and strong constitutions and good builds can be maintained.

Owner:CHONGQING THREE GORGES MEDICAL COLLEGE

Flanging face design method, flanging machining die and method and part

ActiveCN112371805AControlled reboundQuality improvementShaping toolsVehicle componentsStructural engineeringDesign methods

The invention discloses a flanging face design method, a flanging machining die and method and a part with a flanging. The flanging face design method comprises the following steps that 1, a flangingvector direction line is designed, a process face is obtained on the basis of a set flanging line and the flanging vector direction line, and the process face serves as a craft process face and used for guiding flanging face machining; and 2, the flanging vector direction line is designed, a flanging face is designed and needs to be arranged at the outer side, close to the part, of the flanging vector direction line, a certain angle is formed between the flanging face and the flanging vector direction line and determined according to the springback condition of the part, and a theoretical flanging face designed according to the method is infinitely close to the springback part. A die structure is designed through the process face, the flanging vector direction serves as the flanging direction, so that the consistency of die flanging gaps can be guaranteed, and the problems of uneven part appearance fillets and side wall waves caused by uneven flanging gaps are effectively solved; and meanwhile, part springback can be effectively controlled, and the springback part tends to be consistent with the theoretical state.

Owner:DONGFENG MOTOR CORP HUBEI

Nailer driver blade stop

ActiveUS10434634B2Reduces and eliminates misfireControlled reboundNailing toolsKnife bladesEmbedded system

Owner:BLACK & DECKER INC

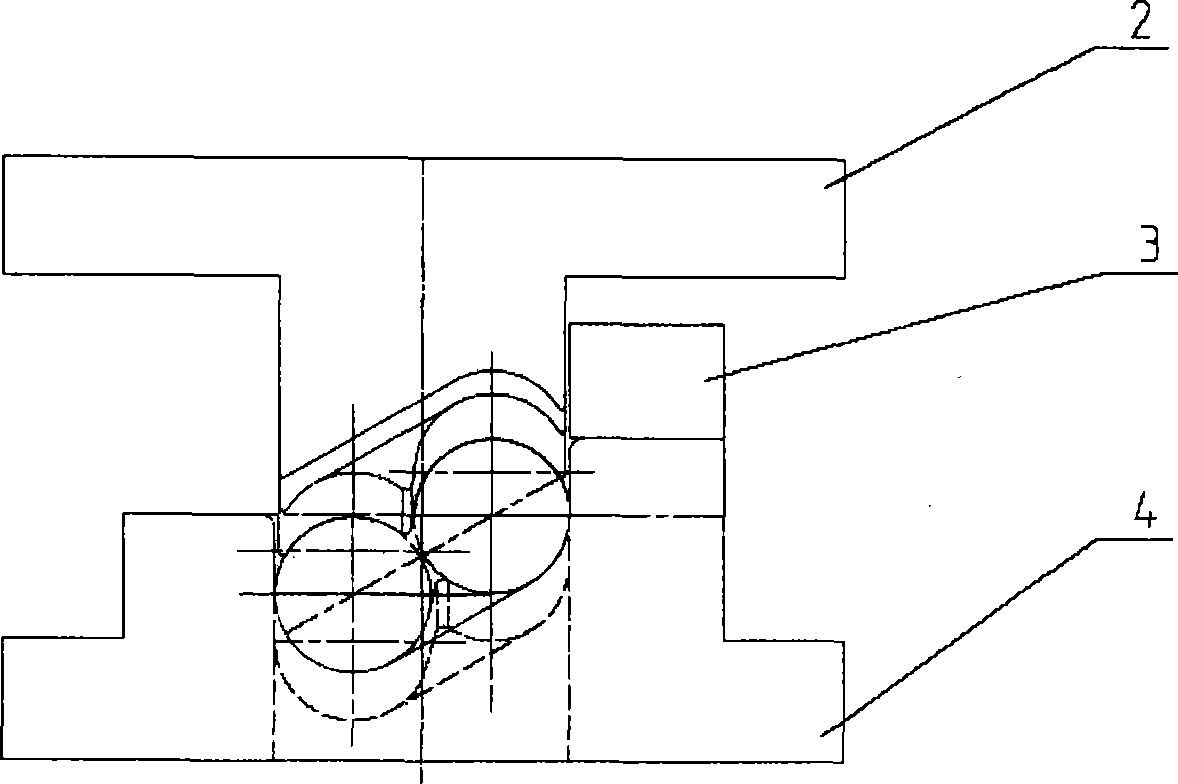

Assembled wedge forming mold for acute-angle U-shaped stamping part

InactiveCN112091081AImprove processing efficiencyLow manufacturing costShaping toolsAcute angleEngineering

The invention discloses an assembled wedge forming mold for an acute-angle U-shaped stamping part, belongs to the technical field of cold stamping mold forming, and can stamp an acute-angle U-shaped part and solve the problem of forming springback of the U-shaped part. A male mold and a male mold guide base move relatively; the male mold moves downwards; a plate is bent into a U shape larger than90 degrees firstly; the male mold continues moving downwards; and a wedge pushes a sliding female mold to move horizontally using a wedge surface to implement forming of an acute angle. The wedge moves upwards; the male mold moves and lags behind under the effect of elastic force of a rubber; and after the sliding female mold is brought back by a spring and the inclined part thereof is receded, alimiting block drives the male mold to return to complete one-time forming. By replacing male and female mold inserts at different angles, multi-angle acute angle forming can be achieved, the manufacturing period of the molds is shortened, and the manufacturing cost of the molds is reduced.

Owner:QIQIHAR NORTH MACHINERY CORP

Weight-reducing konjac beverage

InactiveCN107455629APrevent obesityAvoid absorptionFood ingredient functionsIntestinal wallsIsolation membrane

The invention discloses a weight-reducing konjac beverage and belongs to the field of cold drink. Konjac enriched in gel is eaten into a human body to form a semitransparent coating so as to be attached to intestinal walls, so that absorption of fat is inhibited. The lotus leaf is taken to form a fat isolation membrane on the human intestinal walls, the fat absorption is effectively inhibited, the weight is fundamentally reduced, and bounce is effectively controlled. In addition, auxiliary materials such as apple juice, orange juice, honey, white granulated sugar, sodium carbonate, edible essence and purified water are added to prepare the weight-reducing konjac beverage.

Owner:房县九方魔芋科技有限公司

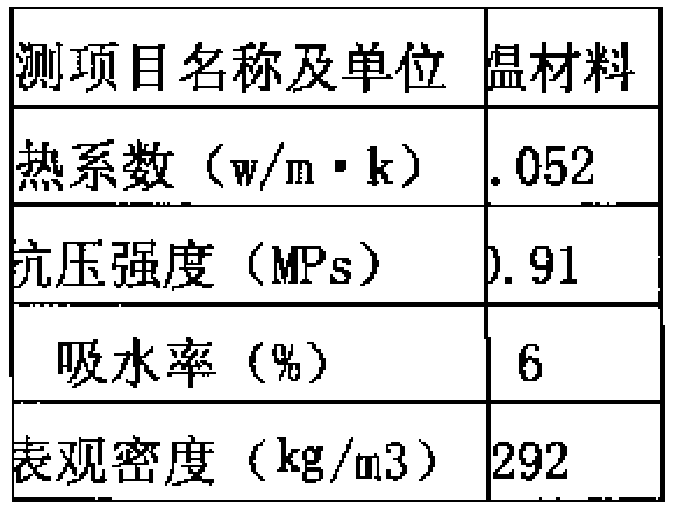

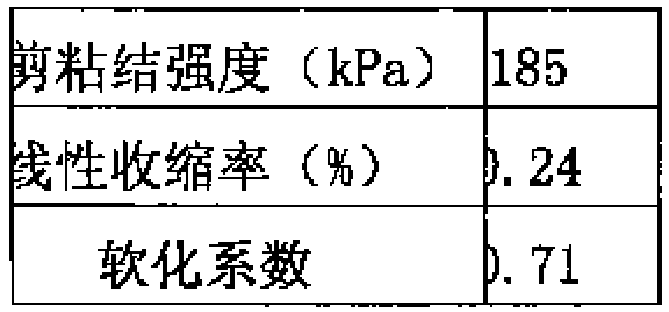

Inner and external wall insulating paste materials, preparation method thereof and application

The invention discloses an inner and outer wall thermal insulation paste material, a preparation method and the application thereof. The inner and outer wall thermal insulation paste material is mainly composed of the following components by the parts by weight: 20 to 40 parts of expanded perlite, 5 to 10 parts of polystyrene particles, 70 to 130 parts of powder and 0.8 to 2 parts of additive. The inner and outer wall thermal insulation paste material has strong thermal insulation performance (the thermal conductivity coefficient is 0.045 to 0.055w / m.k), small volume, high strength (compressive strength is 0.6 to 1.0MPs), strong hydrophobic property, high anti-carbonation property, strong anti-freezing expansion ability and long service life.

Owner:刘贵堂

Production process of special steel pipe for air-conditioning compressor casing

The invention relates to a production process of a special steel pipe for an air-conditioning compressor casing. The production process comprises the following steps of selecting materials, cutting into band steel, loading, forming rolled pipes, extruding into pipes through high-frequency welding, post-processing welding seams, detecting the welding seams, finishing, correcting and performing a hydraulic test according to the technical scheme provided by the invention. The production process optimizes the design of the width dimension of the band steel and the size of an opening angle and improves the precision of the final product; current, voltage and rolling speed are rationally adjusted according to the size of the steel pipe and the sheet thickness, thus ensuring reliable welding quality; and a compressor unit is carefully combined, a rolling line is lengthened and deformation of steel bands among each unit is reduced so as to ensure welding quality of the steel pipe and control rebounding of the steel pipe.

Owner:无锡天龙钢管有限公司

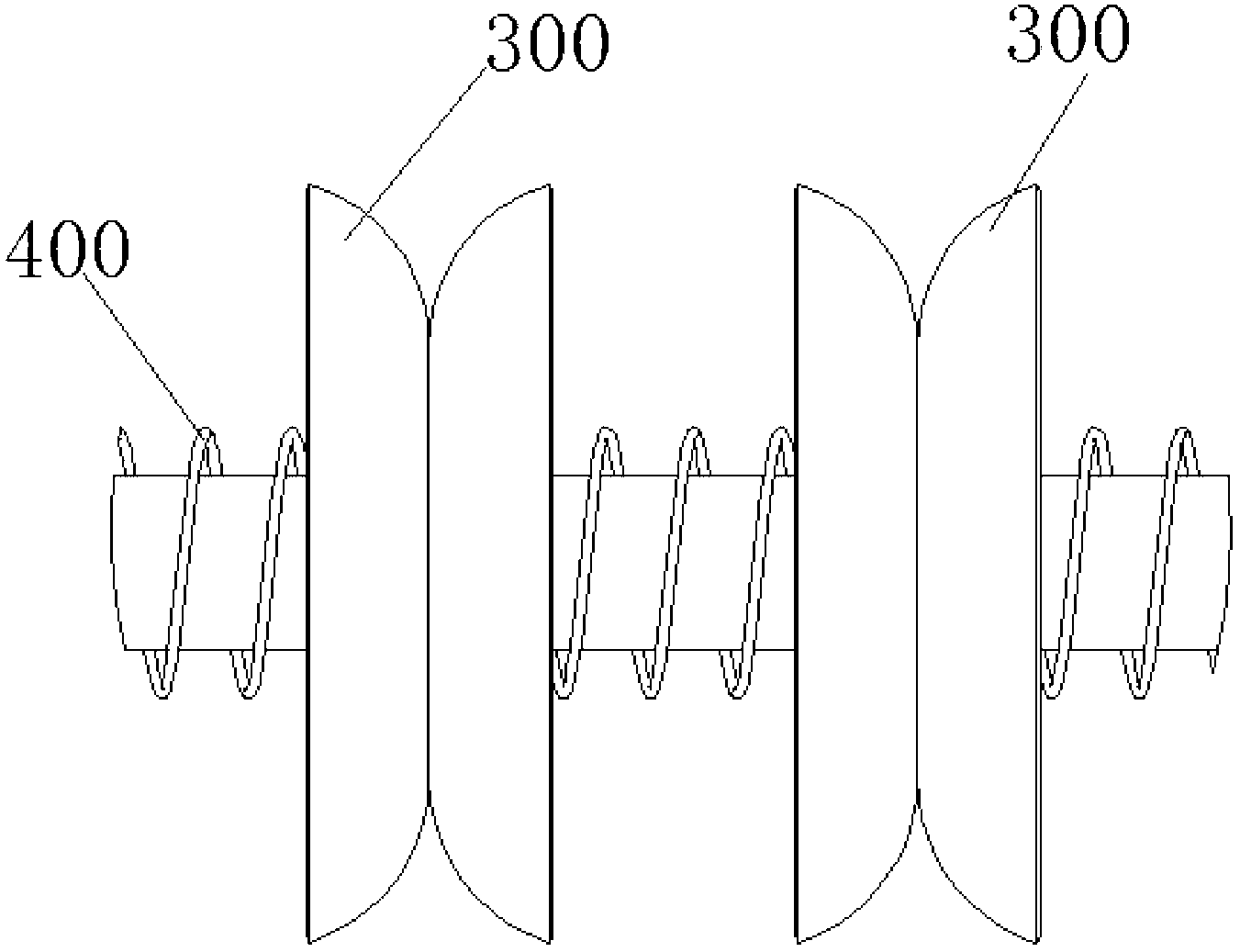

Yarn closing mechanism of yarn guide system

The invention discloses a yarn closing mechanism of a yarn guide system, which includes a taking-up spring mounted on a protective cover; a yarn clamp base is arranged on the other side of the protective cover; a through hole is arranged in the yarn clamping base; a guide rod protruding out of two ends of the through hole is arranged in the through hole; one end of the guide rod transversely penetrates the protective cover and is propped against below the root part of the taking-up spring; the other end of the guide rod protrudes the through hole through transversely penetrating a partition arranged on the through hole; a yarn clamp axle is arranged at the end part of the guide rod; a yarn is arranged between the yarn clamp axle and the partition, and the yarn clamp axle is driven through horizontal movement of the guide rod to approach the partition so as to clamp the yarn; and an elastic device capable of enabling the guide rod to move towards the taking-up spring is arranged on the guide rod. The mechanism disclosed by the invention has small size as well as simple and ingenious structure, can accurately control clamping of the yarn, enables the yarn to be weaved under yarn guidance of balanced tension, improves the quality of braided fabric, has fast yarn guide speed, improves the reciprocating turnaround speed of the machine head, and achieves the effect that the machine head can turnaround rapidly to weave in a reciprocating manner.

Owner:CHANGSHU GUOGUANG MACHINERY

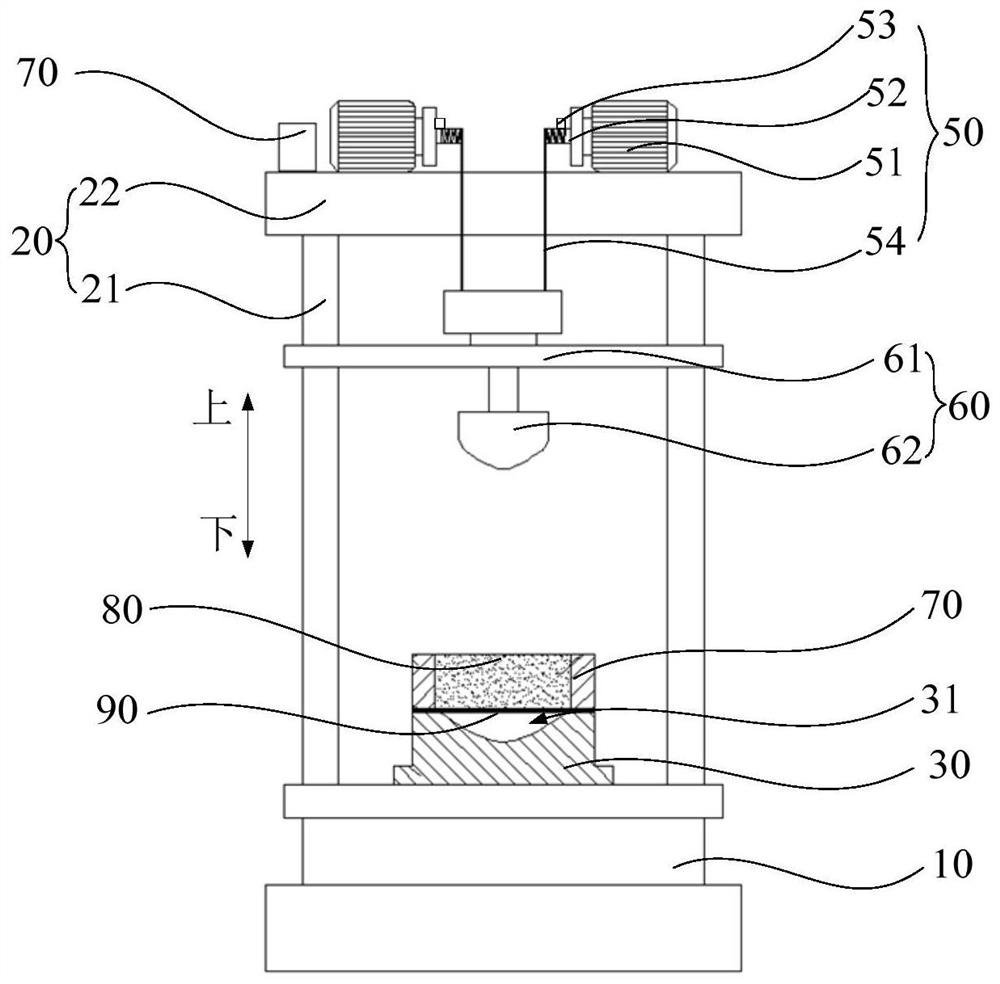

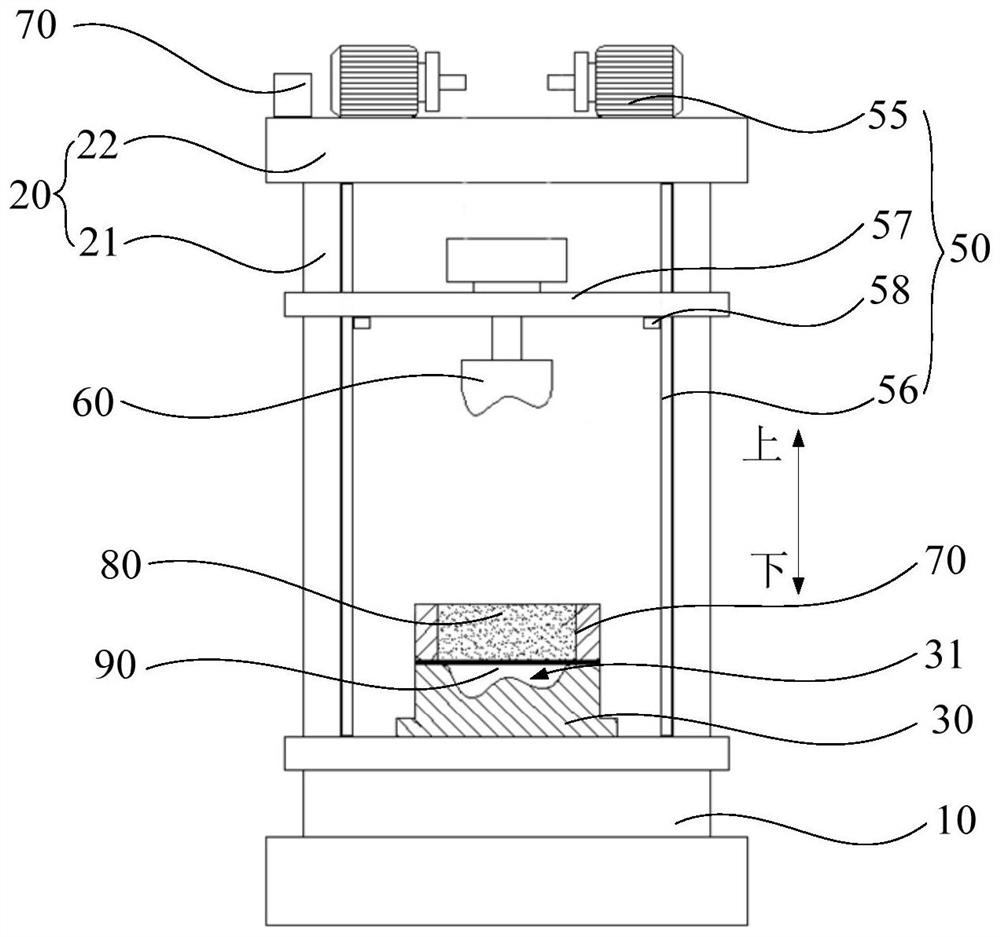

Impact forming method and impact forming die for viscous medium

ActiveCN112893583AFast formingIncreased thickness shear stressShaping toolsEngineeringInternal stress

The invention provides an impact forming method and an impact forming die for a viscous medium. The impact forming method comprises the steps that an impact hammer is released, the impact hammer moves towards a medium bin under the action of gravity, the impact hammer applies an impact load to the viscous medium, and the viscous medium enables a plate to be rapidly attached to a cavity of a female die to form a part. According to the impact forming method, under the action of the high-speed impact load of the impact hammer, the viscous medium instantaneously generates high pressure, so that the strain rate sensitivity of the viscous medium fully plays a role, remarkable non-uniform pressure distribution is generated, and a high-strength plate can be quickly formed; and meanwhile, the internal stress gradient of a formed part is reduced, and the purpose of controlling springback is achieved.

Owner:HARBIN INST OF TECH

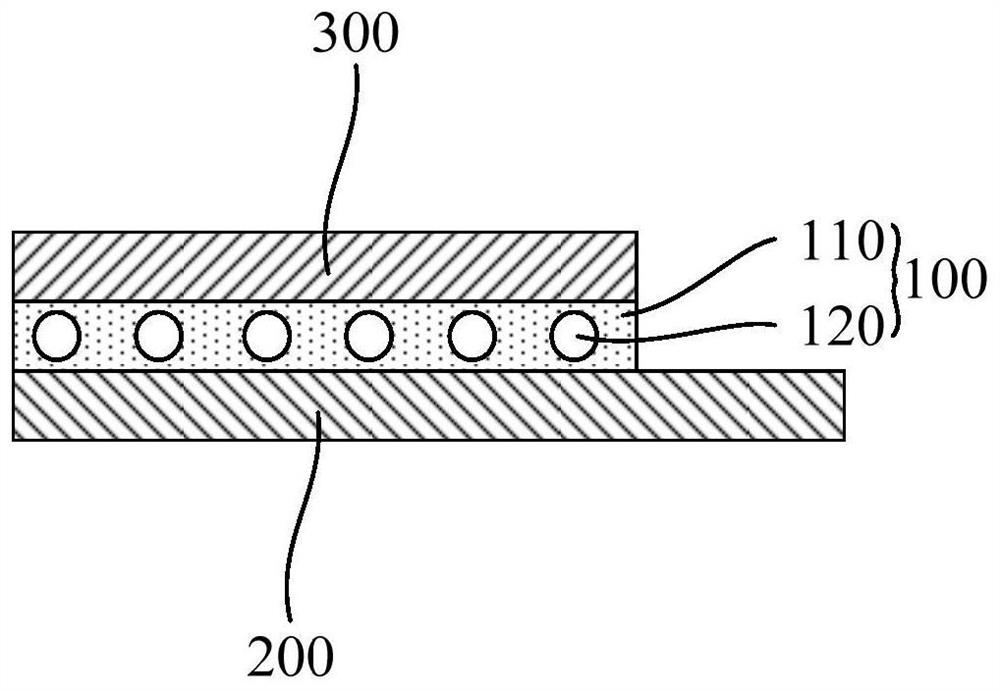

Conductive film, display module and electronic equipment

ActiveCN110938382BPrevent overpressureImprove conductivityFilm/foil adhesives without carriersMetal/alloy conductorsOvervoltageElectrically conductive adhesive

The invention discloses a conductive adhesive film, a display module and electronic equipment. The conductive adhesive film includes a base layer and conductive particles, the base layer wraps the conductive particles, and the conductive particles include a conductive layer, a buffer layer and limiting particles. The conductive layer wraps the buffer layer, the buffer layer wraps the limiting particles, and the hardness of the limiting particles is greater than that of the buffer layer. When implementing the binding process, the conductive adhesive film is under pressure, and the limiting particles can limit the pressure degree of the conductive adhesive film, thereby preventing the conductive adhesive film from being over-pressed, thereby controlling the rebound force generated by the conductive particles, so that the conductive adhesive film It is not easy to peel off from the connected parts, thereby improving the conductivity of the conductive adhesive film.

Owner:VIVO MOBILE COMM CO LTD

Impact forming method of viscous medium and impact forming die

ActiveCN112893583BFast formingIncreased thickness shear stressShaping toolsEngineeringInternal stress

The present application provides an impact forming method for a viscous medium and an impact forming die, wherein the impact forming method includes: releasing the impact hammer, the impact hammer moves toward the medium chamber under the action of gravity, and the impact hammer An impact load is applied to the viscous medium, and the viscous medium causes the plate to quickly adhere to the cavity of the concave mold to form a part. In the impact forming method provided by this application, under the high-speed impact load of the impact hammer, the viscous medium generates high pressure instantaneously, so that the strain rate sensitivity of the viscous medium can fully play its role, resulting in a significant non-uniform pressure distribution, making high-strength The high-quality sheet can be quickly formed, and at the same time reduce the internal stress gradient of the formed part to achieve the purpose of controlling springback.

Owner:HARBIN INST OF TECH

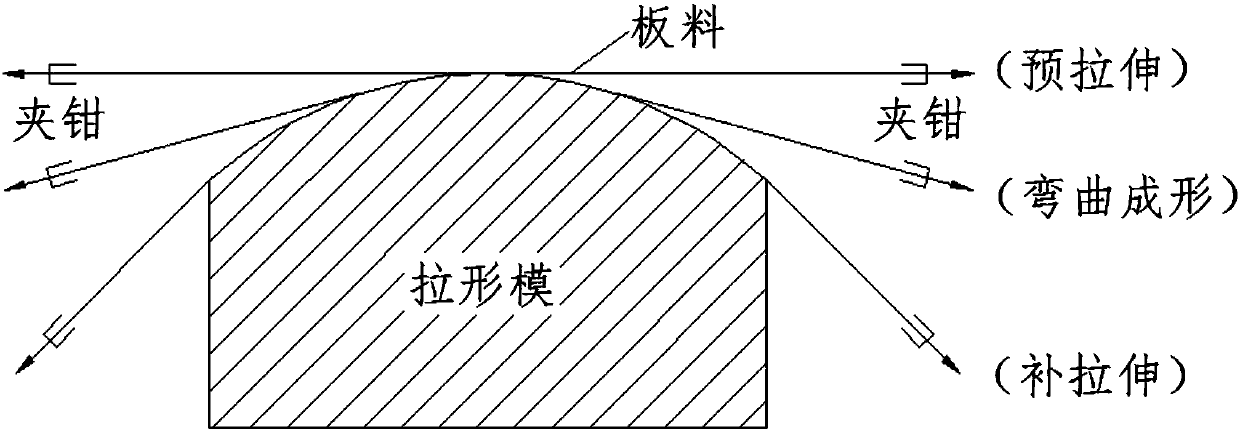

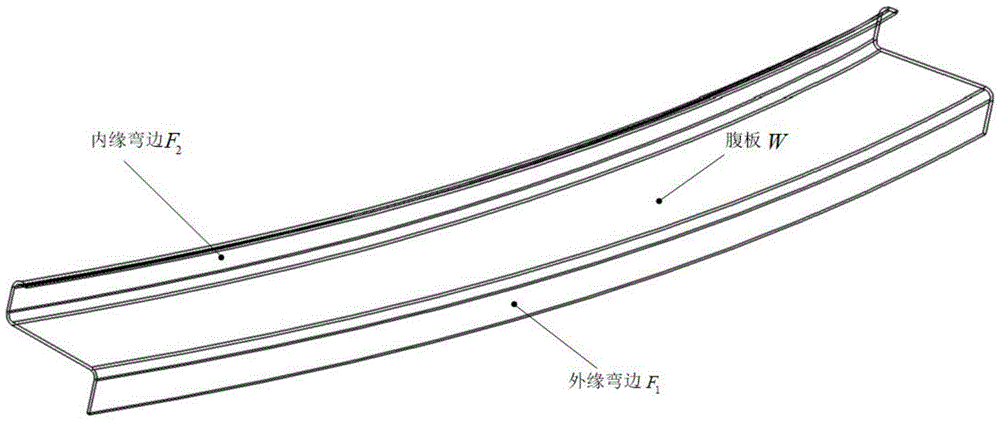

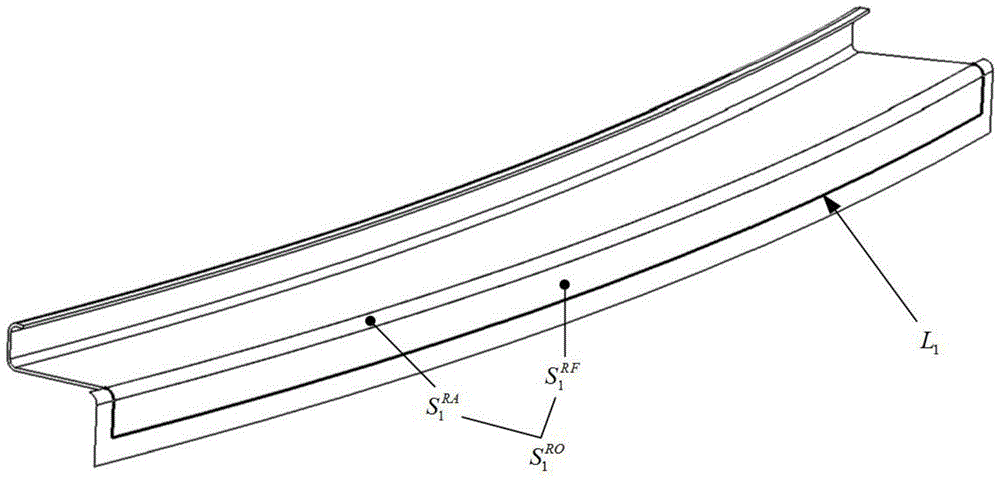

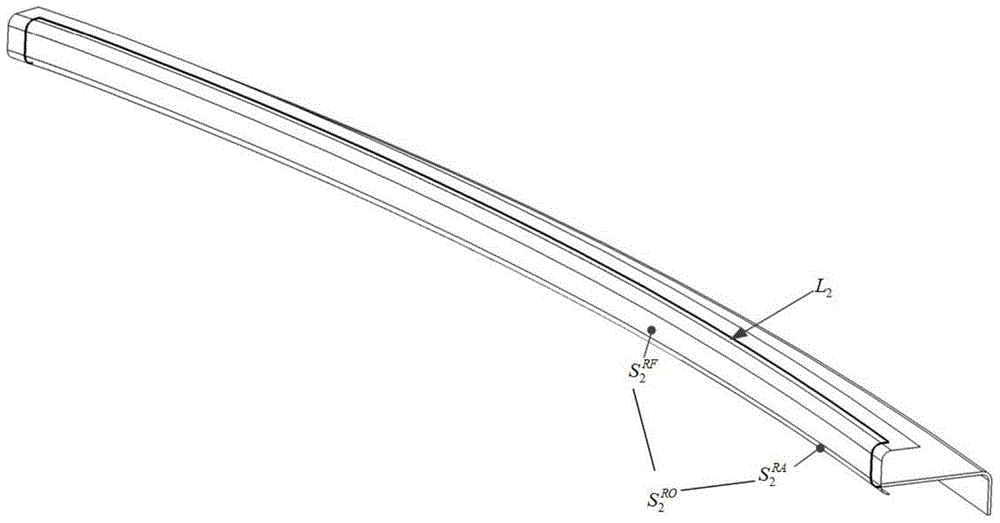

A Web Warpage Control Method for Large Frame Sheet Metal Parts

ActiveCN105081133BControlled reboundControl warpingAircraft componentsEngineeringMechanical engineering

The invention provides a method for controlling warping of a web of a large frame type sheet metal part, and belongs to the technical field of aircraft manufacturing. For a large frame type sheet metal part of which the variable curvature, the variable section and the length are more than 1m, the method is that a technological rib groove structure is added to the outer flank of bent edge of the outer side of frame type rib part, so as to enable uniform distribution of the stress on the bent edge of the outer side of such parts after forming. The method is applicable to further control of the warping of the web of the large frame type part of which the bent edge section is complex and the curvature and the sectional linear dimension are changed constantly according to the bent edge line after forming and unloading, on the basis of springback compensation. With the adoption of the method, the springback of the part can be controlled, and the warping of the web of the part can be effectively controlled; after being formed, the part can simply meet the requirement on accurate formation without or with little manual repair by tapping, so that the forming quality and the production efficiency of the large frame type part can be obviously improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

A buffer anti-collision pier

ActiveCN112195760BSo as not to damageAvoid damageBridge structural detailsRoadway safety arrangementsMechanical engineeringMechanics

Owner:杭州中铭建设有限公司

Making method for dietary therapy fat-reducing and discutient soup

The invention provides a making method for a dietary therapy fat-reducing and discutient soup. The soup is characterized by comprising the following components: big-bone soup-stock, 1 lotus leaf, 80gof hot pot meat slices, 40g of cabbage pieces, 20g of jelly fungi, 2 pieces of lentinus edodes, 20g of coix seeds, 20g of white radish horns, 10g of prunella vulgaris, and a proper amount of shallotsand salt. The making method comprises the following steps: washing the lotus leaf, the prunella vulgaris and the coix seeds, and loading cleaned materials into a gauze bag for use; placing the materials excepting the hot pot meat slices into a soup-stock hot pot together, performing boiling with big fire, and then performing boiling with small fire for 1 hour; and adding the hot pot meat slices before turning off heat, and adding the salt for flavoring after the meat slices are cooked. According to the invention, a heat quantity of the whole pot is just close to 100 calories, people can eat proteins, and the soup is a low-calorie food which is rich in high fibers and various nutrients; and the lotus leaf is a good food material for diuresis and detumescence, and is also a medicinal material with the effect of losing weight. The soup has efficacy of losing weight and beautifying.

Owner:杨江莲

Weight-reducing tea and preparation method thereof

The present invention discloses a weight-reducing tea and a preparation method thereof. The tea is characterized by being prepared from the following components in parts by weight: 90-120 parts of kelp, 20-30 parts of hawthorn fruits, 22-30 parts of giant knotweed rhizomes, 15-20 parts of fleece-flower roots, 15-20 parts of cassia seeds, 15-20 parts of milk-vetch roots, 15-20 parts of bighead atractylodes rhizomes, 15-20 parts of fourstamen stephania roots, 15-20 parts of lotus leaves, 15-20 parts of epimedium herb, 15-20 parts of Chinese thorowax roots, 15-20 parts of kudzuvine roots, 15-20 parts of winter mulberry leaves and 15-20 parts of chrysanthemums. The tea can regulate appetite and control rebound, does not cause adverse reaction, can control hunger sensation and enable people tolike eating light diet, and is simple and convenient to manufacture and low in cost.

Compound fruit and vegetable juice fermented beverage and preparation method thereof

InactiveCN111631332AGood for weight lossAvoid absorptionFood ingredient functionsBiotechnologyIntestinal walls

The invention discloses a compound fruit and vegetable juice fermented beverage and a preparation method thereof. The compound fruit and vegetable juice fermented beverage comprises the following rawmaterials in parts by weight: 20-35% by mass of tomatoes; 10-15% by mass of carrot; 5-10% by mass of apples; 3-5% by mass of bananas; 4-9% by mass of red dates; 3-7% by mass of brown sugar; 1-3% by mass of xanthan gum; 3-8% by mass of a composite strain; 1-10% by mass of compound vitamin; and 10-15% by mass of lotus leaves. The beverage has the anti-cancer effects of inhibiting oxidation and protecting normal cells of an organism from oxidative damage, has the hematopoietic function effect for supplementing blood required by a human body to improve anemia and cold blood, and also has the effects of tonifying spleen and invigorating yang. After being taken, the beverage can form a fat isolating membrane on the intestinal wall of the human body, effectively prevents fat absorption, and fundamentally reduces the weight. In addition, rebound and can be controlled more effectively, and the weight losing effect of the human body is improved.

Owner:安阳昊润农业科技有限公司

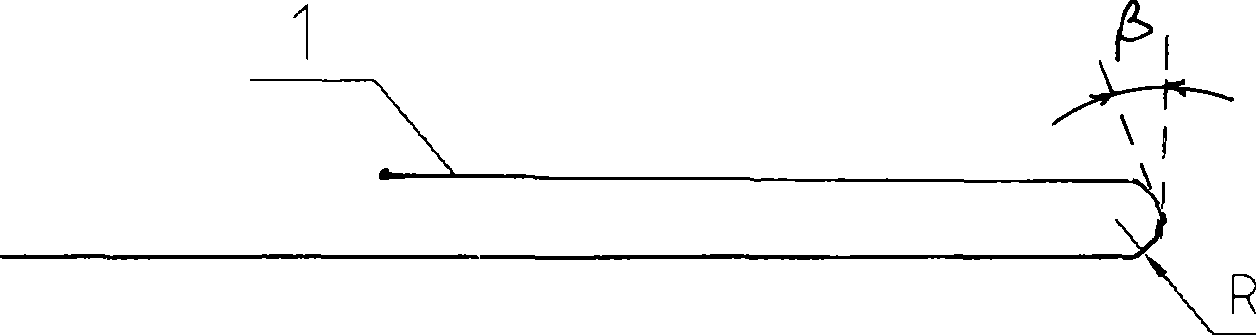

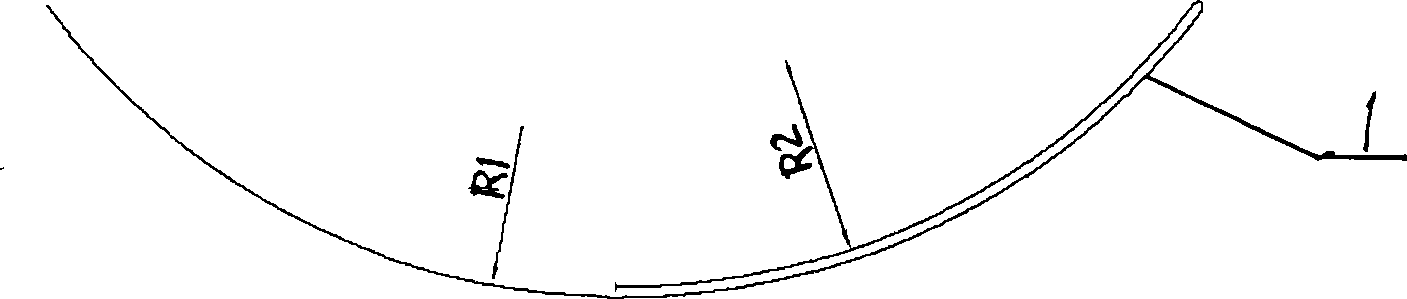

Method for forming 30 degree double-R tube of gasification furnace internal component

ActiveCN101418879ASolving Forming DifficultiesSmall sizeRigid pipesSiphonsEngineeringIntegrated gasification combined cycle

The invention relates to a method for forming a 30-degree double-R pipe internal part of a gasification furnace. The invention is characterized in that the method comprises the following: step 1, using an extruding press to extrude R elbows of a first pipe, a second pipe, a third pipe and a fourth pipe which have the same pipe diameter which is less than 50mm; step 2, using four bending moulds to bend 100 to 150 mm ends of the elbows of the first pipe, the second pipe, the third pipe and the fourth pipe which are bent with R elbows respectively into double-R shapes at angles beta of 30 degrees to a plane of the elbows; and step 3, using four bending moulds to bend the bent first, second, third and fourth pipes in the step 2 into double-R arc shapes respectively and jointing the four pipes. The method has the advantages of solving the problem of extremely complex pipe forming in IGCC(integrated gasification combined cycle) gasification furnace and effectively controlling size and resilience, positive and negative applicability of moulds and commonality of fixture blocks, and greatly simplifying production and processing process.

Owner:SHANGHAI BOILER WORKS

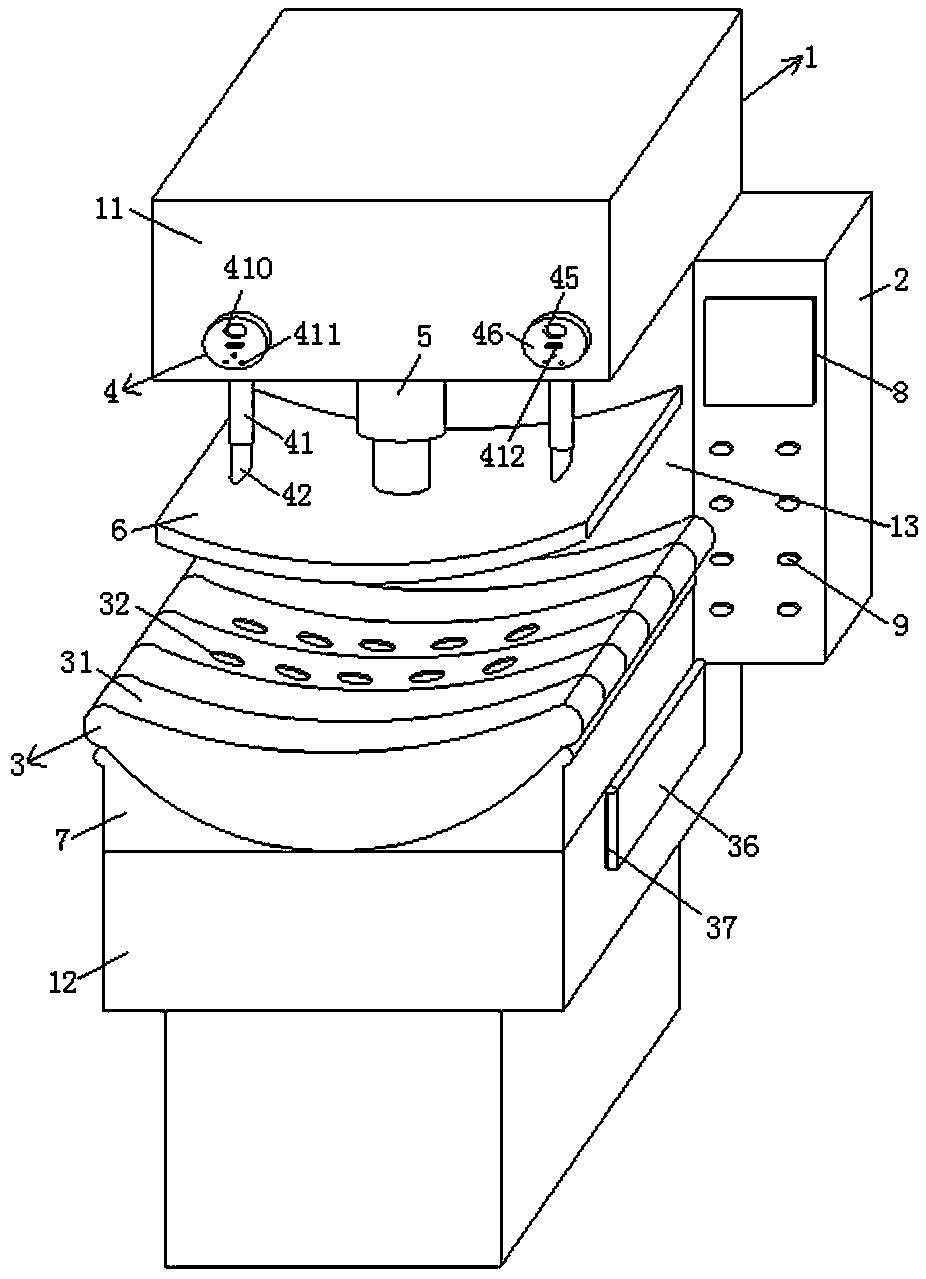

Numerical-control processing machine tool for mechanical parts

The invention provides a numerical-control processing machine tool for mechanical parts and relates to the field of machining. The numerical-control processing machine tool comprises a machine tool support for supporting machine tool equipment, a numerical-control controller for controlling the equipment, a movable suction supporting mechanism for producing a plate and bearing stamping force, a damping bounce reduction mechanism for reducing bounce of the two sides of the plate, a linear actuator, an arc extrusion plate and an arc die. The machine tool support comprises a top supporting block,a bottom supporting block and a side plate. According to the numerical-control processing machine tool for the mechanical parts, in order to control the position of the plate by an existing numerical-control plate bending machine, a complementary special mechanism is designed and completely replaces a rigid limit structure and a stamping die, and accordingly the problems are effectively solved that a common plate bending machine is not suitable for precise processing, a limit device does not fix the plate when a numerical-control plate bending machine is used for processing, the force application point of the plate easily slightly deflects, the limit device bears the bounce impact force, and the precision is easily lowered.

Owner:宁波心生工业设计有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com