Four-connecting-rod mechanism for trolley pole

A technology of four-bar linkage mechanism and collector rod, which is applied in current collectors, power collectors, electric vehicles, etc., can solve problems such as off-line, pantograph collision, and safety accidents, so as to improve maintenance efficiency and reduce Work load, effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

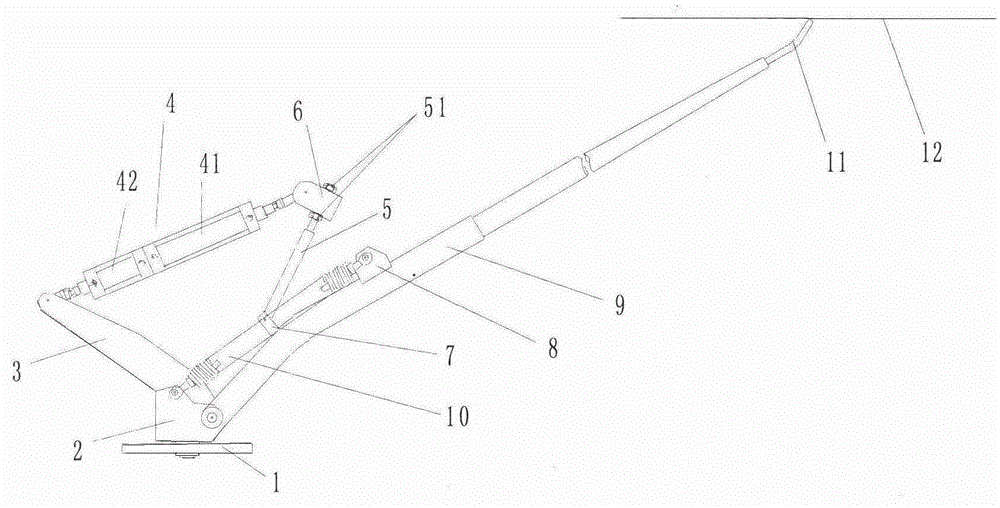

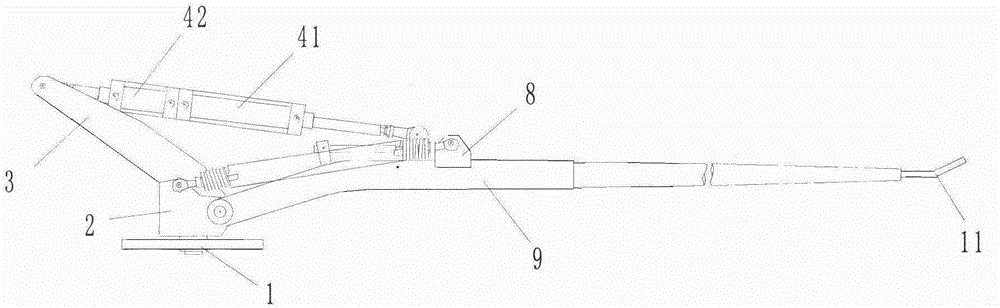

[0028] A four-bar linkage mechanism for collector rods, such as figure 1 As shown, including a bottom plate 1, a through hole (not shown) is opened on the bottom plate 1, and the bottom end of the support seat 2 extends into the through hole (not shown), and the support seat 2 and the The bottom plate 1 is axially connected, and a rotary cylinder (not shown) is installed on the support seat 2, and the support seat 2 can be pushed to rotate relative to the bottom plate 1 by the rotary cylinder (not shown in the figure). .

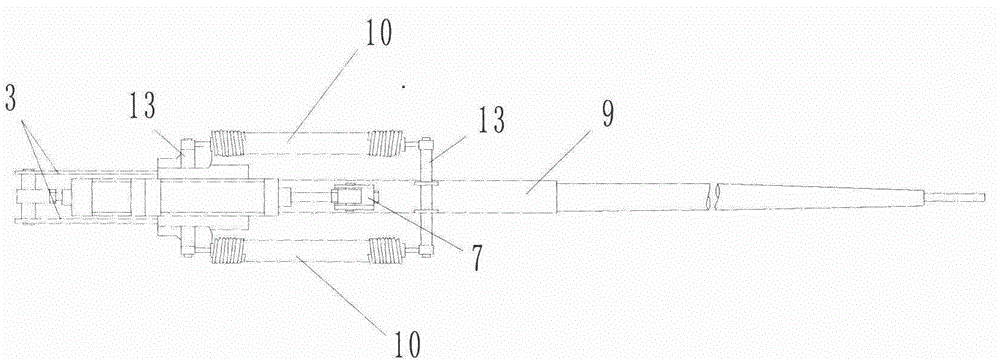

[0029] A boom 9 is connected with a pin shaft on the support base 2, and the boom 9 can rotate integrally with the support base 2; 8 and the support base 2 are respectively pierced with support rods 13, please combine figure 2 , different support rods 13 are in a parallel state, and springs 10 are fixed between the support rods 13, and the springs 10 are distributed on both sides of the boom 9. When the boom 9 is in a horizontal state, the springs 10 is ...

Embodiment 2

[0040] The rest are the same as in Embodiment 1, except that the third connecting rod 5 is a screw rod, and the top end of the third connecting rod 5 is connected to the connecting rod seat 6 through a nut 51. When the vehicle is at different heights, When driving on the catenary road, the driver can adjust the length of the screw mandrel flexibly by manually adjusting the nut 51, so that the boom 9 can be kept in the catenary state at different catenary heights, and the catenary can be lifted. Web flexibility.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com