Spring-back compensation method working out factor reversely

A springback compensation and factor technology, applied in special data processing applications, instruments, electrical and digital data processing, etc., can solve the problems of non-convergence of springback compensation iterations and many times of calculation convergence, so as to reduce the number of trials and improve the The effect of compensation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

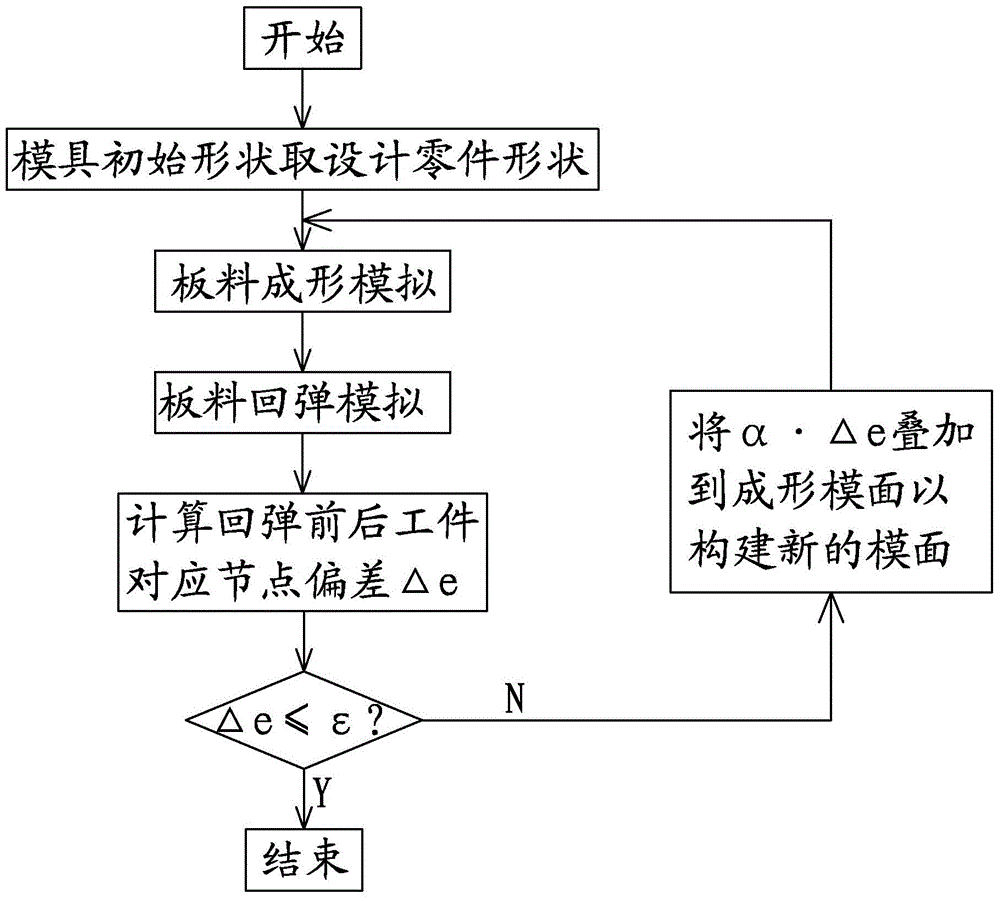

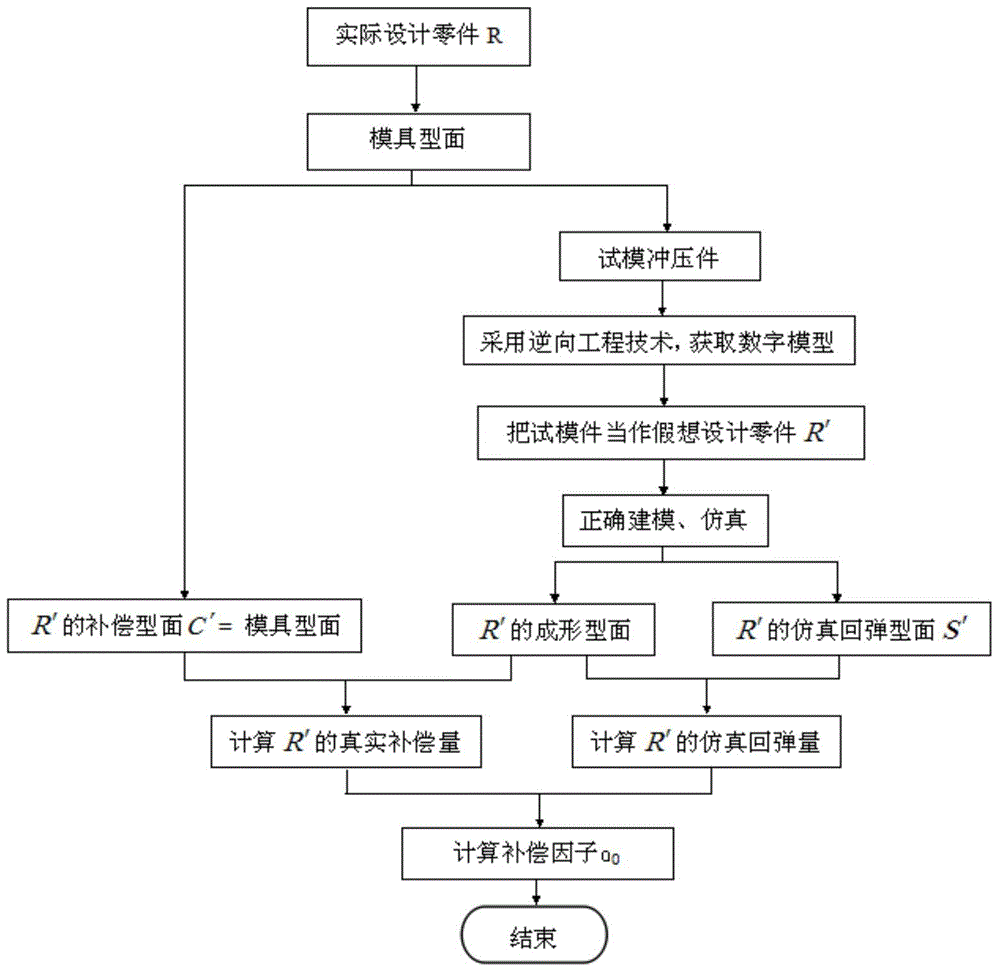

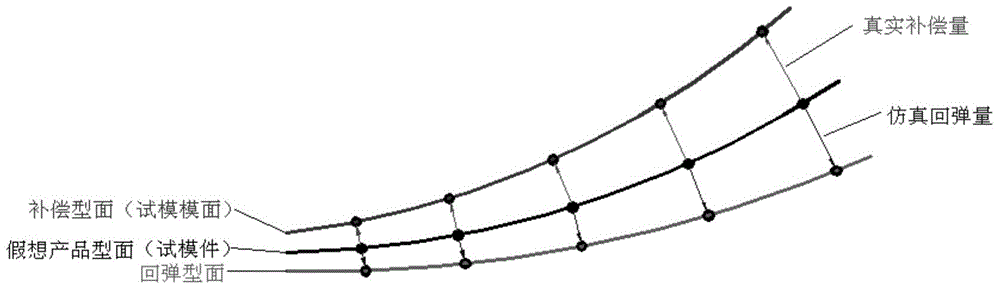

Method used

Image

Examples

Embodiment Construction

[0030] In the geometric correction method of springback compensation, the product parts are discretized into a finite number of unit grids, assuming that the product forming die surface after compensation is C, which is a unit set composed of n nodes, and the product surface after springback is S, which is:

[0031] C={c i |c i ∈C 3} 1≤i≤n (1)

[0032] S={s i |s i ∈ S 3} 1≤i≤n (2) Design product part R, expressed as:

[0033] R={r i | r i ∈ R 3} 1≤i≤n (3) The geometric correction of springback compensation is performed on the product part R, and the correction process can be expressed as:

[0034] C=R-α(S-R) (4)

[0035] where α is the compensation factor;

[0036] Due to the inaccurate pre-determined value of α and the nonlinearity in the forming process, the springback part of the stamped product after compensation often deviates from the designed product shape. To avoid the problem of unknown α value, the compensation geometry correction of the die surface is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com