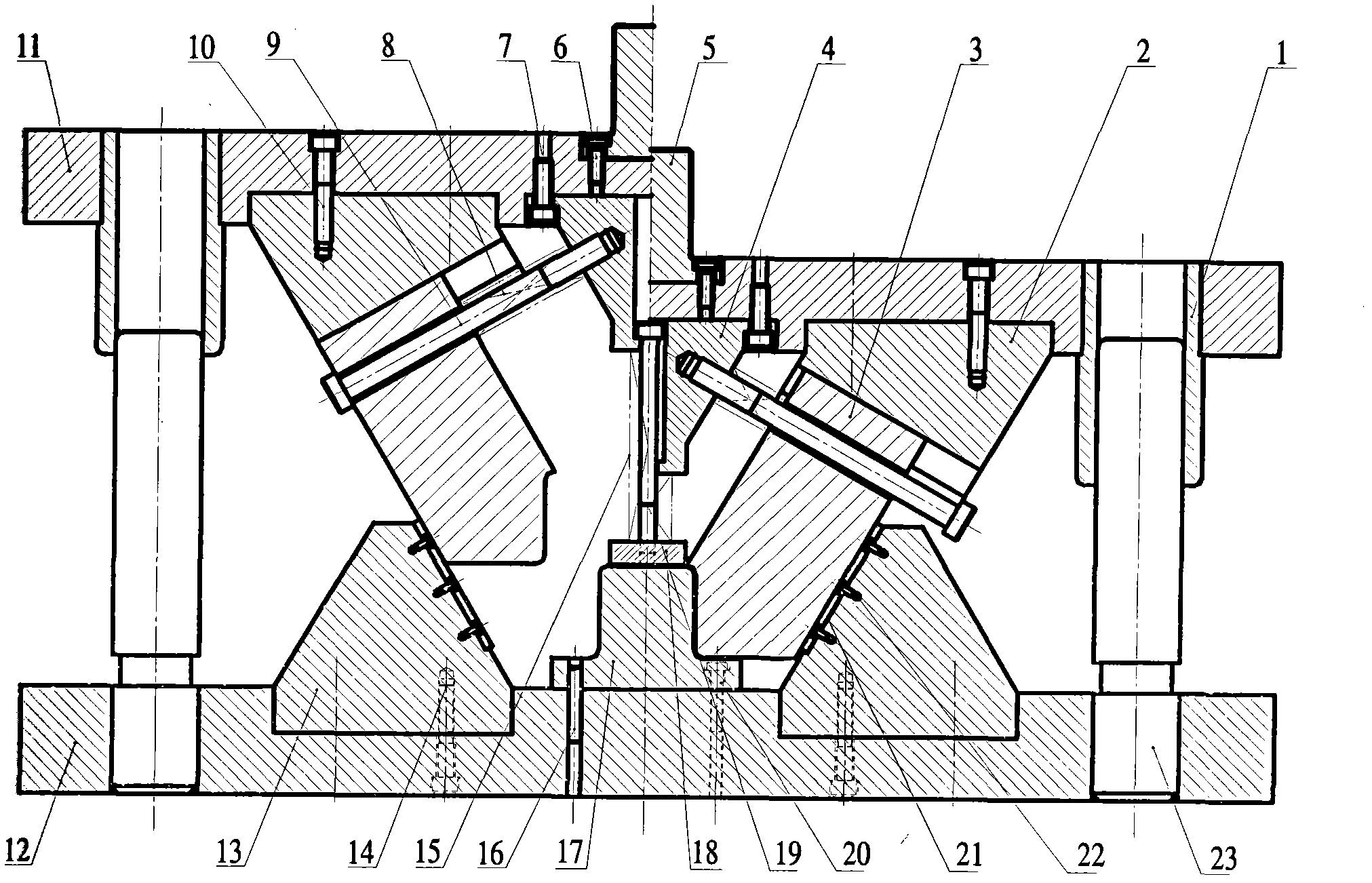

Composite Die for Slanted Wedge Bending and Reshaping of U-like Section Stamping Parts

A technology of stamping parts and composite molds, applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of reduced production efficiency, many factors involved, and complexity, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

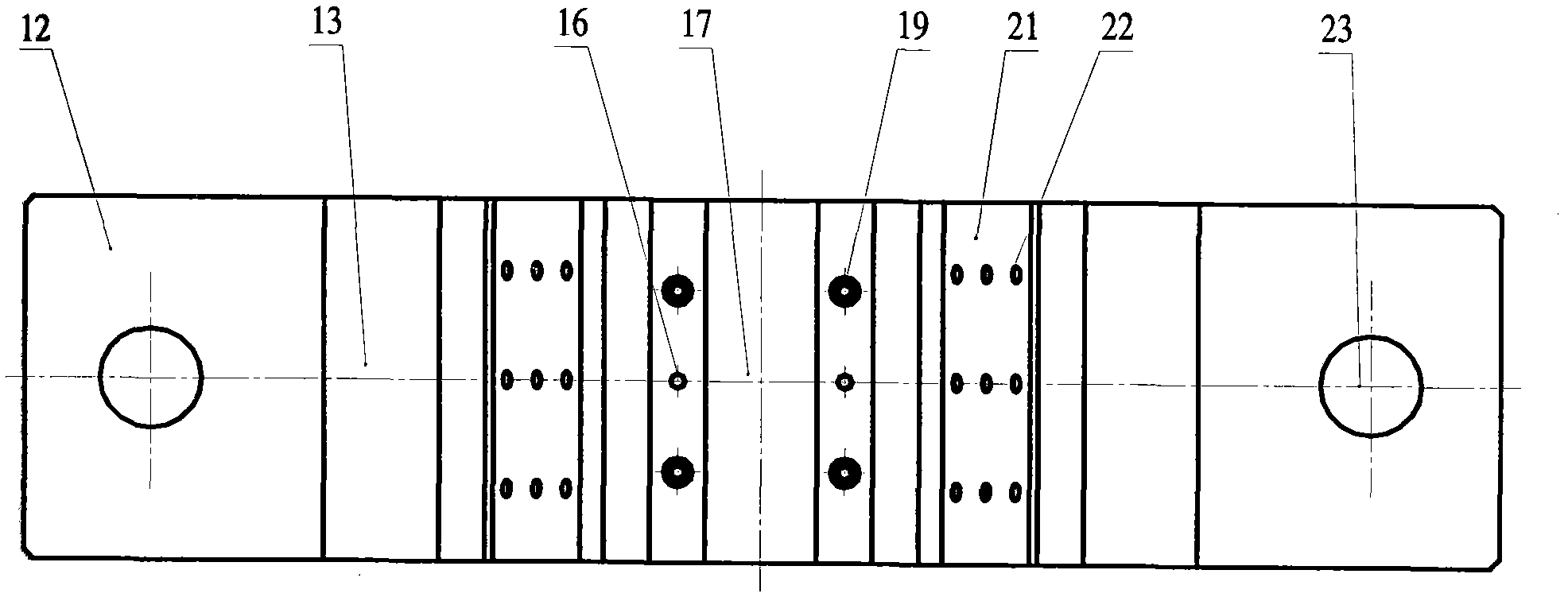

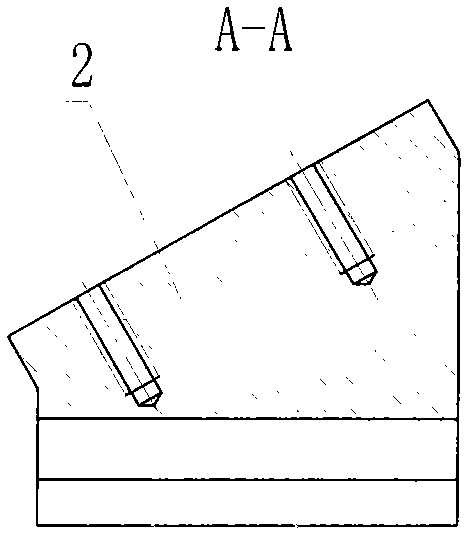

[0012] The following is an example of a wedge bending and shaping composite mold suitable for U-shaped cross-section stamping parts of metal sheets with a length and width of 150-220mm and 50-180mm and a thickness of 0.5-2mm. The wedge bending and shaping composite mold includes an upper mold part and a lower mold part. The upper mold part includes the mold handle (5), the upper mold plate (11), the upper pressure block (4), the upper mold insert (2), the slider (3), the lower pressure plate (18), and the guide sleeve connected with each other by screws. (1) and spring (8) and spring (15). Among them, the upper formwork (11) is an 800mm×200mm×60mm long strip plate with Φ80mm circular through holes at both ends, and three 200mm×160mm×20mm opening shallow grooves on the bottom surface along the horizontal direction, and threaded holes are symmetrically distributed in the shallow grooves and stepped vias. There is a Φ90mm circular groove in the center of the upper surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com